ESP KIA Optima 2006 2.G Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2006, Model line: Optima, Model: KIA Optima 2006 2.GPages: 225, PDF Size: 3.77 MB

Page 207 of 225

7-31

TREAD WEARThe tread wear grade is a comparative

rating based on the wear rate of the tire

when tested under controlled conditions

on a specified government test course.

For example, a tire graded 150 would

wear one-and-a-half times as well on the

government course as a tire graded 100.

The relative performance of tires

depends upon the actual conditions of

their use. Variations in driving habits,

service practices and differences in road

characteristics and climate may

significantly affect performance.TRACTION - A, B AND CThe traction grades, from highest to

lowest, are A, B and C, and they

represent the tire’s ability to stop on wet

pavement as measured under controlled

conditions on specified government test

surfaces of asphalt and concrete. A tire

marked C may have poor traction

performance.

TEMPERATURE-A, B AND CThe temperature grades are A (the

highest), B and C, representing the tire’s

resistance to generate heat and to

dissipate heat when tested under

controlled conditions on a specified

indoor laboratory test wheel. Sustained

high temperatures can cause the material

of the tire to degenerate and reduce tire

life, and excessive temperature can lead

to sudden tire failure. Grade C

corresponds to a level of performance

that all passenger vehicle tires must meet

under the Canadian Motor Vehicle

Safety Standard No. 109: Grades A and

B represent higher levels of performance

on the laboratory test wheel than the

maximum required by law.

WARNING - Tire

Temperature

The temperature grade for a tire

is established for a tire that is

properly inflated and not

overloaded. Excessive speed,

underinflation, or excessive

loading, either separately or in

combination, can cause heat

build-up and possible sudden tire

failure. This can cause loss of

vehicle control and death or

personal injury.

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 31

Page 213 of 225

7-37

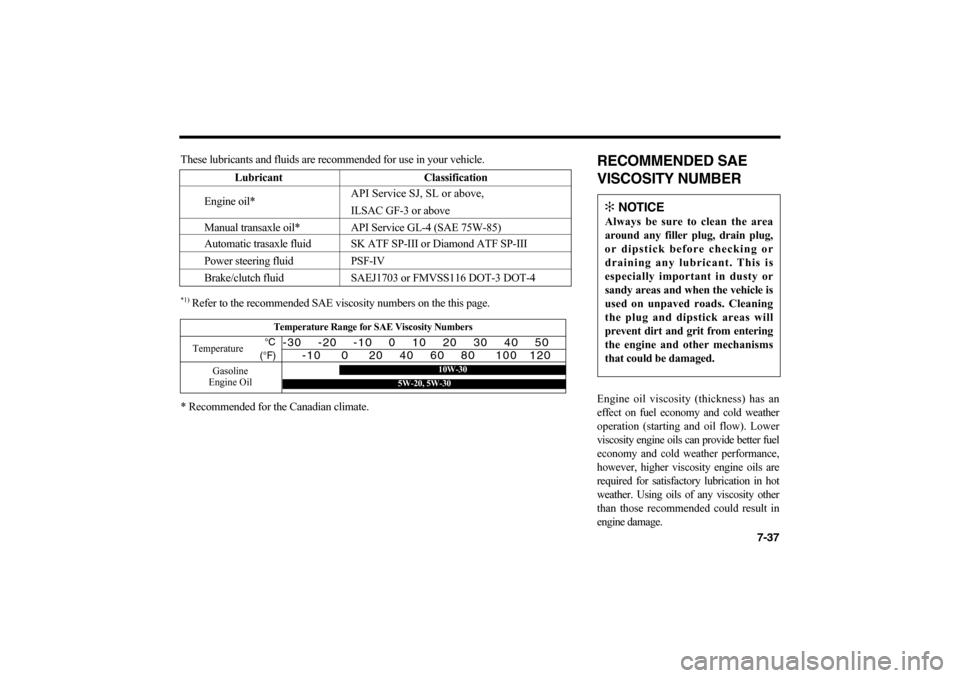

RECOMMENDED SAE

VISCOSITY NUMBEREngine oil viscosity (thickness) has an

effect on fuel economy and cold weather

operation (starting and oil flow). Lower

viscosity engine oils can provide better fuel

economy and cold weather performance,

however, higher viscosity engine oils are

required for satisfactory lubrication in hot

weather. Using oils of any viscosity other

than those recommended could result in

engine damage.

These lubricants and fluids are recommended for use in your vehicle.*1)

Refer to the recommended SAE viscosity numbers on the this page.

* Recommended for the Canadian climate.

Lubricant Classification

Engine oil* API Service SJ, SL or above,

ILSAC GF-3 or above

Manual transaxle oil* API Service GL-4 (SAE 75W-85)

Automatic trasaxle fluid SK ATF SP-III or Diamond ATF SP-III

Power steering fluid PSF-IV

Brake/clutch fluid SAEJ1703 or FMVSS116 DOT-3 DOT-4

✻

NOTICE

Always be sure to clean the area

around any filler plug, drain plug,

or dipstick before checking or

draining any lubricant. This is

especially important in dusty or

sandy areas and when the vehicle is

used on unpaved roads. Cleaning

the plug and dipstick areas will

prevent dirt and grit from entering

the engine and other mechanisms

that could be damaged.

Temperature Range for SAE Viscosity Numbers

Temperature

Gasoline

Engine Oil°C

(°F)

-30 -20 -10 0 10 20 30 40 50

-10 0 20 40 60 80 100 120

10W-30

5W-20, 5W-30

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 37

Page 215 of 225

7-39

FINISH DAMAGE REPAIRDeep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly

rust and may develop into a major repair

expense.

BRIGHT-METAL MAINTENANCE• To remove road tar and insects, use a

tar remover, not a scraper or other

sharp object.

• To protect the surfaces of bright-

metal parts from corrosion, apply a

coating of wax or chrome

preservative and rub to a high luster.

• During winter weather or in coastal

areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

UNDERBODY

MAINTENANCECorrosive materials used for ice and

snow removal or dust control may

collect on the underbody. If these

materials are not removed, accelerated

rusting can occur on underbody parts,

such as the fuel lines, frame, floor pan

and exhaust system, even though they

have been treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month and especially

at the end of each winter. Pay special

attention to these areas because it is

difficult to see all the mud and dirt. The

lower edges of doors, rocker panels, and

frame members have drain holes that

should not be allowed to clog with dirt;

trapped water in these areas can cause

rusting. It will do more harm than good

to wet down the road grime without

removing it.

✻

NOTICE

• Wiping dust or dirt off the body

with a dry cloth will scratch the

inish.

• Do not use steel wool, abrasive

cleaners, or strong detergents

containing highly alkaline or

caustic agents on chrome-plated

or anodized aluminum parts.

This may result in damage to the

protective coating and cause

discoloration or paint

deterioration.

✻

NOTICE

If your vehicle is damaged and

requires any metal repair or

replacement, be sure the body shop

applies anti-corrosion materials to

the parts repaired or replaced.

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 39