brake KIA NIRO 2018 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: NIRO, Model: KIA NIRO 2018Pages: 616, PDF Size: 18.3 MB

Page 546 of 616

877

Maintenance

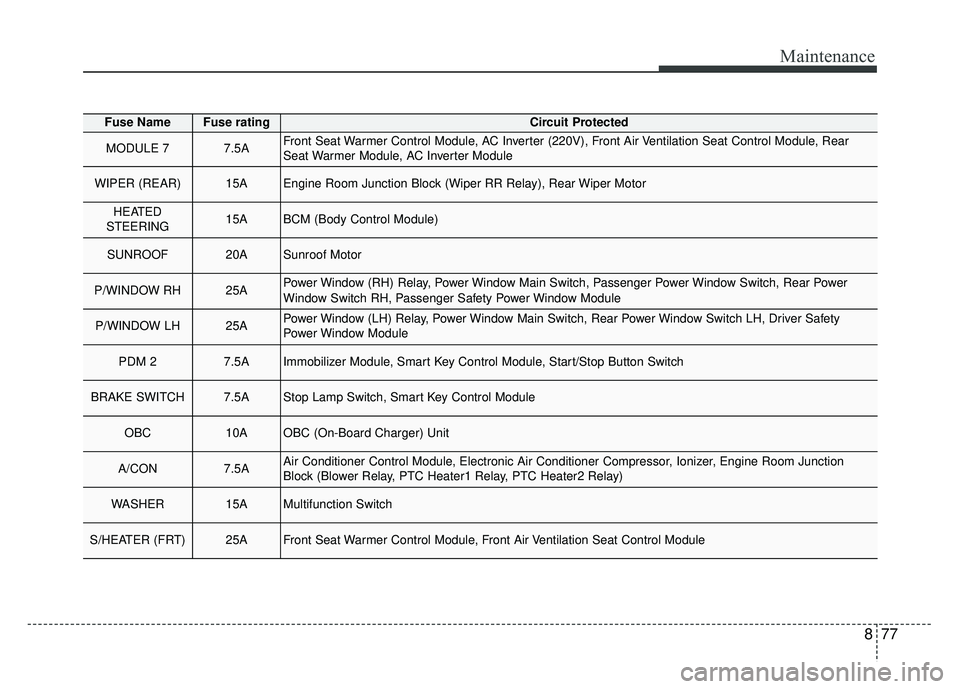

Fuse NameFuse ratingCircuit Protected

MODULE 77.5AFront Seat Warmer Control Module, AC Inverter (220V), Front Air Ventilation Seat Control Module, Rear

Seat Warmer Module, AC Inverter Module

WIPER (REAR)15AEngine Room Junction Block (Wiper RR Relay), Rear Wiper Motor

HEATED

STEERING15ABCM (Body Control Module)

SUNROOF20ASunroof Motor

P/WINDOW RH25APower Window (RH) Relay, Power Window Main Switch, Passenger Power Window Switch, Rear Power

Window Switch RH, Passenger Safety Power Window Module

P/WINDOW LH25APower Window (LH) Relay, Power Window Main Switch, Rear Power Window Switch LH, Driver Safety

Power Window Module

PDM 27.5AImmobilizer Module, Smart Key Control Module, Start/Stop Button Switch

BRAKE SWITCH7.5AStop Lamp Switch, Smart Key Control Module

OBC10AOBC (On-Board Charger) Unit

A/CON7.5AAir Conditioner Control Module, Electronic Air Conditioner Compressor, Ionizer, Engine Room Junction

Block (Blower Relay, PTC Heater1 Relay, PTC Heater2 Relay)

WASHER15AMultifunction Switch

S/HEATER (FRT)25AFront Seat Warmer Control Module, Front Air Ventilation Seat Control Module

Page 550 of 616

881

Maintenance

Fuse NameFuse ratingCircuit Protected

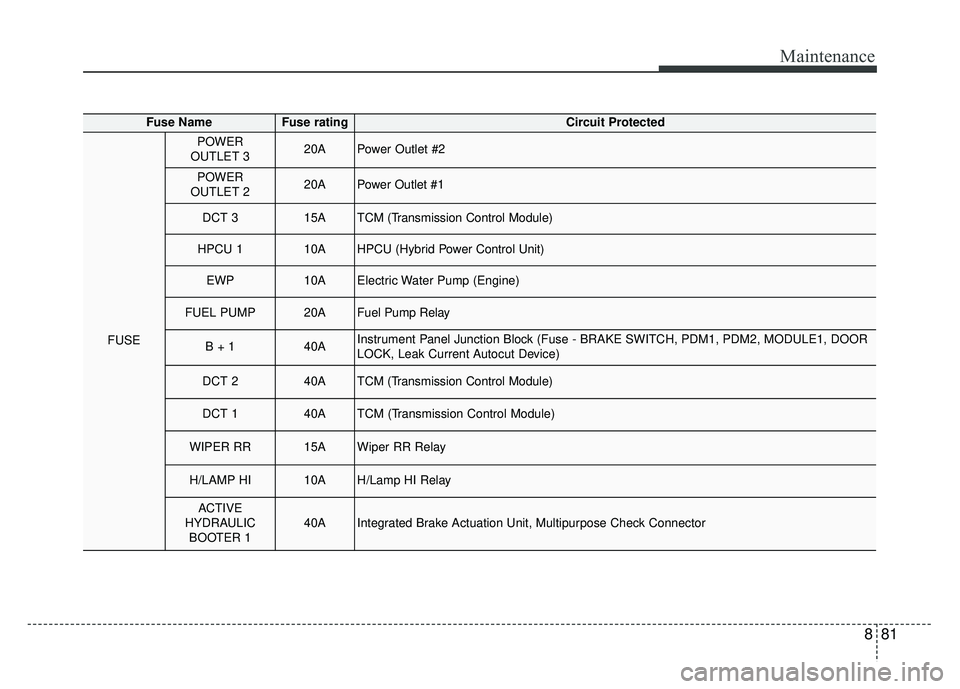

FUSE

POWER

OUTLET 320APower Outlet #2

POWER

OUTLET 220APower Outlet #1

DCT 315ATCM (Transmission Control Module)

HPCU 110AHPCU (Hybrid Power Control Unit)

EWP10AElectric Water Pump (Engine)

FUEL PUMP20AFuel Pump Relay

B + 140AInstrument Panel Junction Block (Fuse - BRAKE SWITCH, PDM1, PDM2, MODULE1, DOOR

LOCK, Leak Current Autocut Device)

DCT 240ATCM (Transmission Control Module)

DCT 140ATCM (Transmission Control Module)

WIPER RR15AWiper RR Relay

H/LAMP HI10AH/Lamp HI Relay

ACTIVE

HYDRAULIC BOOTER 140AIntegrated Brake Actuation Unit, Multipurpose Check Connector

Page 551 of 616

Maintenance

82

8

Fuse NameFuse ratingCircuit Protected

FUSE

ACTIVE

HYDRAULIC BOOTER 230AIntegrated Brake Actuation Unit

INVERTER30AAC Inverter Module

POWER

OUTLET 140APower Outlet Relay

B/UP LAMP10AElectro Chromic Mirror, Back-Up Lamp LH/RH

ECU 310AECM (Engine Control Module)

HPCU 215AHPCU (Hybrid Power Control Unit), Clutch Actuator (HEV)

ACTIVE

HYDRAULIC BOOTER 310AIntegrated Brake Actuation Unit, Multipurpose Check Connector

DCT 415ADCT (Dual clutch transmission) Shift Lever, TCM (Transmission Control Module), Inhibitor

Switch

SENSOR 310AFuel Pump Relay, Oil Control Valve #1/#2 (Intake/Exhaust), Camshaft Position Sensor #1/#2

(Intake/Exhaust)

BATTERY C/FAN15ABattery C/Fan Relay

HORN20AHorn Relay

SENSOR 210APurge Control Solenoid Valve, Cooling Fan Relay, Canister Close Valve, Mass Air Flow Sensor

ECU 120AECM (Engine Control Module)

Page 554 of 616

885

Maintenance

Fuse NameFuse ratingCircuit Protected

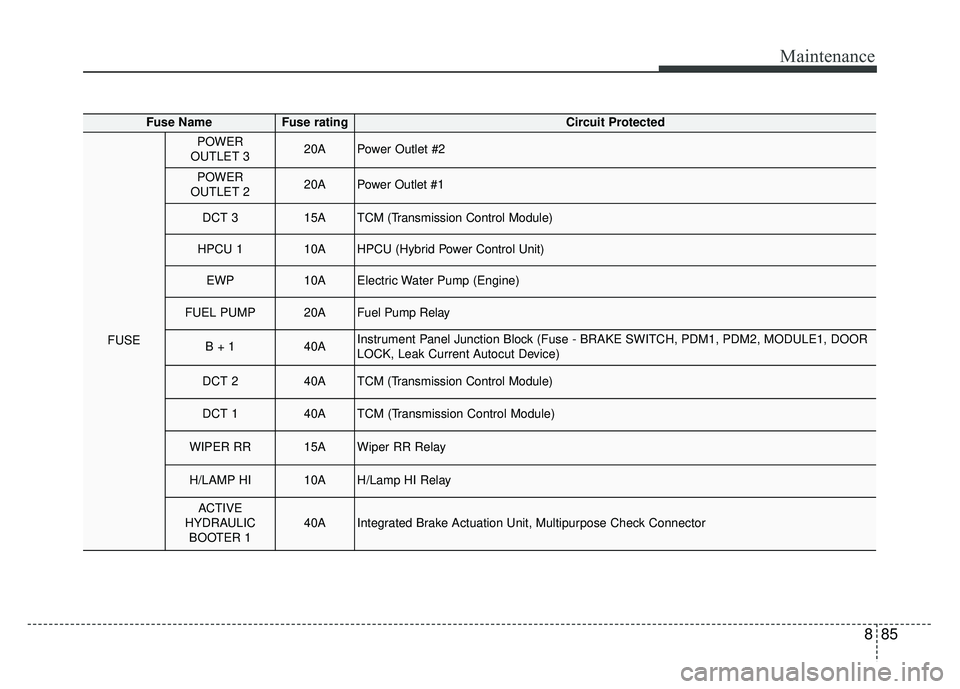

FUSE

POWER

OUTLET 320APower Outlet #2

POWER

OUTLET 220APower Outlet #1

DCT 315ATCM (Transmission Control Module)

HPCU 110AHPCU (Hybrid Power Control Unit)

EWP10AElectric Water Pump (Engine)

FUEL PUMP20AFuel Pump Relay

B + 140AInstrument Panel Junction Block (Fuse - BRAKE SWITCH, PDM1, PDM2, MODULE1, DOOR

LOCK, Leak Current Autocut Device)

DCT 240ATCM (Transmission Control Module)

DCT 140ATCM (Transmission Control Module)

WIPER RR15AWiper RR Relay

H/LAMP HI10AH/Lamp HI Relay

ACTIVE

HYDRAULIC BOOTER 140AIntegrated Brake Actuation Unit, Multipurpose Check Connector

Page 555 of 616

Maintenance

86

8

Fuse NameFuse ratingCircuit Protected

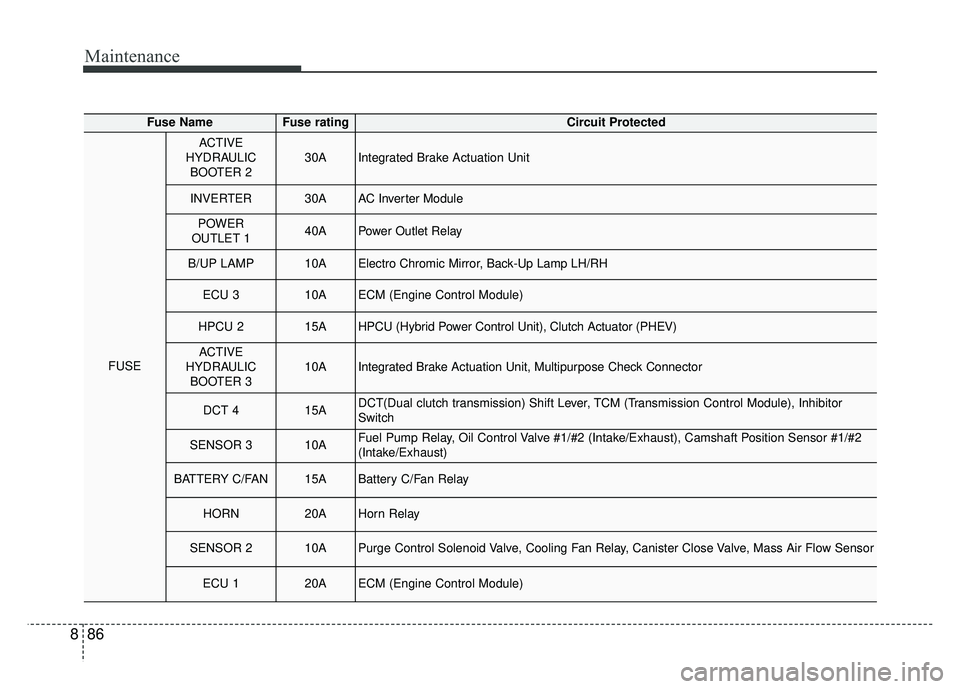

FUSE

ACTIVE

HYDRAULIC BOOTER 230AIntegrated Brake Actuation Unit

INVERTER30AAC Inverter Module

POWER

OUTLET 140APower Outlet Relay

B/UP LAMP10AElectro Chromic Mirror, Back-Up Lamp LH/RH

ECU 310AECM (Engine Control Module)

HPCU 215AHPCU (Hybrid Power Control Unit), Clutch Actuator (PHEV)

ACTIVE

HYDRAULIC BOOTER 310AIntegrated Brake Actuation Unit, Multipurpose Check Connector

DCT 415ADCT(Dual clutch transmission) Shift Lever, TCM (Transmission Control Module), Inhibitor

Switch

SENSOR 310AFuel Pump Relay, Oil Control Valve #1/#2 (Intake/Exhaust), Camshaft Position Sensor #1/#2

(Intake/Exhaust)

BATTERY C/FAN15ABattery C/Fan Relay

HORN20AHorn Relay

SENSOR 210APurge Control Solenoid Valve, Cooling Fan Relay, Canister Close Valve, Mass Air Flow Sensor

ECU 120AECM (Engine Control Module)

Page 560 of 616

891

Maintenance

LIGHT BULBS

Bulb replacement precaution

Please keep extra bulbs on hand

with appropriate wattage ratings in

case of emergencies.

Refer to “Bulb Wattage” in chapter 9.

When changing lamps, first turn off

the engine at a safe place, firmly

apply the parking brake and detach

the battery’s negative (-) terminal.

Use only bulbs of the specifiedwattage.✽ ✽ NOTICE

• If the light bulb or lamp connector

is removed while the lamp is still

on, the fuse box's electronic sys-

tem may log it as a malfunction.

Therefore, a lamp malfunction

incident may be recorded as a

Diagnostic Trouble Code (DTC) in

the fuse box.

• It is normal for an operating lamp to flicker momentarily. This is due

to a stabilization function of the

vehicle’s electronic control device.

If the lamp lights up normally

after momentarily blinking, then

it is functioning as normal.

However, if the lamp continues to

flicker several times or turns off

completely, there may be an error

in the vehicle’s electronic control

device. Please have the vehicle

checked by an authorized Kia

dealer immediately.

WARNING- Working on

the lights

Prior to working on the light,

firmly apply the parking brake,

ensure that the engine

start/stop button is in OFF posi-

tion and turn off the lights to

avoid sudden movement of the

vehicle and burning your fingers

or receiving an electric shock.

CAUTION -Light replace-

ment

Be sure to replace the burned- out bulb with one of the samewattage rating. Otherwise, itmay cause damage to the fuseor electric wiring system.

CAUTION -Headlamp

Lens

To prevent damage, do notclean the headlamp lens withchemical solvents or strongdetergents.

Page 574 of 616

8105

Maintenance

APPEARANCE CARE

Exterior care

Exterior general caution

It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning

and caution statements that appear

on the label.

Finish maintenance

Washing

To help protect your vehicle’s finish

from rust and deterioration, wash it

thoroughly and frequently at least

once a month with lukewarm or cold

water.

If you use your vehicle for off-road

driving, you should wash it after each

off-road trip. Pay special attention to

the removal of any accumulation of

salt, dirt, mud, and other foreign mate-

rials. Make sure the drain holes in the

lower edges of the doors and rocker

panels are kept clear and clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar

deposits can damage your vehicle’s

finish if not removed immediately.

Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, may be used.

After washing, rinse the vehicle thor-

oughly with lukewarm or cold water.

Do not allow soap to dry on the finish.After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired, dry

the brakes by applying them lightly

while maintaining a slow forward

speed.

Page 576 of 616

8107

Maintenance

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly

rust and may develop into a major

repair expense.

If your vehicle is damaged and

requires any metal repair or replace-

ment, be sure the body shop applies

anti-corrosion materials to the parts

repaired or replaced.

Bright-metal maintenance

To remove road tar and insects,use a tar remover, not a scraper or

other sharp object.

To protect the surfaces of bright- metal parts from corrosion, apply a

coating of wax or chrome preser-

vative and rub to a high luster.

During winter weather or in coastal areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

Underbody maintenance

Road salt and other corrosive chemi-

cals are used in cold weather states to

melt snow and prevent ice accumula-

tion. If these chemicals are not regu-

larly removed, they will corrode the

vehicle underbody and over time dam-

age fuel lines, the fuel tank retention

system, the vehicle suspension, the

exhaust system, and even the body

frame. The National Highway Traffic

Safety Administration has warned all

vehicle owners of all brands of the

need to take the following steps: Wash the undercarriage of your

vehicle regularly during the winter

and whenever your vehicle has

been exposed to such salts or

chemicals.

Do a thorough washing of the undercarriage at the end of the

winter.

Use professional service techni- cians or governmental inspection

stations to annually inspect for cor-

rosion.

Immediately seek an inspection of your vehicle if you become visually

aware of corrosion flaking or scal-

ing or if you become aware of a

change in vehicle performance,

such as soft or spongey brakes,

fluids leaking, impairment of direc-

tional control, suspension noises

or rattling metal straps.

CAUTION - Drying vehicle

Wiping dust or dirt off the body with a dry cloth willscratch the finish.

Do not use steel wool, abra- sive cleaners, acid detergentsor strong detergents contain-ing high alkaline or causticagents on chrome-plated oranodized aluminum parts.This may result in damage tothe protective coating andcause discoloration or paintdeterioration.

Page 577 of 616

Maintenance

108

8

Aluminum wheel maintenance

The aluminum wheels are coated with

a clear protective finish.

Do not use any abrasive cleaner,

polishing compound, solvent, or wire

brushes on aluminum wheels. They

may scratch the finish.

Clean the wheel when it has cooled.

Use only a mild soap or neutral detergent, and rinse thoroughly with

water. Also, be sure to clean the

wheels after driving on salted roads.

This helps prevent corrosion.

Avoid washing the wheels with high- speed vehicle wash brushes.

Do not use any alkaline or acid detergents It may damage and cor-

rode the aluminum wheels coated

with a clear protective finish.

Corrosion protection

Protecting your vehicle from corrosion

By using the most advanced design

and construction practices to combat

corrosion, we produce vehicles of

the highest quality. However, this is

only part of the job. To achieve the

long-term corrosion resistance your

vehicle can deliver, the owner's

cooperation and assistance is also

required.

Common causes of corrosion

The most common causes of corro-

sion on your vehicle are:

Road salt, dirt and moisture that isallowed to accumulate underneath

the vehicle.

Removal of paint or protective coatings by stones, gravel, abra-

sion or minor scrapes and dents

which leave unprotected metal

exposed to corrosion. High-corrosion areas

If you live in an area where your vehi-

cle is regularly exposed to corrosive

materials, corrosion protection is

particularly important. Some of the

common causes of accelerated cor-

rosion are road salts, dust control

chemicals, ocean air and industrial

pollution.

Moisture breeds corrosion

Moisture creates the conditions in

which corrosion is most likely to

occur. For example, corrosion is

accelerated by high humidity, partic-

ularly when temperatures are just

above freezing. In such conditions,

the corrosive material is kept in con-

tact with the vehicle’s surface by

moisture that evaporates slowly.

Mud is particularly corrosive

because it dries slowly and holds

moisture in contact with the vehicle.

Although the mud appears to be dry,

it can still retain the moisture and

promote corrosion.

WARNING

After washing the vehicle, test

the brakes while driving slowly

to see if they have been affected

by water. If braking performance

is impaired, dry the brakes by

applying them lightly while main-

taining a slow forward speed.

Page 592 of 616

97

Specifications, Consumer information, Reporting safety defects

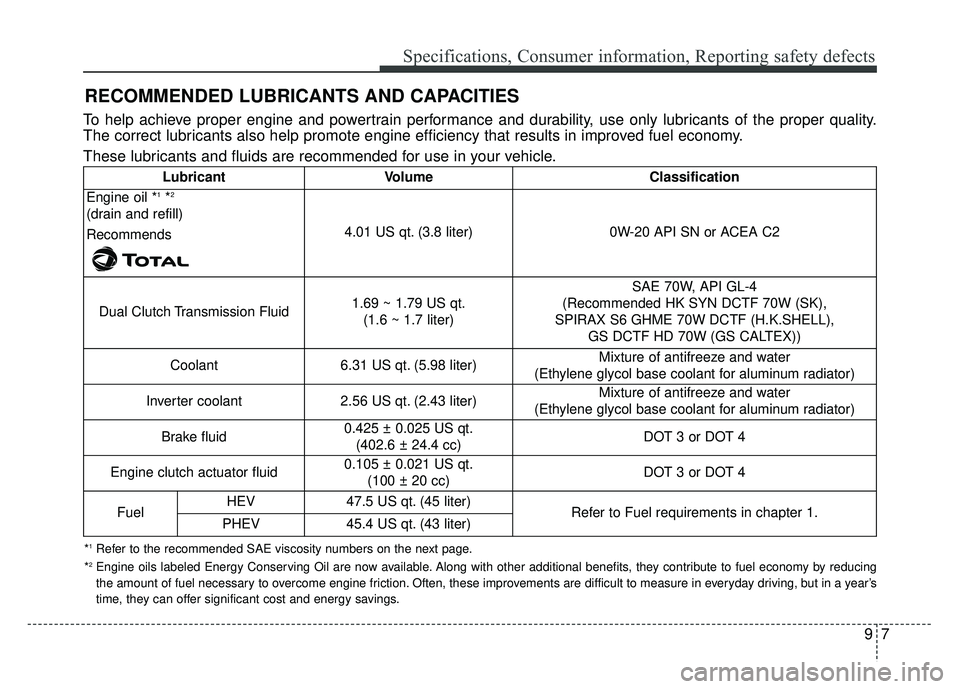

RECOMMENDED LUBRICANTS AND CAPACITIES

To help achieve proper engine and powertrain performance and durability, use only lubricants of the proper quality.

The correct lubricants also help promote engine efficiency that results in improved fuel economy.

These lubricants and fluids are recommended for use in your vehicle.

*1Refer to the recommended SAE viscosity numbers on the next page.

*2Engine oils labeled Energy Conserving Oil are now available. Along with other additional benefits, they contribute to fuel econo my by reducing

the amount of fuel necessary to overcome engine friction. Often, these improvements are difficult to measure in everyday driving, but in a year’s

time, they can offer significant cost and energy savings.

Lubricant VolumeClassification

Engine oil *1*2

(drain and refill)

Recommends

4.01 US qt. (3.8 liter)0W-20 API SN or ACEA C2

Dual Clutch Transmission Fluid1.69 ~ 1.79 US qt. (1.6 ~ 1.7 liter)

SAE 70W, API GL-4

(Recommended HK SYN DCTF 70W (SK),

SPIRAX S6 GHME 70W DCTF (H.K.SHELL), GS DCTF HD 70W (GS CALTEX))

Coolant6.31 US qt. (5.98 liter)Mixture of antifreeze and water

(Ethylene glycol base coolant for aluminum radiator)

Inverter coolant2.56 US qt. (2.43 liter)Mixture of antifreeze and water

(Ethylene glycol base coolant for aluminum radiator)

Brake fluid0.425 ± 0.025 US qt. (402.6 ± 24.4 cc)DOT 3 or DOT 4

Engine clutch actuator fluid0.105 ± 0.021 US qt. (100 ± 20 cc)DOT 3 or DOT 4

FuelHEV47.5 US qt. (45 liter)Refer to Fuel requirements in chapter 1.PHEV45.4 US qt. (43 liter)