fuel KIA STONIC 2018 Service Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: STONIC, Model: KIA STONIC 2018Pages: 523, PDF Size: 24.99 MB

Page 382 of 523

![KIA STONIC 2018 Service Manual Normal Maintenance Schedule - For Diesel Engine [Except Europe (Including Russia)] (continued)

MAINTENANCE IN‐TERVALS

Normal Maintenance Schedule - For Diesel Engine [Except Europe (Including Russia KIA STONIC 2018 Service Manual Normal Maintenance Schedule - For Diesel Engine [Except Europe (Including Russia)] (continued)

MAINTENANCE IN‐TERVALS

Normal Maintenance Schedule - For Diesel Engine [Except Europe (Including Russia](/img/2/40480/w960_40480-381.png)

Normal Maintenance Schedule - For Diesel Engine [Except Europe (Including Russia)] (continued)

MAINTENANCE IN‐TERVALS

Normal Maintenance Schedule - For Diesel Engine [Except Europe (Including Russia)]

Number of months or driving distance, whichever comes first

Months1224364860728496

Miles×1,0001020304050607080

Km×1,000153045607590105120

MAINTENANCE ITEM

Engine oil and en‐ gine oil filter *1

,*2

U-II 1.4L, U-II 1.6L For Russia, Australia and New Zealand :

Replace every 15,000 km(10,000 miles) or 12 months Except Russia, Australia and New Zealand :

Replace every 10,000 km (6,500 miles) or 12 months

Coolant (Engine) *3

At first, Replace 210,000 km (140,000 miles) or 120 months

after that, Replace every 30,000 km (20,000 miles) or 24 months

Drive belts (Engine) *4

At first, Inspect 90,000 km (60,000 miles) or 48 months

after that, Inspect every 30,000 km (20,000 miles) or 24 months

Automatic transaxle fluid - - - I - - - I Manual transaxle fluid *5

- - - I - - - I

Drive shaft and boots - I - I - I - IFuel filter cartridge (Diesel) *6

- I - R - I - R

Fuel lines, hoses and connections - I - I - I - I Air cleaner filter Except China, India, Middle East

I I R I I R I I

For China, India, Mid‐dle East R R R R R R R R

Maintenance

8-36

Page 387 of 523

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in the maintenance schedule. If the vehi‐

cle is being driven in severe conditions,

more frequent oil and filter changes are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu‐ ration and replace if necessary. Drive

belts should be checked periodically for

proper tension and adjusted as neces‐

sary.

CAUTION

When you are inspecting the belt,place the ignition switch in theLOCK/OFF or ACC position.

Fuel filter cartridge (for diesel)

A clogged filter can limit the speed at

which the vehicle may be driven, dam‐

age the emission system and cause multiple issues such as hard starting. If

an excessive amount of foreign matter

accumulates in the fuel tank, the filter may require replacement more fre‐

quently.

After installing a new filter, run the en‐

gine for several minutes, and check for leaks at the connections. Have the fuel

filter replaced by a professional work‐

shop. Kia recommends to visit an au‐ thorized Kia dealer/service partner.

Fuel filter (for gasoline)

Kia gasoline vehicle is equipped a life‐

time fuel filter that integrated with the fuel tank. Regular maintenance or re‐

placement is not needed but depends

on fuel quality. If there are some im‐ portant safety matters like fuel flow

restriction, surging, loss of power, hard

starting problem etc, fuel filter inspec‐ tion or replace is needed.

Have the fuel filter inspected or re‐

placed by a professional workshop. Kia

recommends to visit an authorized Kia dealer/service partner.

Fuel lines, fuel hoses and

connections

Check the fuel lines, fuel hoses and

connections for leakage and damage. Have the fuel lines, fuel hoses and con‐

nections replaced by a professional

workshop. Kia recommends to visit an authorized Kia dealer/service partner.

WARNING

nDiesel only

Never work on the injection systemwith the engine running or within 30seconds after shutting off the en‐gine. High pressure pump, rail, injec‐tors and high pressure pipes aresubject to high pressure even afterthe engine stops. The fuel jet pro‐duced by fuel leaks may cause seri‐ous injury, if it touches the body.People using pacemakers should notmore move than 30 cm closer to theECU or wiring harness within the en‐gine room while the engine is run‐ning, since the high currents in theCommon Rail system produce con‐siderable magnetic fields.

8-41

8

Maintenance

Page 388 of 523

Vapor hose (for gasoline engine)

and fuel filler cap

The vapor hose and fuel filler cap

should be inspected at those intervals specified in the maintenance schedule.

Make sure that a new vapor hose or

fuel filler cap is correctly replaced.

Vacuum crankcase ventilation

hoses (if equipped)

Inspect the surface of hoses for evi‐

dence of heat and/or mechanical dam‐ age. Hard and brittle rubber, cracking,

tears, cuts, abrasions, and excessive

swelling indicate deterioration. Particu‐ lar attention should be paid to examine

those hose surfaces nearest to high

heat sources, such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with

any heat source, sharp edges or mov‐ ing component which might cause heat

damage or mechanical wear. Inspect all

hose connections, such as clamps and couplings, to make sure they are se‐

cure, and that no leaks are present. Ho‐

ses should be replaced immediately if there is any evidence of deterioration

or damage.

Air cleaner filter

Have the air cleaner filter replaced by a

professional workshop. Kia recom‐ mends to visit an authorized Kia dealer/

service partner.

Spark plugs (for gasoline engine)

Make sure to install new spark plugs of

the correct heat range.

WARNING

Do not disconnect and inspect sparkplugs when the engine is hot. Youmay burn yourself.

Valve clearance (for Kappa 1.0L

T-GDI engine)

Inspect for excessive valve noise and/or

engine vibration and adjust if necessa‐ ry. In this case, have the system serv‐

iced by a professional workshop. Kia

recommends to visit an authorized Kia dealer/service partner.

Cooling system

Check the cooling system components,

such as the radiator, coolant reservoir, hoses and connections for leakage and

damage. Replace any damaged parts.

Coolant

The coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid (if

equipped)

Inspect the manual transaxle fluid ac‐

cording to the maintenance schedule.

Automatic transaxle fluid (if

equipped)

Automatic transaxle fluid should not be

checked under normal usage conditions.

Have the automatic transmission fluid changed by a professional workshop

according to the maintenance schedule.

Kia recommends to visit an authorized Kia dealer/service partner.

NOTICE

Automatic transaxle fluid color is ba‐

sically red.

As the vehicle is driven, the auto‐

matic transaxle fluid will begin to

look darker. It is normal condition

and you should not judge the need

(Continued)

Maintenance

8-42

Page 403 of 523

FUEL FILTER (FOR DIESEL)

Draining water from the fuel

filter

The fuel filter for diesel engine plays an

important role of separating water

from fuel and accumulating the water in its bottom.

If water accumulates in the fuel filter,

the warning light comes on when the

ignition switch is in the ON position.

If this warning light illumi‐ nates, take your car to a pro‐

fessional workshop and havedrain the water and check the

system. Kia recommends tovisit an authorized Kia dealer/

service partner.

CAUTION

If the water accumulated in the fuelfilter is not drained at proper times,damages to the major parts such asthe fuel system can be caused bywater permeation in the fuel filter.

Fuel filter cartridge replacement

NOTICE

When replacing the fuel filter car‐

tridge, use parts for replacement

from a professional workshop. Kia

recommends to visit an authorized

Kia dealer/service partner.

8-57

8

Maintenance

Page 413 of 523

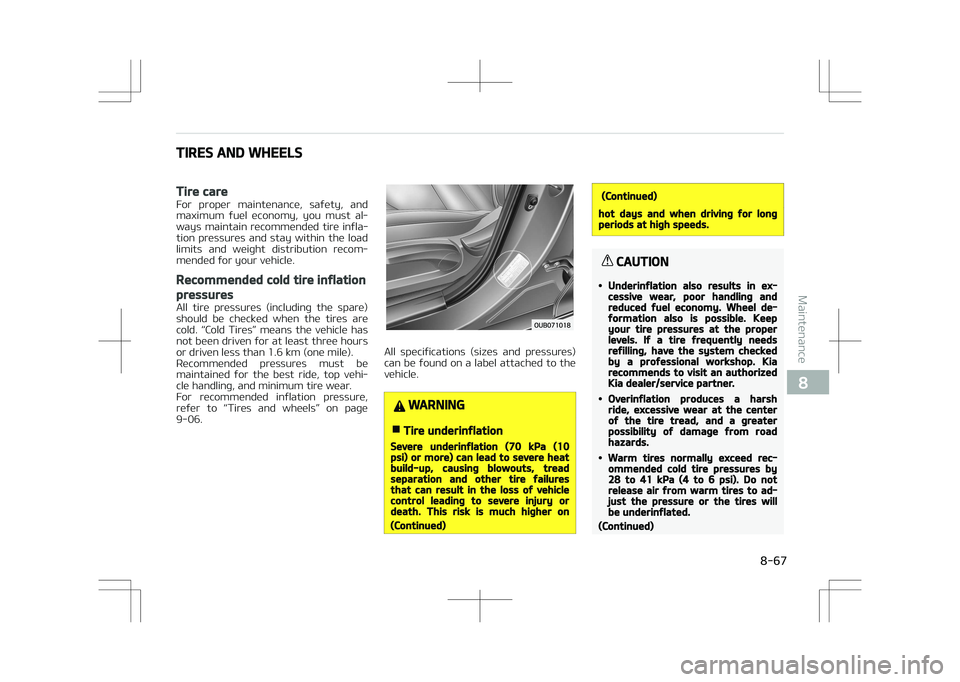

TIRES AND WHEELS

Tire care

For proper maintenance, safety, and

maximum fuel economy, you must al‐

ways maintain recommended tire infla‐ tion pressures and stay within the load

limits and weight distribution recom‐

mended for your vehicle.

Recommended cold tire inflation

pressures

All tire pressures (including the spare)

should be checked when the tires are cold. L

Page 432 of 523

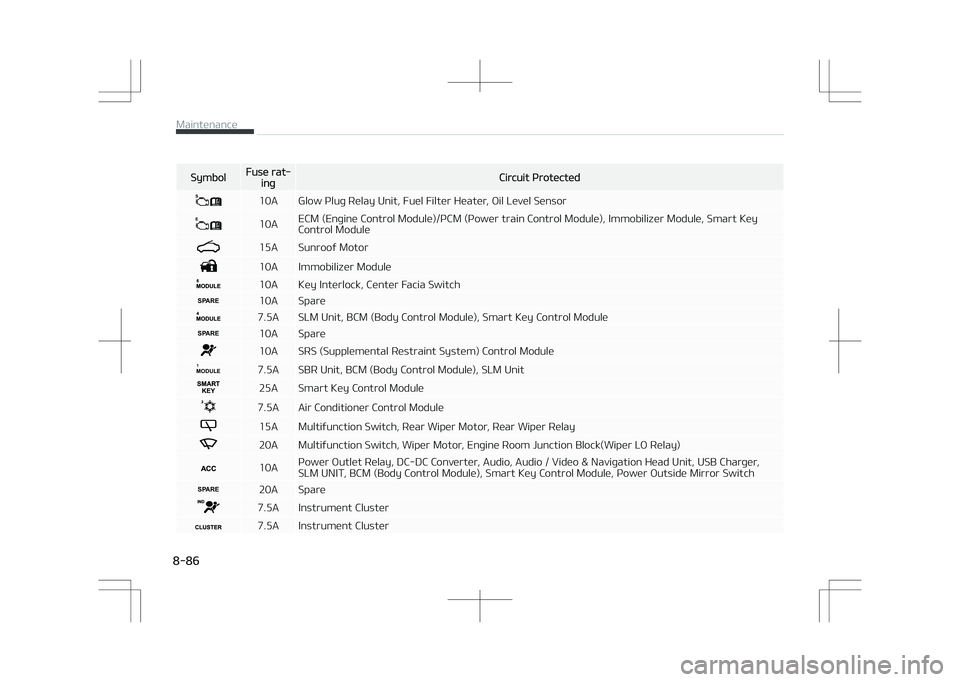

SymbolFuse rat‐ingCircuit Protected

S10A Glow Plug Relay Unit, Fuel Filter Heater, Oil Level Sensor

E10AECM (Engine Control Module)/PCM (Power train Control Module), Immobilizer Module, Smart Key

Control Module

15A Sunroof Motor

10A Immobilizer Module

10A Key Interlock, Center Facia Switch

SPARE10A Spare

7.5A SLM Unit, BCM (Body Control Module), Smart Key Control Module

SPARE10A Spare

10A SRS (Supplemental Restraint System) Control Module

MODULE17.5A SBR Unit, BCM (Body Control Module), SLM Unit

25A Smart Key Control Module

7.5A Air Conditioner Control Module

15A Multifunction Switch, Rear Wiper Motor, Rear Wiper Relay

20A Multifunction Switch, Wiper Motor, Engine Room Junction Block(Wiper LO Relay)

10APower Outlet Relay, DC-DC Converter, Audio, Audio / Video & Navigation Head Unit, USB Charger,

SLM UNIT, BCM (Body Control Module), Smart Key Control Module, Power Outside Mirror Switch

SPARE20A Spare

7.5A Instrument Cluster

7.5A Instrument Cluster

Maintenance

8-86

Page 438 of 523

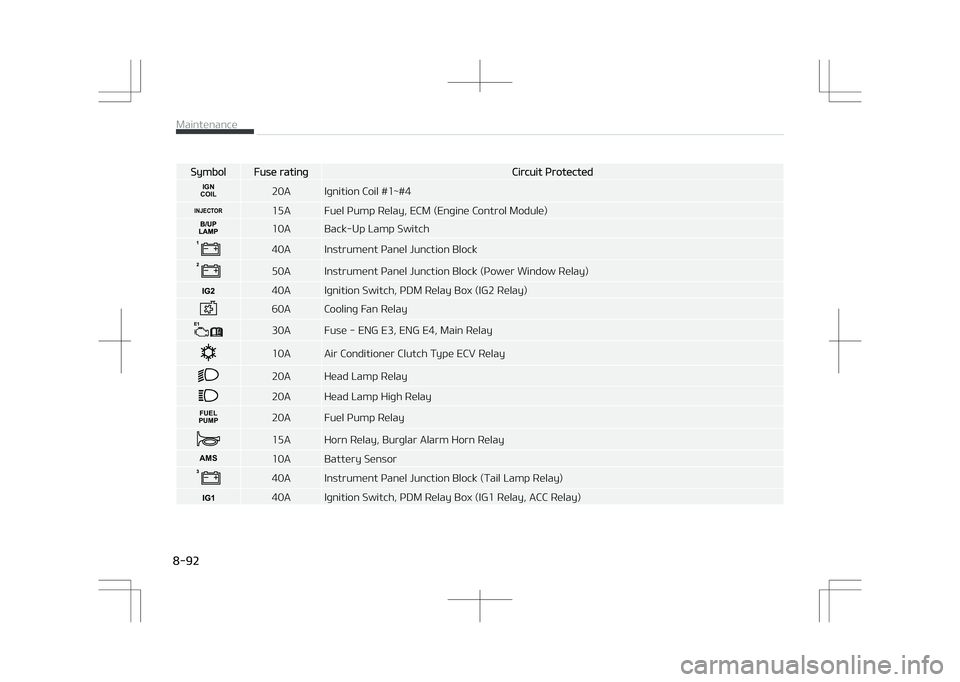

SymbolFuse ratingCircuit Protected

IGN

COIL20A Ignition Coil #1~#4

INJECTOR15A Fuel Pump Relay, ECM (Engine Control Module)

10A Back-Up Lamp Switch

40A Instrument Panel Junction Block

50A Instrument Panel Junction Block (Power Window Relay)

40A Ignition Switch, PDM Relay Box (IG2 Relay)

60A Cooling Fan Relay

30A Fuse - ENG E3, ENG E4, Main Relay

10A Air Conditioner Clutch Type ECV Relay

20A Head Lamp Relay

20A Head Lamp High Relay

FUEL

PUMP20A Fuel Pump Relay

15A Horn Relay, Burglar Alarm Horn Relay

AMS10A Battery Sensor

40A Instrument Panel Junction Block (Tail Lamp Relay)

40A Ignition Switch, PDM Relay Box (IG1 Relay, ACC Relay)

Maintenance

8-92

Page 439 of 523

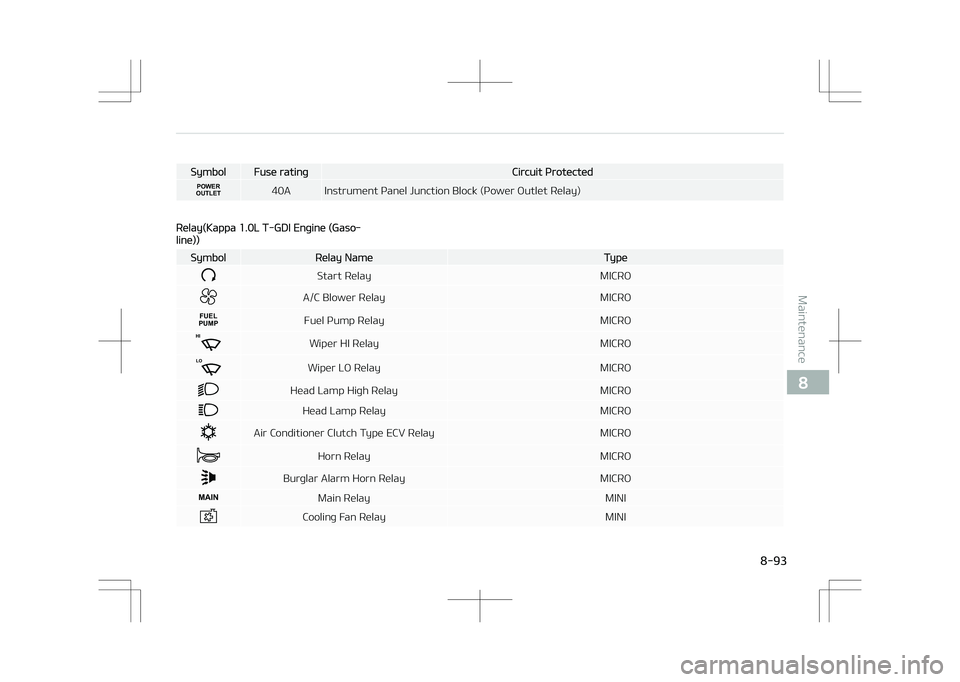

SymbolFuse ratingCircuit Protected

POWER

OUTLET40A Instrument Panel Junction Block (Power Outlet Relay)

Relay(Kappa 1.0L T-GDI Engine (Gaso‐

line))

SymbolRelay NameType

Start Relay MICRO

A/C Blower Relay MICRO

FUEL

PUMPFuel Pump Relay MICRO

Wiper HI RelayMICRO

LOWiper LO Relay MICRO

Head Lamp High Relay MICRO

Head Lamp RelayMICRO

Air Conditioner Clutch Type ECV Relay MICRO

Horn RelayMICRO

Burglar Alarm Horn Relay MICRO

MAINMain RelayMINI

Cooling Fan Relay MINI

8-93

8

Maintenance

Page 440 of 523

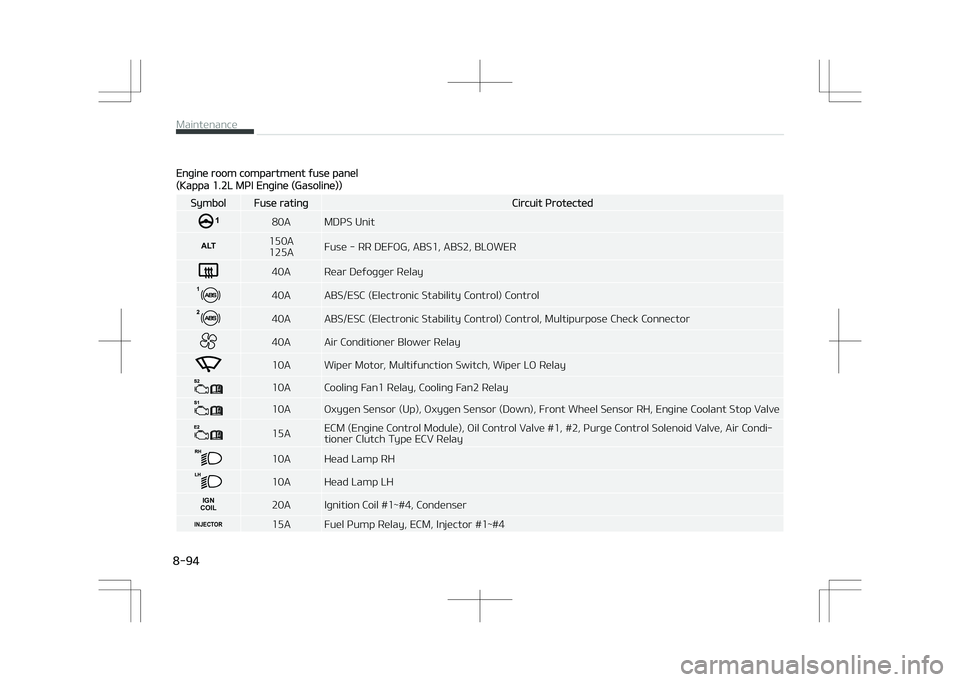

Engine room compartment fuse panel

(Kappa 1.2L MPI Engine (Gasoline))

SymbolFuse ratingCircuit Protected

80A MDPS Unit

ALT150A 125AFuse - RR DEFOG, ABS1, ABS2, BLOWER

40A Rear Defogger Relay

140A ABS/ESC (Electronic Stability Control) Control

40A ABS/ESC (Electronic Stability Control) Control, Multipurpose Check Connector

40A Air Conditioner Blower Relay

10A Wiper Motor, Multifunction Switch, Wiper LO Relay

10A Cooling Fan1 Relay, Cooling Fan2 Relay

10A Oxygen Sensor (Up), Oxygen Sensor (Down), Front Wheel Sensor RH, Engine Coolant Stop Valve

15AECM (Engine Control Module), Oil Control Valve #1, #2, Purge Control Solenoid Valve, Air Condi‐

tioner Clutch Type ECV Relay

10A Head Lamp RH

10A Head Lamp LH

IGN

COIL20A Ignition Coil #1~#4, Condenser

INJECTOR15A Fuel Pump Relay, ECM, Injector #1~#4

Maintenance

8-94

Page 441 of 523

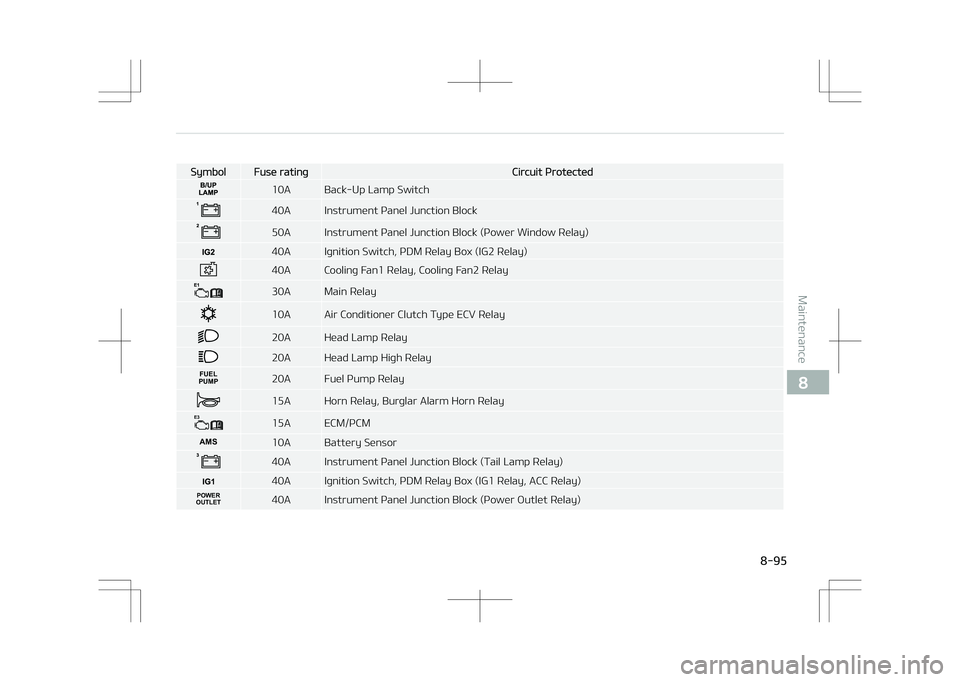

SymbolFuse ratingCircuit Protected

10A Back-Up Lamp Switch

40A Instrument Panel Junction Block

50A Instrument Panel Junction Block (Power Window Relay)

40A Ignition Switch, PDM Relay Box (IG2 Relay)

40A Cooling Fan1 Relay, Cooling Fan2 Relay

30A Main Relay

10A Air Conditioner Clutch Type ECV Relay

20A Head Lamp Relay

20A Head Lamp High Relay

FUEL

PUMP20A Fuel Pump Relay

15A Horn Relay, Burglar Alarm Horn Relay

E315A ECM/PCM

AMS10A Battery Sensor

40A Instrument Panel Junction Block (Tail Lamp Relay)

40A Ignition Switch, PDM Relay Box (IG1 Relay, ACC Relay)

POWER

OUTLET40A Instrument Panel Junction Block (Power Outlet Relay)

8-95

8

Maintenance