sensor KIA STINGER 2020 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2020, Model line: STINGER, Model: KIA STINGER 2020Pages: 555, PDF Size: 13.49 MB

Page 427 of 555

What to do in an emergency

24

6

Ensure any metal parts on the

tiedown straps do not contact

painted surfaces or the face of the

wheels.

Do not place straps over the body panels or through the wheels.

WARNING - Side and

curtain Air bag

If your vehicle is equipped with

side and curtain air bag, set the

the Engine Start/Stop button to

ACC position when the vehicle

is being towed.

The side and curtain air bag

may deploy when the ignition is

ON, and the rollover sensor

detects the situation as a

rollover.

OCK067024

OCK067014

OCK067015

CAUTION - Towing

Do not tow the vehicle back- wards with the rear wheels onthe ground as this may causedamage to the vehicle.

Do not tow with sling-type equipment. Use wheel lift orflatbed equipment.

CAUTION

Attaching straps to the chassis,suspension or other parts of thebody can cause damage.

Page 460 of 555

729

Maintenance

AIR CLEANER

Filter replacement

The air filter must be replaced when

necessary, and should not be

washed.

Have the air cleaner filter inspected or

replaced by an authorized Kia dealer.Replace the filter according to the

Maintenance Schedule.

If the vehicle is operated in extreme-

ly dusty or sandy areas, replace theelement more often than the usualrecommended intervals. (Refer to“Maintenance under severe usageconditions” in this chapter.)

OCK077022

OCK077023

■THETA II 2.0L T-GDI Engine (Gasoline)

■Lambda II PE 3.3L T-GDI Engine

(Gasoline) (Passenger side)

OCK077024

■Lambda II PE 3.3L T-GDI Engine

(Gasoline) (Driver side)

CAUTION - Air filter

maintenance

Do not drive with the air clean- er removed; this will result inexcessive engine wear.

When removing the air cleaner filter, be careful that dust ordirt does not enter the airintake, or damage may result.

Use a Kia genuine part. Use of a non-genuine part coulddamage the air flow sensor.

Page 495 of 555

Maintenance

64

7

Fuse NameFuse ratingCircuit Protected

E-SHIFTER 110AElectronic Auto Transmission Shift Lever (B+)

A/BAG IND.10AInstrument Cluster, Passenger Air Bag IND.

IBU 115AIBU (B+)

DDM10ADriver Door Module, Driver/Passenger Power Outside Mirror

MODULE 210AIBU (IG2)

MODULE 310AAuto Transmission Shift Lever Switch, Driver Door Module, Stop Lamp Switch

DOOR LOCK20ADoor Lock Relay, Door Unlock Relay, Two Turn Unlock Relay

S/HEATER

DRV/PASS25AFront Air Ventilation Seat Control Module, Front Seat Warmer Control Module

TAIL GATE10ATail Gate Lid Relay, Fuel Lid Relay, Crash Pad Switch

IBU 210ARain Sensor

SPARE20ASPARE

Page 496 of 555

765

Maintenance

Fuse NameFuse ratingCircuit Protected

MODULE 810ACooling Fan Controller (BLDC Motor), Around View Monitor, Front Air Ventilation Seat Control Module,

Front/Rear Seat Warmer Control Module

MODULE 710A

IBU, ECS Unit, AWD (All Wheel Drive) ECM (Electronic Control Module), Smart Cruise Control Module,

Auto Transmission Shift Lever Indicator, Console Switch (Front/Upper), Blind-Spot Collision Warning Unit

Left Handle side/Right Handle side, Steering Angle Sensor, Steering Tilt & Telescopic Module, Multi-

Function Camera Unit, Crash Pad Switch

POWER HANDLE15ASteering Tilt & Telescopic Module

MODULE 910ADriver Air Lumbar Control Unit

MODULE 110AData Link Connector, Console Switch (Upper), Mood Lamp Control Unit

MODULE 510A

Air Conditioner Control Module, Air Conditioner Switch, Audio, Head Lamp Left Handle side/Right

Handle side, Low DC-DC Converter (Audio/AMP (Amplifier)), Electro Chromic Mirror, AMP (Amplifier),

Driver Integrated memory system Control Module, Front Air Ventilation Seat Control Module, Front/Rear

Seat Warmer Control Module

SUNROOF20ASunroof Control Unit (Glass)

P/WINDOW RH25APassenger Power Window Module, Rear Power Window Module Right Handle side

CHARGER10AFront/Rear USB Charger

Page 501 of 555

![KIA STINGER 2020 Workshop Manual Maintenance

70

7

Fuse NameFuse ratingCircuit Protected

E-CVVT 220A[THETA II 2.0L T-GDI Engine] ECM (Engine Control Module)

ESC 310AESC (Electronic Stability Control) Control Module, Multipurpose Check KIA STINGER 2020 Workshop Manual Maintenance

70

7

Fuse NameFuse ratingCircuit Protected

E-CVVT 220A[THETA II 2.0L T-GDI Engine] ECM (Engine Control Module)

ESC 310AESC (Electronic Stability Control) Control Module, Multipurpose Check](/img/2/40389/w960_40389-500.png)

Maintenance

70

7

Fuse NameFuse ratingCircuit Protected

E-CVVT 220A[THETA II 2.0L T-GDI Engine] ECM (Engine Control Module)

ESC 310AESC (Electronic Stability Control) Control Module, Multipurpose Check Connector

ECU 310AECM (Engine Control Module)

ECU 215AECM (Engine Control Module)

HORN20AHorn Relay

WIPER 130AWiper Power Relay

TCU 215ATCM (Transmission Control Module)

SENSOR 410ABrake Vacuum Switch, Vacuum Pump Relay, Electric Oil Pump Inverter

TCU 120ATCM (Transmission Control Module)

WIPER 210AIBU (Integrated Body Control Unit), ECM (Electronic Control Module)

SENSOR 115ARear Sub Junction Block (Fuel Pump Relay)

SENSOR520A[THETA II 2.0L T-GDI Engine] Ignition Coil #1/#2/#3/#4

[Lambda II PE 3.3L T-GDI Engine] Ignition Coil #1/#2/#3/#4/#5/#6

Page 502 of 555

![KIA STINGER 2020 Workshop Manual 771

Maintenance

Fuse NameFuse ratingCircuit Protected

H/LAMP HI10AHead Lamp (High) Relay

ECU 120AECM (Engine Control Module)

SENSOR 315A[THETA II 2.0L T-GDI Engine] Oxygen Sensor (Up)

[Lambda II PE 3. KIA STINGER 2020 Workshop Manual 771

Maintenance

Fuse NameFuse ratingCircuit Protected

H/LAMP HI10AHead Lamp (High) Relay

ECU 120AECM (Engine Control Module)

SENSOR 315A[THETA II 2.0L T-GDI Engine] Oxygen Sensor (Up)

[Lambda II PE 3.](/img/2/40389/w960_40389-501.png)

771

Maintenance

Fuse NameFuse ratingCircuit Protected

H/LAMP HI10AHead Lamp (High) Relay

ECU 120AECM (Engine Control Module)

SENSOR 315A[THETA II 2.0L T-GDI Engine] Oxygen Sensor (Up)

[Lambda II PE 3.3L T-GDI Engine] Oxygen Sensor #2/#4

SENSOR 210A

[THETA II 2.0L T-GDI Engine] Electronic Thermostat, Oil Control Valve, Purge Control Solenoid Valve,

RCV (Recirculation Valve Control) Control Solenoid Valve, Canister Close Valve

[Lambda II PE 3.3L T-GDI Engine] Electronic Thermostat, Oil Pressure Solenoid Valve, Oil Control Valve

#1/#2/#3/#4 (Intake/Exhaust), RCV (Recirculation Valve Control) Control Solenoid Valve, Purge Control

Solenoid Valve, Canister Close Valve

B/ALARM HORN15ABurglar Alarm Horn Relay

Page 507 of 555

Maintenance

76

7

Fuse NameFuse ratingCircuit Protected

B+180ARear Sub Junction Block (Fuse - FUEL PUMP / REAR HEATED/ AMP1)

B+280ARear Sub Junction Block (Fuse - ECS / S/HEATER REAR / IG1)

START40AEngine Room Junction Block (Power Outlet Relay), Fuse -START / ECU2 / TCU1)

AMS10ABattery Sensor

Battery box fuse panel

Page 524 of 555

793

Maintenance

High-pressure washing

When using high-pressure wash-ers, make sure to maintain suffi-

cient distance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component

damage or water penetration.

Do not spray the camera, sensors or its surrounding area directly with

a high pressure washer. Shock

applied from high pressure water

may cause the device to not oper-

ate normally.

Do not bring the nozzle tip close to boots (rubber or plastic covers) or

connectors as they may be dam-

aged if they come into contact with

high pressure water. Waxing

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle

before waxing. Use a good quality

liquid or paste wax, and follow the

manufacturer’s instructions. Wax all

metal trim to protect it and to main-

tain its luster.

Removing oil, tar, and similar materi-

als with a spot remover will usually

strip the wax from the finish. Be sure

to re-wax these areas even if the rest

of the vehicle does not yet need wax-

ing.

Do not apply wax on embossed

unpainted unit, as it may tarnish the

unit.

CAUTION - Wet engine

Water washing in the engine

compartment including highpressure water washing maycause the failure of electricalcircuits located in the enginecompartment.

Never allow water or other liq- uids to come in contact withelectrical/electronic compo-nents inside the vehicle asthis may damage them.

OCK077070

Page 549 of 555

Index

4I

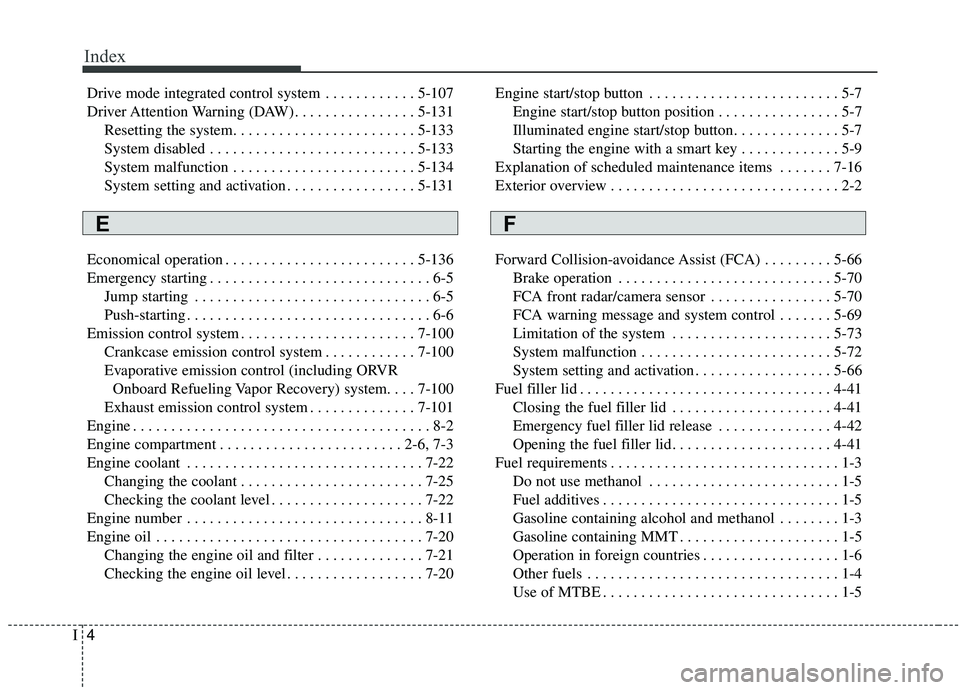

Drive mode integrated control system . . . . . . . . . . . . 5-107

Driver Attention Warning (DAW). . . . . . . . . . . . . . . . 5-131Resetting the system. . . . . . . . . . . . . . . . . . . . . . . . 5-133

System disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-133

System malfunction . . . . . . . . . . . . . . . . . . . . . . . . 5-134

System setting and activation . . . . . . . . . . . . . . . . . 5-131

Economical operation . . . . . . . . . . . . . . . . . . . . . . . . . 5-136

Emergency starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5 Jump starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Push-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Emission control system . . . . . . . . . . . . . . . . . . . . . . . 7-100 Crankcase emission control system . . . . . . . . . . . . 7-100

Evaporative emission control (including ORVR Onboard Refueling Vapor Recovery) system. . . . 7-100

Exhaust emission control system . . . . . . . . . . . . . . 7-101

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . 8-2

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . 2-6, 7-3

Engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22 Changing the coolant . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Checking the coolant level . . . . . . . . . . . . . . . . . . . . 7-22

Engine number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-\

20 Changing the engine oil and filter . . . . . . . . . . . . . . 7-21

Checking the engine oil level . . . . . . . . . . . . . . . . . . 7-20 Engine start/stop button . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Engine start/stop button position . . . . . . . . . . . . . . . . 5-7

Illuminated engine start/stop button. . . . . . . . . . . . . . 5-7

Starting the engine with a smart key . . . . . . . . . . . . . 5-9

Explanation of scheduled maintenance items . . . . . . . 7-16

Exterior overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Forward Collision-avoidance Assist (FCA) . . . . . . . . . 5-66 Brake operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

FCA front radar/camera sensor . . . . . . . . . . . . . . . . 5-70

FCA warning message and system control . . . . . . . 5-69

Limitation of the system . . . . . . . . . . . . . . . . . . . . . 5-73

System malfunction . . . . . . . . . . . . . . . . . . . . . . . . . 5-72

System setting and activation . . . . . . . . . . . . . . . . . . 5-66

Fuel filler lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41 Closing the fuel filler lid . . . . . . . . . . . . . . . . . . . . . 4-41

Emergency fuel filler lid release . . . . . . . . . . . . . . . 4-42

Opening the fuel filler lid. . . . . . . . . . . . . . . . . . . . . 4-41

Fuel requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 Do not use methanol . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Fuel additives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Gasoline containing alcohol and methanol . . . . . . . . 1-3

Gasoline containing MMT . . . . . . . . . . . . . . . . . . . . . 1-5

Operation in foreign countries . . . . . . . . . . . . . . . . . . 1-6

Other fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Use of MTBE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

EF