sensor KIA FORTE 2020 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2020, Model line: FORTE, Model: KIA FORTE 2020Pages: 568, PDF Size: 8.58 MB

Page 412 of 568

613

What to do in an emergency

You may not be able to identify a low

tire by simply looking at it. Always

use a good quality tire pressure

gauge to measure the tire's inflation

pressure. Please note that a tire that

is hot (from being driven) will have a

higher pressure measurement than a

tire that is cold (from sitting station-

ary for at least 3 hours and driven

less than 1.6 km (1 mile) during that

3 hour period).

Allow the tire to cool before measur-

ing the inflation pressure. Always be

sure the tire is cold before inflating to

the recommended pressure.

A cold tire means the vehicle has

been sitting for 3 hours and driven for

less than 1.6 km (1 mile) in that 3

hour period.

Never use tire sealant if your vehicle

is equipped with a Tire Pressure

Monitoring System. A liquid sealant

not approved by Kia may damage

the tire pressure sensors. The TPMS cannot alert you to

severe and sudden tire damage

caused by external factors such as

nails or road debris.

If you feel any vehicle instability, immediately take your foot off the

accelerator, apply the brakes grad-

ually and with light force, and slow-

ly move to a safe position off the

road.

✽ ✽ NOTICE - Protecting TPMS

Tampering with, modifying, or dis-

abling the Tire Pressure Monitoring

System (TPMS) components may

interfere with the system's ability to

warn the driver of low tire pressure

conditions and/or TPMS malfunc-

tions. Tampering with, modifying,

or disabling the Tire Pressure

Monitoring System (TPMS) compo-

nents may void the warranty for

that portion of the vehicle.

This device complies with

Industry Canada licence-exempt

RSS standard(s).

Operation is subject to the following

two conditions:

(1) This device may not cause inter-

ference, and

(2) This device must accept any

interference, including interfer-

ence that may cause undesired

operation of the device.

Page 430 of 568

631

What to do in an emergency

Distributing the sealant

12. Immediately drive approximately7~10 km (4~6 miles) or about 10

minutes to evenly distribute the

sealant in the tire.

When you use the Tire Mobility Kit,

the tire pressure sensors and wheel

may be stained by sealant. Therefore,

remove the tire pressure sensors and

wheel stained by sealant and have

your vehicle inspected by an author-

ized Kia dealer.

Checking the tire inflation

pressure

1.After driving approximately 7~10 km (4~6 miles) or about 10 min-

utes, stop at a suitable location.

2.Connect the filling hose (3) of the compressor (clip mounted side)

directly and then connect the filling

hose (3) (opposite side) to the tire

valve.

3.Connect the compressor to the vehicle power outlet using the

cable and connectors.

4.Adjust the tire inflation pressure to 200 kPa (29 psi). With the ignition

switched on, proceed as follows.

- To increase the inflation pres-sure: Switch on the compressor,

position I. To check the current

inflation pressure setting, briefly

switch off the compressor. - To reduce the inflation pres-

sure: Press the button (9) on the

compressor.

CAUTION - Tire pressure

sensor

Do not use sealant notapproved by Kia as it may dam-age the tire pressure sensors.The sealant on the tire pressuresensor and wheel should beremoved when you replace thetire with a new one and inspectthe tire pressure sensors at anauthorized dealer.

WARNING

Do not let the compressor run

for more than 10 minutes, other-

wise the device will overheat

and may be damaged.

WARNING

The tire inflation pressure must

be at least 200 kPa, 2 bar (29

psi). If it is not, do not continue

driving. Call for road side serv-

ice or towing.

Page 432 of 568

633

What to do in an emergency

TOWING

Towing service

If emergency towing is necessary,

we recommend having it done by an

authorized Kia dealer or a commer-

cial tow-truck service. Proper lifting

and towing procedures are neces-

sary to prevent damage to the vehi-

cle. The use of wheel dollies or

flatbed is recommended.It is acceptable to tow the vehicle

with the rear wheels on the ground

(without dollies) and the front wheels

off the ground.

If any of the loaded wheels or sus-

pension components are damaged

or the vehicle is being towed with the

front wheels on the ground, use a

towing dolly under the front wheels.

When being towed by a commercial

tow truck and wheel dollies are not

used, the front of the vehicle should

always be lifted, not the rear.

✽ ✽

NOTICE

If the EPB does not release normal-

ly, take your vehicle to an author-

ized Kia dealer by loading the vehi-

cle on a flatbed tow truck and have

the system checked.

OBD068011 dollydolly

WARNING - Side and

curtain Air bag

If your vehicle is equipped with

side and curtain air bags, set

the ignition switch to the LOCK

or ACC position when the vehi-

cle is being towed.

The side and curtain air bag

may deploy when the ignition is

in the ON position, and the

rollover sensor detects a

rollover situation.

Page 473 of 568

Maintenance

36

7

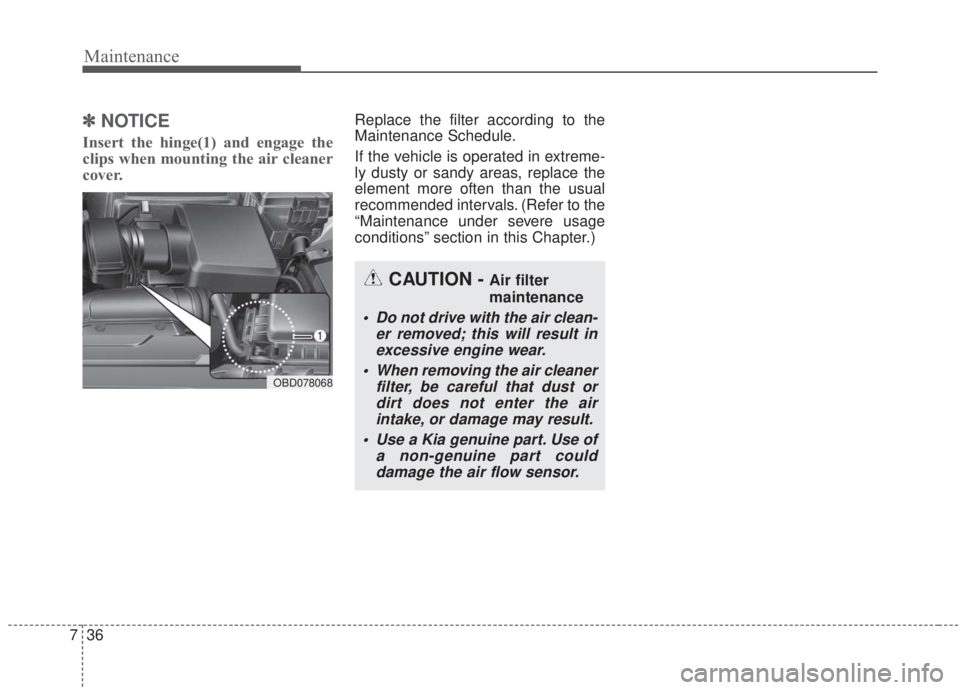

✽ ✽

NOTICE

Insert the hinge(1) and engage the

clips when mounting the air cleaner

cover.

Replace the filter according to the

Maintenance Schedule.

If the vehicle is operated in extreme-

ly dusty or sandy areas, replace the

element more often than the usual

recommended intervals. (Refer to the

“Maintenance under severe usage

conditions” section in this Chapter.)

OBD078068

CAUTION - Air filter

maintenance

Do not drive with the air clean-

er removed; this will result inexcessive engine wear.

When removing the air cleaner filter, be careful that dust ordirt does not enter the airintake, or damage may result.

Use a Kia genuine part. Use of a non-genuine part coulddamage the air flow sensor.

Page 506 of 568

769

Maintenance

Fuse NameFuse ratingCircuit Protected

MODULE 510ACrash Pad Switch, Head Lamp Left Handle side/Right Handle side, Auto Transmission Shift Lever Indicator,

Electro Chromic Mirror, Audio/Video & Navigation Head Unit, Air Conditioner Control Module, Rear Seat

Warmer Control Module, Front Seat Warmer Control Module, Front Air Ventilation Seat Control Module

DOOR LOCK20ADoor Lock/Unlock Relay, ICM (Integrated Circuit Module) Relay Box (Two Turn Unlock Relay), Driver IMS

(Intergrated memory system) Module

IBU 115AIBU (Integrated Body Control Unit)

BRAKE SWITCH10AIBU (Integrated Body Control Unit), Stop Lamp Switch

IG125AEngine Room Junction Block (Fuse - ABS 3, ECU 5, SENSOR 4, TCU 2)

WIPER (LO/HI)10AEngine Room Junction Block (Front Wiper (Low) Relay), Front Wiper Motor, ECM (Engine Control

Module)/PCM (Power train Control Module), IBU (Integrated Body Control Unit)

AIR CONDITIONER17.5AEngine Room Junction Block (Blower, PTC Heater), Air Conditioner Control Module

AIR BAG 210ASRS (Supplemental Restraint System) Control Module

WASHER15AMultifunction Switch

MDPS7.5AMDPS (Motor Driven Power Steering) Unit

MODULE 77.5ARear Seat Warmer Control Module, Front Seat Warmer Control Module, Front Air Ventilation Seat Control

Module

SUNROOF 115ASunroof Motor, ESG_Unit

Page 507 of 568

Maintenance

70

7

Fuse NameFuse ratingCircuit Protected

CLUSTER7.5AInstrument Cluster

MODULE 37.5ASport Mode Switch, Stop Lamp Switch

START7.5AICM (Integrated Circuit Module) Relay Box (Burglar Alarm Relay), Transmission Range Switch, IBU

(Integrated Body Control Unit), ECM (Engine Control Module)/PCM (Power train Control Module),

Engine Room Junction Block (Start)

IBU 27.5AIBU (Integrated Body Control Unit)

AIR BAG

INDICATOR7.5AInstrument Cluster, Air Conditioner Control Module

MODULE 67.5AIBU (Integrated Body Control Unit)

MODULE 210AAudio/Video & Navigation Head Unit, IBU (Integrated Body Control Unit), Rear USB Charger, Wireless

Charger, AMP (Amplifier), Power Outside Mirror Switch, Engine Room Junction Block (Power Outlet)

AIR BAG 115ASRS (Supplemental Restraint System) Control Module, Passenger Occupant Detection Sensor

AIR

CONDITIONER 210AEngine Room Junction Block (BLOWER Relay), Air Conditioner Control Module, Blower Resistor, Blower

Motor

POWER OUTLET20ACigarette Lighter

Page 510 of 568

![KIA FORTE 2020 Workshop Manual 773

Maintenance

Fuse Name Fuse ratingCircuit Protected

FUSE

POWER OUTLET 220AFront Power Outlet

TCU 115A [GAMMA 1.6L T-GDI] TCM (Transmission Control Module)

VACUUM PUMP20A[GAMMA 1.6L T-GDI] Vacuum P KIA FORTE 2020 Workshop Manual 773

Maintenance

Fuse Name Fuse ratingCircuit Protected

FUSE

POWER OUTLET 220AFront Power Outlet

TCU 115A [GAMMA 1.6L T-GDI] TCM (Transmission Control Module)

VACUUM PUMP20A[GAMMA 1.6L T-GDI] Vacuum P](/img/2/40395/w960_40395-509.png)

773

Maintenance

Fuse Name Fuse ratingCircuit Protected

FUSE

POWER OUTLET 220AFront Power Outlet

TCU 115A [GAMMA 1.6L T-GDI] TCM (Transmission Control Module)

VACUUM PUMP20A[GAMMA 1.6L T-GDI] Vacuum Pump

FUEL PUMP20AFuel Pump Relay

COOLING FAN 230A[NU 2.0L AKS] Cooling Fan 2 Relay, Cooling Fan 3 Relay

B+140AInstrument Panel Junction Block (Long Term Load Latch Relay, Fuse : (BRAKE SWITCH, IBU

1, AIR BAG 2, DOOR LOCK, SEAT HEATER REAR, MODULE 1))

DCT 140A[GAMMA 1.6L T-GDI] TCM (Transmission Control Module)

DCT 240A[GAMMA 1.6L T-GDI] TCM (Transmission Control Module)

ABS 140AABS (Anti-lock brake system) Module, ESC (Electronic Stability Control) Module

ABS 230AABS (Anti-lock brake system) Module, ESC (Electronic Stability Control) Module

POWER OUTLET 140APower Outlet Relay

SENSOR 210A

[NU 2.0L AKS] Purge Control Solenoid Valve, Oil Control Valve #1/#2/#3, Canister Close

Valve, Mass Air Folw Sensor, A/Con Relay, E/R Junction Block (Cooling Fan Relay 1), Variable

Intake Sensor

[GAMMA 1.6L T-GDI] Purge Control Solenoid Valve, Oil Control Valve #1/#2, Canister Close

Valve, RCV Control Solenoid Valve, E/R Junction Block (Cooling Fan Relay 1)

ECU 210A[GAMMA 1.6L T-GDI] ECM (Engine Control Module)

ECU 120A[NU 2.0L AKS] PCM (Power train Control Module)

[GAMMA 1.6L T-GDI] ECM (Engine Control Module)

INJECTOR15A[NU 2.0L AKS] Injector #1~#4

Engine room compartment fuse panel

Page 511 of 568

![KIA FORTE 2020 Workshop Manual Maintenance

74

7

Fuse Name Fuse ratingCircuit Protected

FUSE

SENSOR 115A[NU 2.0L AKS] Oxygen Sensor (Up), Oxygen Sensor (Down)

[GAMMA 1.6L T-GDI] Oxygen Sensor (Up), Oxygen Sensor (Down)

IGN COIL20A[ KIA FORTE 2020 Workshop Manual Maintenance

74

7

Fuse Name Fuse ratingCircuit Protected

FUSE

SENSOR 115A[NU 2.0L AKS] Oxygen Sensor (Up), Oxygen Sensor (Down)

[GAMMA 1.6L T-GDI] Oxygen Sensor (Up), Oxygen Sensor (Down)

IGN COIL20A[](/img/2/40395/w960_40395-510.png)

Maintenance

74

7

Fuse Name Fuse ratingCircuit Protected

FUSE

SENSOR 115A[NU 2.0L AKS] Oxygen Sensor (Up), Oxygen Sensor (Down)

[GAMMA 1.6L T-GDI] Oxygen Sensor (Up), Oxygen Sensor (Down)

IGN COIL20A[NU 2.0L AKS] Ignition Coil #1~#4

[GAMMA 1.6L T-GDI] Ignition Coil #1~#4

ECU 315A[NU 2.0L AKS] PCM (Power train Control Module)

[GAMMA 1.6L T-GDI] ECM (Engine Control Module)

A/CON COMP10A[NU 2.0L AKS] A/Con Relay

ECU 510A[NU 2.0L AKS] PCM (Power train Control Module)

[GAMMA 1.6L T-GDI] ECM (Engine Control Module)

SENSOR 415A[GAMMA 1.6L T-GDI] Vacuum Pump

ABS 310AABS (Anti-lock brake system) Module, ESC (Electronic Stability Control) Module

TCU 215A[NU 2.0L AKS] Transmission Range Switch

[GAMMA 1.6L T-GDI] Transmission Range Switch, TCM

SENSOR 310A[NU 2.0L AKS] Fuel Pump Relay

[GAMMA 1.6L T-GDI] Fuel Pump Relay

ECU 415A[NU 2.0L AKS] PCM (Power train Control Module)

[GAMMA 1.6L T-GDI] ECM (Engine Control Module)

WIPER25A[NU 2.0L AKS] Wiper Relay

[GAMMA 1.6L T-GDI] Wiper Relay

HORN15A[NU 2.0L AKS] Horn Relay

[GAMMA 1.6L T-GDI] Horn Relay

Page 534 of 568

797

Maintenance

APPEARANCE CARE

Exterior care

Exterior general caution

It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning

and caution statements that appear

on the label.

Finish maintenance

Washing

To help protect your vehicle’s finish

from rust and deterioration, wash it

thoroughly and frequently at least

once a month with lukewarm or cold

water.

If you use your vehicle for off-road

driving, you should wash it after each

off-road trip. Pay special attention to

the removal of any accumulation of

salt, dirt, mud, and other foreign mate-

rials. Make sure the drain holes in the

lower edges of the doors and rocker

panels are kept clear and clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar

deposits can damage your vehicle’s

finish if not removed immediately.

Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, may be used.

After washing, rinse the vehicle thor-

oughly with lukewarm or cold water.

Do not allow soap to dry on the finish.High-pressure washing

When using high-pressure wash-

ers, make sure to maintain suffi-

cient distance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component

damage or water penetration.

Do not spray the camera, sensors or its surrounding area directly with

a high pressure washer. Shock

applied from high pressure water

may cause the device to not oper-

ate normally.

Do not bring the nozzle tip close to boots (rubber or plastic covers) or

connectors as they may be dam-

aged if they come into contact with

high pressure water.

Page 561 of 568

Index

4I

Emission control system ..............................................7-105Crankcase emission control system ..........................7-105

Evaporative emission control (including ORVR: Onboard Refueling Vapor Recovery) system ........7-105

Exhaust emission control system ..............................7-106

Engine ........................................................................\

......8-3

Engine compartment ................................................2-6, 7-4

Engine coolant ..............................................................7-28 Changing the coolant ..................................................7-31

Checking the coolant level..........................................7-28

Engine number ..............................................................8-12

Engine oil ......................................................................7-\

26 Changing the engine oil and filter ..............................7-27

Checking the engine oil level ....................................7-26

Engine start/stop button ................................................5-11 Engine start/stop button position ................................5-11

Illuminated engine start/stop button ..........................5-11

Starting the engine ......................................................5-14

Stopping the engine (Manual transmission) ..............5-17

Explanation of scheduled maintenance items ..............7-21

Exterior overview ............................................................2-2

Forward Collision-avoidance Assist (FCA) (Camera + Radar type) ................................................5-72Brake operation ..........................................................5-75

FCA warning message and system control ................5-74 Limitation of the system ............................................5-80

Limitation of the system ............................................5-83

Recognizing pedestrians ............................................5-84

Sensor to detect the distance from the vehicle in front (front radar/camera) ..................................................5-76

System malfunction ....................................................5-78

System setting and activation ....................................5-72

Forward Collision-avoidance Assist (FCA) (Camera type) ..............................................................5-59Brake operation ..........................................................5-62

FCA front view camera sensor ..................................5-63

FCA warning message and system control ................5-61

Limitation of the system ............................................5-67

System malfunction ....................................................5-65

System setting and activation ....................................5-59

Fuel filler lid ..................................................................4-38 Closing the fuel filler lid ............................................4-38

Opening the fuel filler lid ..........................................4-38

Fuel requirements ............................................................1-3 Do not use methanol ....................................................1-4

Fuel Additives ..............................................................1-5

Gasoline containing alcohol and methanol ..................1-3

Operation in foreign countries ......................................1-5

Fuses ........................................................................\

......7-61 Engine compartment fuse replacement ......................7-64

Fuse/relay panel description ......................................7-67

Inner panel fuse replacement ......................................7-63

F