fuel KIA QUORIS 2013 Service Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2013, Model line: QUORIS, Model: KIA QUORIS 2013Pages: 485, PDF Size: 31.55 MB

Page 391 of 485

715

Maintenance

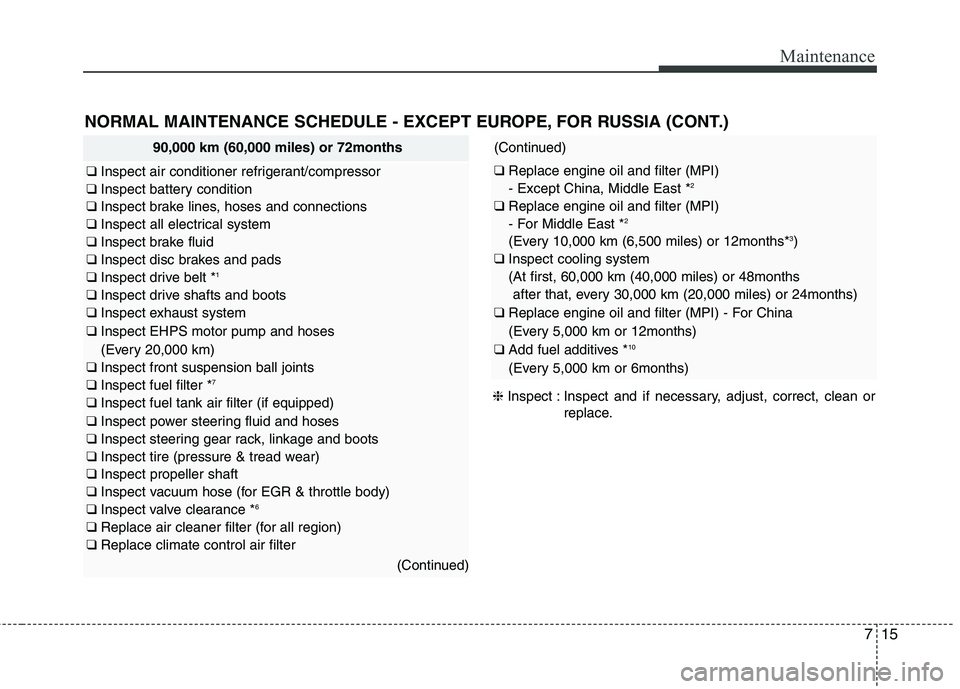

NORMAL MAINTENANCE SCHEDULE - EXCEPT EUROPE, FOR RUSSIA (CONT.)

90,000 km (60,000 miles) or 72months

β Inspect air conditioner refrigerant/compressor

β Inspect battery condition

β Inspect brake lines, hoses and connections

β Inspect all electrical system

β Inspect brake fluid

β Inspect disc brakes and pads

β Inspect drive belt * 1

β Inspect drive shafts and boots

β Inspect exhaust system

β Inspect EHPS motor pump and hoses

(Every 20,000 km)

β Inspect front suspension ball joints

β Inspect fuel filter * 7

β Inspect fuel tank air filter (if equipped)

β Inspect power steering fluid and hoses

β Inspect steering gear rack, linkage and boots

β Inspect tire (pressure & tread wear)

β Inspect propeller shaft

β Inspect vacuum hose (for EGR & throttle body)

β Inspect valve clearance * 6

β Replace air cleaner filter (for all region)

β Replace climate control air filter

(Continued)

(Continued)

β Replace engine oil and filter (MPI) - Except China, Middle East * 2

β Replace engine oil and filter (MPI)

- For Middle East * 2

(Every 10,000 km (6,500 miles) or 12months* 3

)

β Inspect cooling system

(At first, 60,000 km (40,000 miles) or 48months

after that, every 30,000 km (20,000 miles) or 24months)

β Replace engine oil and filter (MPI) - For China

(Every 5,000 km or 12months)

β Add fuel additives * 10

(Every 5,000 km or 6months)

β Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 392 of 485

Maintenance

16

7

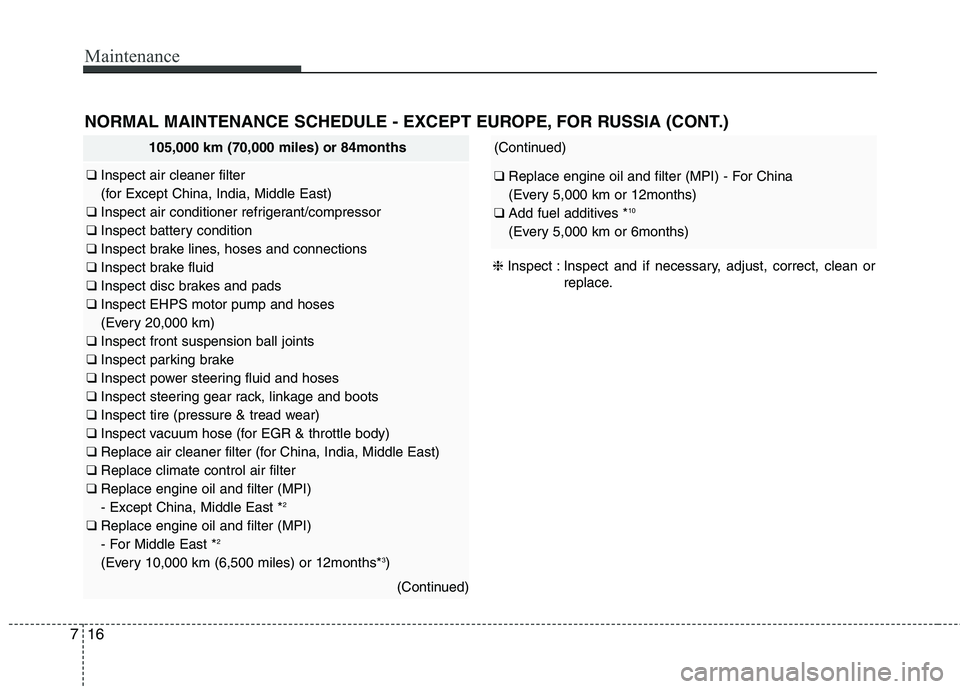

NORMAL MAINTENANCE SCHEDULE - EXCEPT EUROPE, FOR RUSSIA (CONT.)

105,000 km (70,000 miles) or 84months

β Inspect air cleaner filter

(for Except China, India, Middle East)

β Inspect air conditioner refrigerant/compressor

β Inspect battery condition

β Inspect brake lines, hoses and connections

β Inspect brake fluid

β Inspect disc brakes and pads

β Inspect EHPS motor pump and hoses

(Every 20,000 km)

β Inspect front suspension ball joints

β Inspect parking brake

β Inspect power steering fluid and hoses

β Inspect steering gear rack, linkage and boots

β Inspect tire (pressure & tread wear)

β Inspect vacuum hose (for EGR & throttle body)

β Replace air cleaner filter (for China, India, Middle East)

β Replace climate control air filter

β Replace engine oil and filter (MPI) - Except China, Middle East * 2

β Replace engine oil and filter (MPI)

- For Middle East * 2

(Every 10,000 km (6,500 miles) or 12months* 3

)

(Continued)

(Continued)

β Replace engine oil and filter (MPI) - For China

(Every 5,000 km or 12months)

β Add fuel additives * 10

(Every 5,000 km or 6months)

β Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 393 of 485

717

Maintenance

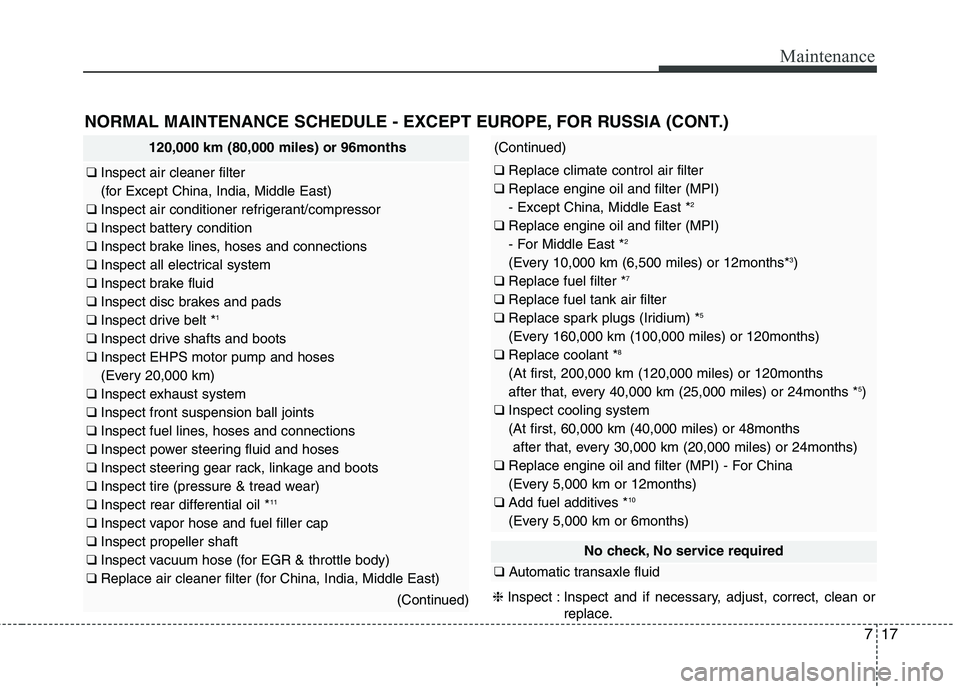

NORMAL MAINTENANCE SCHEDULE - EXCEPT EUROPE, FOR RUSSIA (CONT.)

120,000 km (80,000 miles) or 96months

β Inspect air cleaner filter

(for Except China, India, Middle East)

β Inspect air conditioner refrigerant/compressor

β Inspect battery condition

β Inspect brake lines, hoses and connections

β Inspect all electrical system

β Inspect brake fluid

β Inspect disc brakes and pads

β Inspect drive belt * 1

β Inspect drive shafts and boots

β Inspect EHPS motor pump and hoses

(Every 20,000 km)

β Inspect exhaust system

β Inspect front suspension ball joints

β Inspect fuel lines, hoses and connections

β Inspect power steering fluid and hoses

β Inspect steering gear rack, linkage and boots

β Inspect tire (pressure & tread wear)

β Inspect rear differential oil * 11

β Inspect vapor hose and fuel filler cap

β Inspect propeller shaft

β Inspect vacuum hose (for EGR & throttle body)

β Replace air cleaner filter (for China, India, Middle East)

(Continued)

(Continued)

β Replace climate control air filter

β Replace engine oil and filter (MPI) - Except China, Middle East * 2

β Replace engine oil and filter (MPI)

- For Middle East * 2

(Every 10,000 km (6,500 miles) or 12months* 3

)

β Replace fuel filter * 7

β Replace fuel tank air filter

β Replace spark plugs (Iridium) * 5

(Every 160,000 km (100,000 miles) or 120months)

β Replace coolant * 8

(At first, 200,000 km (120,000 miles) or 120months

after that, every 40,000 km (25,000 miles) or 24months * 5

)

β Inspect cooling system

(At first, 60,000 km (40,000 miles) or 48months

after that, every 30,000 km (20,000 miles) or 24months)

β Replace engine oil and filter (MPI) - For China

(Every 5,000 km or 12months)

β Add fuel additives * 10

(Every 5,000 km or 6months)

No check, No service required

β Automatic transaxle fluid

β Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 396 of 485

Maintenance

20

7

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the car

is being driven in severe conditions,more frequent oil and filter changesare required. Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary. Fuel filter A clogged filter can limit the speed at

which the vehicle may be driven,damage the emission system and

cause multiple issues such as hard

starting. If an excessive amount of

foreign matter accumulates in the

fuel tank, the filter may require

replacement more frequently.

After installing a new filter, run the

engine for several minutes, and

check for leaks at the connections.

We recommend that the fuel lines,fuel hoses and connectionsr be

replaced by an authoized Kia dealer.

Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. We recommend that the fuel

lines, fuel hoses and connectionsr be

replaced by an authoized Kia dealer.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure that a new

vapor hose or fuel filler cap is cor-rectly replaced.

Page 419 of 485

743

Maintenance

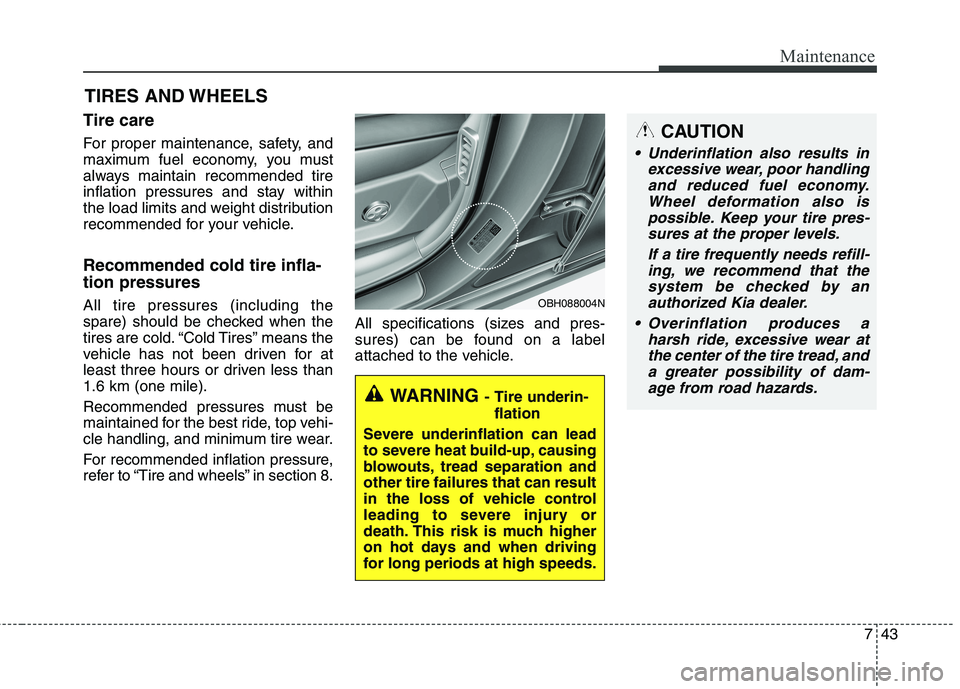

TIRES AND WHEELS

Tire care

For proper maintenance, safety, and

maximum fuel economy, you must

always maintain recommended tire

inflation pressures and stay within

the load limits and weight distribution

recommended for your vehicle. Recommended cold tire infla- tion pressures All tire pressures (including the

spare) should be checked when the

tires are cold. βCold Tiresβ means the

vehicle has not been driven for at

least three hours or driven less than1.6 km (one mile).

Recommended pressures must be

maintained for the best ride, top vehi-

cle handling, and minimum tire wear.

For recommended inflation pressure,

refer to βTire and wheelsβ in section 8. All specifications (sizes and pres-

sures) can be found on a label

attached to the vehicle.

WARNING

- Tire underin-

flation

Severe underinflation can lead

to severe heat build-up, causing

blowouts, tread separation andother tire failures that can result

in the loss of vehicle control

leading to severe injury or

death. This risk is much higher

on hot days and when driving

for long periods at high speeds.

OBH088004N

CAUTION

Underinflation also results in excessive wear, poor handlingand reduced fuel economy. Wheel deformation also ispossible. Keep your tire pres-sures at the proper levels.

If a tire frequently needs refill-ing, we recommend that thesystem be checked by anauthorized Kia dealer.

Overinflation produces a harsh ride, excessive wear atthe center of the tire tread, anda greater possibility of dam-age from road hazards.

Page 443 of 485

767

Maintenance

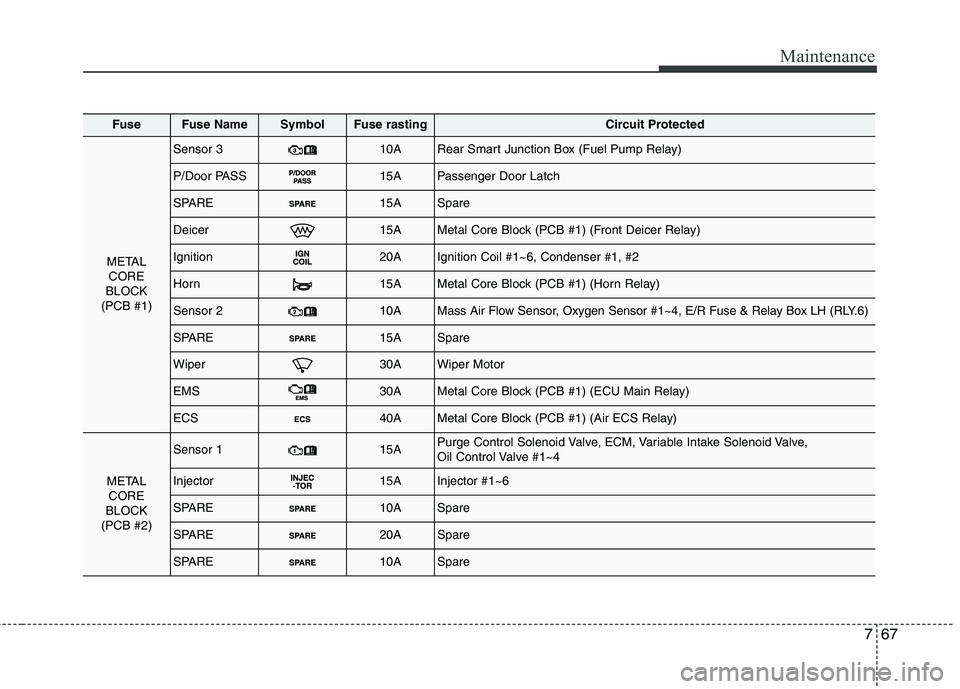

FuseFuse NameSymbolFuse rastingCircuit Protected

METALCORE

BLOCK

(PCB #1)

Sensor 310ARear Smart Junction Box (Fuel Pump Relay)

P/Door PASS15APassenger Door Latch

SPARE15ASpare

Deicer15AMetal Core Block (PCB #1) (Front Deicer Relay)

Ignition20AIgnition Coil #1~6, Condenser #1, #2

Horn15AMetal Core Block (PCB #1) (Horn Relay)

Sensor 210AMass Air Flow Sensor, Oxygen Sensor #1~4, E/R Fuse & Relay Box LH (RLY.6)

SPARE15ASpare

Wiper30AWiper Motor

EMS30AMetal Core Block (PCB #1) (ECU Main Relay)

ECS40AMetal Core Block (PCB #1) (Air ECS Relay)

METAL CORE

BLOCK

(PCB #2)

Sensor 115APurge Control Solenoid Valve, ECM, Variable Intake Solenoid Valve,

Oil Control Valve #1~4

Injector15AInjector #1~6

SPARE10ASpare

SPARE20ASpare

SPARE10ASpare

Page 446 of 485

Maintenance

70

7

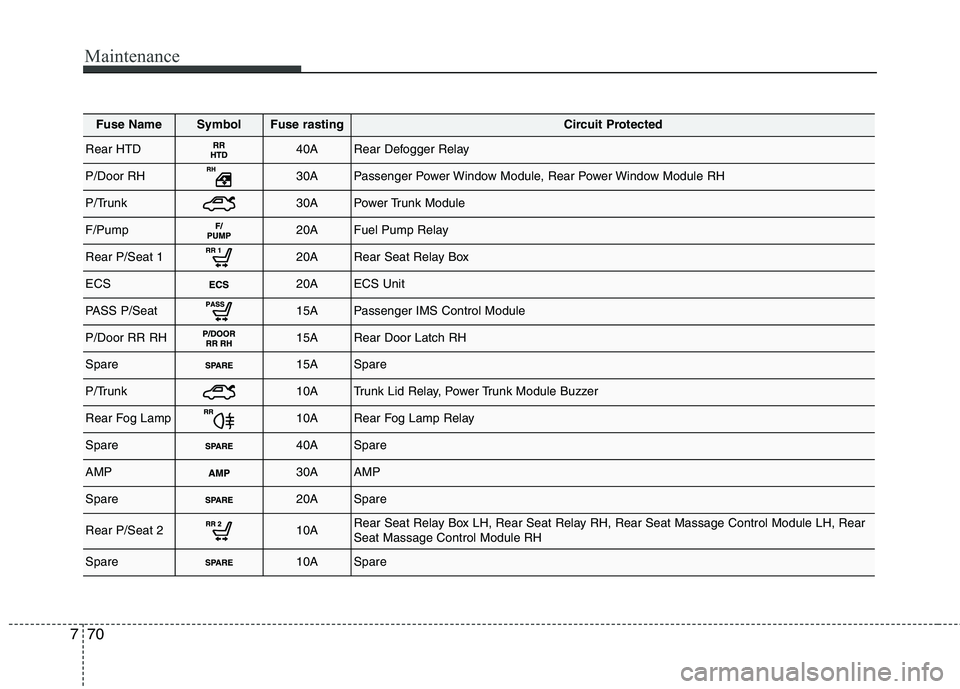

Fuse NameSymbolFuse rastingCircuit Protected

Rear HTD40ARear Defogger Relay

P/Door RH30APassenger Power Window Module, Rear Power Window Module RH

P/Trunk30APower Trunk Module

F/Pump20AFuel Pump Relay

Rear P/Seat 120ARear Seat Relay Box

ECS20AECS Unit

PASS P/Seat15APassenger IMS Control Module

P/Door RR RH15ARear Door Latch RH

Spare15ASpare

P/Trunk10ATrunk Lid Relay, Power Trunk Module Buzzer

Rear Fog Lamp10ARear Fog Lamp Relay

Spare40ASpare

AMP30AAMP

Spare20ASpare

Rear P/Seat 210ARear Seat Relay Box LH, Rear Seat Relay RH, Rear Seat Massage Control Module LH, Rear Seat Massage Control Module RH

Spare10ASpare

Page 456 of 485

Maintenance

80

7

Bright-metal maintenance

To remove road tar and insects,

use a tar remover, not a scraper or

other sharp object.

To protect the surfaces of bright- metal parts from corrosion, apply a

coating of wax or chrome preser-

vative and rub to a high luster.

During winter weather or in coastal areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may

collect on the underbody. If these

materials are not removed, acceler-

ated rusting can occur on underbody

parts such as the fuel lines, frame,

floor pan and exhaust system, even

though they have been treated with

rust protection.

Thoroughly flush the vehicle under-

body and wheel openings with luke-

warm or cold water once a month,

after off-road driving and at the end of

each winter. Pay special attention tothese areas because it is difficult to

see all the mud and dirt. It will do

more harm than good to wet down the

road grime without removing it. The

lower edges of doors, rocker panels,

and frame members have drain holes

that should not be allowed to clog with

dirt; trapped water in these areas can

cause rusting.WARNING

After washing the vehicle, test

the brakes while driving slowly

to see if they have been affected

by water. If braking performance

is impaired, dry the brakes by

applying them lightly while

maintaining a slow forwardspeed.

Page 461 of 485

785

Maintenance

EMISSION CONTROL SYSTEM (IF EQUIPPED)

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the Service

Passport in your vehicle.

Your vehicle is equipped with an emission control system to meet all

applicable emission regulations. There are three emission control

systems, as follows.

(1) Crankcase emission control sys- tem

(2) Evaporative emission control sys- tem (3) Exhaust emission control system In order to assure the proper function

of the emission control systems, it is

recommended that you have your

car inspected and maintained by an

authorized Kia dealer in accordancewith the maintenance schedule in

this manual. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from mis-

firing during dynamometer test-

ing, turn the Electronic Stability

Control (ESC) system off by

pressing the ESC switch.

After dynamometer testing is completed, turn the ESC system

back on by pressing the ESC

switch again. 1. Crankcase emission control

system

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative emission con- trol system

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

Page 462 of 485

Maintenance

86

7

Canister

Fuel vapors generated inside the fuel tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in

the canister are drawn into the surgetank through the purge control sole-

noid valve.

Purge Control Solenoid Valve

(PCSV)

The purge control solenoid valve is

controlled by the Engine Control

Module (ECM); when the engine

coolant temperature is low during

idling, the PCSV closes so that evap-

orated fuel is not taken into the

engine. After the engine warms-up

during ordinary driving, the PCSV

opens to introduce evaporated fuel to

the engine. 3. Exhaust emission control

system

The Exhaust Emission Control

System is a highly effective system

which controls exhaust emissions

while maintaining good vehicle per-

formance.

Vehicle modifications

This vehicle should not be modified.

Modification of your vehicle could

affect its performance, safety or

durability and may even violate gov-

ernmental safety and emissions reg-

ulations.

In addition, damage or performance

problems resulting from any modifi-

cation may not be covered under

warranty.

If you use unauthorized electronic devices, it may cause the vehicle to

operate abnormally, wire damage,

battery discharge and fire. For your

safety, do not use unauthorized

electronic devices.

Engine exhaust gas precautions

(carbon monoxide)

Carbon monoxide can be present with other exhaust fumes.

Therefore, if you smell exhaust

fumes of any kind inside your vehi-

cle, have it inspected and repaired

immediately. If you ever suspect

exhaust fumes are coming into

your vehicle, drive it only with all

the windows fully open. Have your

vehicle checked and repaired

immediately.

WARNING - Exhaust

Engine exhaust gases contain

carbon monoxide (CO). Though

colorless and odorless, it is

dangerous and could be lethal if

inhaled. Follow the instructions

on this page to avoid CO poi-soning.