oil KIA Sedona 2014 3.G Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2014, Model line: Sedona, Model: KIA Sedona 2014 3.GPages: 382, PDF Size: 4.67 MB

Page 335 of 382

619

Maintenance

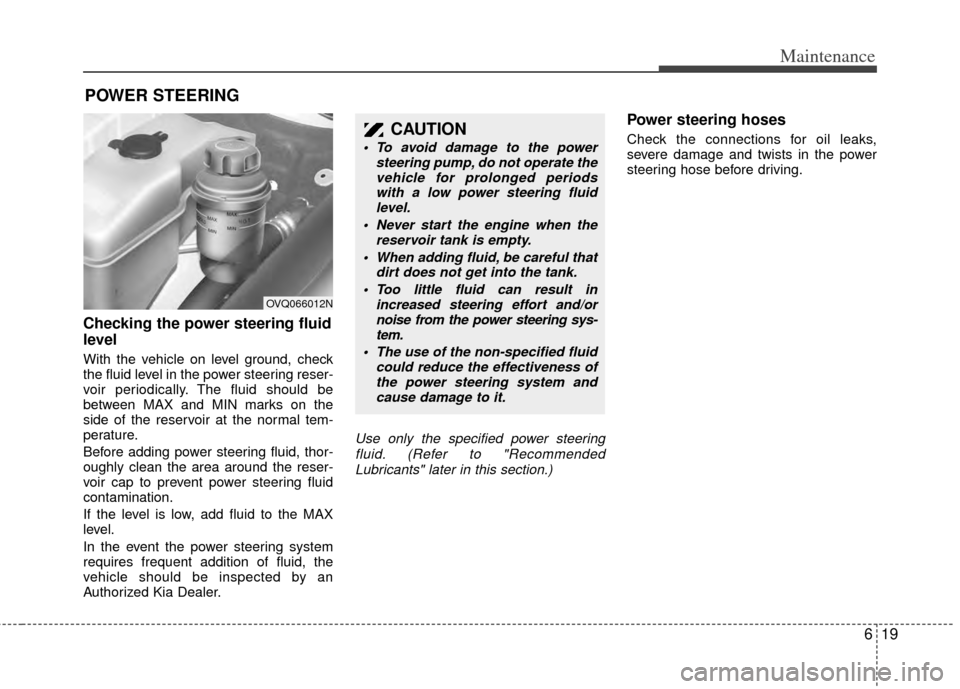

POWER STEERING

Checking the power steering fluid

level

With the vehicle on level ground, check

the fluid level in the power steering reser-

voir periodically. The fluid should be

between MAX and MIN marks on the

side of the reservoir at the normal tem-

perature.

Before adding power steering fluid, thor-

oughly clean the area around the reser-

voir cap to prevent power steering fluid

contamination.

If the level is low, add fluid to the MAX

level.

In the event the power steering system

requires frequent addition of fluid, the

vehicle should be inspected by an

Authorized Kia Dealer.

Use only the specified power steeringfluid. (Refer to "RecommendedLubricants" later in this section.)

Power steering hoses

Check the connections for oil leaks,

severe damage and twists in the power

steering hose before driving.CAUTION

To avoid damage to the power steering pump, do not operate thevehicle for prolonged periods with a low power steering fluidlevel.

Never start the engine when the reservoir tank is empty.

When adding fluid, be careful that dirt does not get into the tank.

Too little fluid can result in increased steering effort and/ornoise from the power steering sys-tem.

The use of the non-specified fluid could reduce the effectiveness ofthe power steering system andcause damage to it.

OVQ066012N

Page 339 of 382

623

Maintenance

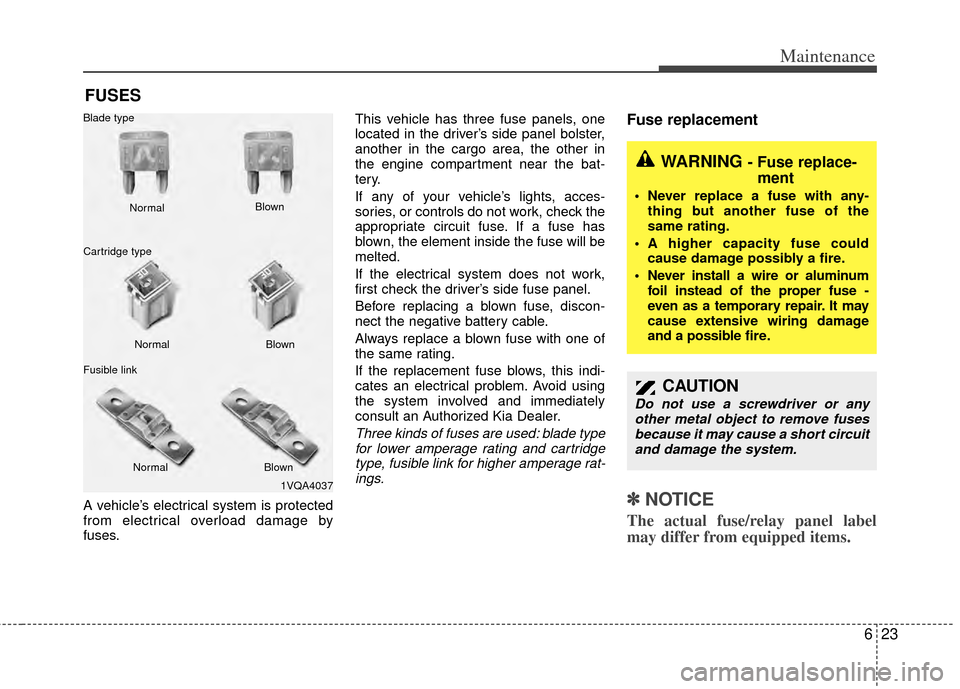

FUSES

A vehicle’s electrical system is protected

from electrical overload damage by

fuses.This vehicle has three fuse panels, one

located in the driver’s side panel bolster,

another in the cargo area, the other in

the engine compartment near the bat-

tery.

If any of your vehicle’s lights, acces-

sories, or controls do not work, check the

appropriate circuit fuse. If a fuse has

blown, the element inside the fuse will be

melted.

If the electrical system does not work,

first check the driver’s side fuse panel.

Before replacing a blown fuse, discon-

nect the negative battery cable.

Always replace a blown fuse with one of

the same rating.

If the replacement fuse blows, this indi-

cates an electrical problem. Avoid using

the system involved and immediately

consult an Authorized Kia Dealer.

Three kinds of fuses are used: blade type

for lower amperage rating and cartridgetype, fusible link for higher amperage rat-ings.

Fuse replacement

✽ ✽ NOTICE

The actual fuse/relay panel label

may differ from equipped items.

1VQA4037

Normal

Normal

Blade type

Cartridge type

Fusible link Blown

Blown

Normal Blown

WARNING - Fuse replace-

ment

Never replace a fuse with any-

thing but another fuse of the

same rating.

A higher capacity fuse could cause damage possibly a fire.

Never install a wire or aluminum foil instead of the proper fuse -

even as a temporary repair. It may

cause extensive wiring damage

and a possible fire.

CAUTION

Do not use a screwdriver or anyother metal object to remove fuses because it may cause a short circuitand damage the system.

Page 345 of 382

629

Maintenance

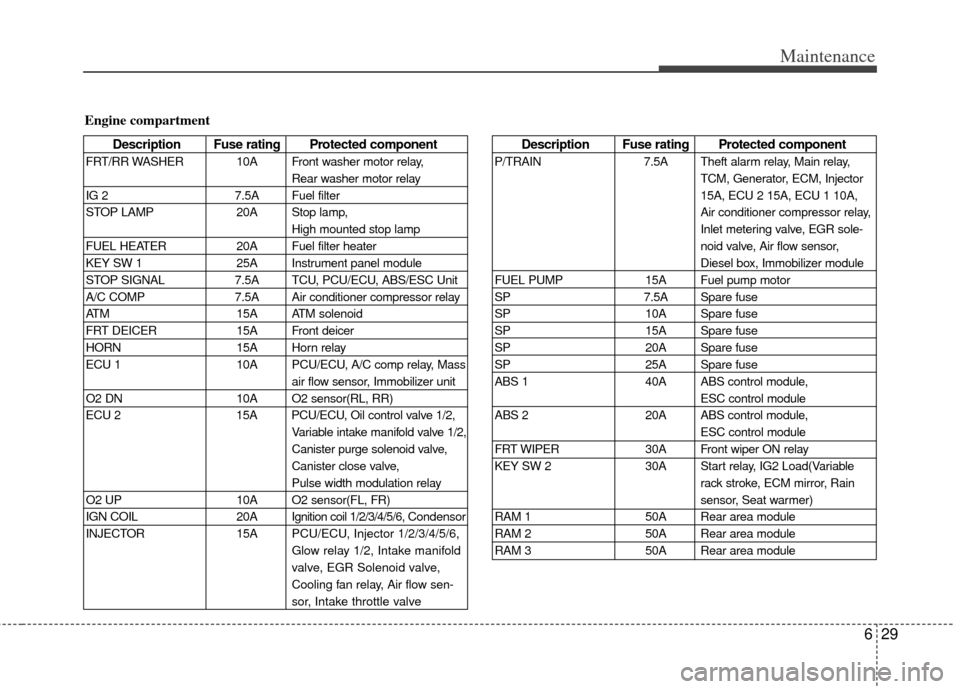

Description Fuse rating Protected component

P/TRAIN7.5A Theft alarm relay, Main relay,

TCM, Generator, ECM, Injector

15A, ECU 2 15A, ECU 1 10A,

Air conditioner compressor relay,

Inlet metering valve, EGR sole-

noid valve, Air flow sensor,

Diesel box, Immobilizer module

FUEL PUMP 15A Fuel pump motor

SP 7.5A Spare fuse

SP 10A Spare fuse

SP 15A Spare fuse

SP 20A Spare fuse

SP 25A Spare fuse

ABS 1 40A ABS control module,

ESC control module

ABS 2 20A ABS control module,

ESC control module

FRT WIPER 30A Front wiper ON relay

KEY SW 2 30A Start relay, IG2 Load(Variable

rack stroke, ECM mirror, Rain

sensor, Seat warmer)

RAM 1 50A Rear area module

RAM 2 50A Rear area module

RAM 3 50A Rear area module

Engine compartment

Description Fuse rating Protected component

FRT/RR WASHER 10A Front washer motor relay,

Rear washer motor relay

IG 2 7.5A Fuel filter

STOP LAMP 20A Stop lamp, High mounted stop lamp

FUEL HEATER 20A Fuel filter heater

KEY SW 1 25A Instrument panel module

STOP SIGNAL 7.5A TCU, PCU/ECU, ABS/ESC Unit

A/C COMP 7.5A Air conditioner compressor relay

ATM 15A ATM solenoid

FRT DEICER 15A Front deicer

HORN 15A Horn relay

ECU 1 10A PCU/ECU, A/C comp relay, Mass air flow sensor, Immobilizer unit

O2 DN 10A O2 sensor(RL, RR)

ECU 2 15A PCU/ECU, Oil control valve 1/2, Variable intake manifold valve 1/2,

Canister purge solenoid valve,

Canister close valve,

Pulse width modulation relay

O2 UP 10A O2 sensor(FL, FR)

IGN COIL 20A Ignition coil 1/2/3/4/5/6, Condensor

INJECTOR 15APCU/ECU, Injector 1/2/3/4/5/6,

Glow relay 1/2, Intake manifold

valve, EGR Solenoid valve,

Cooling fan relay, Air flow sen-

sor, Intake throttle valve

Page 349 of 382

633

Maintenance

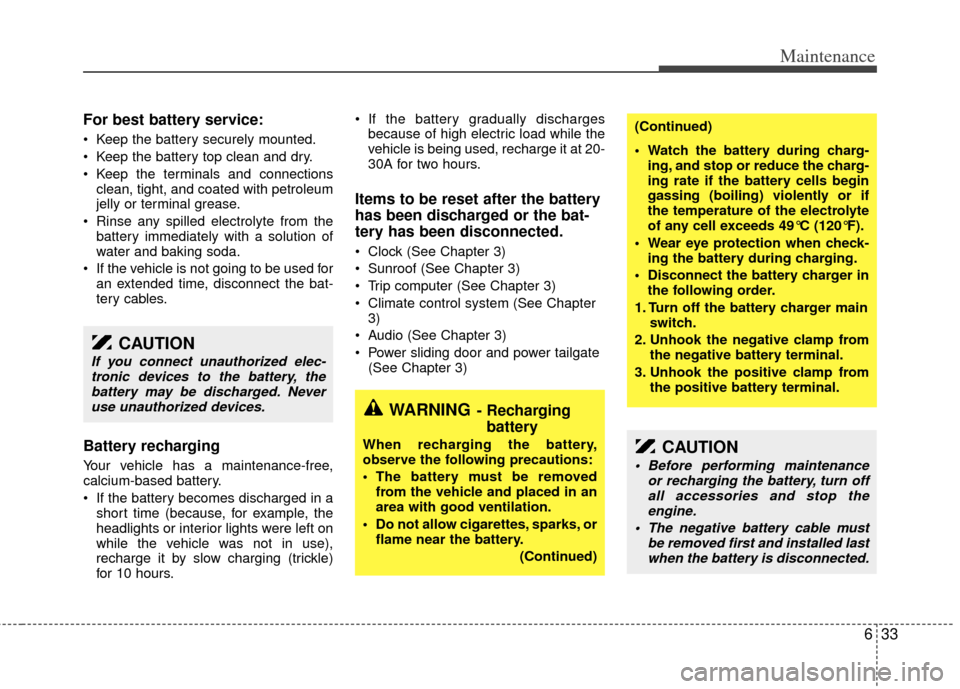

For best battery service:

Keep the battery securely mounted.

Keep the battery top clean and dry.

Keep the terminals and connectionsclean, tight, and coated with petroleum

jelly or terminal grease.

Rinse any spilled electrolyte from the battery immediately with a solution of

water and baking soda.

If the vehicle is not going to be used for an extended time, disconnect the bat-

tery cables.

Battery recharging

Your vehicle has a maintenance-free,

calcium-based battery.

If the battery becomes discharged in ashort time (because, for example, the

headlights or interior lights were left on

while the vehicle was not in use),

recharge it by slow charging (trickle)

for 10 hours. If the battery gradually discharges

because of high electric load while the

vehicle is being used, recharge it at 20-

30A for two hours.

Items to be reset after the battery

has been discharged or the bat-

tery has been disconnected.

Clock (See Chapter 3)

Sunroof (See Chapter 3)

Trip computer (See Chapter 3)

Climate control system (See Chapter3)

Audio (See Chapter 3)

Power sliding door and power tailgate (See Chapter 3)

CAUTION

If you connect unauthorized elec-tronic devices to the battery, thebattery may be discharged. Neveruse unauthorized devices.

CAUTION

Before performing maintenance or recharging the battery, turn offall accessories and stop theengine.

The negative battery cable must be removed first and installed lastwhen the battery is disconnected.

WARNING- Recharging battery

When recharging the battery,

observe the following precautions:

The battery must be removed

from the vehicle and placed in an

area with good ventilation.

Do not allow cigarettes, sparks, or flame near the battery.

(Continued)

(Continued)

Watch the battery during charg-ing, and stop or reduce the charg-

ing rate if the battery cells begin

gassing (boiling) violently or if

the temperature of the electrolyte

of any cell exceeds 49°C (120°F).

Wear eye protection when check- ing the battery during charging.

Disconnect the battery charger in the following order.

1. Turn off the battery charger main switch.

2. Unhook the negative clamp from the negative battery terminal.

3. Unhook the positive clamp from the positive battery terminal.

Page 359 of 382

643

Maintenance

Tire terminology and definitions

Air Pressure: The amount of air

inside the tire pressing outward on

the tire. Air pressure is expressed in

kilopascal (kPa) or pounds per

square inch (psi).

Accessory Weight: This means the

combined weight of optional acces-

sories. Some examples of optional

accessories are, automatic transmis-

sion, power seats, and air condition-

ing.

Aspect Ratio : The relationship of a

tire's height to its width.

Belt: A rubber coated layer of cords

that is located between the plies and

the tread. Cords may be made from

steel or other reinforcing materials.

Bead: The tire bead contains steel

wires wrapped by steel cords that

hold the tire onto the rim.

Bias Ply Tire : A pneumatic tire in

which the plies are laid at alternate

angles less than 90 degrees to the

centerline of the tread. Cold Tire Pressure: The amount of

air pressure in a tire, measured in

kilopascals (kPa) or pounds per

square inch (psi) before a tire has

built up heat from driving.

Curb Weight: This means the weight

of a motor vehicle with standard and

optional equipment including the

maximum capacity of fuel, oil and

coolant, but without passengers and

cargo.

DOT Markings: The DOT code

includes the Tire Identification

Number (TIN), an alphanumeric des-

ignator which can also identify the

tire manufacturer, production plant,

brand and date of production.

GVWR: Gross Vehicle Weight Rating

GAWR FRT: Gross Axle Weight

Rating for the front Axle.

GAWR RR: Gross Axle Weight

Rating for the rear axle.

Intended Outboard Sidewall

: The

side of an asymmetrical tire, that

must always face outward when

mounted on a vehicle.

Kilopascal (kPa): The metric unit for

air pressure.

Load Index: An assigned number

ranging from 1 to 279 that corre-

sponds to the load carrying capacity

of a tire.

Maximum Inflation Pressure: The

maximum air pressure to which a

cold tire may be inflated. The maxi-

mum air pressure is molded onto the

sidewall.

Maximum Load Rating : The load

rating for a tire at the maximum per-

missible inflation pressure for that

tire.

Maximum Loaded Vehicle Weight:

The sum of curb weight; accessory

weight; vehicle capacity weight; and

production options weight.

Normal Occupant Weight: The

number of occupants a vehicle is

designed to seat multiplied by 68 kg

(150 pounds).

Page 363 of 382

647

Maintenance

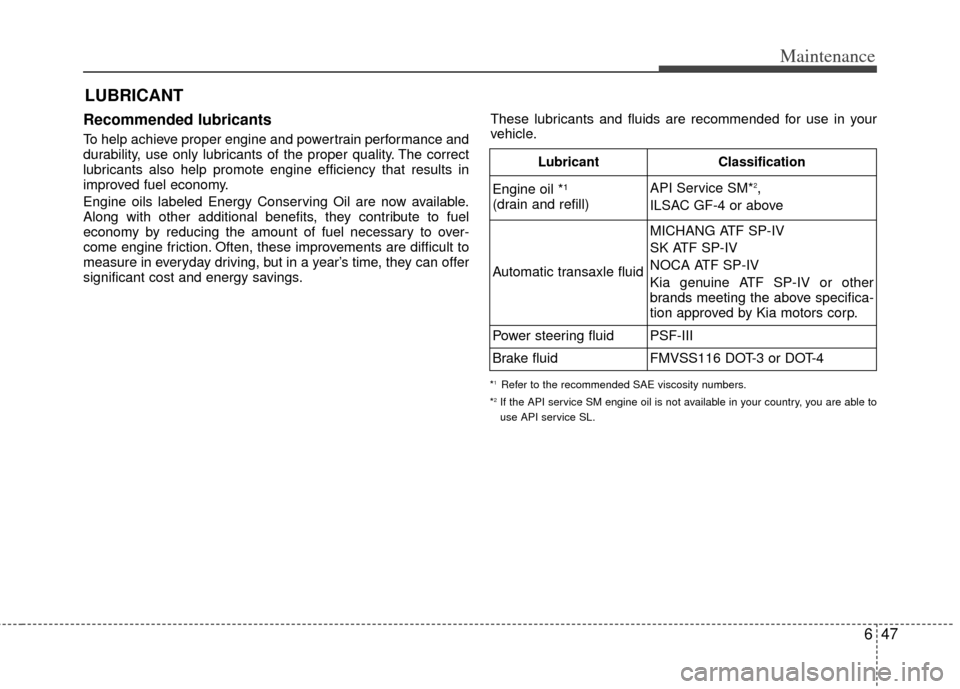

LUBRICANT

Recommended lubricants

To help achieve proper engine and powertrain performance and

durability, use only lubricants of the proper quality. The correct

lubricants also help promote engine efficiency that results in

improved fuel economy.

Engine oils labeled Energy Conserving Oil are now available.

Along with other additional benefits, they contribute to fuel

economy by reducing the amount of fuel necessary to over-

come engine friction. Often, these improvements are difficult to

measure in everyday driving, but in a year’s time, they can offer

significant cost and energy savings.

*1Refer to the recommended SAE viscosity numbers.

*2If the API service SM engine oil is not available in your country, you are able to

use API service SL.

These lubricants and fluids are recommended for use in your

vehicle.

LubricantClassification

Engine oil *¹

(drain and refill)API Service SM*2,

ILSAC GF-4 or above

Automatic transaxle fluid

MICHANG ATF SP-IV

SK ATF SP-IV

NOCA ATF SP-IV

Kia genuine ATF SP-IV or other

brands meeting the above specifica-

tion approved by Kia motors corp.

Power steering fluidPSF-III

Brake fluidFMVSS116 DOT-3 or DOT-4

Page 364 of 382

Maintenance

48

6

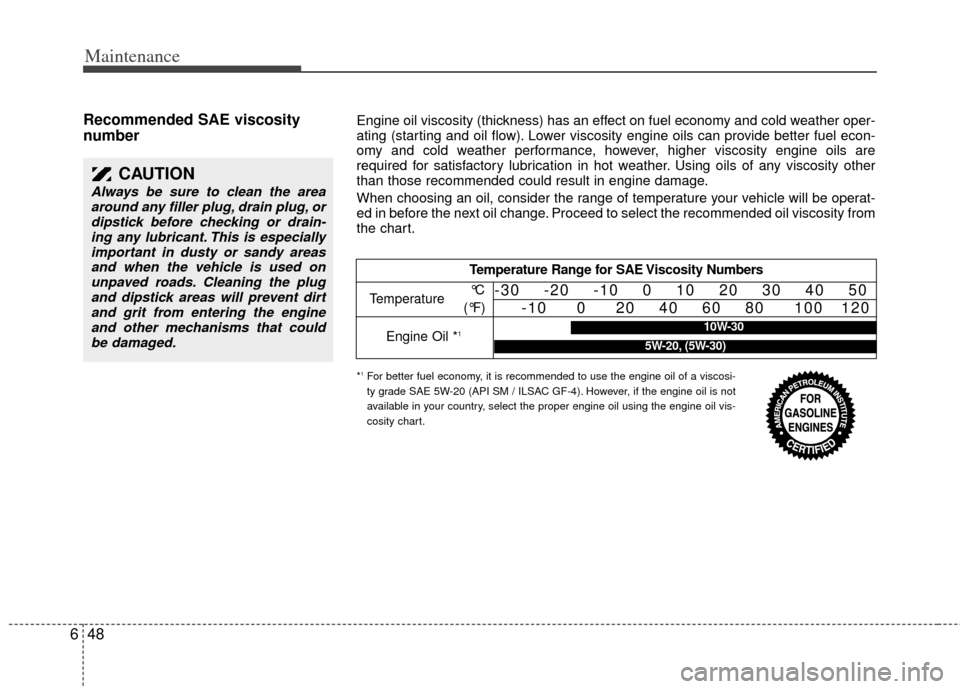

Recommended SAE viscosity

number

CAUTION

Always be sure to clean the area

around any filler plug, drain plug, ordipstick before checking or drain-ing any lubricant. This is especiallyimportant in dusty or sandy areasand when the vehicle is used onunpaved roads. Cleaning the plugand dipstick areas will prevent dirt and grit from entering the engineand other mechanisms that couldbe damaged.

Temperature Range for SAE Viscosity Numbers

Temperature

Engine Oil *

1

°C

(°F)-30 -20 -10 0 10 20 30 40 50 -10 0 20 40 60 80 100 120

10W-30

5W-20, (5W-30)

*1For better fuel economy, it is recommended to use the engine oil of a viscosi-

ty grade SAE 5W-20 (API SM / ILSAC GF-4). However, if the engine oil is not

available in your country, select the proper engine oil using the engine oil vis-

cosity chart.

Engine oil viscosity (thickness) has an effect on fuel economy and cold weather oper-

ating (starting and oil flow). Lower viscosity engine oils can provide better fuel econ-

omy and cold weather performance, however, higher viscosity engine oils are

required for satisfactory lubrication in hot weather. Using oils of any viscosity other

than those recommended could result in engine damage.

When choosing an oil, consider the range of temperature your vehicle will be operat-

ed in before the next oil change. Proceed to select the recommended oil viscosity from

the chart.

Page 366 of 382

Maintenance

50

6

Waxing

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim to protect

it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly rust

and may develop into a major repair

expense.

✽ ✽

NOTICE

If your vehicle is damaged and requires

any metal repair or replacement, be sure

the body shop applies anti-corrosion

materials to the parts repaired or

replaced.

Bright-metal maintenance

To remove road tar and insects, use a

tar remover, not a scraper or other

sharp object.

To protect the surfaces of bright-metal parts from corrosion, apply a coating of

wax or chrome preservative and rub to

a high luster.

During winter weather or in coastal areas, cover the bright metal parts with

a heavier coating of wax or preserva-

tive. If necessary, coat the parts with

non-corrosive petroleum jelly or other

protective compound.CAUTION

Wiping dust or dirt off the body with a dry cloth will scratch thefinish.

Do not use steel wool, abrasive cleaners, or strong detergentscontaining highly alkaline or caustic agents on chrome-platedor anodized aluminum parts. Thismay result in damage to the pro-tective coating and cause discol-oration or paint deterioration.

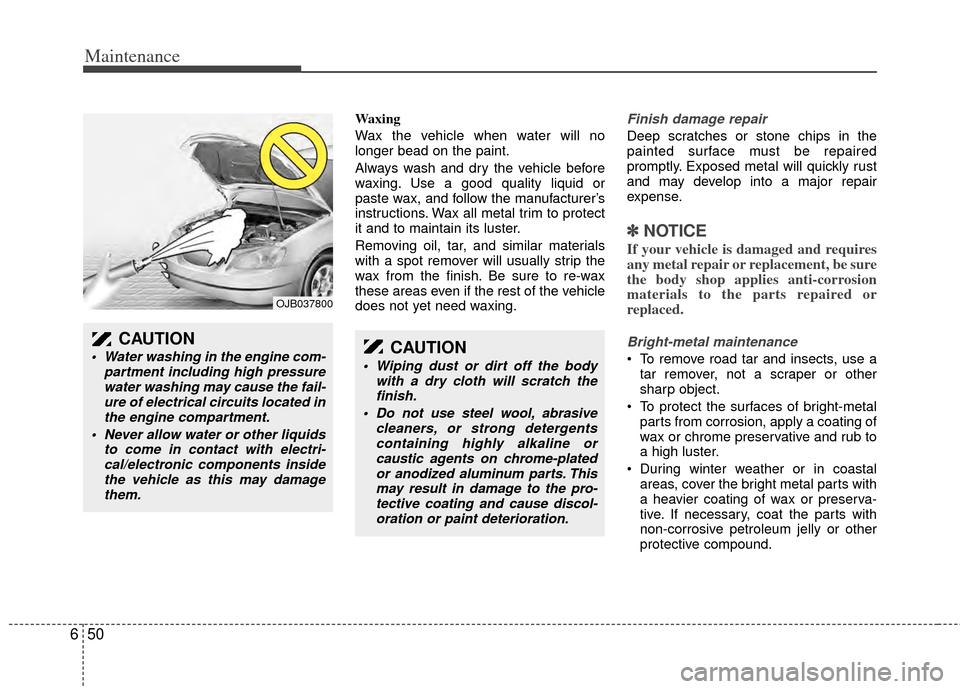

CAUTION

Water washing in the engine com- partment including high pressurewater washing may cause the fail- ure of electrical circuits located inthe engine compartment.

Never allow water or other liquids to come in contact with electri-cal/electronic components insidethe vehicle as this may damagethem.

OJB037800

Page 367 of 382

651

Maintenance

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may col-

lect on the underbody. If these materials

are not removed, accelerated rusting can

occur on underbody parts such as the

fuel lines, frame, floor pan and exhaust

system, even though they have been

treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month at the end of

each winter. Pay special attention to

these areas because it is difficult to see

all the mud and dirt. It will do more harm

than good to wet down the road grime

without removing it. The lower edges of

doors, rocker panels, and frame mem-

bers have drain holes that should not be

allowed to clog with dirt; trapped water in

these areas can cause rusting.

Aluminum or chrome wheel mainte-nance

The aluminum or chrome wheels are

coated with a clear protective finish.

Do not use any abrasive cleaner, pol- ishing compound, solvent, or wire

brushes on aluminum or chrome

wheels. They may scratch or damage

the finish.

Clean the wheel when it has cooled.

Use only a mild soap or neutral deter- gent, and rinse thoroughly with water.

Also, be sure to clean the wheels after

driving on salted roads. This helps pre-

vent corrosion.

Avoid washing the wheels with high- speed car wash brushes.

Do not use any alkaline or acid deter- gents. It may damage and corrode the

aluminum or chrome wheels coated

with a clear protective finish.

Interior care

Interior general precautions

Prevent chemicals such as perfume, cos-

metic oil, sun cream, hand cleaner, and

air freshener from contacting the interior

parts because they may cause damage

or discoloration. If they do contact the

interior parts, wipe them off immediately.

See the instructions for the proper way to

clean vinyl.

✽ ✽ NOTICE

Never allow water or other liquids to

come in contact with electrical/ electron-

ic components inside the vehicle as this

may damage them.

WARNING

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

CAUTION

When cleaning leather products

(steering wheel, seats etc.), use neutral detergents or low alcoholcontent solutions. If you use high alcohol content solutions oracid/alkaline detergents, the colorof the leather may fade or the sur-face may get stripped off.

Page 368 of 382

Maintenance

52

6

Cleaning the upholstery and interior

trim

Vinyl

Remove dust and loose dirt from vinyl

with a whisk broom or vacuum cleaner.

Clean vinyl surfaces with a vinyl cleaner.

Fabric

Remove dust and loose dirt from fabric

with a whisk broom or vacuum cleaner.

Clean with a mild soap solution recom-

mended for upholstery or carpets.

Remove fresh spots immediately with a

fabric spot cleaner. If fresh spots do not

receive immediate attention, the fabric

can be stained and its color can be

affected. Also, its fire-resistant properties

can be reduced if the material is not

properly maintained.

Cleaning the lap/shoulder belt web-bing

Clean the belt webbing with any mild

soap solution recommended for cleaning

upholstery or carpet. Follow the instruc-

tions provided with the soap. Do not

bleach or re-dye the webbing because

this may weaken it.

Cleaning the interior window glass

If the interior glass surfaces of the vehi-

cle become fogged (that is, covered with

an oily, greasy or waxy film), they should

be cleaned with glass cleaner. Follow the

directions on the glass cleaner container.

CAUTION

Do not scrape or scratch the insideof the rear window. This may resultin damage to the rear window defroster grid.

CAUTION

Using anything but recommendedcleaners and procedures may affectthe fabric’s appearance and fire-resistant properties.