cooling KIA NIRO 2021 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2021, Model line: NIRO, Model: KIA NIRO 2021Pages: 710, PDF Size: 14.77 MB

Page 570 of 710

Maintenance

6 7

(Continued)

• Wash the undercarriage of your

vehicle regularly during the win-

ter and whenever your vehicle has

been exposed to such salts or

chemicals.

• Do a thorough washing of the

undercarriage at the end of the

winter.

• Use professional service techni-

cians or governmental inspection

stations to annually inspect for

corrosion.

• Immediately seek an inspection of

your vehicle if you become visual-

ly aware of corrosion flaking or

scaling or if you become aware of

a change in vehicle performance,

such as soft or spongy brakes, flu-

ids leaking, impairment of direc-

tional control, suspension noises

or rattling metal straps.

NHTSA further advises that after

a vehicle is 7 years old, it is essen-

tial that you take these indicated

maintenance steps to ensure that

you protect yourself from unsafe

corrosion conditions.Owner maintenance precau-

tions

Improper or incomplete service may

result in problems. This section gives

instructions only for the maintenance

items that are easy to perform.

As explained earlier in this section,

several procedures can be done only

by an authorized Kia dealer with spe-

cial tools.

✽ ✽

NOTICE

Improper owner maintenance dur-

ing the warranty period may affect

warranty coverage. For details, read

the separate Warranty & Consumer

Information manual provided with

the vehicle. If you're unsure about

any servicing or maintenance proce-

dure, have it done by an authorized

Kia dealer.

WARNING- Maintenance

work

Do not wear jewelry or loose

clothing while working under

the hood of your vehicle with

the engine running. These can

become entangled in moving

parts, if you must run the

engine while working under the

hood, make certain that you

remove all jewelry (especially

rings, bracelets, watches, and

necklaces) and all neckties,

scarves, and similar loose

clothing before getting near the

engine or cooling fans.

WARNING- Touching

metal parts

Do not touch metal parts

(including strut bars) while the

engine is operating or hot.

Doing so could result in serious

bodily injury. Turn the engine off

and wait until the metal parts

cool down to perform any main-

tenance work on the vehicle.

Page 576 of 710

Maintenance

12

7

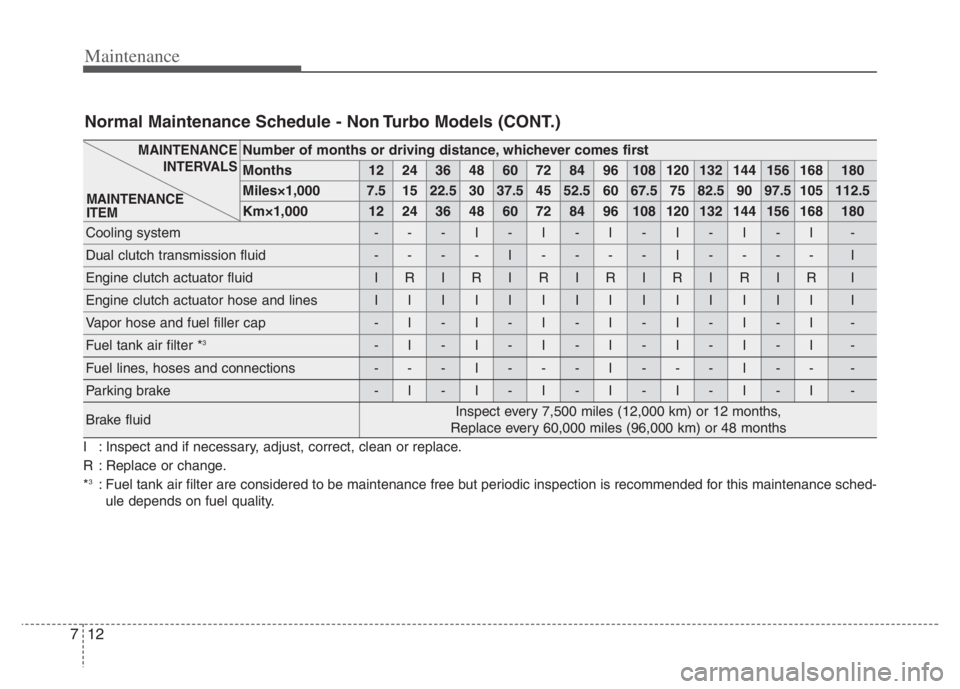

Number of months or driving distance, whichever comes first

Months1224364860728496108120132144156168180

Miles×1,0007.51522.530 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5

Km×1,00012 24 36 48 60 72 84 96 108 120 132 144 156 168 180

Cooling system---I-I-I-I-I-I-

Dual clutch transmission fluid----I----I----I

Engine clutch actuator fluidIRIRIRIRIRIRIRI

Engine clutch actuator hose and linesIIIIIIIIIIIIIII

Vapor hose and fuel filler cap-I-I-I-I-I-I-I-

Fuel tank air filter *3-I-I-I-I-I-I-I-

Fuel lines, hoses and connections---I---I---I---

Parking brake-I-I-I-I-I-I-I-

Brake fluidInspect every 7,500 miles (12,000 km) or 12 months,

Replace every 60,000 miles (96,000 km) or 48 months

MAINTENANCE INTERVALS

MAINTENANCE

ITEM

Normal Maintenance Schedule - Non Turbo Models (CONT.)

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

3: Fuel tank air filter are considered to be maintenance free but periodic inspection is recommended for this maintenance sched- ule depends on fuel quality.

Page 580 of 710

Maintenance

16 7

Vacuum crankcase ventilation

hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold.

Inspect the hose routing to assure

that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component which

might cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

Air cleaner filter

A Genuine Kia air cleaner filter is

recommended when the filter is

replaced.

Spark plugs

Make sure to install new spark plugs

of the correct heat range.

When assembling parts, be sure to

wipe the inside and outside of the

boot bottom of the ignition coil and

the insulator of the spark plug with a

soft cloth to prevent contamination of

the spark plug insulator.

Cooling system

Check the cooling system compo-

nents, such as the radiator, coolant

reservoir, hoses and connections for

leakage and damage. Replace any

damaged parts.

Coolant (Engine / Inverter)

The coolant should be changed at

the intervals specified in the mainte-

nance schedule.

Dual clutch transmission Fluid

Inspect the dual clutch transmission

fluid according to the maintenance

schedule.

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and

any leakage. Replace any deteriorat-

ed or damaged parts immediately.

Page 583 of 710

719

Maintenance

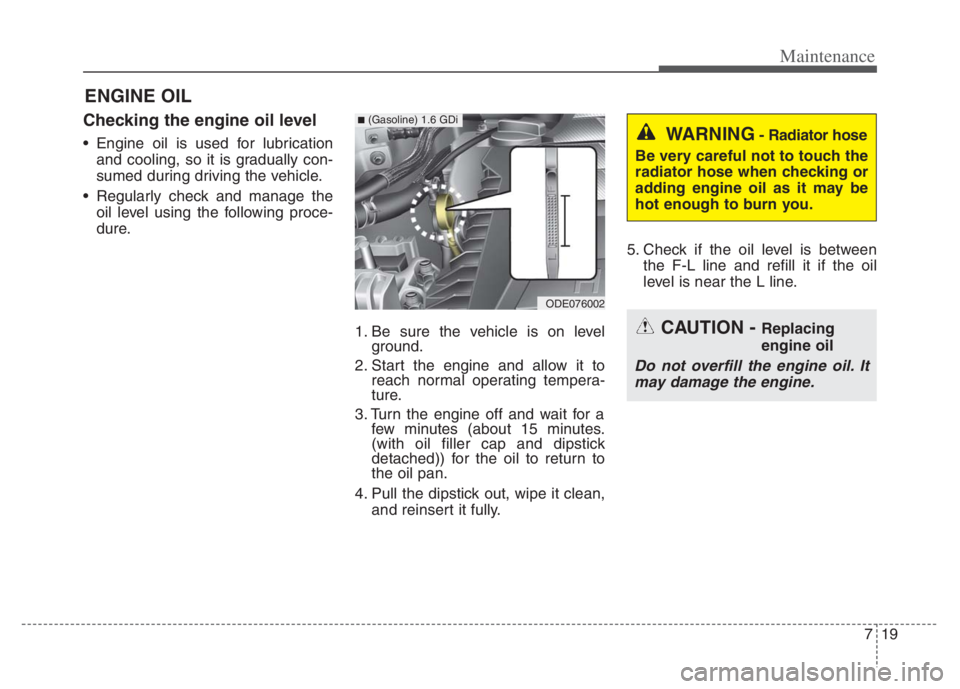

ENGINE OIL

Checking the engine oil level

Engine oil is used for lubrication

and cooling, so it is gradually con-

sumed during driving the vehicle.

Regularly check and manage the

oil level using the following proce-

dure.

1. Be sure the vehicle is on level

ground.

2. Start the engine and allow it to

reach normal operating tempera-

ture.

3. Turn the engine off and wait for a

few minutes (about 15 minutes.

(with oil filler cap and dipstick

detached)) for the oil to return to

the oil pan.

4. Pull the dipstick out, wipe it clean,

and reinsert it fully.5. Check if the oil level is between

the F-L line and refill it if the oil

level is near the L line.

CAUTION - Replacing

engine oil

Do not overfill the engine oil. It

may damage the engine.

WARNING- Radiator hose

Be very careful not to touch the

radiator hose when checking or

adding engine oil as it may be

hot enough to burn you.

ODE076002

■(Gasoline) 1.6 GDi

Page 585 of 710

721

Maintenance

COOLANT

The high-pressure cooling system

has a reservoir filled with year round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant level at least once a year: at

the beginning of the winter season,

and before traveling to a colder cli-

mate.Checking the coolant level Turn the engine off and wait until it

cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back while the

pressure is released from the cool-

ing system.

When you are sure all the pressure

has been released, press down on

the cap, using a thick towel, and

continue turning counterclockwise

to remove it.

Even if the engine is not operating,

do not remove the radiator cap or

the drain plug while the engine and

radiator are hot. Hot coolant and

steam may still blow out under

pressure, causing serious injury.

The engine coolant and/or inverter

coolant level is influenced by the

hybrid system temperature. Before

checking or refilling the engine

coolant and/or inverter coolant,

turn the hybrid vehicle off.

WARNING

Removing radiator

cap

Never attempt to remove the

radiator cap while the engine is

operating or hot. Doing so

might lead to cooling system

and engine damage and could

result in serious personal injury

from escaping hot coolant or

steam.

CAUTION - Radiator cap

Never attempt to remove the

radiator cap while the engine is

operating or hot. Doing so

might lead to cooling system

and engine damage.

Page 586 of 710

Maintenance

22

7

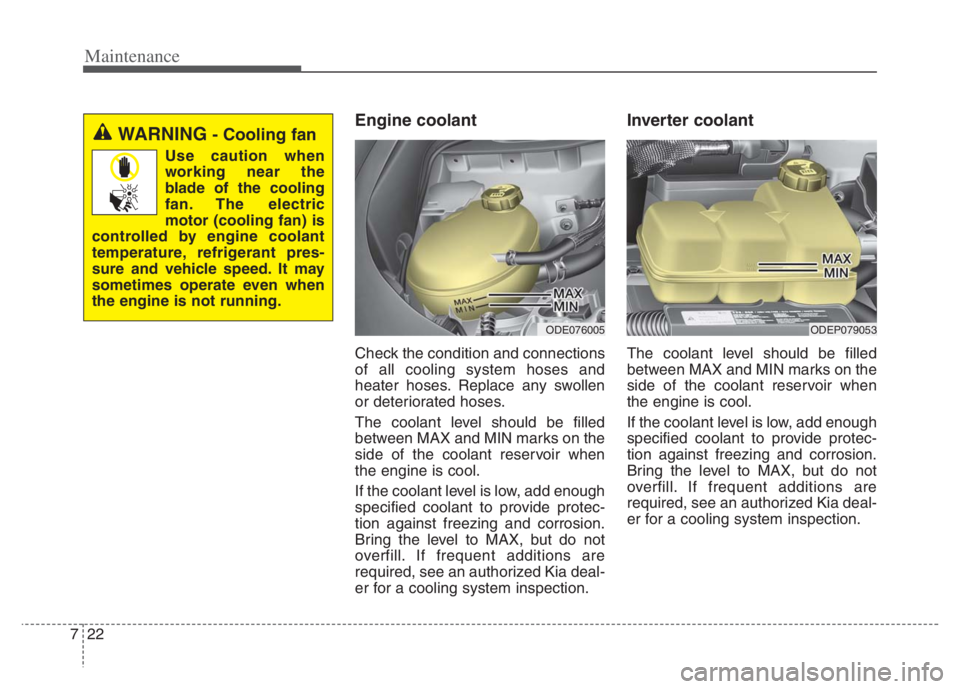

Engine coolant

Check the condition and connections

of all cooling system hoses and

heater hoses. Replace any swollen

or deteriorated hoses.

The coolant level should be filled

between MAX and MIN marks on the

side of the coolant reservoir when

the engine is cool.

If the coolant level is low, add enough

specified coolant to provide protec-

tion against freezing and corrosion.

Bring the level to MAX, but do not

overfill. If frequent additions are

required, see an authorized Kia deal-

er for a cooling system inspection.

Inverter coolant

The coolant level should be filled

between MAX and MIN marks on the

side of the coolant reservoir when

the engine is cool.

If the coolant level is low, add enough

specified coolant to provide protec-

tion against freezing and corrosion.

Bring the level to MAX, but do not

overfill. If frequent additions are

required, see an authorized Kia deal-

er for a cooling system inspection.

WARNING- Cooling fan

Use caution when

working near the

blade of the cooling

fan. The electric

motor (cooling fan) is

controlled by engine coolant

temperature, refrigerant pres-

sure and vehicle speed. It may

sometimes operate even when

the engine is not running.

ODE076005ODEP079053

Page 639 of 710

775

Maintenance

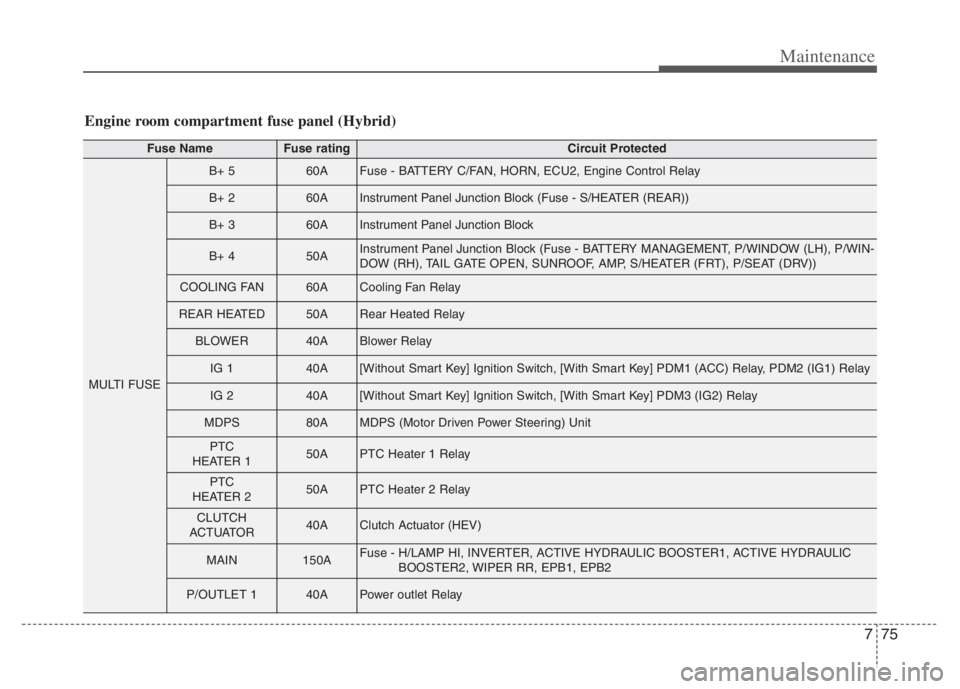

Engine room compartment fuse panel (Hybrid)

Fuse NameFuse ratingCircuit Protected

MULTI FUSE

B+ 560AFuse - BATTERY C/FAN, HORN, ECU2, Engine Control Relay

B+ 260AInstrument Panel Junction Block (Fuse - S/HEATER (REAR))

B+ 360AInstrument Panel Junction Block

B+ 450AInstrument Panel Junction Block (Fuse - BATTERY MANAGEMENT, P/WINDOW (LH), P/WIN-

DOW (RH), TAIL GATE OPEN, SUNROOF, AMP, S/HEATER (FRT), P/SEAT (DRV))

COOLING FAN60ACooling Fan Relay

REAR HEATED50ARear Heated Relay

BLOWER40ABlower Relay

IG 140A[Without Smart Key] Ignition Switch, [With Smart Key] PDM1 (ACC) Relay, PDM2 (IG1) Relay

IG 240A[Without Smart Key] Ignition Switch, [With Smart Key] PDM3 (IG2) Relay

MDPS80AMDPS (Motor Driven Power Steering) Unit

PTC

HEATER 150APTC Heater 1 Relay

PTC

HEATER 250APTC Heater 2 Relay

CLUTCH

ACTUATOR40AClutch Actuator (HEV)

MAIN150AFuse - H/LAMP HI, INVERTER, ACTIVE HYDRAULIC BOOSTER1, ACTIVE HYDRAULIC

BOOSTER2, WIPER RR, EPB1, EPB2

P/OUTLET 140APower outlet Relay

Page 641 of 710

777

Maintenance

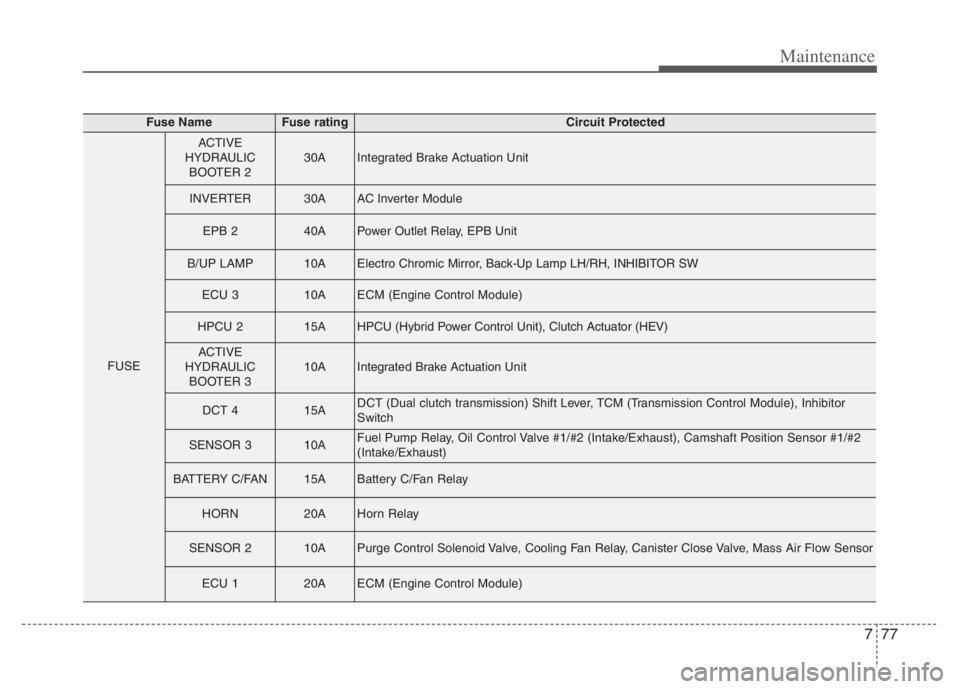

Fuse NameFuse ratingCircuit Protected

FUSE

ACTIVE

HYDRAULIC

BOOTER 230AIntegrated Brake Actuation Unit

INVERTER30AAC Inverter Module

EPB 240APower Outlet Relay, EPB Unit

B/UP LAMP10AElectro Chromic Mirror, Back-Up Lamp LH/RH, INHIBITOR SW

ECU 310AECM (Engine Control Module)

HPCU 215AHPCU (Hybrid Power Control Unit), Clutch Actuator (HEV)

ACTIVE

HYDRAULIC

BOOTER 310AIntegrated Brake Actuation Unit

DCT 415ADCT (Dual clutch transmission) Shift Lever, TCM (Transmission Control Module), Inhibitor

Switch

SENSOR 310AFuel Pump Relay, Oil Control Valve #1/#2 (Intake/Exhaust), Camshaft Position Sensor #1/#2

(Intake/Exhaust)

BATTERY C/FAN15ABattery C/Fan Relay

HORN20AHorn Relay

SENSOR 210APurge Control Solenoid Valve, Cooling Fan Relay, Canister Close Valve, Mass Air Flow Sensor

ECU 120AECM (Engine Control Module)

Page 643 of 710

779

Maintenance

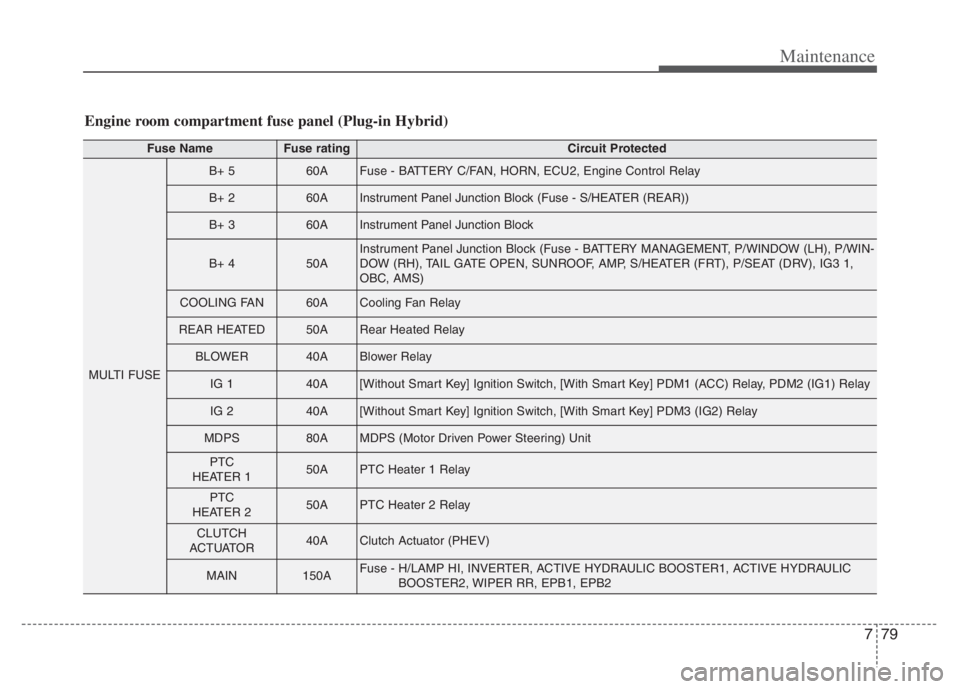

Engine room compartment fuse panel (Plug-in Hybrid)

Fuse NameFuse ratingCircuit Protected

MULTI FUSE

B+ 560AFuse - BATTERY C/FAN, HORN, ECU2, Engine Control Relay

B+ 260AInstrument Panel Junction Block (Fuse - S/HEATER (REAR))

B+ 360AInstrument Panel Junction Block

B+ 450AInstrument Panel Junction Block (Fuse - BATTERY MANAGEMENT, P/WINDOW (LH), P/WIN-

DOW (RH), TAIL GATE OPEN, SUNROOF, AMP, S/HEATER (FRT), P/SEAT (DRV), IG3 1,

OBC, AMS)

COOLING FAN60ACooling Fan Relay

REAR HEATED50ARear Heated Relay

BLOWER40ABlower Relay

IG 140A[Without Smart Key] Ignition Switch, [With Smart Key] PDM1 (ACC) Relay, PDM2 (IG1) Relay

IG 240A[Without Smart Key] Ignition Switch, [With Smart Key] PDM3 (IG2) Relay

MDPS80AMDPS (Motor Driven Power Steering) Unit

PTC

HEATER 150APTC Heater 1 Relay

PTC

HEATER 250APTC Heater 2 Relay

CLUTCH

ACTUATOR40AClutch Actuator (PHEV)

MAIN150AFuse - H/LAMP HI, INVERTER, ACTIVE HYDRAULIC BOOSTER1, ACTIVE HYDRAULIC

BOOSTER2, WIPER RR, EPB1, EPB2

Page 645 of 710

781

Maintenance

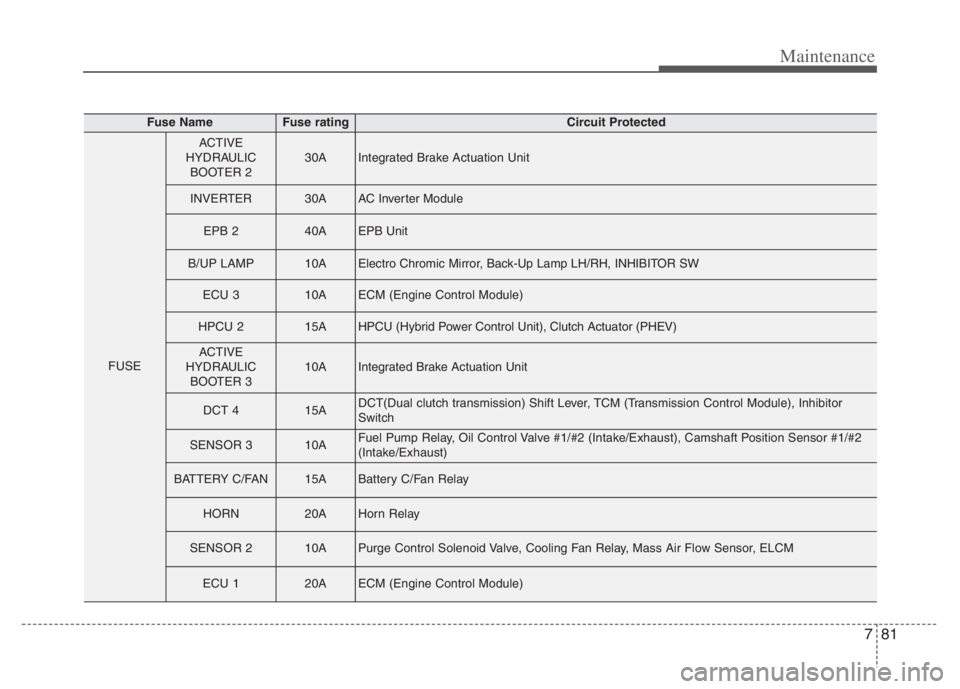

Fuse NameFuse ratingCircuit Protected

FUSE

ACTIVE

HYDRAULIC

BOOTER 230AIntegrated Brake Actuation Unit

INVERTER30AAC Inverter Module

EPB 240AEPB Unit

B/UP LAMP10AElectro Chromic Mirror, Back-Up Lamp LH/RH, INHIBITOR SW

ECU 310AECM (Engine Control Module)

HPCU 215AHPCU (Hybrid Power Control Unit), Clutch Actuator (PHEV)

ACTIVE

HYDRAULIC

BOOTER 310AIntegrated Brake Actuation Unit

DCT 415ADCT(Dual clutch transmission) Shift Lever, TCM (Transmission Control Module), Inhibitor

Switch

SENSOR 310AFuel Pump Relay, Oil Control Valve #1/#2 (Intake/Exhaust), Camshaft Position Sensor #1/#2

(Intake/Exhaust)

BATTERY C/FAN15ABattery C/Fan Relay

HORN20AHorn Relay

SENSOR 210APurge Control Solenoid Valve, Cooling Fan Relay, Mass Air Flow Sensor, ELCM

ECU 120AECM (Engine Control Module)