brake KIA NIRO 2018 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: NIRO, Model: KIA NIRO 2018Pages: 616, PDF Size: 18.3 MB

Page 490 of 616

821

Maintenance

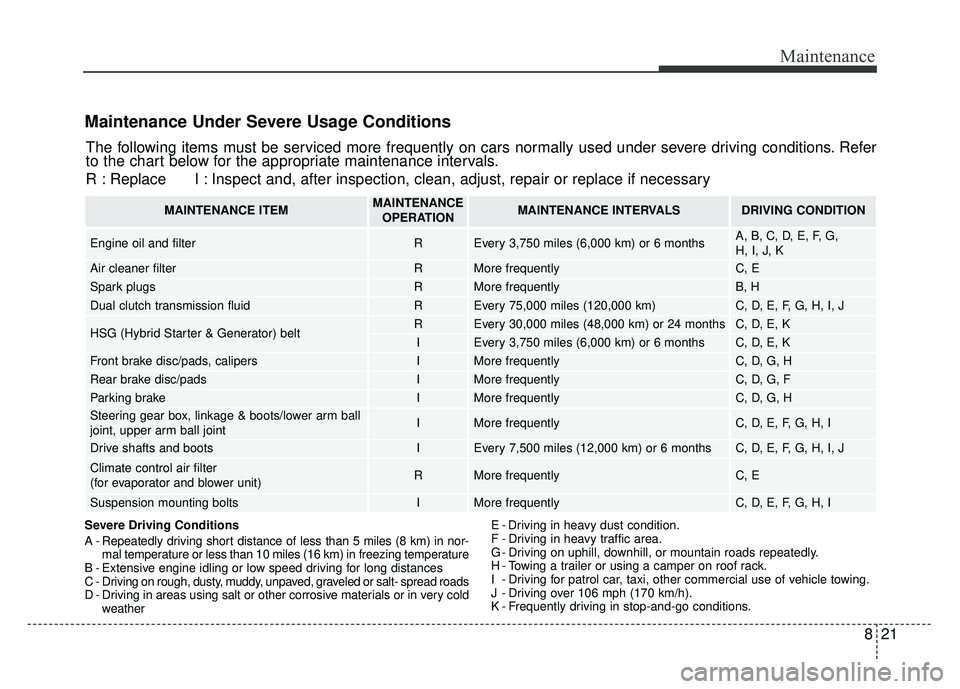

Maintenance Under Severe Usage Conditions

Severe Driving Conditions

A - Repeatedly driving short distance of less than 5 miles (8 km) in nor-mal temperature or less than 10 miles (16 km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads

D - Driving in areas using salt or other corrosive materials or in very cold weather E - Driving in heavy dust condition.

F - Driving in heavy traffic area.

G - Driving on uphill, downhill, or mountain roads repeatedly.

H - Towing a trailer or using a camper on roof rack.

I - Driving for patrol car, taxi, other commercial use of vehicle towing.

J - Driving over 106 mph (170 km/h).

K - Frequently driving in stop-and-go conditions.

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer

to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if neces\

sary

MAINTENANCE ITEMMAINTENANCE

OPERATIONMAINTENANCE INTERVALSDRIVING CONDITION

Engine oil and filter REvery 3,750 miles (6,000 km) or 6 monthsA, B, C, D, E, F, G,

H, I, J, K

Air cleaner filterRMore frequentlyC, E

Spark plugsRMore frequentlyB, H

Dual clutch transmission fluid REvery 75,000 miles (120,000 km)C, D, E, F, G, H, I, J

HSG (Hybrid Starter & Generator) beltREvery 30,000 miles (48,000 km) or 24 monthsC, D, E, K

IEvery 3,750 miles (6,000 km) or 6 monthsC, D, E, K

Front brake disc/pads, calipersIMore frequentlyC, D, G, H

Rear brake disc/padsIMore frequentlyC, D, G, F

Parking brakeIMore frequentlyC, D, G, H

Steering gear box, linkage & boots/lower arm ball

joint, upper arm ball jointIMore frequentlyC, D, E, F, G, H, I

Drive shafts and bootsIEvery 7,500 miles (12,000 km) or 6 monthsC, D, E, F, G, H, I, J

Climate control air filter

(for evaporator and blower unit)RMore frequentlyC, E

Suspension mounting boltsIMore frequentlyC, D, E, F, G, H, I

Page 492 of 616

823

Maintenance

Vacuum crankcase ventilation

hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold.

Inspect the hose routing to assure

that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component which

might cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

Air cleaner filter

A Genuine Kia air cleaner filter is

recommended when the filter is

replaced.

Spark plugs

Make sure to install new spark plugs

of the correct heat range.

Cooling system

Check the cooling system compo-

nents, such as the radiator, coolant

reservoir, hoses and connections for

leakage and damage. Replace any

damaged parts.

Coolant (Engine / Inverter)

The coolant should be changed at

the intervals specified in the mainte-

nance schedule.

Dual clutch transmission Fluid

Inspect the dual clutch transmission

fluid according to the maintenance

schedule.

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and

any leakage. Replace any deteriorat-

ed or damaged parts immediately.

Page 493 of 616

Maintenance

24

8

✽

✽

NOTICE - NHTSA Safety

Corrosion Alert

NHTSA has warned all vehicle own-

ers of all brands that they must main-

tain their vehicles in a manner which

will prevent brake hose and brake line

failures due to corrosion when such

vehicles are exposed to winter road

salt and related chemicals. While seri-

ous corrosion conditions typically only

manifest themselves as safety issues

after 7 years of vehicle use, the corro-

sion process starts immediately and

thus underbody cleaning maintenance

must commence from your vehicle's

first exposure to road salts and chem-

icals. NHTSA urges vehicle owners to

take the following steps to prevent

corrosion:

(Continued)(Continued)

1. Wash the undercarriage of your

vehicle regularly throughout the

winter and do a thorough washing

in the spring to remove road salt

and other de-icing chemicals.

2. Monitor the brake system for signs of corrosion by having regu-

lar professional inspections and

watching for signs of problems,

including loss of brake fluid,

unusual leaks and soft or spongy

feel in the brake pedal.

3. Replace the entire brake pipe assembly if you find severe corro-

sion that causes scaling or flaking

of brake components.

Brake fluid

Check the brake fluid level in the

brake fluid reservoir. The level should

be between “MIN” and “MAX” marks

on the side of the reservoir. Use only

hydraulic brake fluid conforming to

DOT 3 or DOT 4 specification.

Parking brake

Inspect the parking brake system

including the parking brake pedal

and cables.

Brake discs, pads, calipers

and rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

Page 494 of 616

825

Maintenance

Exhaust pipe and muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine

off, check for excessive free-play in

the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or

damage. Replace any damaged

parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.When checking engine oil, engine

coolant, brake fluid, and washer fluid,

always be sure to clean the area

around any filler plug, drain plug, or

dipstick before checking or draining

any lubricant or fluid. This is espe-

cially important in dusty or sandy

areas and when the vehicle is used

on unpaved roads. Cleaning the plug

and dipstick areas will prevent dirt

and grit from entering the engine and

other mechanisms that could be

damaged.

CHECKING FLUID LEVELS

Page 502 of 616

833

Maintenance

BRAKE FLUID

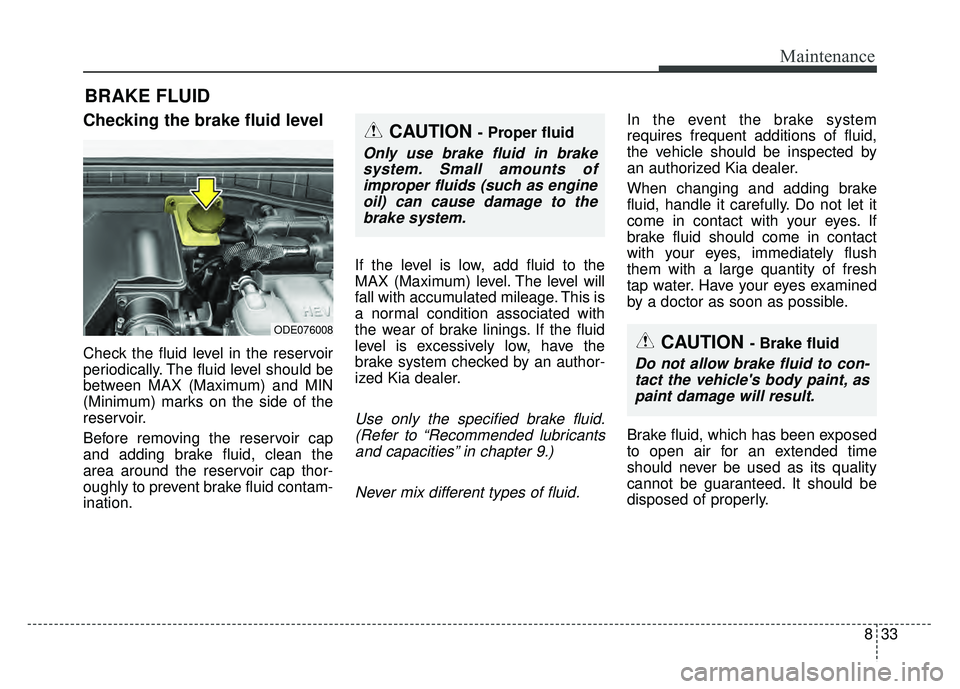

Checking the brake fluid level

Check the fluid level in the reservoir

periodically. The fluid level should be

between MAX (Maximum) and MIN

(Minimum) marks on the side of the

reservoir.

Before removing the reservoir cap

and adding brake fluid, clean the

area around the reservoir cap thor-

oughly to prevent brake fluid contam-

ination.If the level is low, add fluid to the

MAX (Maximum) level. The level will

fall with accumulated mileage. This is

a normal condition associated with

the wear of brake linings. If the fluid

level is excessively low, have the

brake system checked by an author-

ized Kia dealer.

Use only the specified brake fluid.

(Refer to “Recommended lubricantsand capacities” in chapter 9.)

Never mix different types of fluid.

In the event the brake system

requires frequent additions of fluid,

the vehicle should be inspected by

an authorized Kia dealer.

When changing and adding brake

fluid, handle it carefully. Do not let it

come in contact with your eyes. If

brake fluid should come in contact

with your eyes, immediately flush

them with a large quantity of fresh

tap water. Have your eyes examined

by a doctor as soon as possible.

Brake fluid, which has been exposed

to open air for an extended time

should never be used as its quality

cannot be guaranteed. It should be

disposed of properly.

CAUTION - Brake fluid

Do not allow brake fluid to con-tact the vehicle's body paint, aspaint damage will result.

CAUTION - Proper fluid

Only use brake fluid in brakesystem. Small amounts ofimproper fluids (such as engineoil) can cause damage to thebrake system.

ODE076008

Page 506 of 616

837

Maintenance

Checking the parking brake

Check whether the stroke is within

specification when the parking brake

pedal is depressed with 66 lb, 294 N

(30 kg) of force. Also, the parking

brake alone should securely hold the

vehicle on a fairly steep grade. If the

stroke is more or less than specified,

have the parking brake adjusted by

an authorized Kia dealer.

Stroke : 6~7 notch

PARKING BRAKE

OJF055017

Page 520 of 616

851

Maintenance

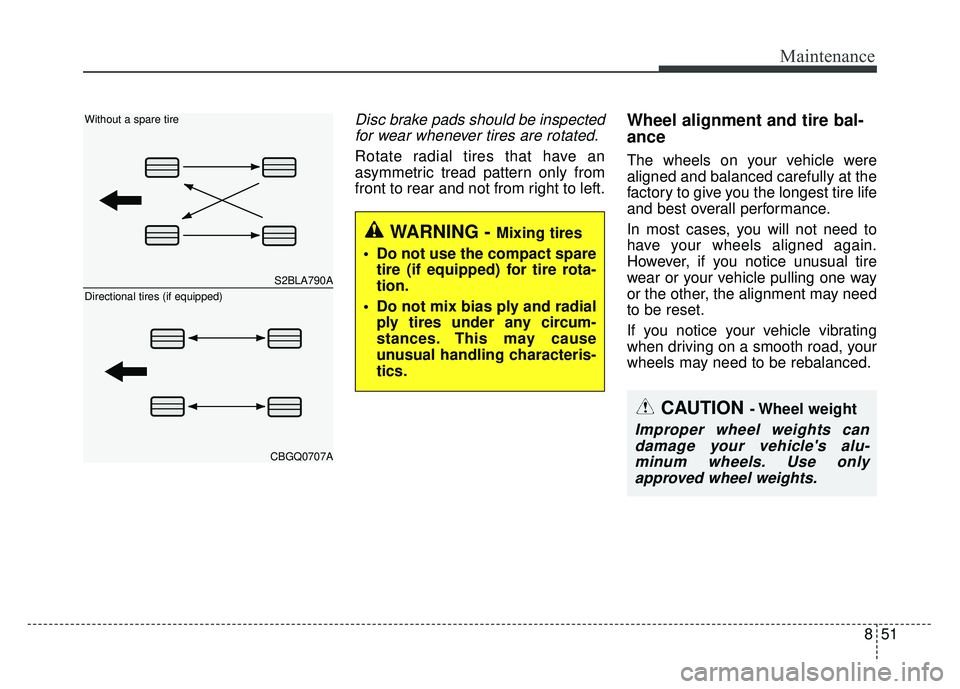

Disc brake pads should be inspectedfor wear whenever tires are rotated.

Rotate radial tires that have an

asymmetric tread pattern only from

front to rear and not from right to left.

Wheel alignment and tire bal-

ance

The wheels on your vehicle were

aligned and balanced carefully at the

factory to give you the longest tire life

and best overall performance.

In most cases, you will not need to

have your wheels aligned again.

However, if you notice unusual tire

wear or your vehicle pulling one way

or the other, the alignment may need

to be reset.

If you notice your vehicle vibrating

when driving on a smooth road, your

wheels may need to be rebalanced.

WARNING - Mixing tires

Do not use the compact spare tire (if equipped) for tire rota-

tion.

Do not mix bias ply and radial ply tires under any circum-

stances. This may cause

unusual handling characteris-

tics.

CAUTION - Wheel weight

Improper wheel weights candamage your vehicle's alu-minum wheels. Use onlyapproved wheel weights.

S2BLA790A

CBGQ0707A

Without a spare tire

Directional tires (if equipped)

Page 521 of 616

Maintenance

52

8

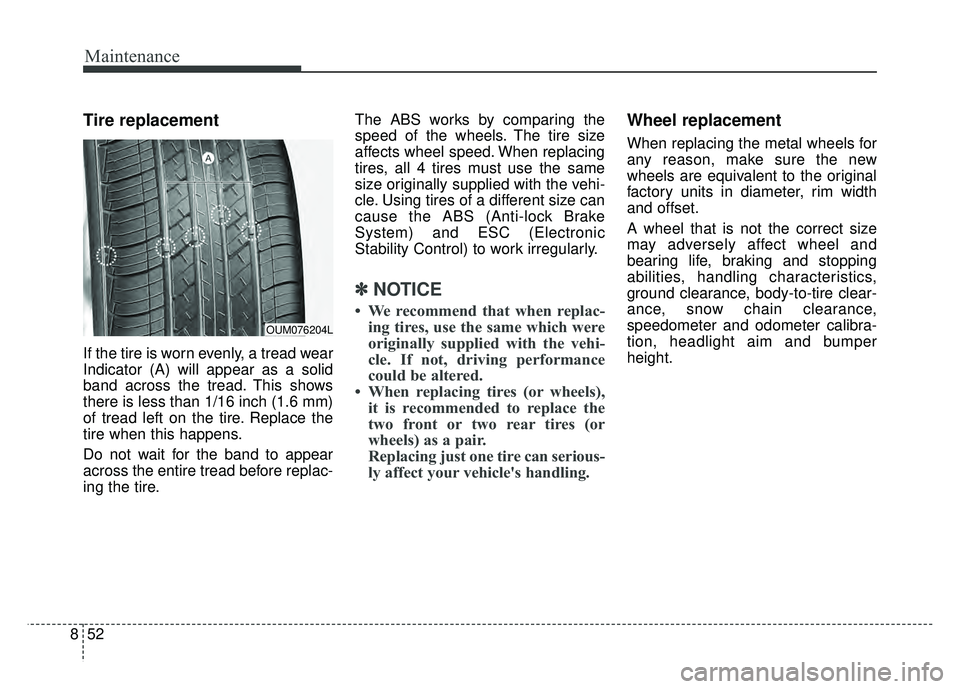

Tire replacement

If the tire is worn evenly, a tread wear

Indicator (A) will appear as a solid

band across the tread. This shows

there is less than 1/16 inch (1.6 mm)

of tread left on the tire. Replace the

tire when this happens.

Do not wait for the band to appear

across the entire tread before replac-

ing the tire. The ABS works by comparing the

speed of the wheels. The tire size

affects wheel speed. When replacing

tires, all 4 tires must use the same

size originally supplied with the vehi-

cle. Using tires of a different size can

cause the ABS (Anti-lock Brake

System) and ESC (Electronic

Stability Control) to work irregularly.

✽ ✽

NOTICE

• We recommend that when replac-

ing tires, use the same which were

originally supplied with the vehi-

cle. If not, driving performance

could be altered.

• When replacing tires (or wheels), it is recommended to replace the

two front or two rear tires (or

wheels) as a pair.

Replacing just one tire can serious-

ly affect your vehicle's handling.

Wheel replacement

When replacing the metal wheels for

any reason, make sure the new

wheels are equivalent to the original

factory units in diameter, rim width

and offset.

A wheel that is not the correct size

may adversely affect wheel and

bearing life, braking and stopping

abilities, handling characteristics,

ground clearance, body-to-tire clear-

ance, snow chain clearance,

speedometer and odometer calibra-

tion, headlight aim and bumper

height.

OUM076204L

Page 528 of 616

859

Maintenance

Production options weight:The

combined weight of installed regular

production options weighing over 5

lb.(2.3 kg) in excess of the standard

items which they replace, not previ-

ously considered in curb weight or

accessory weight, including heavy

duty brakes, ride levelers, roof rack,

heavy duty battery, and special trim.

Recommended Inflation Pressure:

Vehicle manufacturer's recommend-

ed tire inflation pressure and shown

on the tire placard.

Radial Ply Tire: A pneumatic tire in

which the ply cords that extend to the

beads are laid at 90 degrees to the

centerline of the tread.

Rim: A metal support for a tire and

upon which the tire beads are seat-

ed.

Sidewall: The portion of a tire

between the tread and the bead. Speed Rating:

An alphanumeric

code assigned to a tire indicating the

maximum speed at which a tire can

operate.

Traction: The friction between the

tire and the road surface. The

amount of grip provided.

Tread: The portion of a tire that

comes into contact with the road.

Treadwear Indicators: Narrow

bands, sometimes called "wear

bars," that show across the tread of a

tire when only 1/16 inch of tread

remains.

UTQGS: Uniform Tire Quality

Grading Standards, a tire information

system that provides consumers with

ratings for a tire's traction, tempera-

ture and treadwear. Ratings are

determined by tire manufacturers

using government testing proce-

dures. The ratings are molded into

the sidewall of the tire.

Vehicle Capacity Weight: The num-

ber of designated seating positions

multiplied by 150 lbs. (68kg) plus the

rated cargo and luggage load. Vehicle Maximum Load on the

Tire:

Load on an individual tire due

to curb and accessory weight plus

maximum occupant and cargo

weight.

Vehicle Normal Load on the Tire:

Load on an individual tire that is

determined by distributing to each

axle its share of the curb weight,

accessory weight, and normal occu-

pant weight and driving by 2.

Vehicle Placard: A label permanent-

ly attached to a vehicle showing the

original equipment tire size and rec-

ommended inflation pressure.

Page 542 of 616

873

Maintenance

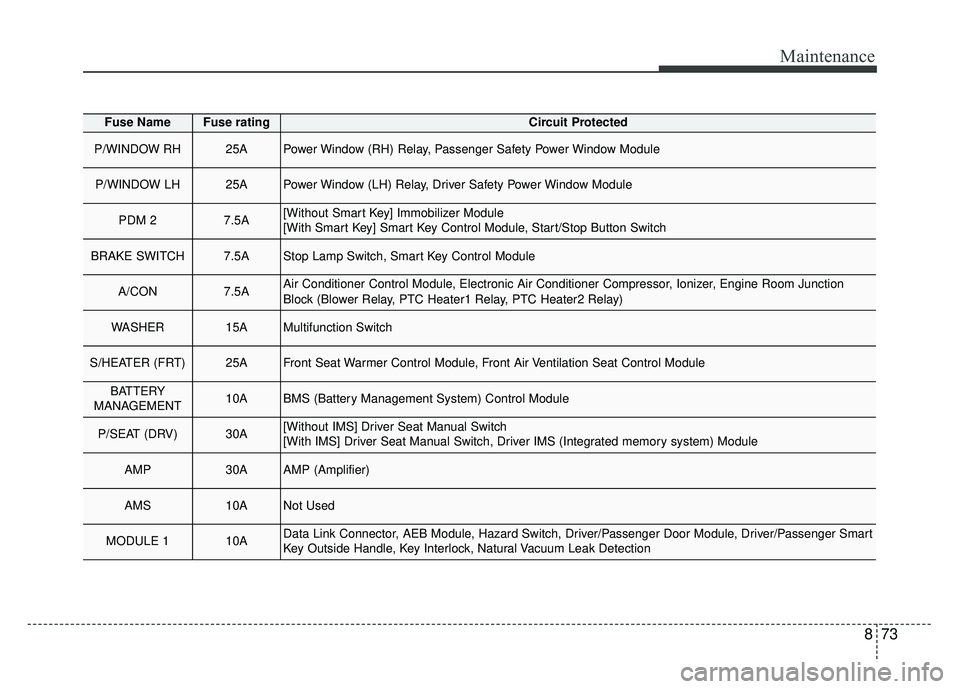

Fuse NameFuse ratingCircuit Protected

P/WINDOW RH25APower Window (RH) Relay, Passenger Safety Power Window Module

P/WINDOW LH25APower Window (LH) Relay, Driver Safety Power Window Module

PDM 27.5A[Without Smart Key] Immobilizer Module

[With Smart Key] Smart Key Control Module, Start/Stop Button Switch

BRAKE SWITCH7.5AStop Lamp Switch, Smart Key Control Module

A/CON7.5AAir Conditioner Control Module, Electronic Air Conditioner Compressor, Ionizer, Engine Room Junction

Block (Blower Relay, PTC Heater1 Relay, PTC Heater2 Relay)

WASHER15AMultifunction Switch

S/HEATER (FRT)25AFront Seat Warmer Control Module, Front Air Ventilation Seat Control Module

BATTERY

MANAGEMENT10ABMS (Battery Management System) Control Module

P/SEAT (DRV)30A[Without IMS] Driver Seat Manual Switch

[With IMS] Driver Seat Manual Switch, Driver IMS (Integrated memory system) Module

AMP30AAMP (Amplifier)

AMS10ANot Used

MODULE 110AData Link Connector, AEB Module, Hazard Switch, Driver/Passenger Door Module, Driver/Passenger Smart

Key Outside Handle, Key Interlock, Natural Vacuum Leak Detection