KIA Sportage 2015 QL / 4.G Owner's Manual

Manufacturer: KIA, Model Year: 2015, Model line: Sportage, Model: KIA Sportage 2015 QL / 4.GPages: 499, PDF Size: 16.07 MB

Page 421 of 499

75

Maintenance

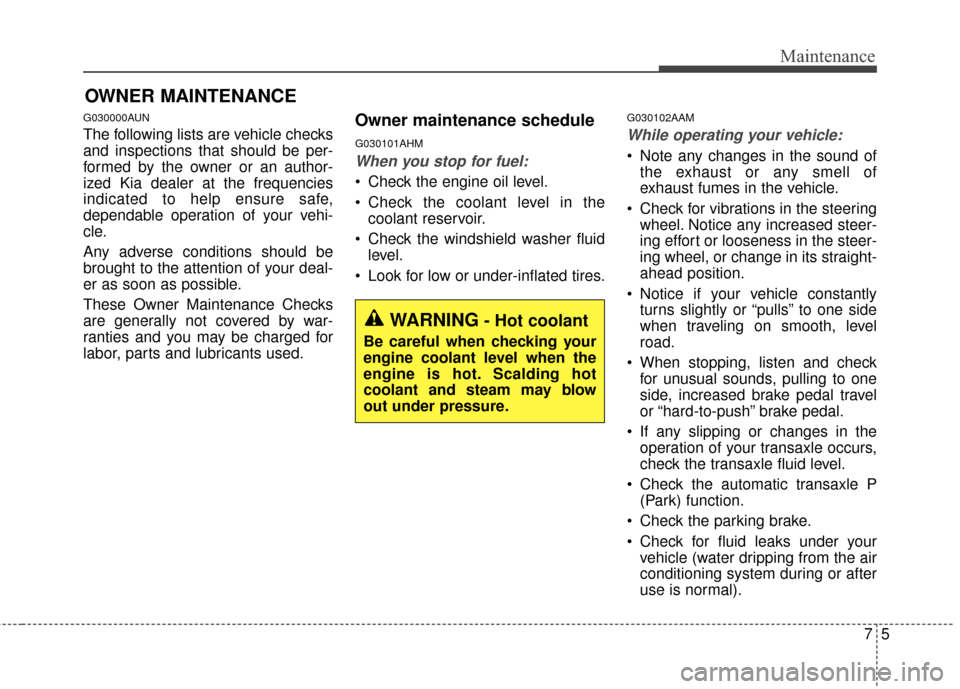

OWNER MAINTENANCE

G030000AUN

The following lists are vehicle checks

and inspections that should be per-

formed by the owner or an author-

ized Kia dealer at the frequencies

indicated to help ensure safe,

dependable operation of your vehi-

cle.

Any adverse conditions should be

brought to the attention of your deal-

er as soon as possible.

These Owner Maintenance Checks

are generally not covered by war-

ranties and you may be charged for

labor, parts and lubricants used.Owner maintenance schedule

G030101AHM

When you stop for fuel:

Check the engine oil level.

Check the coolant level in thecoolant reservoir.

Check the windshield washer fluid level.

Look for low or under-inflated tires.

G030102AAM

While operating your vehicle:

Note any changes in the sound of the exhaust or any smell of

exhaust fumes in the vehicle.

Check for vibrations in the steering wheel. Notice any increased steer-

ing effort or looseness in the steer-

ing wheel, or change in its straight-

ahead position.

Notice if your vehicle constantly turns slightly or “pulls” to one side

when traveling on smooth, level

road.

When stopping, listen and check for unusual sounds, pulling to one

side, increased brake pedal travel

or “hard-to-push” brake pedal.

If any slipping or changes in the operation of your transaxle occurs,

check the transaxle fluid level.

Check the automatic transaxle P (Park) function.

Check the parking brake.

Check for fluid leaks under your vehicle (water dripping from the air

conditioning system during or after

use is normal).

WARNING- Hot coolant

Be careful when checking your

engine coolant level when the

engine is hot. Scalding hot

coolant and steam may blow

out under pressure.

Page 422 of 499

Maintenance

67

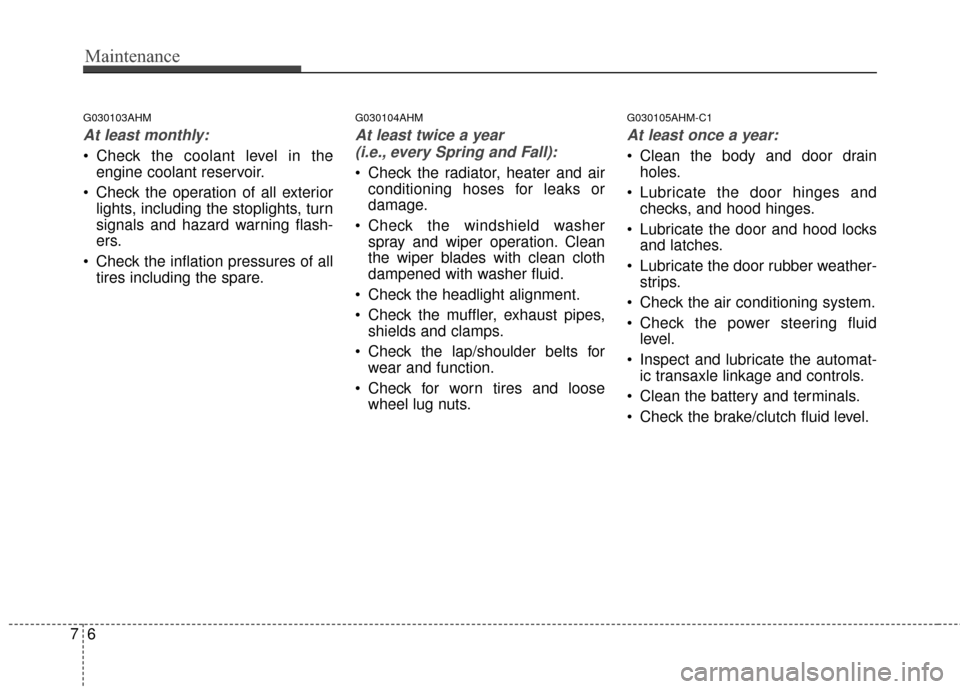

G030103AHM

At least monthly:

Check the coolant level in theengine coolant reservoir.

Check the operation of all exterior lights, including the stoplights, turn

signals and hazard warning flash-

ers.

Check the inflation pressures of all tires including the spare.

G030104AHM

At least twice a year

(i.e., every Spring and Fall):

Check the radiator, heater and air conditioning hoses for leaks or

damage.

Check the windshield washer spray and wiper operation. Clean

the wiper blades with clean cloth

dampened with washer fluid.

Check the headlight alignment.

Check the muffler, exhaust pipes, shields and clamps.

Check the lap/shoulder belts for wear and function.

Check for worn tires and loose wheel lug nuts.

G030105AHM-C1

At least once a year:

Clean the body and door drainholes.

Lubricate the door hinges and checks, and hood hinges.

Lubricate the door and hood locks and latches.

Lubricate the door rubber weather- strips.

Check the air conditioning system.

Check the power steering fluid level.

Inspect and lubricate the automat- ic transaxle linkage and controls.

Clean the battery and terminals.

Check the brake/clutch fluid level.

Page 423 of 499

77

Maintenance

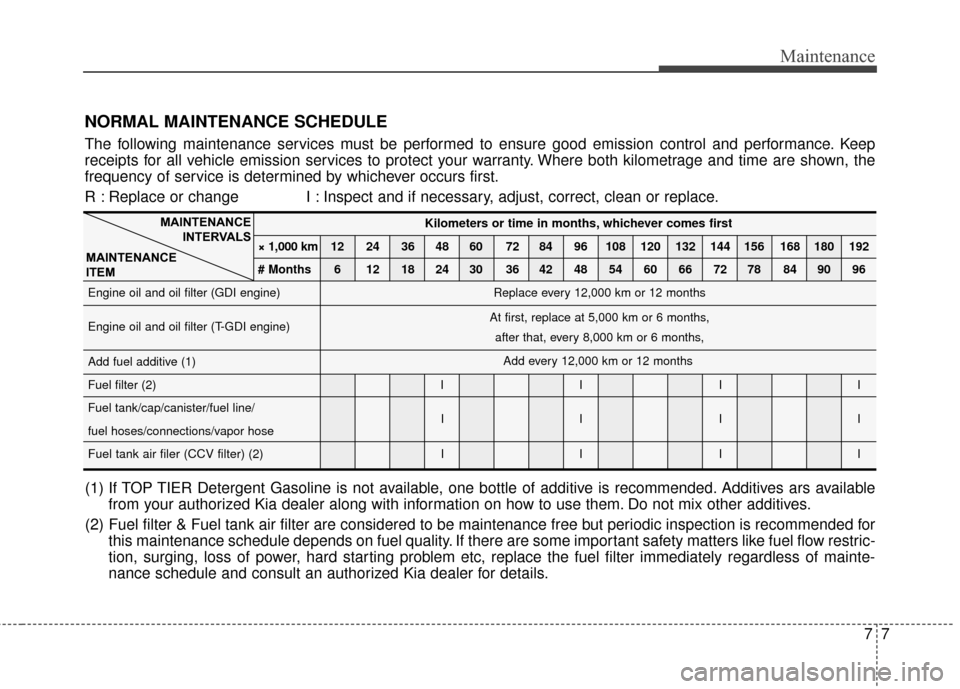

Kilometers or time in months, whichever comes first

× 1,000 km 12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192

# Months 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96

Engine oil and oil filter (GDI engine)

Engine oil and oil filter (T-GDI engine)

Add fuel additive (1)

Fuel filter (2) I I I I

Fuel tank/cap/canister/fuel line/ II II

fuel hoses/connections/vapor hose

Fuel tank air filer (CCV filter) (2) II II

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

Replace every 12,000 km or 12 months

At first, replace at 5,000 km or 6 months, after that, every 8,000 km or 6 months,

Add every 12,000 km or 12 months

(1) If TOP TIER Detergent Gasoline is not available, one bottle of additive is recommended. Additives ars available from your authorized Kia dealer along with information on how to use them. Do not mix other additives.

(2) Fuel filter & Fuel tank air filter are considered to be maintenance free\

but periodic inspection is recommended for this maintenance schedule depends on fuel quality. If there are some important safety matters like fuel flow restric-

tion, surging, loss of power, hard starting problem etc, replace the fuel filter immediately regardless of mainte-

nance schedule and consult an authorized Kia dealer for details.

The following maintenance services must be performed to ensure good emission control and performance. Keep

receipts for all vehicle emission services to protect your warranty. Where both kilometrage and time are shown, the

frequency of service is determined by whichever occurs first.

R : Replace or change I : Inspect and if necessary, adjust, correct, clean or replace.

NORMAL MAINTENANCE SCHEDULE

Page 424 of 499

Maintenance

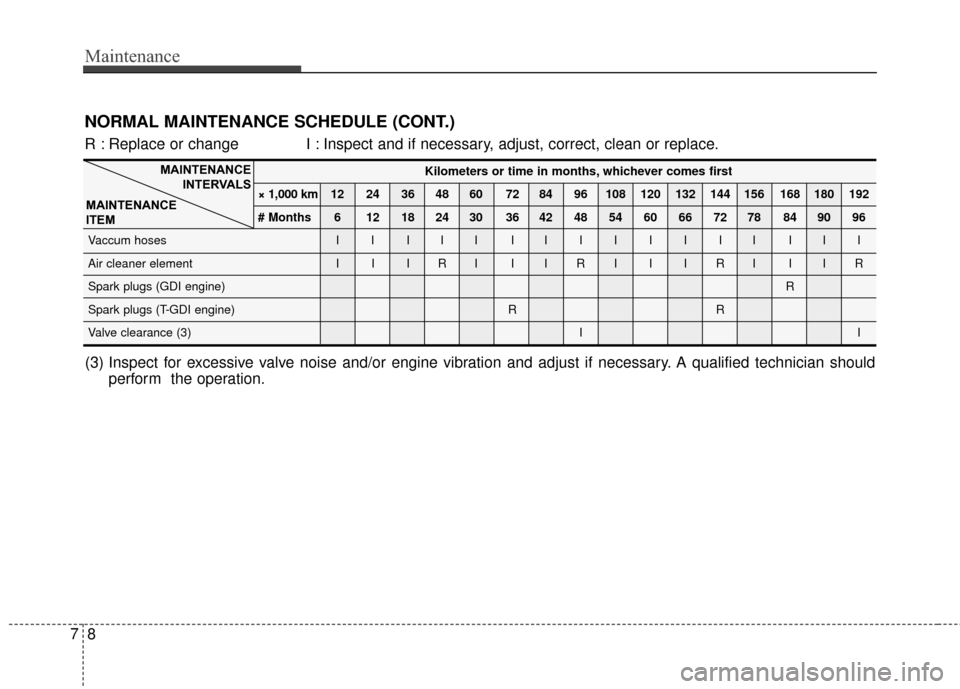

87

Kilometers or time in months, whichever comes first

× 1,000 km 12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192

# Months 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96

Vaccum hoses I I I I I I IIIIIII III

Air cleaner element I I I R I I I R I I I R I I I R

Spark plugs (GDI engine) R

Spark plugs (T-GDI engine) R R

Valve clearance (3) II

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

(3) Inspect for excessive valve noise and/or engine vibration and adjust if necessary. A qualified technician should perform the operation.

R : Replace or change I : Inspect and if necessary, adjust, correct, clean or replace.

NORMAL MAINTENANCE SCHEDULE (CONT.)

Page 425 of 499

79

Maintenance

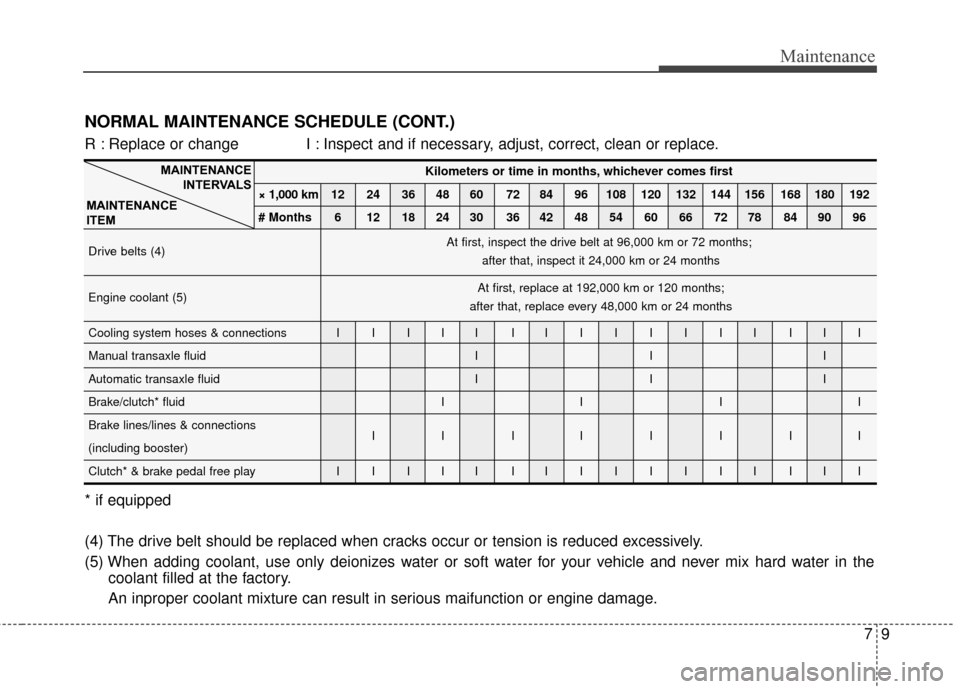

NORMAL MAINTENANCE SCHEDULE (CONT.)

MAINTENANCEINTERVALS

MAINTENANCE

ITEM

R : Replace or change I : Inspect and if necessary, adjust, correct, clean or replace.

* if equipped

(4) The drive belt should be replaced when cracks occur or tension is reduced excessively.

(5) When adding coolant, use only deionizes water or soft water for your vehicle and never mix hard water in the coolant filled at the factory.

An inproper coolant mixture can result in serious maifunction or engine damage.

Kilometers or time in months, whichever comes first

× 1,000 km 12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192

# Months 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96

Drive belts (4)

Engine coolant (5)

Cooling system hoses & connections I I I I I I IIIIIII III

Manual transaxle fluid I I I

Automatic transaxle fluid I I I

Brake/clutch* fluid I I I I

Brake lines/lines & connections IIIIIIII

(including booster)

Clutch* & brake pedal free play I I I I I I IIIIIII III

At first, inspect the drive belt at 96,000 km or 72 months;

after that, inspect it 24,000 km or 24 months

At first, replace at 192,000 km or 120 months;

after that, replace every 48,000 km or 24 months

Page 426 of 499

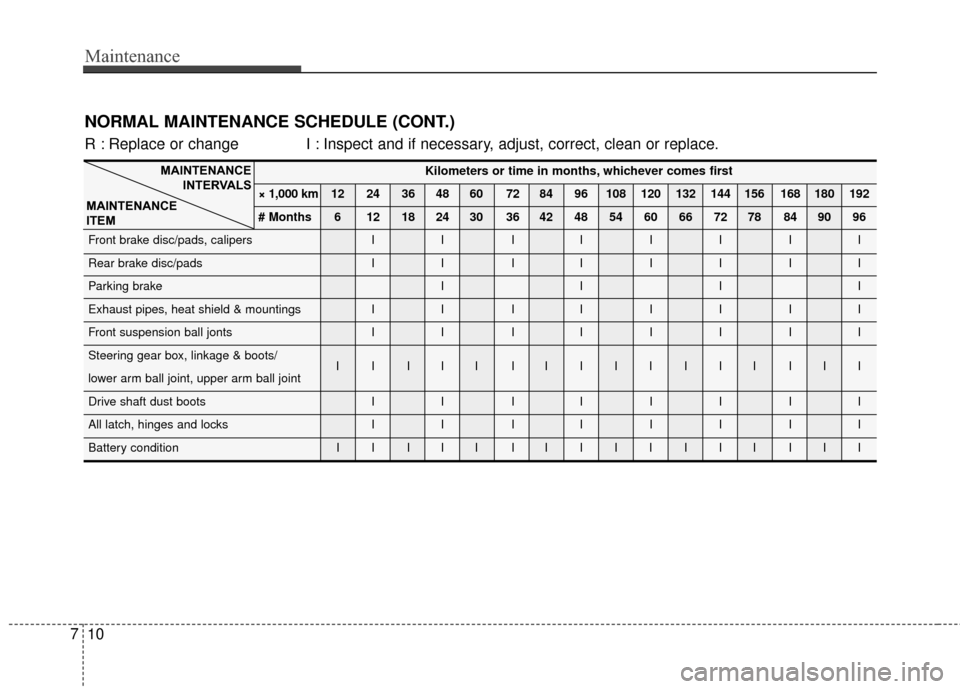

Maintenance

10

7

Kilometers or time in months, whichever comes first

× 1,000 km 12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192

# Months 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96

Front brake disc/pads, calipers I I I IIIII

Rear brake disc/pads I I I IIIII

Parking brake I I I I

Exhaust pipes, heat shield & mountings I I I IIIII

Front suspension ball jonts I I I IIIII

Steering gear box, linkage & boots/ IIIII IIIIIIII III

lower arm ball joint, upper arm ball joint

Drive shaft dust boots I I I IIIII

All latch, hinges and locks I I I IIIII

Battery condition I I I I I I IIIIIII III

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

NORMAL MAINTENANCE SCHEDULE (CONT.)

R : Replace or change I : Inspect and if necessary, adjust, correct, clean or replace.

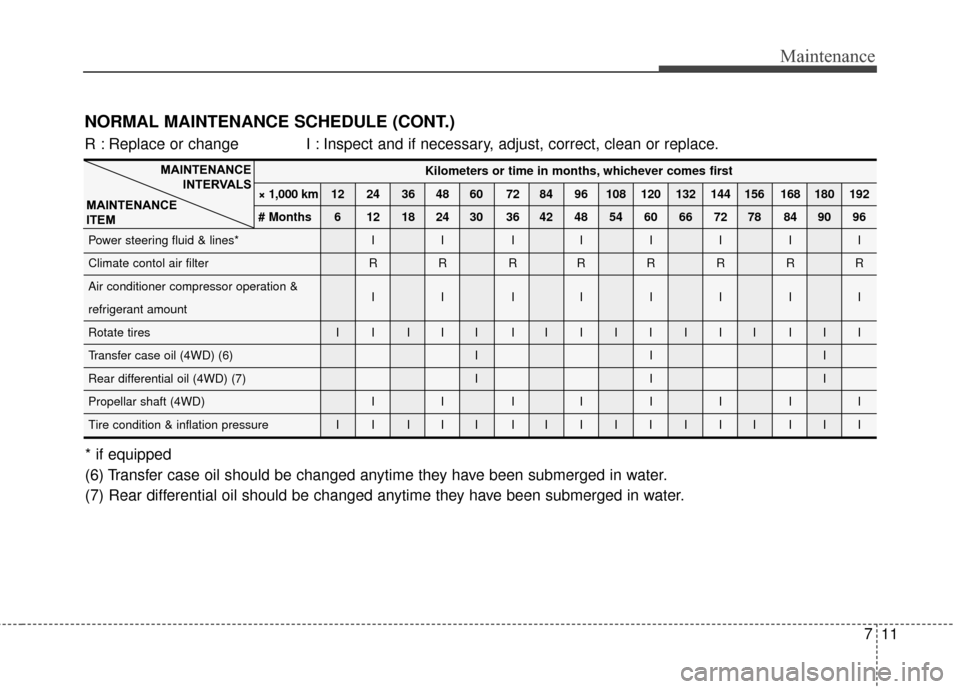

Page 427 of 499

711

Maintenance

Kilometers or time in months, whichever comes first

× 1,000 km 12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192

# Months 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96

Power steering fluid & lines* I I I IIIII

Climate contol air filter R R R RRRRR

Air conditioner compressor operation & IIIIIIII

refrigerant amount

Rotate tires I I I I I I IIIIIII III

Transfer case oil (4WD) (6) I I I

Rear differential oil (4WD) (7) I I I

Propellar shaft (4WD) I I I IIIII

Tire condition & inflation pressure I I I I I I IIIIIII III

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

NORMAL MAINTENANCE SCHEDULE (CONT.)

R : Replace or change I : Inspect and if necessary, adjust, correct, clean or replace.

* if equipped

(6) Transfer case oil should be changed anytime they have been submerged in water.

(7) Rear differential oil should be changed anytime they have been submerged in water.

Page 428 of 499

Maintenance

12

7

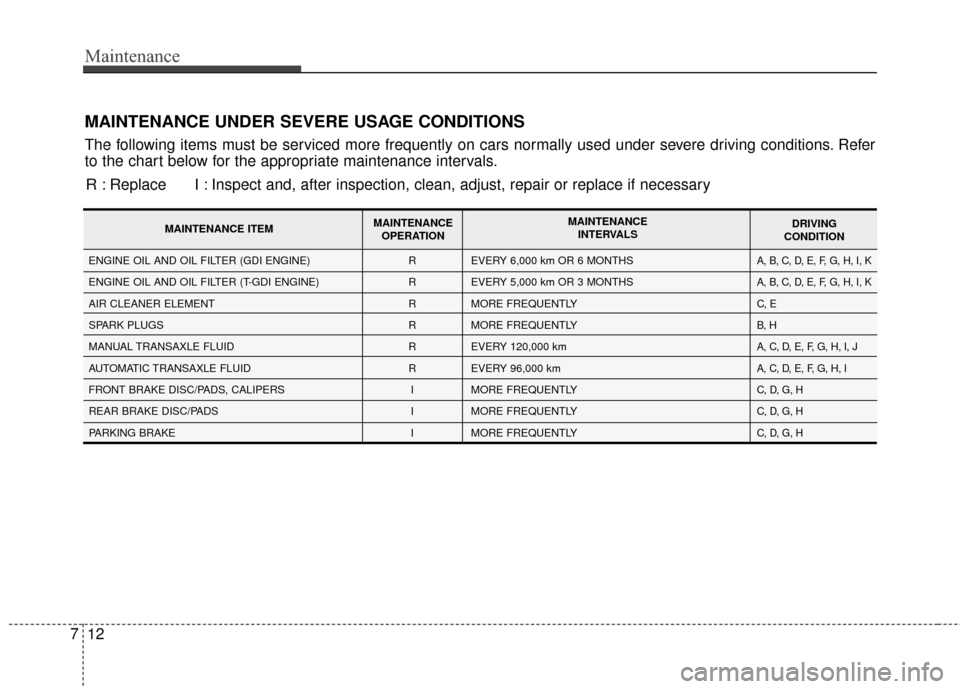

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer

to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if neces\

sary

R

R

R

R

R

R

I

I

I EVERY 6,000 km OR 6 MONTHS

EVERY 5,000 km OR 3 MONTHS

MORE FREQUENTLY

MORE FREQUENTLY

EVERY 120,000 km

EVERY 96,000 km

MORE FREQUENTLY

MORE FREQUENTLY

MORE FREQUENTLYA, B, C, D, E, F, G, H, I, K

A, B, C, D, E, F, G, H, I, K

C, E

B, H

A, C, D, E, F, G, H, I, J

A, C, D, E, F, G, H, I

C, D, G, H

C, D, G, H

C, D, G, H ENGINE OIL AND OIL FILTER (GDI ENGINE)

ENGINE OIL AND OIL FILTER (T-GDI ENGINE)

AIR CLEANER ELEMENT

SPARK PLUGS

MANUAL TRANSAXLE FLUID

AUTOMATIC TRANSAXLE FLUID

FRONT BRAKE DISC/PADS, CALIPERS

REAR BRAKE DISC/PADS

PARKING BRAKE

MAINTENANCE ITEM MAINTENANCE

OPERATION MAINTENANCE

INTERVALS DRIVING

CONDITION

Page 429 of 499

713

Maintenance

SEVERE DRIVING CONDITIONS

A - Repeatedly driving shorts distanse of less than 8 km(5 miles) in normal temperature or less than 16 km

(10 miles) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt-spread roads

D - Driving in areas using salt or other corrosive materi- als or in very cold weather E - Driving in sandy areas

F - Driving in heavy traffic area over 32°C (90°F)

G - Driving on uphill, downhill, or mountain road

H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use or

vehicle towing

J - Driving over 170 km/h (100 mph)

K - Frequently driving in stop-and-go conditions

I

I

R

R

R I MORE FREQUENTLY

EVERY 12,000 km OR 6 MONTHS

MORE FREQUENTLY

EVERY 120,000 km

EVERY 120,000 km

EVERY 12,000 km OR 6 MONTHSC, D, E, F, G, H, I

C, D, E, F, G

C, E

C, E, G, H, I, J

C, E, G, H, I, J

C, ESTEERING GEAR BOX, LINKAGE & BOOTS/

LOWER ARM BALL JOINT, UPPER ARM BSALL JOINT

DRIVE SHAFTS AND BOOTS

CLIMATE CONTROL AIR FILTER

(FOR EVAPORATOR AND BLOWER UNIT)

TRANSFER CASE OIL (4WD) (1)

REAR DIFFERENTIAL OIL (1)

PROPELLAR SHAFT

MAINTENANCE ITEM MAINTENANCE

OPERATION MAINTENANCE

INTERVALS DRIVING

CONDITION

(1) Transfer case Oil and Rear Axle Oil should be changed anytime they have abeen submerged in water.

Page 430 of 499

Maintenance

14

7

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

G050100AHM

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the

vehicle is being driven in severe con-

ditions, more frequent oil and filter

changes are required.

G050200AUN

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

G050300AUN

Fuel filter (cartridge)

A clogged filter can limit the speed at

which the vehicle may be driven,

damage the emission system and

cause multiple issues such as hard

starting. If an excessive amount of

foreign matter accumulates in the

fuel tank, the filter may require

replacement more frequently. After installing a new filter, run the

engine for several minutes, and

check for leaks at the connections.

Fuel filters should be installed by an

authorized Kia dealer.

G050400AUN-EU

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. Have an authorized Kia dealer

replace any damaged or leaking

parts immediately.

G050600AUN

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap

should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure that a new

vapor hose or fuel filler cap is cor-

rectly replaced.

G050700AUN

Vacuum crankcase ventilation

hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold.

Inspect the hose routing to assure

that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component which

might cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.