sensor KIA FORTE KOUP 2018 Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: FORTE KOUP, Model: KIA FORTE KOUP 2018Pages: 584, PDF Size: 15.16 MB

Page 421 of 584

Driving your vehicle

80

5

- A fixed object is near such as a

guardrail, etc.

- A substantial amount of metallic objects such as a construction

area.

- A large vehicle is nearby such as a bus or truck.

- A motorcycle or bicycle is near.

- A flat trailer is near.

- If two vehicles near each other accelerate together.

- When another vehicle passes by at a high rate of speed.

- When changing lanes.

- When going down or up a steep, uneven road.

- When another vehicle drives very close the back bumper/trunk.

- When a trailer or carrier is installed. - When the temperature of the rear

bumper is very high or low.

- When bike racks, etc. cover the sensor.

- When reversing from a parking space with pillars or metal struc-

tures.

- When you are reversing and if the detected vehicle is simultaneously

reversing.

- If there are small objects like shop- ping carts and baby carriages.

- If there is a vehicle with decreased ride height (lowered).

- When the vehicle is close to anoth- er vehicle.

- When driving through a narrow road with many plants.

- When driving on wet surface.Outside rearview mirror may not alert the driver when:

- The outside rearview mirror hous- ing is very dirty.

- The window is very dirty.

- The windows are tinted very dark.

- When driving through a narrow road with many plants.

Page 448 of 584

611

What to do in an emergency

Distributing the sealant

11. Immediately drive approximately7~10 km (4~6 miles or, about

10min) to evenly distribute the

sealant in the tire.

Do not exceed a speed of 80 km/h

(50 mph). If possible, do not fall

below a speed of 20 km/h (12 mph).

While driving, if you experience any

unusual vibration, ride disturbance or

noise, reduce your speed and drive

with caution until you can safely pull

off of the side of the road.

Call for road side service or towing.

When you use the Tire Mobility Kit,

the tire pressure sensors and wheel

may be stained by sealant.

Therefore, remove the tire pressure

sensors and wheel stained by

sealant and we recommend that

inspect at an authorized Kia dealer.

Checking the tire inflation

pressure

1.After driving approximately 7 ~ 10 km (4 ~ 6 miles or about 10 min),

stop at a safe location.

2.Connect connection hose (9) of the compressor directly to the tire

valve.

3.Plug the compressor power cord into the vehicle power outlet.

4.Adjust the tire inflation pressure to the recomended tire inflation.

With the ignition switch on, pro-

ceed as follows.

- To increase the inflation pres-sure : Switch on the compressor,

position I. To check the current

inflation pressure setting, briefly

switch off the compressor.

✽ ✽ NOTICE

The pressure gauge may show high-

er than actual reading when the

compressor is running. To get an

accurate tire reading, the compres-

sor needs to be turned off.

- To reduce the inflation pres-

sure: Press the button 8 on the

compressor.

Page 449 of 584

What to do in an emergency

12

6

Technical Data

System voltage : DC 12 V

Working voltage : DC 10 - 15 V

Amperage rating : max. 15 A

Suitable for use at temperatures :

-30 ~ +70°C (-22 ~ +158°F)

Max. working pressure : 6 bar (87 psi)

Size

Compressor : 168 x 150 x 68 mm (6.6 x 5.9 x 2.7 in.)

Sealant bottle : 104 x ø 85 mm (4.1 x ø 3.3 in.)

Compressor weight : 1.05 kg (2.31 lbs)

Sealant volume : 300 ml (18.3 cu. in.)

Sealant warranty : 5 years (sealant.)CAUTION - Tire pressuresensor

When you use the Tire Mobility

Kit including sealant notapproved by Kia, the tire pres-sure sensors may be damagedby sealant. The sealant on thetire pressure sensor and wheelshould be removed when youreplace the tire with a new oneand inspect the tire pressuresensors at an authorized dealer.

Page 459 of 584

What to do in an emergency

22

6

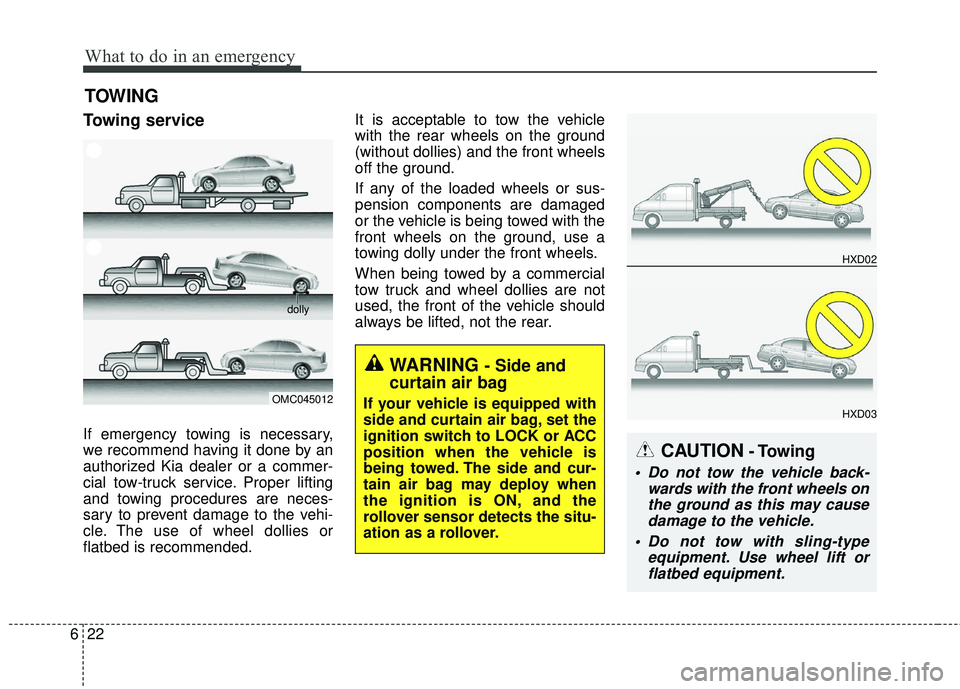

TOWING

Towing service

If emergency towing is necessary,

we recommend having it done by an

authorized Kia dealer or a commer-

cial tow-truck service. Proper lifting

and towing procedures are neces-

sary to prevent damage to the vehi-

cle. The use of wheel dollies or

flatbed is recommended. It is acceptable to tow the vehicle

with the rear wheels on the ground

(without dollies) and the front wheels

off the ground.

If any of the loaded wheels or sus-

pension components are damaged

or the vehicle is being towed with the

front wheels on the ground, use a

towing dolly under the front wheels.

When being towed by a commercial

tow truck and wheel dollies are not

used, the front of the vehicle should

always be lifted, not the rear.

CAUTION- Towing

Do not tow the vehicle back-

wards with the front wheels onthe ground as this may causedamage to the vehicle.

Do not tow with sling-type equipment. Use wheel lift orflatbed equipment.

OMC045012

dolly

HXD02

HXD03

WARNING - Side and

curtain air bag

If your vehicle is equipped with

side and curtain air bag, set the

ignition switch to LOCK or ACC

position when the vehicle is

being towed. The side and cur-

tain air bag may deploy when

the ignition is ON, and the

rollover sensor detects the situ-

ation as a rollover.

Page 503 of 584

741

Maintenance

Replace the filter according to the

Maintenance Schedule.

If the vehicle is operated in extreme-ly dusty or sandy areas, replace theelement more often than the usualrecommended intervals. (Refer to“Maintenance under severe usageconditions” in this chapter.)

CAUTION - Air filter

maintenance

Do not drive with the air clean- er removed; this will result inexcessive engine wear.

When removing the air cleaner filter, be careful that dust ordirt does not enter the airintake, or damage may result.

Use a Kia genuine part. Use of nongenuine part could dam-age the air flow sensor.

Page 535 of 584

773

Maintenance

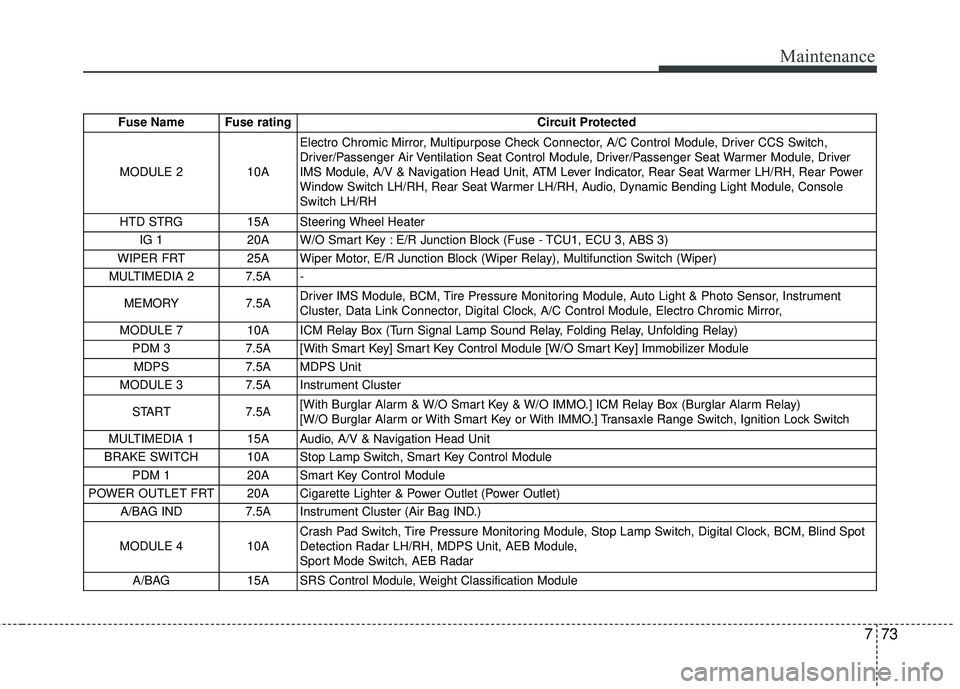

Fuse Name Fuse ratingCircuit Protected

MODULE 2 10A Electro Chromic Mirror, Multipurpose Check Connector, A/C Control Module, Driver CCS Switch,

Driver/Passenger Air Ventilation Seat Control Module, Driver/Passenger Seat Warmer Module, Driver

IMS Module, A/V & Navigation Head Unit, ATM Lever Indicator, Rear Seat Warmer LH/RH, Rear Power

Window Switch LH/RH, Rear Seat Warmer LH/RH, Audio, Dynamic Bending Light Module, Console

Switch LH/RH

HTD STRG 15A Steering Wheel Heater

IG 1 20A W/O Smart Key : E/R Junction Block (Fuse - TCU1, ECU 3, ABS 3)

WIPER FRT 25A Wiper Motor, E/R Junction Block (Wiper Relay), Multifunction Switch (Wiper)

MULTIMEDIA 2 7.5A -

MEMORY 7.5ADriver IMS Module, BCM, Tire Pressure Monitoring Module, Auto Light & Photo Sensor, Instrument

Cluster, Data Link Connector, Digital Clock, A/C Control Module, Electro Chromic Mirror,

MODULE 7 10A ICM Relay Box (Turn Signal Lamp Sound Relay, Folding Relay, Unfolding Relay)

PDM 3 7.5A [With Smart Key] Smart Key Control Module [W/O Smart Key] Immobilizer Module

MDPS 7.5A MDPS Unit

MODULE 3 7.5A Instrument Cluster

START 7.5A[With Burglar Alarm & W/O Smart Key & W/O IMMO.] ICM Relay Box (Burglar Alarm Relay)

[W/O Burglar Alarm or With Smart Key or With IMMO.] Transaxle Range Switch, Ignition Lock Switch

MULTIMEDIA 1 15A Audio, A/V & Navigation Head Unit

BRAKE SWITCH 10A Stop Lamp Switch, Smart Key Control Module PDM 1 20A Smart Key Control Module

POWER OUTLET FRT 20A Cigarette Lighter & Power Outlet (Power Outlet) A/BAG IND 7.5A Instrument Cluster (Air Bag IND.)

MODULE 4 10ACrash Pad Switch, Tire Pressure Monitoring Module, Stop Lamp Switch, Digital Clock, BCM, Blind Spot

Detection Radar LH/RH, MDPS Unit, AEB Module,

Sport Mode Switch, AEB Radar

A/BAG 15A SRS Control Module, Weight Classification Module

Page 539 of 584

777

Maintenance

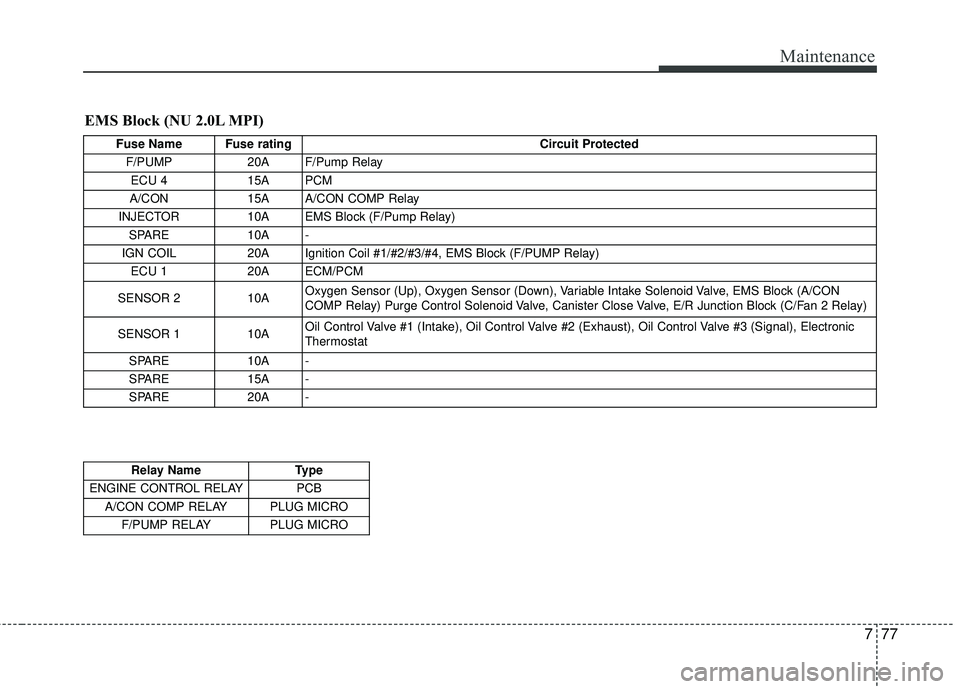

EMS Block (NU 2.0L MPI)

Fuse Name Fuse ratingCircuit Protected

F/PUMP 20A F/Pump Relay

ECU 4 15A PCM

A/CON 15A A/CON COMP Relay

INJECTOR 10A EMS Block (F/Pump Relay)

SPARE 10A -

IGN COIL 20A Ignition Coil #1/#2/#3/#4, EMS Block (F/PUMP Relay)

ECU 1 20A ECM/PCM

SENSOR 2 10A Oxygen Sensor (Up), Oxygen Sensor (Down), Variable Intake Solenoid Valve, EMS Block (A/CON

COMP Relay) Purge Control Solenoid Valve, Canister Close Valve, E/R Junction Block (C/Fan 2 Relay)

SENSOR 1 10A Oil Control Valve #1 (Intake), Oil Control Valve #2 (Exhaust), Oil Control Valve #3 (Signal), Electronic

Thermostat

SPARE 10A -

SPARE 15A -

SPARE 20A -

Relay Name Type

ENGINE CONTROL RELAY PCB A/CON COMP RELAY PLUG MICRO F/PUMP RELAY PLUG MICRO

Page 540 of 584

Maintenance

78

7

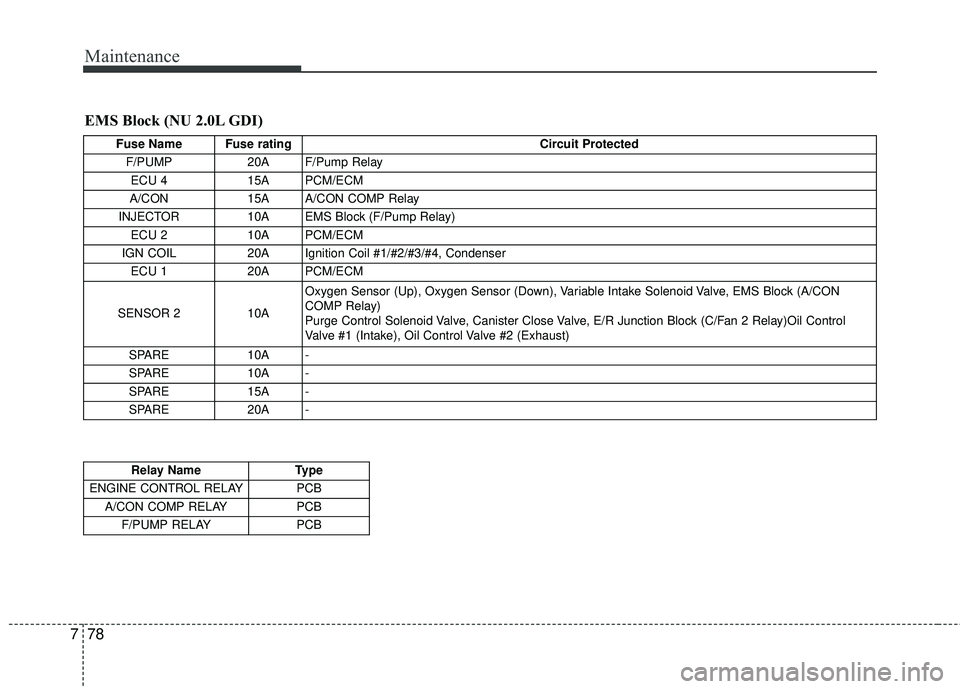

EMS Block (NU 2.0L GDI)

Fuse Name Fuse rating Circuit Protected

F/PUMP 20A F/Pump Relay

ECU 4 15A PCM/ECM

A/CON 15A A/CON COMP Relay

INJECTOR 10A EMS Block (F/Pump Relay)

ECU 2 10A PCM/ECM

IGN COIL 20A Ignition Coil #1/#2/#3/#4, Condenser

ECU 1 20A PCM/ECM

SENSOR 2 10A Oxygen Sensor (Up), Oxygen Sensor (Down), Variable Intake Solenoid Valve, EMS Block (A/CON

COMP Relay)

Purge Control Solenoid Valve, Canister Close Valve, E/R Junction Block (C/Fan 2 Relay)Oil Control

Valve #1 (Intake), Oil Control Valve #2 (Exhaust)

SPARE 10A -

SPARE 10A -

SPARE 15A -

SPARE 20A -

Relay Name Type

ENGINE CONTROL RELAY PCB A/CON COMP RELAY PCB

F/PUMP RELAY PCB

Page 541 of 584

779

Maintenance

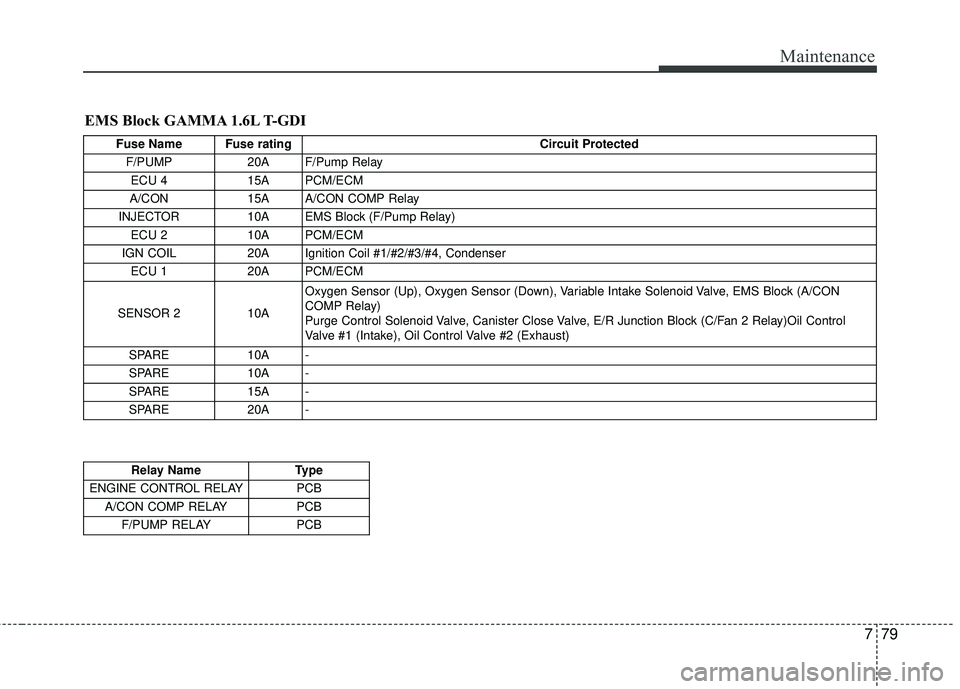

EMS Block GAMMA 1.6L T-GDI

Fuse Name Fuse ratingCircuit Protected

F/PUMP 20A F/Pump Relay

ECU 4 15A PCM/ECM

A/CON 15A A/CON COMP Relay

INJECTOR 10A EMS Block (F/Pump Relay)

ECU 2 10A PCM/ECM

IGN COIL 20A Ignition Coil #1/#2/#3/#4, Condenser

ECU 1 20A PCM/ECM

SENSOR 2 10A Oxygen Sensor (Up), Oxygen Sensor (Down), Variable Intake Solenoid Valve, EMS Block (A/CON

COMP Relay)

Purge Control Solenoid Valve, Canister Close Valve, E/R Junction Block (C/Fan 2 Relay)Oil Control

Valve #1 (Intake), Oil Control Valve #2 (Exhaust)

SPARE 10A -

SPARE 10A -

SPARE 15A -

SPARE 20A -

Relay Name Type

ENGINE CONTROL RELAY PCB A/CON COMP RELAY PCB

F/PUMP RELAY PCB

Page 556 of 584

Maintenance

94

7

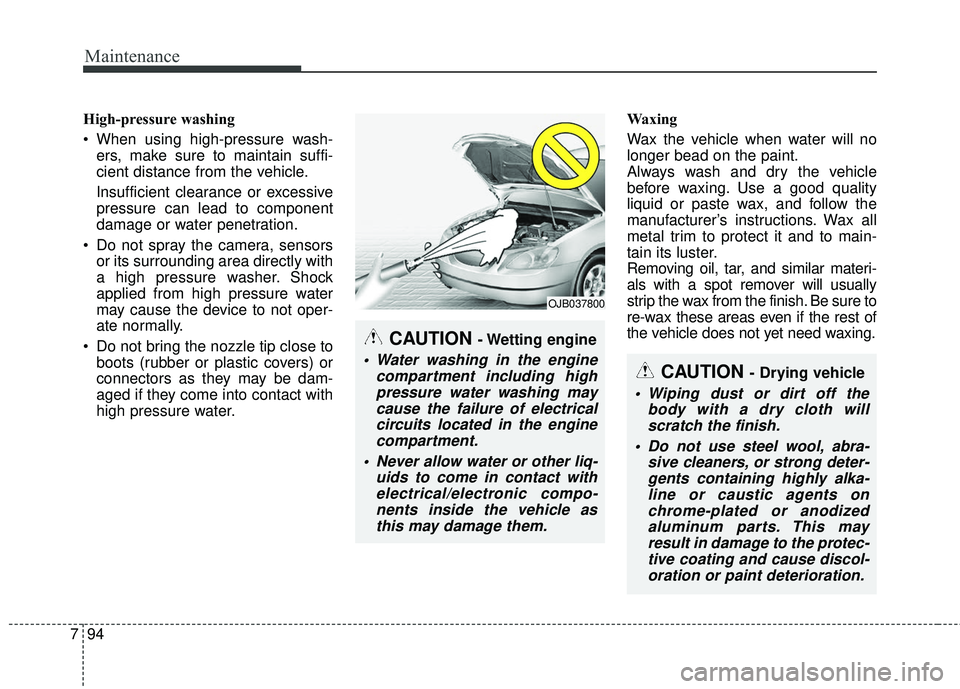

High-pressure washing

When using high-pressure wash-

ers, make sure to maintain suffi-

cient distance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component

damage or water penetration.

Do not spray the camera, sensors or its surrounding area directly with

a high pressure washer. Shock

applied from high pressure water

may cause the device to not oper-

ate normally.

Do not bring the nozzle tip close to boots (rubber or plastic covers) or

connectors as they may be dam-

aged if they come into contact with

high pressure water. Waxing

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle

before waxing. Use a good quality

liquid or paste wax, and follow the

manufacturer’s instructions. Wax all

metal trim to protect it and to main-

tain its luster.

Removing oil, tar, and similar materi-

als with a spot remover will usually

strip the wax from the finish. Be sure to

re-wax these areas even if the rest of

the vehicle does not yet need waxing.

CAUTION - Wetting engine

Water washing in the engine

compartment including highpressure water washing maycause the failure of electricalcircuits located in the enginecompartment.

Never allow water or other liq- uids to come in contact withelectrical/electronic compo-nents inside the vehicle asthis may damage them.

OJB037800

CAUTION - Drying vehicle

Wiping dust or dirt off the body with a dry cloth willscratch the finish.

Do not use steel wool, abra- sive cleaners, or strong deter-gents containing highly alka-line or caustic agents onchrome-plated or anodizedaluminum parts. This mayresult in damage to the protec-tive coating and cause discol-oration or paint deterioration.