KIA SOUL EV 2018 Owners Manual

Manufacturer: KIA, Model Year: 2018, Model line: SOUL EV, Model: KIA SOUL EV 2018Pages: 496, PDF Size: 15.13 MB

Page 401 of 496

711

Maintenance

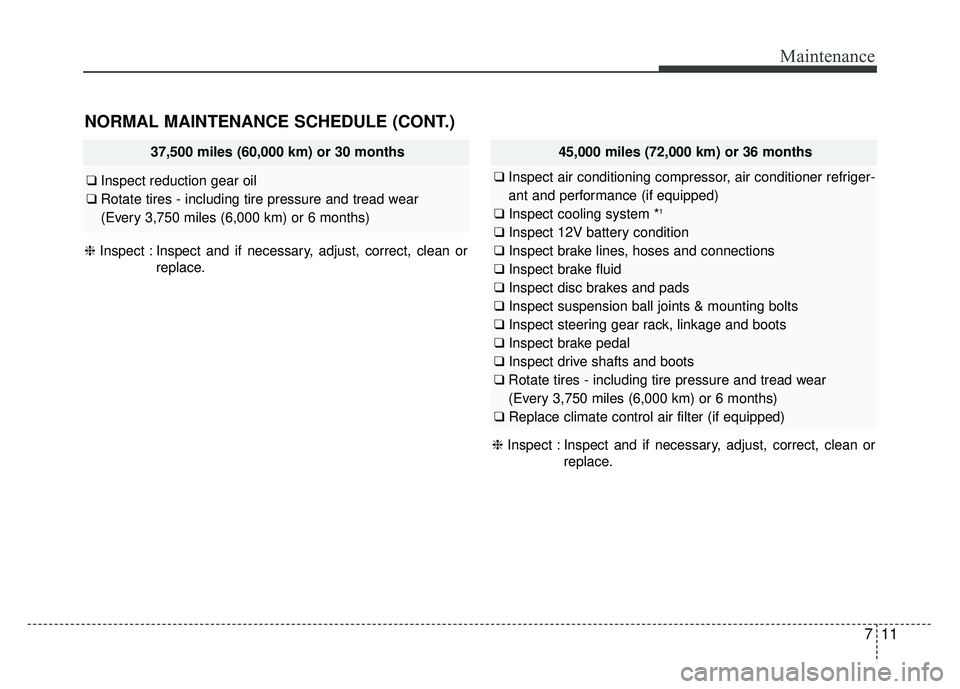

NORMAL MAINTENANCE SCHEDULE (CONT.)

❈Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

37,500 miles (60,000 km) or 30 months

❑Inspect reduction gear oil

❑ Rotate tires - including tire pressure and tread wear

(Every 3,750 miles (6,000 km) or 6 months)

45,000 miles (72,000 km) or 36 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 3,750 miles (6,000 km) or 6 months)

❑ Replace climate control air filter (if equipped)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 402 of 496

Maintenance

12

7

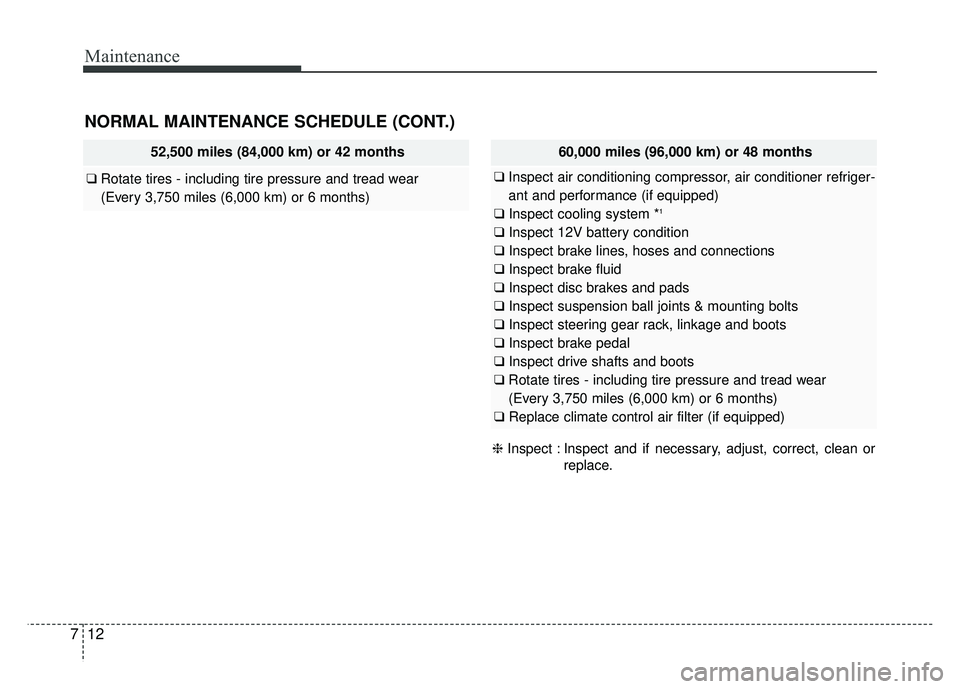

NORMAL MAINTENANCE SCHEDULE (CONT.)

52,500 miles (84,000 km) or 42 months

❑ Rotate tires - including tire pressure and tread wear

(Every 3,750 miles (6,000 km) or 6 months)

60,000 miles (96,000 km) or 48 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 3,750 miles (6,000 km) or 6 months)

❑ Replace climate control air filter (if equipped)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 403 of 496

713

Maintenance

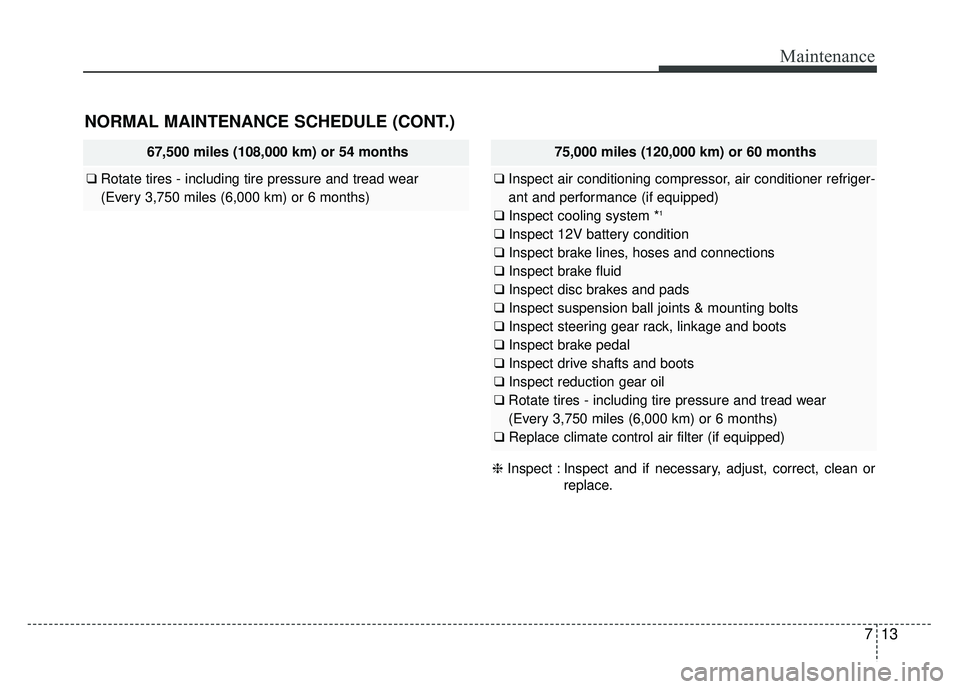

NORMAL MAINTENANCE SCHEDULE (CONT.)

67,500 miles (108,000 km) or 54 months

❑Rotate tires - including tire pressure and tread wear

(Every 3,750 miles (6,000 km) or 6 months)

75,000 miles (120,000 km) or 60 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Inspect reduction gear oil

❑ Rotate tires - including tire pressure and tread wear

(Every 3,750 miles (6,000 km) or 6 months)

❑ Replace climate control air filter (if equipped)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 404 of 496

Maintenance

14

7

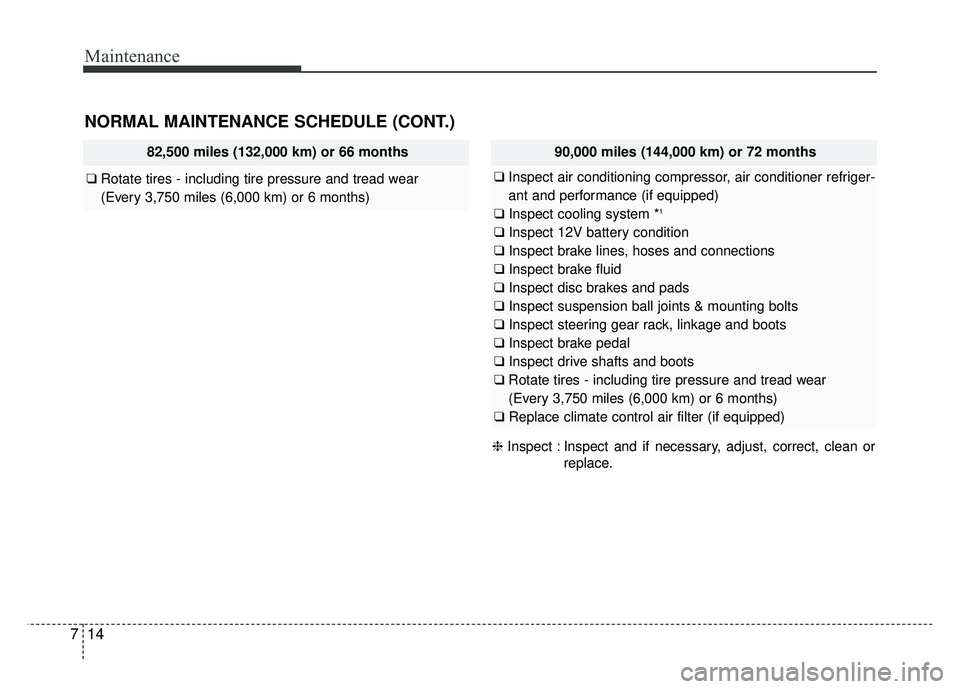

NORMAL MAINTENANCE SCHEDULE (CONT.)

82,500 miles (132,000 km) or 66 months

❑ Rotate tires - including tire pressure and tread wear

(Every 3,750 miles (6,000 km) or 6 months)

90,000 miles (144,000 km) or 72 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 3,750 miles (6,000 km) or 6 months)

❑ Replace climate control air filter (if equipped)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 405 of 496

715

Maintenance

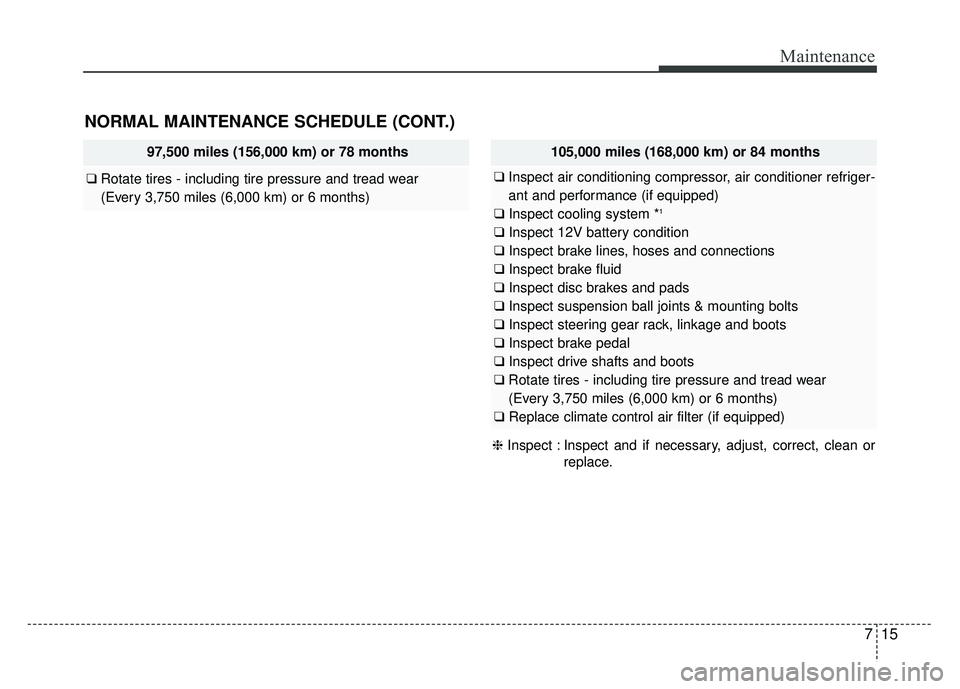

97,500 miles (156,000 km) or 78 months

❑Rotate tires - including tire pressure and tread wear

(Every 3,750 miles (6,000 km) or 6 months)

NORMAL MAINTENANCE SCHEDULE (CONT.)

105,000 miles (168,000 km) or 84 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 3,750 miles (6,000 km) or 6 months)

❑ Replace climate control air filter (if equipped)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 406 of 496

Maintenance

16

7

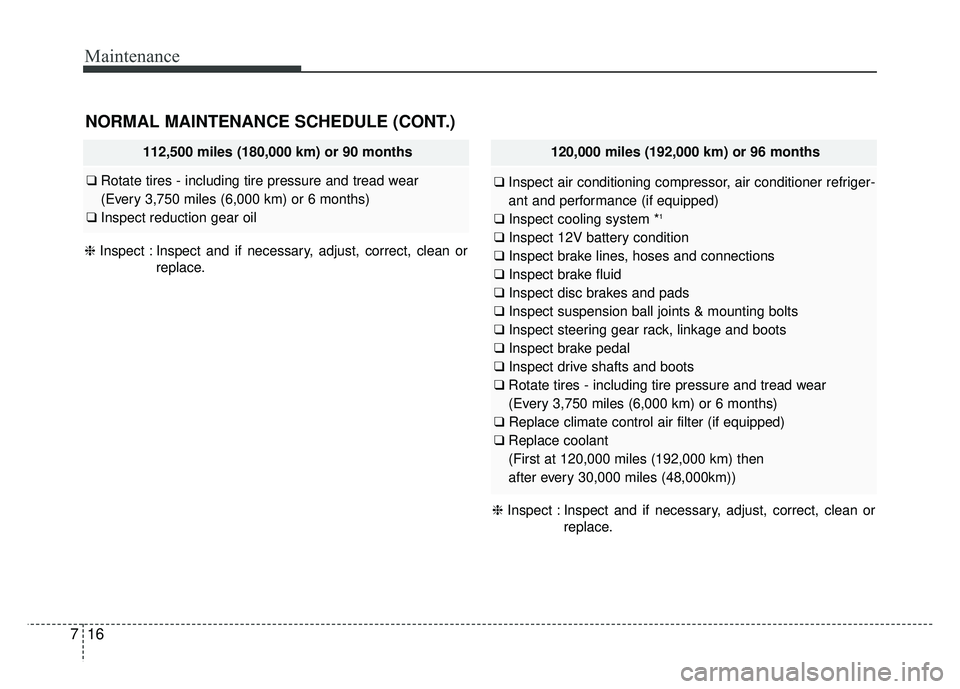

NORMAL MAINTENANCE SCHEDULE (CONT.)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

112,500 miles (180,000 km) or 90 months

❑Rotate tires - including tire pressure and tread wear

(Every 3,750 miles (6,000 km) or 6 months)

❑ Inspect reduction gear oil

120,000 miles (192,000 km) or 96 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 3,750 miles (6,000 km) or 6 months)

❑ Replace climate control air filter (if equipped)

❑ Replace coolant

(First at 120,000 miles (192,000 km) then

after every 30,000 miles (48,000km))

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 407 of 496

717

Maintenance

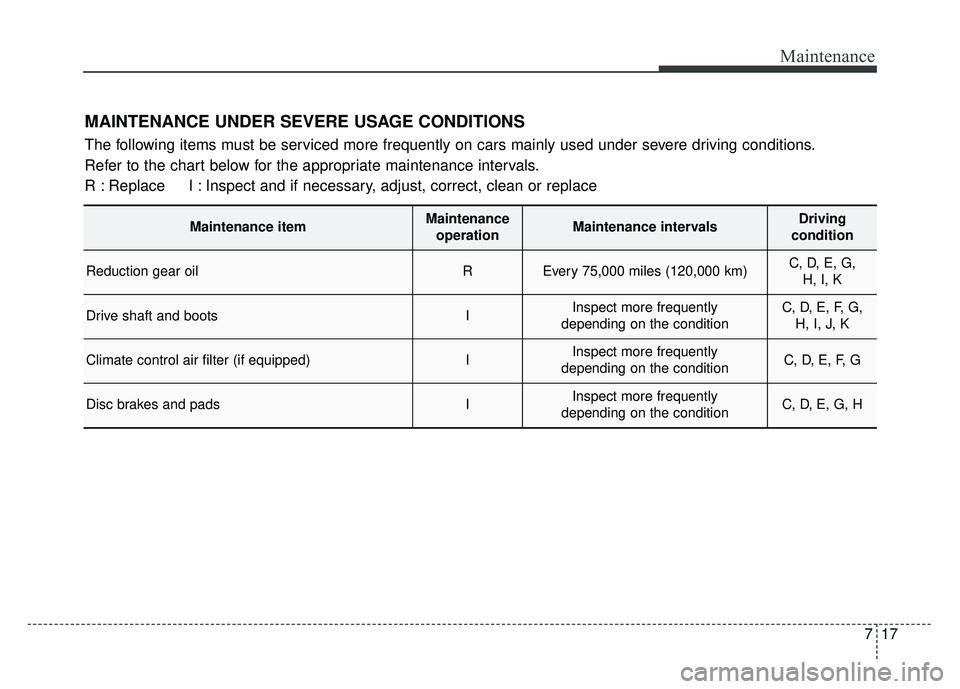

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars mainly used under severe driving conditions.

Refer to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and if necessary, adjust, correct, clean or replace

Maintenance itemMaintenanceoperationMaintenance intervalsDriving

condition

Reduction gear oilREvery 75,000 miles (120,000 km)C, D, E, G, H, I, K

Drive shaft and bootsIInspect more frequently

depending on the conditionC, D, E, F, G, H, I, J, K

Climate control air filter (if equipped)IInspect more frequently

depending on the conditionC, D, E, F, G

Disc brakes and padsIInspect more frequently

depending on the conditionC, D, E, G, H

Page 408 of 496

Maintenance

18

7

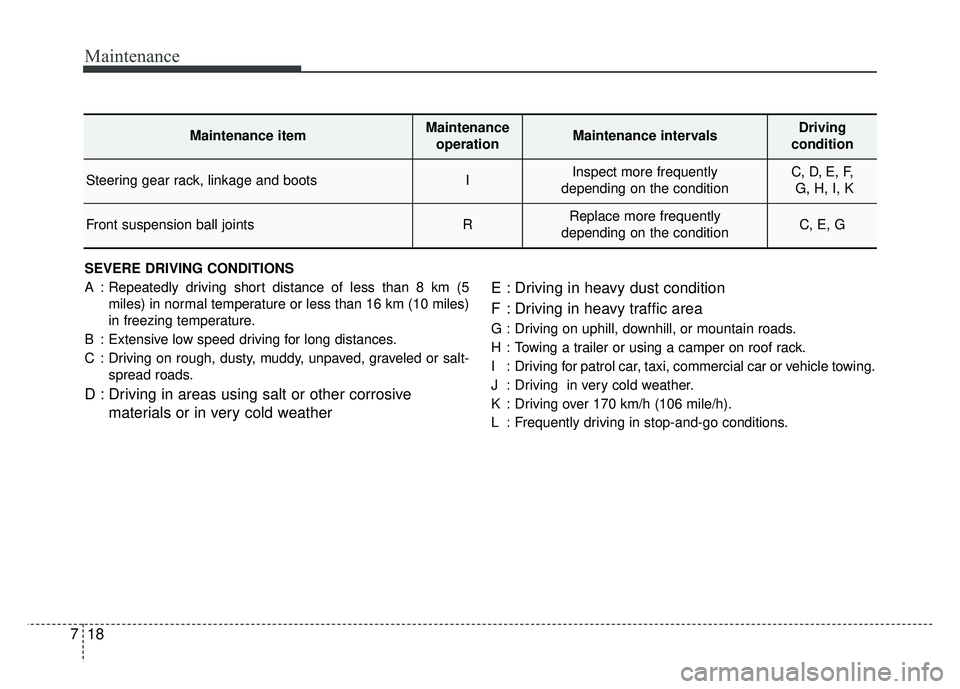

SEVERE DRIVING CONDITIONS

A : Repeatedly driving short distance of less than 8 km (5

miles) in normal temperature or less than 16 km (10 miles)

in freezing temperature.

B : Extensive low speed driving for long distances.

C : Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads.

D : Driving in areas using salt or other corrosive materials or in very cold weather E : Driving in heavy dust condition

F : Driving in heavy traffic area

G : Driving on uphill, downhill, or mountain roads.

H : Towing a trailer or using a camper on roof rack.

I : Driving for patrol car, taxi, commercial car or vehicle towing.

J : Driving in very cold weather.

K : Driving over 170 km/h (106 mile/h).

L : Frequently driving in stop-and-go conditions.

Maintenance itemMaintenance

operationMaintenance intervalsDriving

condition

Steering gear rack, linkage and bootsIInspect more frequently

depending on the conditionC, D, E, F, G, H, I, K

Front suspension ball jointsRReplace more frequently

depending on the conditionC, E, G

Page 409 of 496

719

Maintenance

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Cooling system

Check the cooling system compo-

nents, such as the radiator, coolant

reservoir, hoses and connections ,

coolant 3way valve, chiller for leak-

age and damage. Replace any dam-

aged parts.

Coolant

The coolant should be changed at

the intervals specified in the mainte-

nance schedule.

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and

any leakage. Replace any deteriorat-

ed or damaged parts immediately.

✽ ✽NOTICE - NHTSA Safety

Corrosion Alert

NHTSA has warned all vehicle own-

ers of all brands that they must main-

tain their vehicles in a manner which

will prevent brake hose and brake line

failures due to corrosion when such

vehicles are exposed to winter road

salt and related chemicals. While seri-

ous corrosion conditions typically only

manifest themselves as safety issues

after 7 years of vehicle use, the corro-

sion process starts immediately and

thus underbody cleaning maintenance

must commence from your vehicle's

first exposure to road salts and chem-

icals. NHTSA urges vehicle owners to

take the following steps to prevent

corrosion:

(Continued)(Continued)

1. Wash the undercarriage of your

vehicle regularly throughout the

winter and do a thorough washing

in the spring to remove road salt

and other de-icing chemicals.

2. Monitor the brake system for signs of corrosion by having regu-

lar professional inspections and

watching for signs of problems,

including loss of brake fluid,

unusual leaks and soft or spongy

feel in the brake pedal.

3. Replace the entire brake pipe assembly if you find severe corro-

sion that causes scaling or flaking

of brake components.

Page 410 of 496

Maintenance

20

7

Brake fluid

Check the brake fluid level in the

brake fluid reservoir. The level should

be between “MIN” and “MAX” marks

on the side of the reservoir. Use only

hydraulic brake fluid conforming to

DOT 3 or DOT 4 specification.

Brake discs, pads, calipers

and rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and off,

check for excessive free-play in the

steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or

damage. Replace any damaged

parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.