fuel KIA OPTIMA 2017 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2017, Model line: OPTIMA, Model: KIA OPTIMA 2017Pages: 629, PDF Size: 15.24 MB

Page 550 of 629

847

Maintenance

Underinflation also results inexcessive wear, poor handling and

reduced fuel economy. Wheel

deformation also is possible. Keep

your tire pressures at the proper

levels. If a tire frequently needs

refilling, have it checked by an

authorized Kia dealer.

Overinflation produces a harsh ride, excessive wear at the center

of the tire tread, and a greater pos-

sibility of damage from road haz-

ards.

Warm tires normally exceed rec- ommended cold tire pressures by

28 to 41 kPa (4 to 6 psi). Do not

release air from warm tires to

adjust the pressure or the tires will

be underinflated.

Be sure to reinstall the tire inflation valve caps. Without the valve cap,

dirt or moisture could get into the

valve core and cause air leakage. If

a valve cap is missing, install a

new one as soon as possible.Tire pressure

Always observe the following:

Check tire pressure when the tiresare cold. (After vehicle has been

parked for at least three hours or

hasn't been driven more than 1.6

km (1 mile) since startup.)

Check the pressure of your spare tire each time you check the pres-

sure of other tires.

Never overload your vehicle. Be careful not to overload a vehicle

luggage rack if your vehicle is

equipped with one.

Checking tire inflation pres-

sure

Check your tires once a month or

more.

Also, check the tire pressure of the

spare tire.

How to check

Use a good quality gauge to check

tire pressure. You can not tell if your

tires are properly inflated simply by

looking at them. Radial tires may

look properly inflated even when

they're underinflated.

Check the tire's inflation pressure

when the tires are cold. - "Cold"

means your vehicle has been sitting

for at least three hours or driven no

more than 1.6 km (1 mile).

WARNING - Tire Inflation

Overinflation or underinflation

can reduce tire life, adversely

affect vehicle handling, and

lead to sudden tire failure. This

could result in loss of vehicle

control and potential injury.

JF CAN (ENG) 8.qxp 2016-09-23 10:24 Page 47

Page 558 of 629

855

Maintenance

Temperature -A, B & C

The temperature grades are A (the

highest), B and C representing the

tire’s resistance to the generation of

heat and its ability to dissipate heat

when tested under controlled condi-

tions on a specified indoor laboratory

test wheel.

Sustained high temperature can

cause the material of the tire to

degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure. Grades B and A

represent higher levels of perform-

ance on the laboratory test wheel

than the minimum required by law.Tire terminology and definitions

Air Pressure:

The amount of air

inside the tire pressing outward on

the tire. Air pressure is expressed in

kilopascal (kPa) or pounds per

square inch (psi).

Accessory Weight: This means the

combined weight of optional acces-

sories. Some examples of optional

accessories are, automatic

transaxle, power seats, and air con-

ditioning.

Aspect Ratio: The relationship of a

tire's height to its width.

Belt: A rubber coated layer of cords

that is located between the plies and

the tread. Cords may be made from

steel or other reinforcing materials.

Bead: The tire bead contains steel

wires wrapped by steel cords that

hold the tire onto the rim.

Bias Ply Tire: A pneumatic tire in

which the plies are laid at alternate

angles less than 90 degrees to the

centerline of the tread. Cold Tire Pressure:

The amount of

air pressure in a tire, measured in

kilopascals (kPa) or pounds per

square inch (psi) before a tire has

built up heat from driving.

Curb Weight: This means the weight

of a motor vehicle with standard and

optional equipment including the

maximum capacity of fuel, oil and

coolant, but without passengers and

cargo.

DOT Markings: The DOT code

includes the Tire Identification

Number (TIN), an alphanumeric des-

ignator which can also identify the

tire manufacturer, production plant,

brand and date of production.

JF CAN (ENG) 8.qxp 2016-09-23 10:24 Page 55

Page 571 of 629

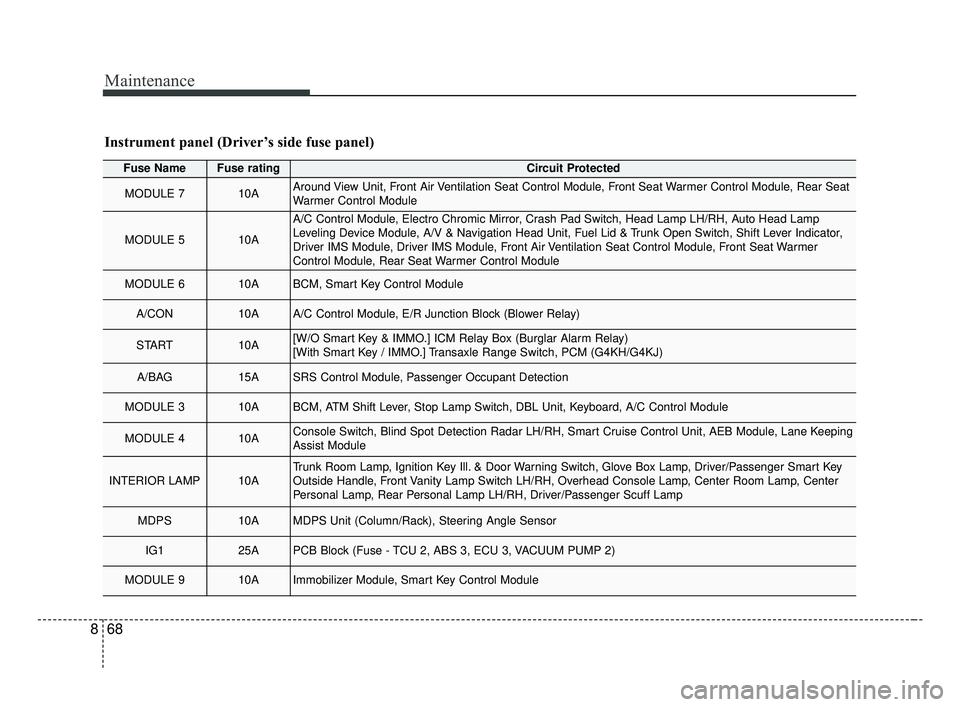

Maintenance

68

8

Fuse NameFuse ratingCircuit Protected

MODULE 710AAround View Unit, Front Air Ventilation Seat Control Module, Front Seat Warmer Control Module, Rear Seat

Warmer Control Module

MODULE 510A

A/C Control Module, Electro Chromic Mirror, Crash Pad Switch, Head Lamp LH/RH, Auto Head Lamp

Leveling Device Module, A/V & Navigation Head Unit, Fuel Lid & Trunk Open Switch, Shift Lever Indicator,

Driver IMS Module, Driver IMS Module, Front Air Ventilation Seat Control Module, Front Seat Warmer

Control Module, Rear Seat Warmer Control Module

MODULE 610ABCM, Smart Key Control Module

A/CON10AA/C Control Module, E/R Junction Block (Blower Relay)

START10A[W/O Smart Key & IMMO.] ICM Relay Box (Burglar Alarm Relay)

[With Smart Key / IMMO.] Transaxle Range Switch, PCM (G4KH/G4KJ)

A/BAG15ASRS Control Module, Passenger Occupant Detection

MODULE 310ABCM, ATM Shift Lever, Stop Lamp Switch, DBL Unit, Keyboard, A/C Control Module

MODULE 410AConsole Switch, Blind Spot Detection Radar LH/RH, Smart Cruise Control Unit, AEB Module, Lane Keeping

Assist Module

INTERIOR LAMP10ATrunk Room Lamp, Ignition Key Ill. & Door Warning Switch, Glove Box Lamp, Driver/Passenger Smart Key

Outside Handle, Front Vanity Lamp Switch LH/RH, Overhead Console Lamp, Center Room Lamp, Center

Personal Lamp, Rear Personal Lamp LH/RH, Driver/Passenger Scuff Lamp

MDPS10AMDPS Unit (Column/Rack), Steering Angle Sensor

IG125APCB Block (Fuse - TCU 2, ABS 3, ECU 3, VACUUM PUMP 2)

MODULE 910AImmobilizer Module, Smart Key Control Module

Instrument panel (Driver’s side fuse panel)

JF CAN (ENG) 8.qxp 2016-09-23 10:24 Page 68

Page 572 of 629

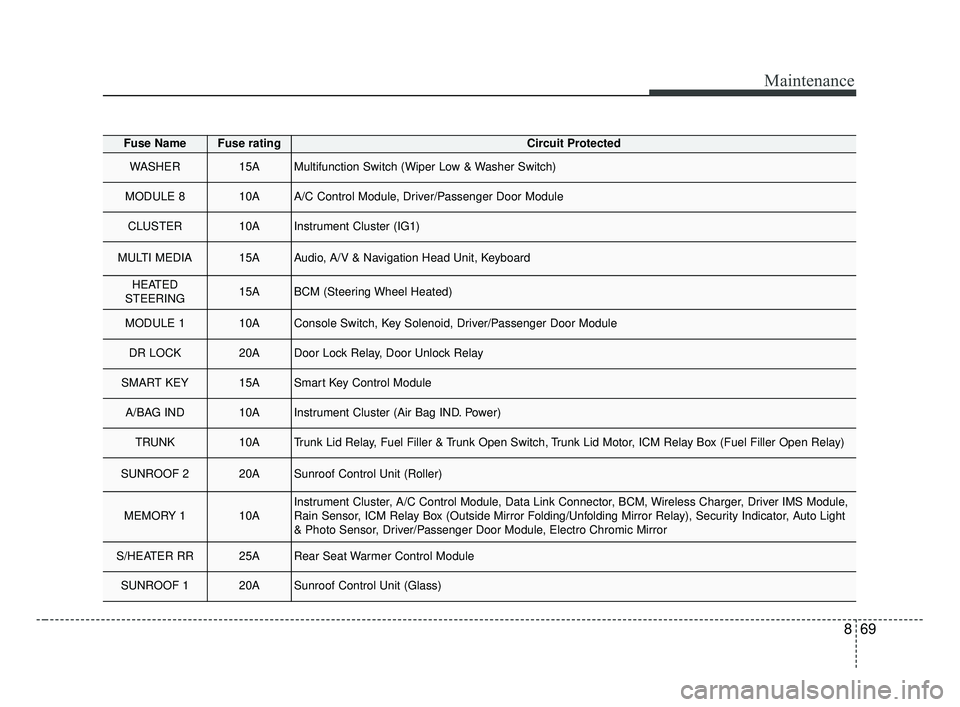

869

Maintenance

Fuse NameFuse ratingCircuit Protected

WASHER15AMultifunction Switch (Wiper Low & Washer Switch)

MODULE 810AA/C Control Module, Driver/Passenger Door Module

CLUSTER10AInstrument Cluster (IG1)

MULTI MEDIA15AAudio, A/V & Navigation Head Unit, Keyboard

HEATED

STEERING15ABCM (Steering Wheel Heated)

MODULE 110AConsole Switch, Key Solenoid, Driver/Passenger Door Module

DR LOCK20ADoor Lock Relay, Door Unlock Relay

SMART KEY15ASmart Key Control Module

A/BAG IND10AInstrument Cluster (Air Bag IND. Power)

TRUNK10ATrunk Lid Relay, Fuel Filler & Trunk Open Switch, Trunk Lid Motor, ICM Relay Box (Fuel Filler Open Relay)

SUNROOF 220ASunroof Control Unit (Roller)

MEMORY 110AInstrument Cluster, A/C Control Module, Data Link Connector, BCM, Wireless Charger, Driver IMS Module,

Rain Sensor, ICM Relay Box (Outside Mirror Folding/Unfolding Mirror Relay), Security Indicator, Auto Light

& Photo Sensor, Driver/Passenger Door Module, Electro Chromic Mirror

S/HEATER RR25ARear Seat Warmer Control Module

SUNROOF 120ASunroof Control Unit (Glass)

JF CAN (ENG) 8.qxp 2016-09-23 10:24 Page 69

Page 575 of 629

![KIA OPTIMA 2017 Workshop Manual Maintenance

72

8

Fuse NameFuse ratingCircuit Protected

MULTI

FUSE

MDPS 180AMDPS Unit (Column)

COOLING FAN 260A[G4KH/G4FJ] Cooling Fan1 Relay, Cooling Fan2 Relay

COOLINGFAN 150A[G4KJ] Cooling Fan1 Rel KIA OPTIMA 2017 Workshop Manual Maintenance

72

8

Fuse NameFuse ratingCircuit Protected

MULTI

FUSE

MDPS 180AMDPS Unit (Column)

COOLING FAN 260A[G4KH/G4FJ] Cooling Fan1 Relay, Cooling Fan2 Relay

COOLINGFAN 150A[G4KJ] Cooling Fan1 Rel](/img/2/40406/w960_40406-574.png)

Maintenance

72

8

Fuse NameFuse ratingCircuit Protected

MULTI

FUSE

MDPS 180AMDPS Unit (Column)

COOLING FAN 260A[G4KH/G4FJ] Cooling Fan1 Relay, Cooling Fan2 Relay

COOLINGFAN 150A[G4KJ] Cooling Fan1 Relay

B+ 350ASmart Junction Block (IPS 2 (IPS 5), IPS 3 (IPS 6), IPS 7, IPS 8)

REAR

HEATED50ARear Heated Relay

DCT140A[G4FJ-DCT] TCM

BLOWER40ABlower Relay

POWER

OUTLET 140APower Outlet Relay

IG230A[W/O Smart Key] Start Relay, Ignition Switch, [With Smart Key] Start Relay, PCB Block (IG2 Relay)

MDPS 2100AMDPS Unit (Rack)

B+160ASmart Junction Block (Fuse - SUNROOF1, SUNROOF2, S/HEATER RR, P/SEAT DRV, P/SEAT PASS,

P/WINDOW LH, P/WINDOW RH, TRUNK)

B+560APCB Block (Engine Control Relay, Fuse - TCU1, ECU2, FUEL PUMP, HORN, WIPER1)

B+260ASmart Junction Block (IPS 1, IPS 4, Fuse - AMP, S/HEATER FRT)

ABS 140AESC Module

IG140A[W/O Smart Key] Ignition Switch, [With Smart Key] PCB Block (IG1/ACC Relay)

DCT 240A[G4FJ-DCT] TCM

ABS 230AESC Module, Multipurpose Check Connector

Engine room compartment fuse panel

JF CAN (ENG) 8.qxp 2016-09-23 10:24 Page 72

Page 577 of 629

![KIA OPTIMA 2017 Workshop Manual Maintenance

74

8

Fuse NameFuse ratingCircuit Protected

FUSE

FUEL PUMP20AFuel Pump Relay

ECU 120APCM/ECM

SENSORS 210A

E/R Junction Block (Fuel Pump Relay, Cooling Fan 1/2 Relay)

[G4KJ] Oil Control Valv KIA OPTIMA 2017 Workshop Manual Maintenance

74

8

Fuse NameFuse ratingCircuit Protected

FUSE

FUEL PUMP20AFuel Pump Relay

ECU 120APCM/ECM

SENSORS 210A

E/R Junction Block (Fuel Pump Relay, Cooling Fan 1/2 Relay)

[G4KJ] Oil Control Valv](/img/2/40406/w960_40406-576.png)

Maintenance

74

8

Fuse NameFuse ratingCircuit Protected

FUSE

FUEL PUMP20AFuel Pump Relay

ECU 120APCM/ECM

SENSORS 210A

E/R Junction Block (Fuel Pump Relay, Cooling Fan 1/2 Relay)

[G4KJ] Oil Control Valve (Exhaust), Purge Control Solenoid Valve, Variable Intake Solenoid Valve, Canister

Close Valve

[G4KH] Oil Control Valve (Exhaust), Purge Control Solenoid Valve, RCV Control Solenoid Valve, Canister Close Valve

[G4FJ] Oil Control Valve #1/#2, Purge Control Solenoid Valve, RCV Control Solenoid Valve, Canister Close Va l ve

TCU 215ATransaxle Range Switch, TCM

ABS 310AESC Module, Multipurpose Check Connector

POWER

OUTLET 320ARear Power Outlet

B/UP LAMP10APCM/TCM, Transaxle Range Switch, Audio, Electro Chromic Mirror, Rear Combination Lamp (IN) LH/RH

SENSOR 115AOxygen Sensor (Up/Down)

IGN COIL20AIgnition Coil #1/#2/#3/#4

ECU 210APCM/ECM

TCU 110APCM/TCM

VACUUM PUMP 210AVacuum Pump, Vacuum Switch

ECU 310APCM/ECM

POWER

OUTLET 220AFront Power Outlet #1

HORN20AHorn Relay, ICM Relay Box (Burglar Alarm Horn Relay)

WIPER 130AWiper Power Relay

JF CAN (ENG) 8.qxp 2016-09-23 10:24 Page 74

Page 598 of 629

895

Maintenance

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly

rust and may develop into a major

repair expense.

If your vehicle is damaged and

requires any metal repair or replace-

ment, be sure the body shop applies

anti-corrosion materials to the parts

repaired or replaced.

Bright-metal maintenance

To remove road tar and insects,use a tar remover, not a scraper or

other sharp object.

To protect the surfaces of bright- metal parts from corrosion, apply a

coating of wax or chrome preser-

vative and rub to a high luster.

During winter weather or in coastal areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

Underbody maintenance

Road salt and other corrosive chemi-

cals are used in cold weather country

to melt snow and prevent ice accumu-

lation. If these chemicals are not regu-

larly removed, they will corrode the

vehicle underbody and over time dam-

age fuel lines, the fuel tank retention

system, the vehicle suspension, the

exhaust system, and even the body

frame.

Wash the undercarriage of yourvehicle regularly during the winter

and whenever your vehicle has

been exposed to such salts or

chemicals.CAUTION - Drying vehicle

Wiping dust or dirt off the body with a dry cloth willscratch the finish.

Do not use steel wool, abra- sive cleaners, acid detergentsor strong detergents contain-ing high alkaline or causticagents on chrome-plated oranodized aluminum parts.This may result in damage tothe protective coating andcause discoloration or paintdeterioration.

JF CAN (ENG) 8.qxp 2016-09-23 10:25 Page 95

Page 604 of 629

8101

Maintenance

EMISSION CONTROL SYSTEM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the

Warranty & Consumer Information

manual in your vehicle.

Your vehicle is equipped with an

emission control system to meet all

applicable emission regulations.

There are three emission control

systems, as follows.

(1) Crankcase emission control sys-tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control system

In order to assure the proper function

of the emission control systems, it is

recommended that you have your

vehicle inspected and maintained by

an authorized Kia dealer in accor-

dance with the maintenance sched-

ule in this manual. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from mis-

firing during dynamometer test-

ing, turn the Electronic Stability

Control (ESC) system off by

pressing the ESC switch.

After dynamometer testing is completed, turn the ESC system

back on by pressing the ESC

switch again.1. Crankcase emission control system

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.

This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative emission con-trol (including ORVR:

Onboard Refueling Vapor

Recovery)

system

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

(The ORVR system is designed to

allow the vapors from the fuel tank to

be loaded into a canister while refu-

eling at the gas station, preventing

the escape of fuel vapors into the

atmosphere.)

JF CAN (ENG) 8.qxp 2016-09-23 10:25 Page 101

Page 605 of 629

Maintenance

102

8

Canister

Fuel vapors generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in

the canister are drawn into the surge

tank through the purge control sole-

noid valve.

Purge Control Solenoid Valve

(PCSV)

The purge control solenoid valve is

controlled by the Engine Control

Module (ECM); when the engine

coolant temperature is low during

idling, the PCSV closes so that evap-

orated fuel is not taken into the

engine. After the engine warms up

during ordinary driving, the PCSV

opens to introduce evaporated fuel to

the engine.

3. Exhaust emission control system

The Exhaust Emission Control

System is a highly effective system

which controls exhaust emissions

while maintaining good vehicle per-

formance.

Vehicle modifications

This vehicle should not be modified.

Modification of your vehicle could

affect its performance, safety or

durability and may even violate gov-

ernmental safety and emissions reg-

ulations.

In addition, damage or performance

problems resulting from any modifi-

cation may not be covered under

warranty.

If you use unauthorized electronic

devices, it may cause the vehicle to

operate abnormally, wire damage,

battery discharge and fire. For your

safety, do not use unauthorized

electronic devices.

Engine exhaust gas precautions

(carbon monoxide)

Carbon monoxide can be present with other exhaust fumes.

Therefore, if you smell exhaust

fumes of any kind inside your vehi-

cle, have it inspected and repaired

immediately. If you ever suspect

exhaust fumes are coming into

your vehicle, drive it only with all

the windows fully open. Have your

vehicle checked and repaired

immediately.

WARNING - Exhaust

Engine exhaust gases contain

carbon monoxide (CO). Though

colorless and odorless, it is

dangerous and could be lethal if

inhaled. Follow the instructions

on this page to avoid CO poi-

soning.

JF CAN (ENG) 8.qxp 2016-09-23 10:25 Page 102

Page 607 of 629

Maintenance

104

8

Your vehicle is equipped with a cat-

alytic converter emission control

device.

Therefore, the following precautions

must be observed:

Use only UNLEADED FUEL for

gasoline engines.

Do not operate the vehicle when there are signs of engine malfunc-

tion, such as misfire or a noticeable

loss of performance.

Do not misuse or abuse the engine. Examples of misuse are

coasting with the ignition off and

descending steep grades in gear

with the ignition off.

Do not operate the engine at high idle speed for extended periods (5

minutes or more).

Do not modify or tamper with any part of the engine or emission con-

trol system. All inspections and

adjustments must be made by an

authorized Kia dealer.

Avoid driving with an extremely low fuel level. Running out of fuel could

cause the engine to misfire, dam-

aging the catalytic converter. Failure to observe these precautions

could result in damage to the catalyt-

ic converter and to your vehicle.

Additionally, such actions could void

your warranties.

JF CAN (ENG) 8.qxp 2016-09-23 10:26 Page 104