engine KIA PICANTO 2012 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2012, Model line: PICANTO, Model: KIA PICANTO 2012Pages: 840, PDF Size: 41.16 MB

Page 347 of 840

715

Maintenance

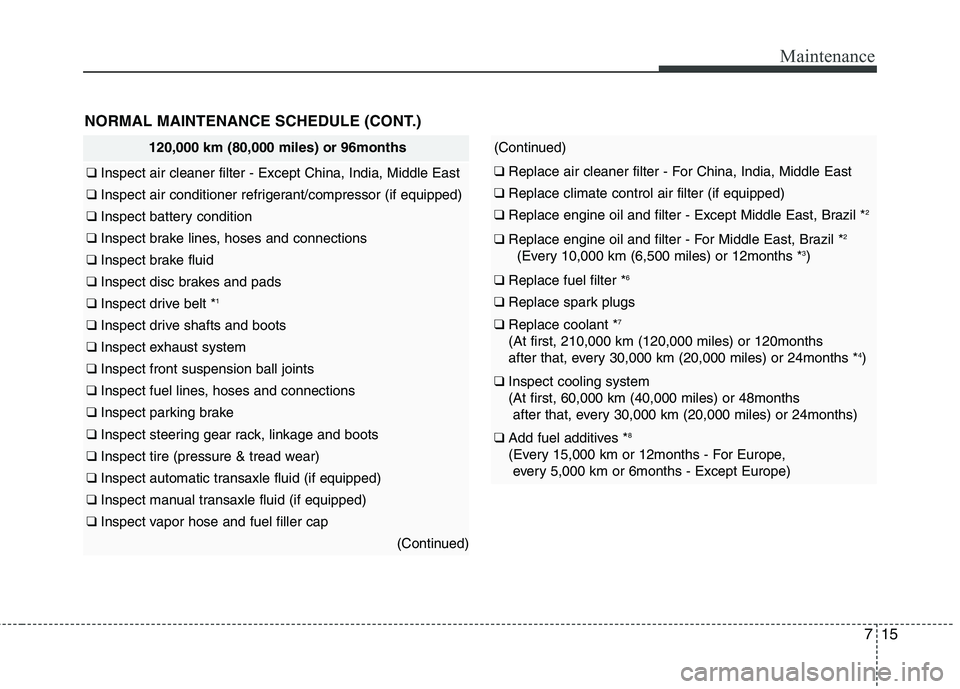

NORMAL MAINTENANCE SCHEDULE (CONT.)

120,000 km (80,000 miles) or 96months

❑ Inspect air cleaner filter - Except China, India, Middle East

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect drive belt * 1

❑

Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel lines, hoses and connections

❑ Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tire (pressure & tread wear)

❑ Inspect automatic transaxle fluid (if equipped)

❑ Inspect manual transaxle fluid (if equipped)

❑ Inspect vapor hose and fuel filler cap

(Continued)

(Continued)

❑ Replace air cleaner filter - For China, India, Middle East

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter - Except Middle East, Brazil * 2

❑

Replace engine oil and filter - For Middle East, Brazil * 2

(Every 10,000 km (6,500 miles) or 12months * 3

)

❑ Replace fuel filter * 6

❑

Replace spark plugs

❑ Replace coolant * 7

(At first, 210,000 km (120,000 miles) or 120months

after that, every 30,000 km (20,000 miles) or 24months * 4

)

❑ Inspect cooling system

(At first, 60,000 km (40,000 miles) or 48months

after that, every 30,000 km (20,000 miles) or 24months)

❑ Add fuel additives * 8

(Every 15,000 km or 12months - For Europe, every 5,000 km or 6months - Except Europe)

Page 348 of 840

Maintenance

16

7

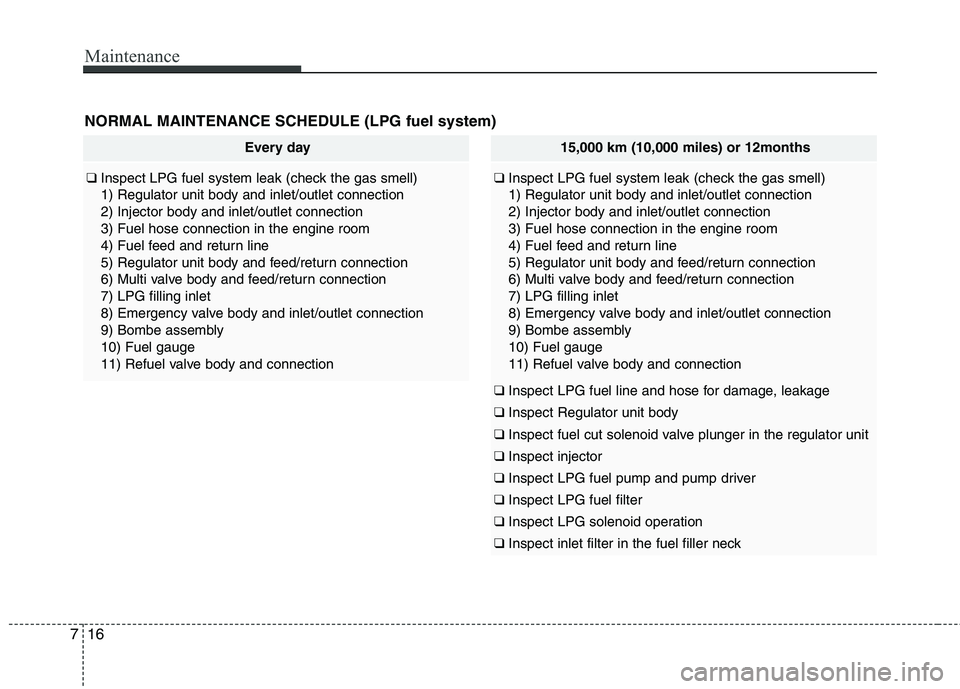

Every day

❑ Inspect LPG fuel system leak (check the gas smell) 1) Regulator unit body and inlet/outlet connection2) Injector body and inlet/outlet connection3) Fuel hose connection in the engine room

4) Fuel feed and return line

5) Regulator unit body and feed/return connection

6) Multi valve body and feed/return connection7) LPG filling inlet

8) Emergency valve body and inlet/outlet connection

9) Bombe assembly10) Fuel gauge

11) Refuel valve body and connection

NORMAL MAINTENANCE SCHEDULE (LPG fuel system)

15,000 km (10,000 miles) or 12months

❑ Inspect LPG fuel system leak (check the gas smell) 1) Regulator unit body and inlet/outlet connection2) Injector body and inlet/outlet connection3) Fuel hose connection in the engine room

4) Fuel feed and return line

5) Regulator unit body and feed/return connection

6) Multi valve body and feed/return connection7) LPG filling inlet

8) Emergency valve body and inlet/outlet connection

9) Bombe assembly10) Fuel gauge

11) Refuel valve body and connection

❑ Inspect LPG fuel line and hose for damage, leakage

❑ Inspect Regulator unit body

❑ Inspect fuel cut solenoid valve plunger in the regulator unit

❑ Inspect injector

❑ Inspect LPG fuel pump and pump driver

❑ Inspect LPG fuel filter

❑ Inspect LPG solenoid operation

❑ Inspect inlet filter in the fuel filler neck

Page 349 of 840

717

Maintenance

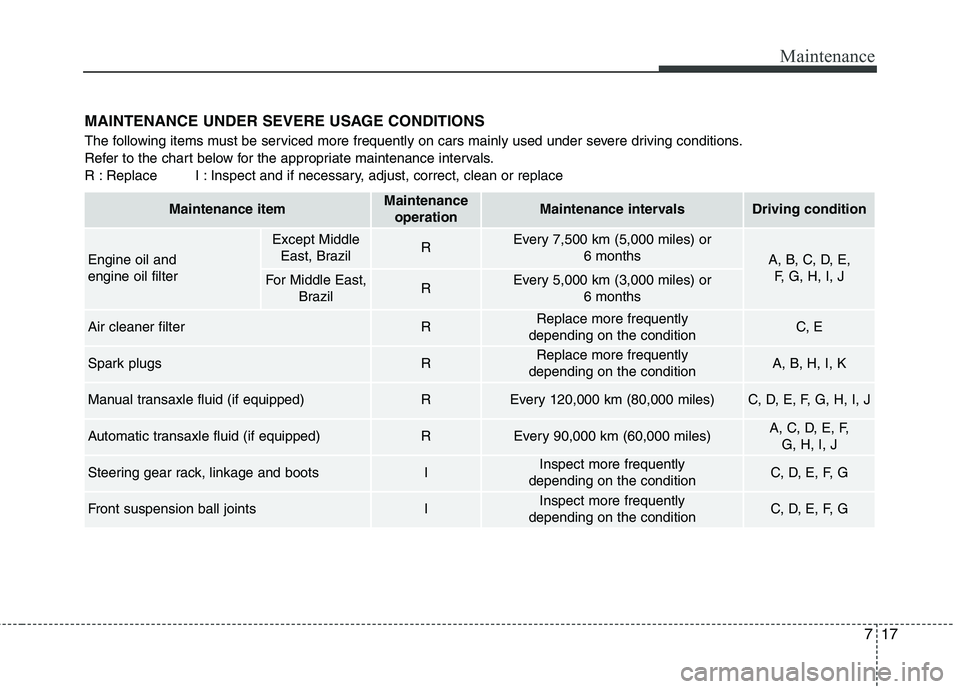

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars mainly used under severe driving conditions.

Refer to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and if necessary, adjust, correct, clean or replace

Maintenance itemMaintenanceoperationMaintenance intervalsDriving condition

Engine oil and engine oil filter

Except MiddleEast, Brazil REvery 7,500 km (5,000 miles) or 6 months

A, B, C, D, E, F, G, H, I, J

For Middle East, Brazil REvery 5,000 km (3,000 miles) or 6 months

Air cleaner filterRReplace more frequently

depending on the conditionC, E

Spark plugs RReplace more frequently

depending on the conditionA, B, H, I, K

Manual transaxle fluid (if equipped)REvery 120,000 km (80,000 miles)C, D, E, F, G, H, I, J

Automatic transaxle fluid (if equipped)REvery 90,000 km (60,000 miles)A, C, D, E, F, G, H, I, J

Steering gear rack, linkage and bootsIInspect more frequently

depending on the conditionC, D, E, F, G

Front suspension ball jointsIInspect more frequently

depending on the conditionC, D, E, F, G

Page 351 of 840

719

Maintenance

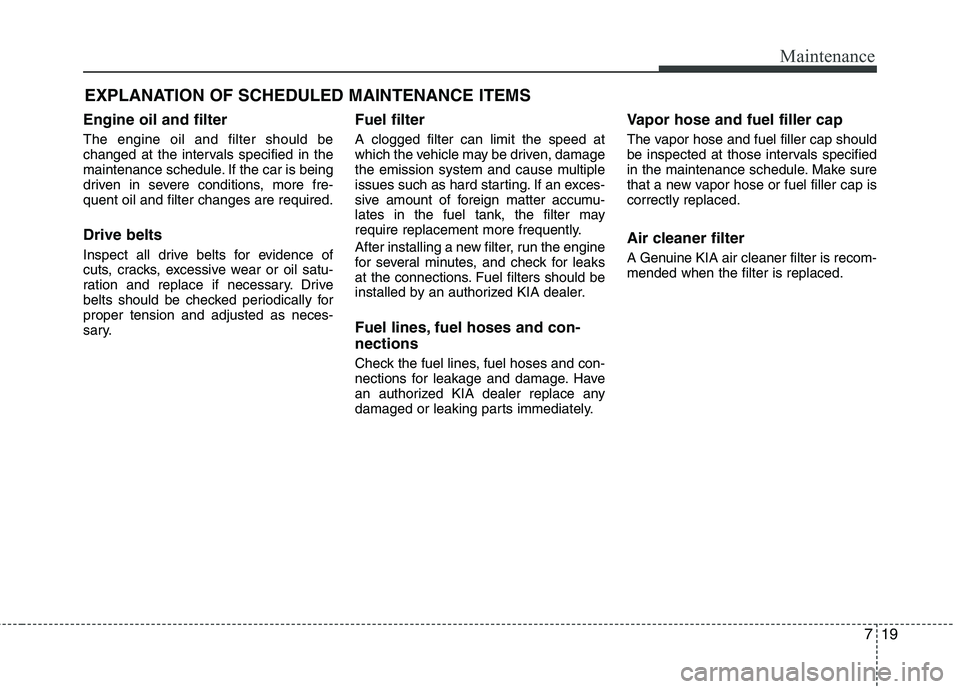

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-quent oil and filter changes are required. Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically forproper tension and adjusted as neces-

sary. Fuel filter A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. Fuel filters should be

installed by an authorized KIA dealer.

Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. Have

an authorized KIA dealer replace any

damaged or leaking parts immediately.Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap iscorrectly replaced.

Air cleaner filter

A Genuine KIA air cleaner filter is recom- mended when the filter is replaced.

Page 352 of 840

Maintenance

20

7

Spark plugs

Make sure to install new spark plugs of

the correct heat range.

Valve clearance

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

An authorized KIA dealer should perform

the operation. Cooling system

Check cooling system components, such

as radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts. Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid (if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

Automatic transaxle fluid (if equipped)

The fluid level should be in the "HOT"

range of the dipstick, after the engine

and transaxle are at normal operating

temperature. Check the automatic

transaxle fluid level with the engine run-

ning and the transaxle in neutral, with the

parking brake properly applied.

Page 353 of 840

721

Maintenance

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately. Brake fluid

Check brake fluid level in the brake fluid

reservoir. The level should be between

“MIN” and “MAX” marks on the side of

the reservoir. Use only hydraulic brake

fluid conforming to DOT 3 or DOT 4specification.

Parking brake

Inspect the parking brake system includ-

ing the parking brake lever and cables. Rear brake drums and linings (if equipped)

Check the rear brake drums and linings

for scoring, burning, leaking fluid, broken

parts, and excessive wear.Brake discs, pads, calipers and

rotors

Check the pads for excessive wear, discs

for run out and wear, and calipers for fluid

leakage. Suspension mounting bolts

Check the suspension connections for

looseness or damage. Retighten to the

specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine off,

check for excessive free-play in the

steering wheel.

Check the linkage for bends or damage.

Check the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts.

Drive shafts and boots

Check the drive shafts, boots and clamps

for cracks, deterioration, or damage.

Replace any damaged parts and, if nec-

essary, repack the grease.

Air conditioning refrigerant (if equipped)

Check the air conditioning lines and con-

nections for leakage and damage.

Page 354 of 840

Maintenance

22

7

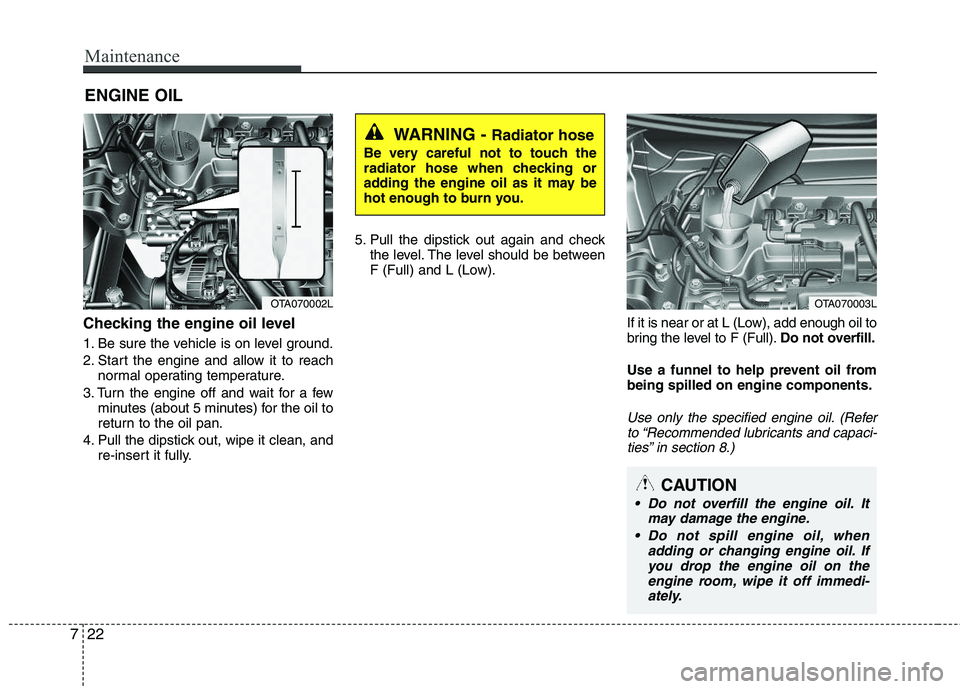

ENGINE OIL

Checking the engine oil level

1. Be sure the vehicle is on level ground.

2. Start the engine and allow it to reach normal operating temperature.

3. Turn the engine off and wait for a few minutes (about 5 minutes) for the oil to

return to the oil pan.

4. Pull the dipstick out, wipe it clean, and re-insert it fully. 5. Pull the dipstick out again and check

the level. The level should be between

F (Full) and L (Low).

If it is near or at L (Low), add enough oil to

bring the level to F (Full).Do not overfill.

Use a funnel to help prevent oil frombeing spilled on engine components.

Use only the specified engine oil. (Refer to “Recommended lubricants and capaci- ties” in section 8.)

WARNING - Radiator hose

Be very careful not to touch the

radiator hose when checking or

adding the engine oil as it may be

hot enough to burn you.

OTA070002LOTA070003L

CAUTION

Do not overfill the engine oil. It may damage the engine.

Do not spill engine oil, when adding or changing engine oil. Ifyou drop the engine oil on the engine room, wipe it off immedi-

ately.

Page 355 of 840

723

Maintenance

Changing the engine oil and filter

Have engine oil and filter changed by an

authorized KIA dealer according to theMaintenance Schedule at the beginningof this section.

WARNING

Used engine oil may cause irrita- tion or cancer of the skin if left in

contact with the skin for prolonged

periods of time. Used engine oil

contains chemicals that have

caused cancer in laboratory ani-

mals. Always protect your skin by

washing your hands thoroughlywith soap and warm water as soon

as possible after handling used oil.

Page 356 of 840

Maintenance

24

7

ENGINE COOLANT

The high-pressure cooling system has a

reservoir filled with year-round antifreeze

coolant. The reservoir is filled at the fac-

tory.

Check the antifreeze protection and

coolant level at least once a year, at thebeginning of the winter season, and

before traveling to a colder climate. Checking the coolant level

WARNING

Removing radiatorcap

Never attempt to remove the radi- ator cap while the engine is oper-

ating or hot. Doing so might leadto cooling system and engine

damage and could result in seri-

ous personal injury from escap-ing hot coolant or steam.

Turn the engine off and wait until it cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back while the

pressure is released from the

cooling system. When you aresure all the pressure has been

released, press down on the cap,

using a thick towel, and continue

turning counterclockwise to

remove it.

(Continued)

(Continued)

Even if the engine is not operat-ing, do not remove the radiator cap or the drain plug while the

engine and radiator are hot. Hot

coolant and steam may still blow

out under pressure, causing seri-

ous injury.

WARNING

The electric motor (cool-

ing fan) is controlled byengine coolant tempera-

ture, refrigerant pres-

sure and vehicle speed.

It may sometimes operate evenwhen the engine is not running.

Use extreme caution when working

near the blades of the cooling fan

so that you are not injured by a

rotating fan blades. As the engine

coolant temperature decreases, the

electric motor will automatically

shut off. This is a normal condition.

Page 357 of 840

725

Maintenance

Check the condition and connections of all cooling system hoses and heater

hoses. Replace any swollen or deterio-

rated hoses.

The coolant level should be filled

between F (Full) and L (Low) marks on

the side of the coolant reservoir when theengine is cool.

If the coolant level is low, add enough

distilled (deionized) or soft water to pro-vide protection against freezing and cor-

rosion. Bring the level to F (Full) , but do

not overfill. If frequent additions are

required, see an authorized KIA dealer

for a cooling system inspection.

Recommended engine coolant

When adding coolant, use only deion-ized water or soft water for your vehicle

and never mix hard water in the

coolant filled at the factory. An improp-

er coolant mixture can result in serious

malfunction or engine damage.

The engine in your vehicle has alu- minum engine parts and must be pro-

tected by an ethylene-glycol-based

coolant to prevent corrosion and freez-ing.

DO NOT USE alcohol or methanol coolant or mix them with the specifiedcoolant.

Do not use a solution that contains more than 60% antifreeze or less than

35% antifreeze, which would reduce

the effectiveness of the solution. For mixture percentage, refer to the fol-

lowing table.

-15°C (5°F) 35 65

-25°C (-13°F) 40 60

-35°C (-31°F) 50 50

-45°C (-49°F) 60 40

Ambient

Temperature Mixture Percentage (volume)

Antifreeze Water

OTA070004L