maintenance schedule KIA RIO 2017 Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2017, Model line: RIO, Model: KIA RIO 2017Pages: 449, PDF Size: 14.88 MB

Page 364 of 449

Maintenance

28

7

NORMAL MAINTENANCE SCHEDULE

No check, No service required

❑ Automatic transaxle fluid (if equipped)

Page 367 of 449

731

Maintenance

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the vehicle is

being driven in severe conditions, more

frequent oil and filter changes are

required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically for

proper tension and adjusted as neces-

sary.

Fuel filter (cartridge)

A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. Fuel filters should be

installed by an authorized Kia dealer.

Fuel filter (for gasoline)

Kia gasoline vehicle is equipped a life-

time fuel filter that integrated with the fuel

tank. Regular maintenance or replace-

ment is not needed but depends on fuel

quality. If there are some important safe-

ty matters like fuel flow restriction, surg-

ing, loss of power, hard starting problem

etc, fuel filter inspection or replace is

needed.

The fuel filter be Inspected or replaced

by an authorized Kia dealer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. Have

an authorized Kia dealer replace any

damaged or leaking parts immediately.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap is

correctly replaced.

Vacuum crankcase ventilation

hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with

any heat source, sharp edges or moving

component which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

Page 368 of 449

Maintenance

32

7

Air cleaner filter

A Genuine Kia air cleaner filter is recom-

mended when the filter is replaced.

Spark plugs

Make sure to install new spark plugs of

the correct heat range.

Valve clearance (if equipped)

Inspect for excessive valve noise and/or

engine vibration and adjust if necessary.

An authorized Kia dealer should perform

the operation.

Cooling system

Check the cooling system components,

such as the radiator, coolant reservoir,

hoses and connections for leakage and

damage. Replace any damaged parts.

Coolant

The coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid

(if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

Automatic transaxle fluid

(if equipped)

Automatic transaxle fluid should not be

checked under normal usage conditions.

But in severe conditions, the fluid should

be changed at an authorized Kia dealer

in accordance to the scheduled mainte-

nance at the beginning of this chapter.

✽ ✽

NOTICE

Automatic transaxle fluid color is basi-

cally red.

As the vehicle is driven, the automatic

transaxle fluid will begin to look darker.

This is a normal condition and you

should not judge the need to replace the

fluid based upon the changed color.

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.

Brake/Clutch (if equipped) fluid

Check the brake fluid level in the brake

fluid reservoir. The level should be

between “MIN” and “MAX” marks on the

side of the reservoir. Use only hydraulic

brake fluid conforming to DOT 3 or DOT

4 specification.

Parking brake

Inspect the parking brake system includ-

ing the parking brake lever and cables.

CAUTION - Specified fluid

The use of a non-specified fluid

could result in transaxle malfunc-tion and failure.

Use only specified automatictransaxle fluid. (Refer to“Recommended lubricants andcapacities” in section 8.)

Page 371 of 449

735

Maintenance

Changing the engine oil and filter

Have engine oil and filter changed by an

authorized Kia dealer according to the

Maintenance Schedule at the beginning

of this section.

WARNING

Used engine oil may cause irrita-

tion or cancer of the skin if left in

contact with the skin for prolonged

periods of time. Used engine oil

contains chemicals that have

caused cancer in laboratory ani-

mals. Always protect your skin by

washing your hands thoroughly

with soap and warm water as soon

as possible after handling used oil.

Page 374 of 449

Maintenance

38

7

Changing the coolant

Have the coolant changed by an author-

ized Kia dealer according to the

Maintenance Schedule at the beginning

of this section.

Put a thick cloth or fabric around the radi-

ator cap before refilling the coolant in

order to prevent the coolant from over-

flowing into engine parts such as the

alternator.

Page 376 of 449

Maintenance

40

7

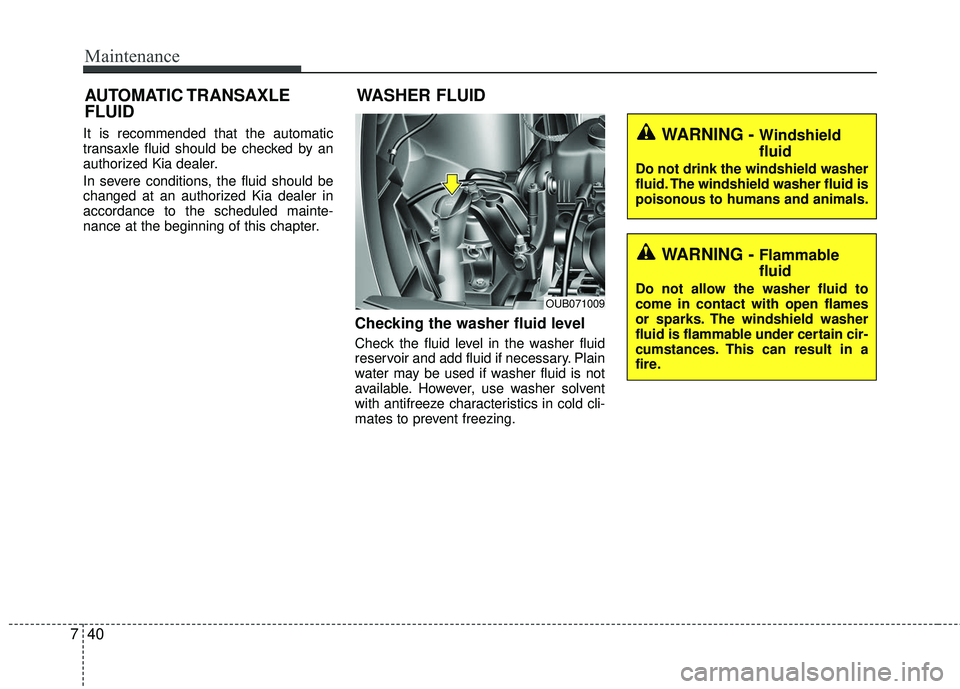

It is recommended that the automatic

transaxle fluid should be checked by an

authorized Kia dealer.

In severe conditions, the fluid should be

changed at an authorized Kia dealer in

accordance to the scheduled mainte-

nance at the beginning of this chapter.

Checking the washer fluid level

Check the fluid level in the washer fluid

reservoir and add fluid if necessary. Plain

water may be used if washer fluid is not

available. However, use washer solvent

with antifreeze characteristics in cold cli-

mates to prevent freezing.

WARNING - Windshield

fluid

Do not drink the windshield washer

fluid. The windshield washer fluid is

poisonous to humans and animals.

WARNING - Flammable

fluid

Do not allow the washer fluid to

come in contact with open flames

or sparks. The windshield washer

fluid is flammable under certain cir-

cumstances. This can result in a

fire.

WASHER FLUID

AUTOMATIC TRANSAXLE

FLUID

OUB071009

Page 377 of 449

741

Maintenance

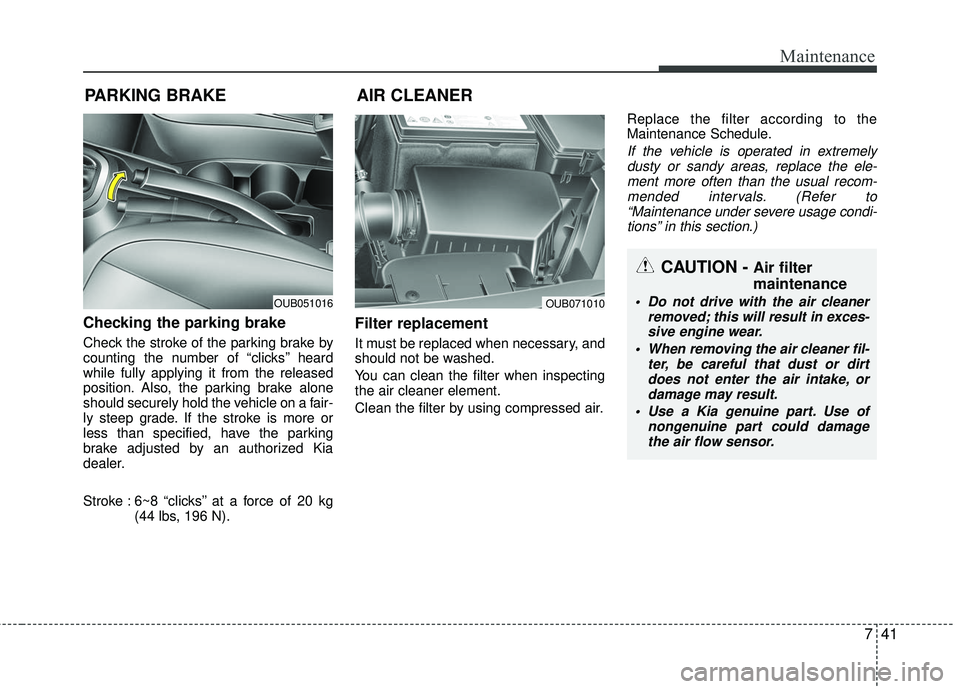

PARKING BRAKE

Checking the parking brake

Check the stroke of the parking brake by

counting the number of “clicks’’ heard

while fully applying it from the released

position. Also, the parking brake alone

should securely hold the vehicle on a fair-

ly steep grade. If the stroke is more or

less than specified, have the parking

brake adjusted by an authorized Kia

dealer.

Stroke : 6~8 “clicks’’ at a force of 20 kg (44 lbs, 196 N).

Filter replacement

It must be replaced when necessary, and

should not be washed.

You can clean the filter when inspecting

the air cleaner element.

Clean the filter by using compressed air. Replace the filter according to the

Maintenance Schedule.

If the vehicle is operated in extremely

dusty or sandy areas, replace the ele- ment more often than the usual recom-mended intervals. (Refer to“Maintenance under severe usage condi- tions” in this section.)

AIR CLEANER

OUB051016OUB071010

CAUTION - Air filter

maintenance

Do not drive with the air cleaner removed; this will result in exces-sive engine wear.

When removing the air cleaner fil- ter, be careful that dust or dirtdoes not enter the air intake, or damage may result.

Use a Kia genuine part. Use of nongenuine part could damagethe air flow sensor.

Page 378 of 449

Maintenance

42

7

Filter inspection

The climate control air filter should be

replaced according to the Maintenance

Schedule. If the vehicle is operated in

severely air-polluted cities or on dusty

rough roads for a long period, it should

be inspected more frequently and

replaced earlier. When you replace the

climate control air filter, replace it per-

forming the following procedure, and be

careful to avoid damaging other compo-

nents.

Blade inspection

Commercial hot waxes applied by auto-

matic car washes have been known to

make the windshield difficult to clean. Contamination of either the windshield or

the wiper blades with foreign matter can

reduce the effectiveness of the wind-

shield wipers. Common sources of con-

tamination are insects, tree sap, and hot

wax treatments used by some commer-

cial car washes. If the blades are not wip-

ing properly, clean both the window and

the blades with a good cleaner or mild

detergent, and rinse thoroughly with

clean water.

CLIMATE CONTROL AIR FIL-

TER (IF EQUIPPED)

WIPER BLADES

1JBA5122CAUTION - Wiper blades

To prevent damage to the wiper

blades, do not use gasoline,kerosene, paint thinner, or other solvents on or near them.

Page 428 of 449

Maintenance

92

7

EMISSION CONTROL SYSTEM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Warranty &

Consumer Information manual in your

vehicle.

Your vehicle is equipped with an emis-

sion control system to meet all applicable

emission regulations.

There are three emission control sys-

tems, as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system

(3) Exhaust emission control system

In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your vehicle

inspected and maintained by an author-

ized Kia dealer in accordance with the

maintenance schedule in this manual. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability Control

(ESC) system off by pressing the

ESC switch.

After dynamometer testing is com- pleted, turn the ESC system back on

by pressing the ESC switch again.1. Crankcase emission control system

The positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valve

into the induction system.

2. Evaporative emission control(including ORVR: Onboard

Refueling Vapor Recovery)

system

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

(The ORVR system is designed to allow

the vapors from the fuel tank to be

loaded into a canister while refueling at

the gas station, preventing the escape of

fuel vapors into the atmosphere.)

Page 444 of 449

Index

4I

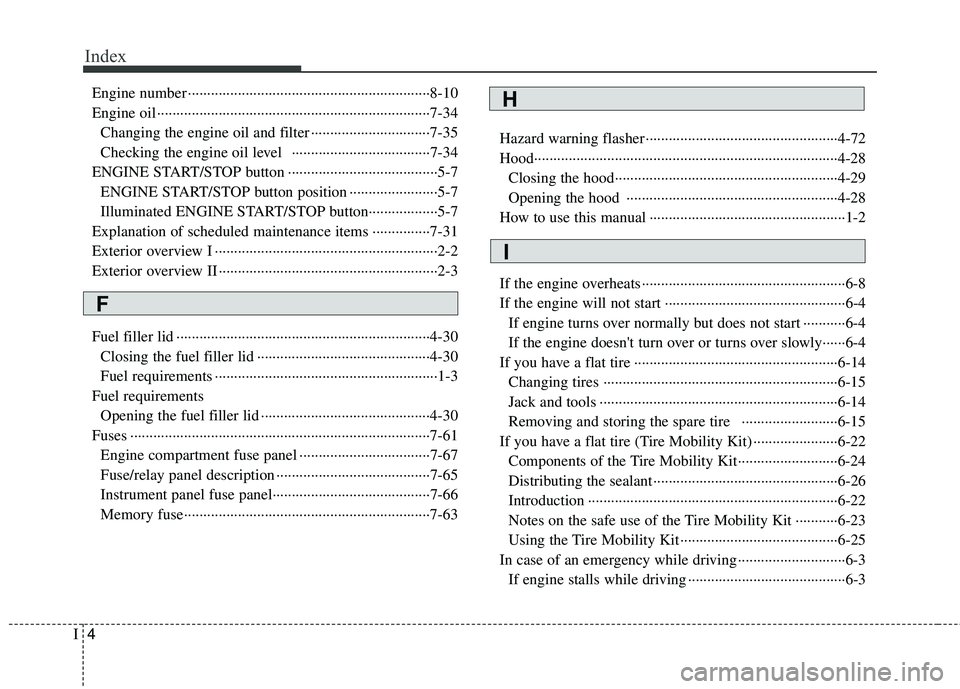

Engine number ··················\

··················\

··················\

·········8-10

Engine oil ··················\

··················\

··················\

·················7-34\

Changing the engine oil and filter ··················\

·············7-35

Checking the engine oil level ··················\

··················\

7-34

ENGINE START/STOP button ··················\

··················\

···5-7 ENGINE START/STOP button position ··················\

·····5-7

Illuminated ENGINE START/STOP button·················\

·5-7

Explanation of scheduled maintenance items ···············7-31

Exterior overview I ··················\

··················\

··················\

····2-2

Exterior overview II ··················\

··················\

··················\

···2-3

Fuel filler lid ··················\

··················\

··················\

············4-30 Closing the fuel filler lid ··················\

··················\

·········4-30

Fuel requirements ··················\

··················\

··················\

····1-3

Fuel requirements Opening the fuel filler lid ··················\

··················\

········4-30

Fuses ··················\

··················\

··················\

··················\

······7-61 Engine compartment fuse panel ··················\

················7-67

Fuse/relay panel description ··················\

··················\

····7-65

Instrument panel fuse panel··················\

··················\

·····7-66

Memory fuse··················\

··················\

··················\

··········7-63 Hazard warning flasher ··················\

··················\

··············4-72

Hood··················\

··················\

··················\

··················\

·······4-28

Closing the hood··················\

··················\

··················\

····4-29

Opening the hood ··················\

··················\

··················\

·4-28

How to use this manual ··················\

··················\

···············1-2

If the engine overheats··················\

··················\

·················6-8

If the engine will not start ··················\

··················\

···········6-4 If engine turns over normally but does not start ···········6-4

If the engine doesn't turn over or turns over slowly······6-4

If you have a flat tire ··················\

··················\

·················6-14\

Changing tires ···············\

··················\

··················\

··········6-15

Jack and tools ··················\

··················\

··················\

········6-14

Removing and storing the spare tire ··················\

·······6-15

If you have a flat tire (Tire Mobility Kit) ··················\

····6-22 Components of the Tire Mobility Kit··················\

········6-24

Distributing the sealant ··················\

··················\

············6-26

Introduction ··················\

··················\

··················\

···········6-22

Notes on the safe use of the Tire Mobility Kit ···········6-23

Using the Tire Mobility Kit ··················\

··················\

·····6-25

In case of an emergency while driving ··················\

··········6-3 If engine stalls while driving ··················\

··················\

·····6-3H

F

I