engine oil KIA STINGER 2020 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2020, Model line: STINGER, Model: KIA STINGER 2020Pages: 555, PDF Size: 13.49 MB

Page 457 of 555

Maintenance

26

7

BRAKE FLUID

Checking the brake fluid level

Check the fluid level in the reservoir

periodically. The fluid level should be

between MAX (Maximum) and MIN

(Minimum) marks on the side of the

reservoir.

Before removing the reservoir cap

and adding brake fluid, clean the

area around the reservoir cap thor-

oughly to prevent brake fluid contam-

ination. If the level is low, add fluid to the

MAX (Maximum) level. The level will

fall with accumulated mileage. This is

a normal condition associated with

the wear of brake linings. If the fluid

level is excessively low, have the

brake system checked by an author-

ized Kia dealer.

Use only the specified brake fluid.

(Refer to “Recommended lubricantsand capacities” in chapter 8.)

Never mix different types of fluid.

In the event the brake system

requires frequent additions of fluid,

the vehicle should be inspected by

an authorized Kia dealer.

When changing and adding brake

fluid, handle it carefully. Do not let it

come in contact with your eyes. If

brake fluid should come in contact

with your eyes, immediately flush

them with a large quantity of fresh

tap water. Have your eyes examined

by a doctor as soon as possible.

Brake fluid, which has been exposed

to open air for an extended time

should never be used as its quality

cannot be guaranteed. It should be

disposed of properly.

CAUTION - Brake fluid

Do not allow brake fluid to con-tact the vehicle's body paint, aspaint damage will result.

CAUTION - Proper fluid

Only use brake fluid in brakesystem. Small amounts ofimproper fluids (such as engineoil) can cause damage to thebrake system.

OCK077019

Page 468 of 555

737

Maintenance

Recharging the battery

Your vehicle has a maintenance-free,

calcium-based battery.

If the battery becomes dischargedin a short time (because, for exam-

ple, the headlamps or interior

lamps were left on while the vehi-

cle was not in use), recharge it by

slow charging (trickle) for 10 hours.

If the battery gradually discharges because of high electric load while

the vehicle is being used, recharge

it at 20-30A for two hours. When recharging the battery,

observe the following precautions:

The battery must be removed from

the vehicle and placed in an area

with good ventilation.

Do not allow cigarettes, sparks, or flame near the battery.

Watch the battery during charging, and stop or reduce the charging

rate if the battery cells begin

gassing (boiling) violently or if the

temperature of the electrolyte of

any cell exceeds 49°C (120°F).

Wear eye protection when check- ing the battery during charging.

Disconnect the battery charger in the following order.

1. Turn off the battery charger main switch.

2. Unhook the negative clamp from the negative battery terminal.

3. Unhook the positive clamp from the positive battery terminal. Before performing maintenance or

recharging the battery, turn off all

accessories and stop the engine.

The negative battery cable must be removed first and installed last

when the battery is disconnected.

Page 485 of 555

Maintenance

54

7

FUSES

❈ Left side : Normal , Right side : Blown

A vehicle’s electrical system is pro-

tected from electrical overload dam-

age by fuses.

This vehicle has 4 (or 5) fuse panels,

one located in the driver’s side panel

bolster, the other in the engine com-

partment near the battery.

If any of your vehicle’s lights, acces-

sories, or controls do not work, check

the appropriate circuit fuse. If a fuse

has blown, the element inside the

fuse will melt.

If the electrical system does not

work, first check the driver’s side

fuse panel.

Always replace a blown fuse with

one of the same rating.

If the replacement fuse blows, this

indicates an electrical problem. Avoid

using the system involved and imme-

diately consult an authorized Kia

dealer.

Three kinds of fuses are used: blade

type for lower amperage rating, car-tridge type, and multi fuse for higheramperage ratings.

Do not arbitrarily modify or add-on electric wiring to the vehicle.

WARNING- Fuse replace-

ment

Never replace a fuse with any- thing but another fuse of the

same rating.

A higher capacity fuse could cause damage and possibly a

fire.

Never install a wire or alu- minum foil instead of the

proper fuse - even as a tem-

porary repair. It may cause

extensive wiring damage and

a possible fire.

CAUTION

Do not use a screwdriver or anyother metal object to removefuses because it may cause ashort circuit and damage thesystem.

OCK077071

■

Blade type

■ Cartridge type

■ Multi fuse

■ Fusible link

Page 499 of 555

Maintenance

68

7

Fuse NameFuse ratingCircuit Protected

ALT175A

200AAlternator, Multi Fuse

- COOLING FAN 1 / B+5 / B+4 / B+3 / OPCU / ESC1 / ESC2 / BLOWER / POWER TAIL GATE

COOLING FAN 2100A[BLDC (Brushless Direct Current) Motor] Cooling Fan Controller

START30AStart Relay

COOLING FAN 180A[BLDC (Brushless Direct Current) Motor] Cooling Fan Controller

B+550AInstrument Panel Junction Block

(Fuse - STOP LAMP / Leak Current Autocut Device Fuse / INTERIOR LAMP)

B+450AInstrument Panel Junction Block

(Fuse - DOOR LOCK / POWER HANDLE / SUNROOF / P/SEAT (DRV) / P/SEAT (PASS))

B+350AInstrument Panel Junction Block

(Fuse - S/HEATER DRV/PASS / TAIL GATE / MODULE9 / P/WINDOW RH / P/WINDOW LH)

OPCU50AElectric Oil Pump Inverter

ESC 140AESC (Electronic Stability Control) Control Module

ESC 240AESC (Electronic Stability Control) Control Module, Multipurpose Check Connector

BLOWER40ABlower Relay

POWER TAIL GATE30APower Tail Gate Module

Engine room compartment fuse panel

Page 501 of 555

![KIA STINGER 2020 Owners Manual Maintenance

70

7

Fuse NameFuse ratingCircuit Protected

E-CVVT 220A[THETA II 2.0L T-GDI Engine] ECM (Engine Control Module)

ESC 310AESC (Electronic Stability Control) Control Module, Multipurpose Check KIA STINGER 2020 Owners Manual Maintenance

70

7

Fuse NameFuse ratingCircuit Protected

E-CVVT 220A[THETA II 2.0L T-GDI Engine] ECM (Engine Control Module)

ESC 310AESC (Electronic Stability Control) Control Module, Multipurpose Check](/img/2/40389/w960_40389-500.png)

Maintenance

70

7

Fuse NameFuse ratingCircuit Protected

E-CVVT 220A[THETA II 2.0L T-GDI Engine] ECM (Engine Control Module)

ESC 310AESC (Electronic Stability Control) Control Module, Multipurpose Check Connector

ECU 310AECM (Engine Control Module)

ECU 215AECM (Engine Control Module)

HORN20AHorn Relay

WIPER 130AWiper Power Relay

TCU 215ATCM (Transmission Control Module)

SENSOR 410ABrake Vacuum Switch, Vacuum Pump Relay, Electric Oil Pump Inverter

TCU 120ATCM (Transmission Control Module)

WIPER 210AIBU (Integrated Body Control Unit), ECM (Electronic Control Module)

SENSOR 115ARear Sub Junction Block (Fuel Pump Relay)

SENSOR520A[THETA II 2.0L T-GDI Engine] Ignition Coil #1/#2/#3/#4

[Lambda II PE 3.3L T-GDI Engine] Ignition Coil #1/#2/#3/#4/#5/#6

Page 502 of 555

![KIA STINGER 2020 Owners Manual 771

Maintenance

Fuse NameFuse ratingCircuit Protected

H/LAMP HI10AHead Lamp (High) Relay

ECU 120AECM (Engine Control Module)

SENSOR 315A[THETA II 2.0L T-GDI Engine] Oxygen Sensor (Up)

[Lambda II PE 3. KIA STINGER 2020 Owners Manual 771

Maintenance

Fuse NameFuse ratingCircuit Protected

H/LAMP HI10AHead Lamp (High) Relay

ECU 120AECM (Engine Control Module)

SENSOR 315A[THETA II 2.0L T-GDI Engine] Oxygen Sensor (Up)

[Lambda II PE 3.](/img/2/40389/w960_40389-501.png)

771

Maintenance

Fuse NameFuse ratingCircuit Protected

H/LAMP HI10AHead Lamp (High) Relay

ECU 120AECM (Engine Control Module)

SENSOR 315A[THETA II 2.0L T-GDI Engine] Oxygen Sensor (Up)

[Lambda II PE 3.3L T-GDI Engine] Oxygen Sensor #2/#4

SENSOR 210A

[THETA II 2.0L T-GDI Engine] Electronic Thermostat, Oil Control Valve, Purge Control Solenoid Valve,

RCV (Recirculation Valve Control) Control Solenoid Valve, Canister Close Valve

[Lambda II PE 3.3L T-GDI Engine] Electronic Thermostat, Oil Pressure Solenoid Valve, Oil Control Valve

#1/#2/#3/#4 (Intake/Exhaust), RCV (Recirculation Valve Control) Control Solenoid Valve, Purge Control

Solenoid Valve, Canister Close Valve

B/ALARM HORN15ABurglar Alarm Horn Relay

Page 524 of 555

793

Maintenance

High-pressure washing

When using high-pressure wash-ers, make sure to maintain suffi-

cient distance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component

damage or water penetration.

Do not spray the camera, sensors or its surrounding area directly with

a high pressure washer. Shock

applied from high pressure water

may cause the device to not oper-

ate normally.

Do not bring the nozzle tip close to boots (rubber or plastic covers) or

connectors as they may be dam-

aged if they come into contact with

high pressure water. Waxing

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle

before waxing. Use a good quality

liquid or paste wax, and follow the

manufacturer’s instructions. Wax all

metal trim to protect it and to main-

tain its luster.

Removing oil, tar, and similar materi-

als with a spot remover will usually

strip the wax from the finish. Be sure

to re-wax these areas even if the rest

of the vehicle does not yet need wax-

ing.

Do not apply wax on embossed

unpainted unit, as it may tarnish the

unit.

CAUTION - Wet engine

Water washing in the engine

compartment including highpressure water washing maycause the failure of electricalcircuits located in the enginecompartment.

Never allow water or other liq- uids to come in contact withelectrical/electronic compo-nents inside the vehicle asthis may damage them.

OCK077070

Page 541 of 555

87

Specifications & Consumer information

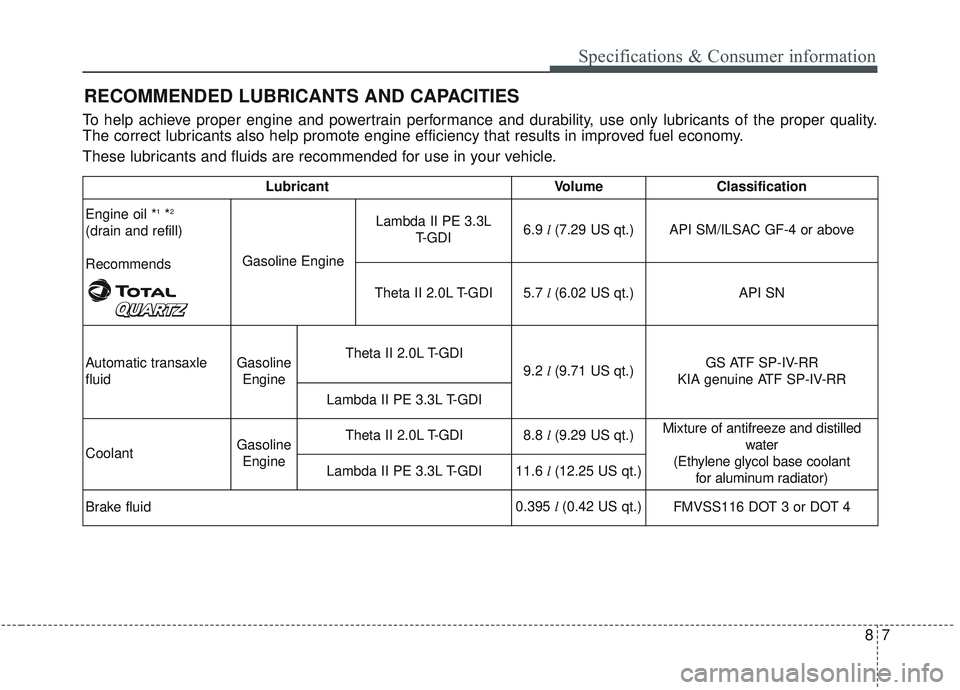

RECOMMENDED LUBRICANTS AND CAPACITIES

To help achieve proper engine and powertrain performance and durability, use only lubricants of the proper quality.

The correct lubricants also help promote engine efficiency that results in improved fuel economy.

These lubricants and fluids are recommended for use in your vehicle.

Lubricant VolumeClassification

Engine oil *1*2

(drain and refill)

Recommends

Gasoline Engine

Lambda II PE 3.3L T-GDI6.9 l (7.29 US qt.)API SM/ILSAC GF-4 or above

Theta II 2.0L T-GDI5.7 l (6.02 US qt.)API SN

Automatic transaxle

fluidGasoline

Engine Theta II 2.0L T-GDI

9.2 l (9.71 US qt.)GS ATF SP-IV-RR

KIA genuine ATF SP-IV-RR

Lambda II PE 3.3L T-GDI

CoolantGasoline EngineTheta II 2.0L T-GDI8.8 l (9.29 US qt.)Mixture of antifreeze and distilled

water

(Ethylene glycol base coolant for aluminum radiator)

Lambda II PE 3.3L T-GDI11.6 l (12.25 US qt.)

Brake fluid0.395 l (0.42 US qt.)FMVSS116 DOT 3 or DOT 4

Page 542 of 555

88

Specifications & Consumer information

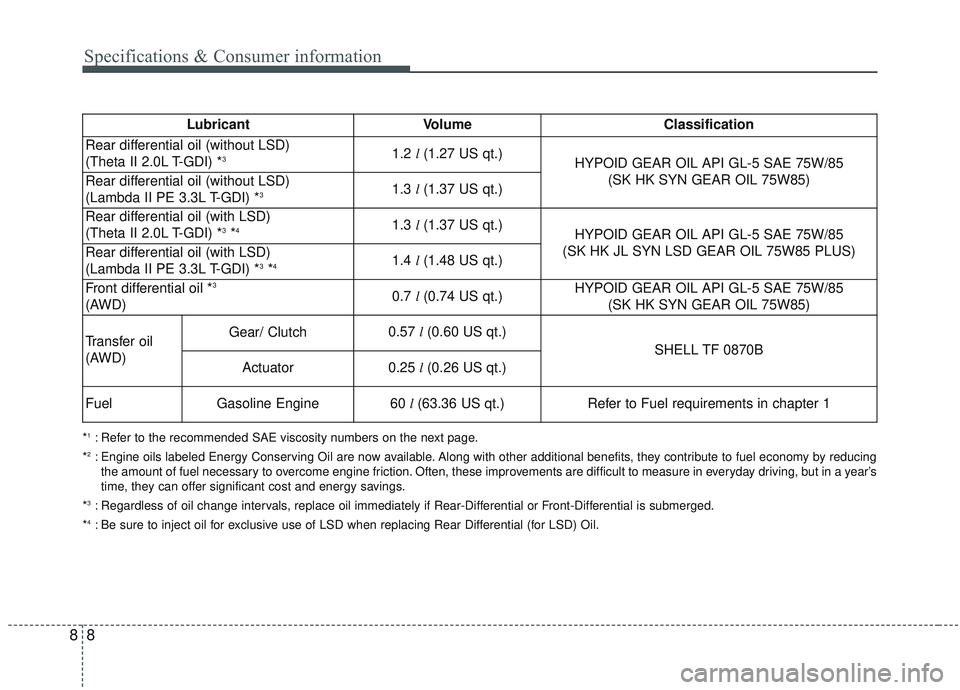

Lubricant VolumeClassification

Rear differential oil (without LSD)

(Theta II 2.0L T-GDI) *31.2 l (1.27 US qt.)HYPOID GEAR OIL API GL-5 SAE 75W/85

(SK HK SYN GEAR OIL 75W85)

Rear differential oil (without LSD)

(Lambda II PE 3.3L T-GDI) *31.3 l (1.37 US qt.)

Rear differential oil (with LSD)

(Theta II 2.0L T-GDI) *3*41.3 l (1.37 US qt.)HYPOID GEAR OIL API GL-5 SAE 75W/85

(SK HK JL SYN LSD GEAR OIL 75W85 PLUS)

Rear differential oil (with LSD)

(Lambda II PE 3.3L T-GDI) *3*41.4 l (1.48 US qt.)

Front differential oil *3

(AWD)0.7 l (0.74 US qt.)HYPOID GEAR OIL API GL-5 SAE 75W/85

(SK HK SYN GEAR OIL 75W85)

Transfer oil

(AWD)Gear/ Clutch0.57 l (0.60 US qt.)

SHELL TF 0870B

Actuator0.25 l (0.26 US qt.)

FuelGasoline Engine60 l (63.36 US qt.)Refer to Fuel requirements in chapter 1

*1: Refer to the recommended SAE viscosity numbers on the next page.

*2: Engine oils labeled Energy Conserving Oil are now available. Along with other additional benefits, they contribute to fuel economy by reducing the amount of fuel necessary to overcome engine friction. Often, these improvements are difficult to measure in everyday driving, but in a year’s

time, they can offer significant cost and energy savings.

*

3: Regardless of oil change intervals, replace oil immediately if Rear-Differential or Front-Differential is submerged.

*4: Be sure to inject oil for exclusive use of LSD when replacing Rear Differential (for LSD) Oil.

Page 543 of 555

89

Specifications & Consumer information

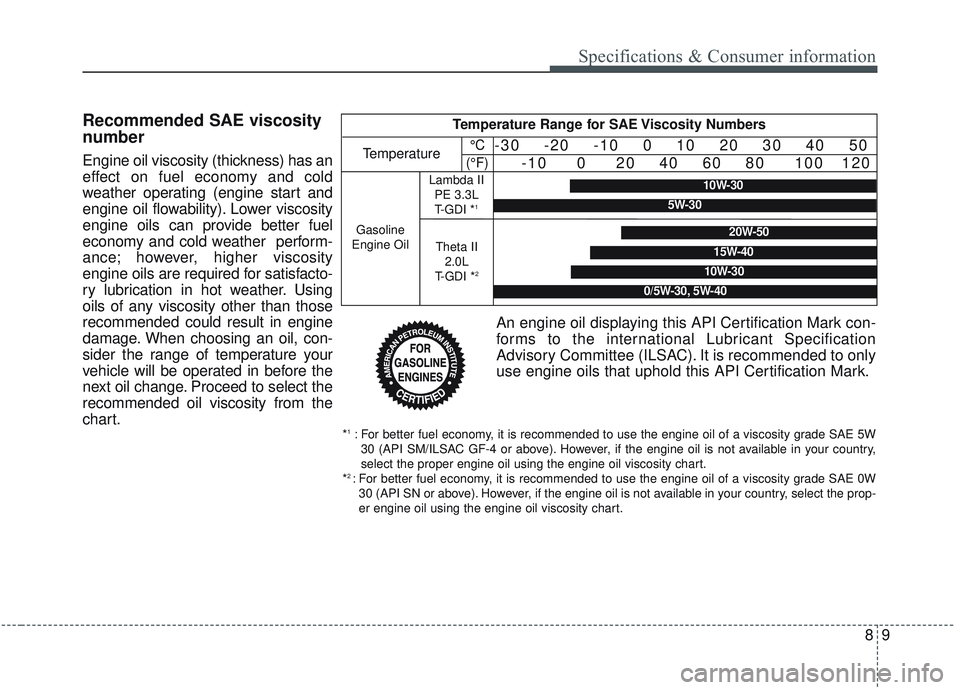

Recommended SAE viscosity

number

Engine oil viscosity (thickness) has an

effect on fuel economy and cold

weather operating (engine start and

engine oil flowability). Lower viscosity

engine oils can provide better fuel

economy and cold weather perform-

ance; however, higher viscosity

engine oils are required for satisfacto-

ry lubrication in hot weather. Using

oils of any viscosity other than those

recommended could result in engine

damage. When choosing an oil, con-

sider the range of temperature your

vehicle will be operated in before the

next oil change. Proceed to select the

recommended oil viscosity from the

chart.

An engine oil displaying this API Certification Mark con-

forms to the international Lubricant Specification

Advisory Committee (ILSAC). It is recommended to only

use engine oils that uphold this API Certification Mark.

Temperature Range for SAE Viscosity Numbers

Temperature°C

(°F)-30 -20 -10 0 10 20 30 40 50 -10 0 20 40 60 80 100 120

Gasoline

Engine Oil

Lambda II PE 3.3L T-GDI *

1

Theta II 2.0L

T-GDI *

2

20W-50

10W-30

15W-40

0/5W-30, 5W-40

*1: For better fuel economy, it is recommended to use the engine oil of a viscosity grade SAE 5W 30 (API SM/ILSAC GF-4 or above). However, if the engine oil is not available in your country,

select the proper engine oil using the engine oil viscosity chart.

*

2 : For better fuel economy, it is recommended to use the engine oil of a viscosity grade SAE 0W 30 (API SN or above). However, if the engine oil is not available in your country, select the prop-

er engine oil using the engine oil viscosity chart.

10W-30

5W-30