cooling KIA VENGA 2011 Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2011, Model line: VENGA, Model: KIA VENGA 2011Pages: 761, PDF Size: 34.65 MB

Page 656 of 761

Maintenance

16

7

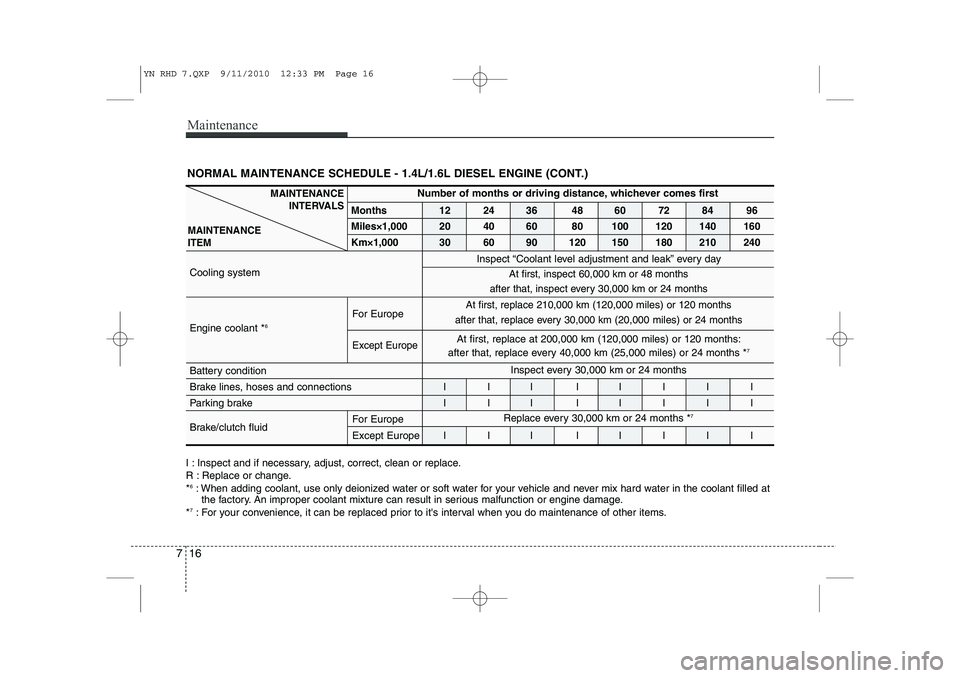

NORMAL MAINTENANCE SCHEDULE - 1.4L/1.6L DIESEL ENGINE (CONT.)

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.* 6

: When adding coolant, use only deionized water or soft water for your vehicle and never mix hard water in the coolant filled at

the factory. An improper coolant mixture can result in serious malfunction or engine damage.

* 7

: For your convenience, it can be replaced prior to it's interval when you do maintenance of other items.

MAINTENANCE

INTERVALS

MAINTENANCE ITEM

Inspect every 30,000 km or 24 months

Number of months or driving distance, whichever comes first

Months 12 24 36 48 60 72 84 96

Miles×1,000 20 40 60 80 100 120 140 160

Km×1,000 30 60 90 120 150 180 210 240

Cooling system

For Europe

Engine coolant * 6

Except Europe

Battery condition

Brake lines, hoses and connections I I I I I I I I

Parking brake

I I I I I I I I

Brake/clutch fluid For Europe

Except Europe I I I I I I I IInspect “Coolant level adjustment and leak” every day

At first, inspect 60,000 km or 48 months

after that, inspect every 30,000 km or 24 months

Replaceevery 30,000 km or 24 months * 7

At first, replace 210,000 km (120,000 miles) or 120 months

after that, replace every 30,000 km

(20,000 miles) or 24 months

At first, replace at 200,000 km (120,000 miles) or 120 months:

after that, replace every 40,000 km (25,000 miles) or 24 months * 7

YN RHD 7.QXP 9/11/2010 12:33 PM Page 16

Page 662 of 761

Maintenance

22

7

Cooling system

Check cooling system components, such

as radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts. Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid (if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule. Automatic transaxle fluid (if equipped)

The fluid level should be in the "HOT"

range of the dipstick, after the engine

and transaxle are at normal operating

temperature. Check the automatic

transaxle fluid level with the engine run-

ning and the transaxle in neutral, with the

parking brake properly applied. Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately. Brake fluid

Check brake fluid level in the brake fluid

reservoir. The level should be between

“MIN” and “MAX” marks on the side of

the reservoir. Use only hydraulic brake

fluid conforming to DOT 3 or DOT 4specification.Parking brake

Inspect the parking brake system includ-

ing the parking brake pedal and cables.

Brake discs, pads, calipers and

rotors

Check the pads for excessive wear, discs

for run out and wear, and calipers for fluid

leakage. Suspension mounting bolts

Check the suspension connections for

looseness or damage. Retighten to the

specified torque.

YN RHD 7.QXP 10/20/2009 4:45 PM Page 22

Page 665 of 761

725

Maintenance

Changing the engine oil and filter

Have the engine oil and filter changed by

an authorised KIA dealer according tothe Maintenance Schedule at the begin-ning of this section.The high-pressure cooling system has a

reservoir filled with year-round antifreeze

coolant. The reservoir is filled at the fac-

tory.

Check the antifreeze protection and

coolant level at least once a year, at thebeginning of the winter season, and

before travelling to a colder climate.

Checking the coolant level

WARNING

Used engine oil may cause skin irri- tation or cancer if left in contact

with the skin for prolonged periods

of time. Used engine oil contains

chemicals that have caused cancer

in laboratory animals. Always pro-

tect your skin by washing your

hands thoroughly with soap and

warm water as soon as possibleafter handling used oil.

ENGINE COOLANT

WARNING - Removing

radiator cap

Never attempt to remove the radi- ator cap whilst the engine is

operating or hot. Doing so mightlead to cooling system and

engine damage. Also hot coolantor steam could cause serious

personal injury.

(Continued)

(Continued)

Turn the engine off and wait untilit cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back whilst

the pressure is released from the

cooling system. When you aresure all the pressure has been

released, press down on the cap,

using a thick towel, and continue

turning counterclockwise to

remove it.

Even if the engine is not operat- ing, do not remove the radiatorcap or the drain plug whilst the

engine and radiator are hot. Hot

coolant and steam may still blow

out under pressure, causing seri-

ous injury.

YN RHD 7.QXP 10/20/2009 4:45 PM Page 25

Page 666 of 761

Maintenance

26

7

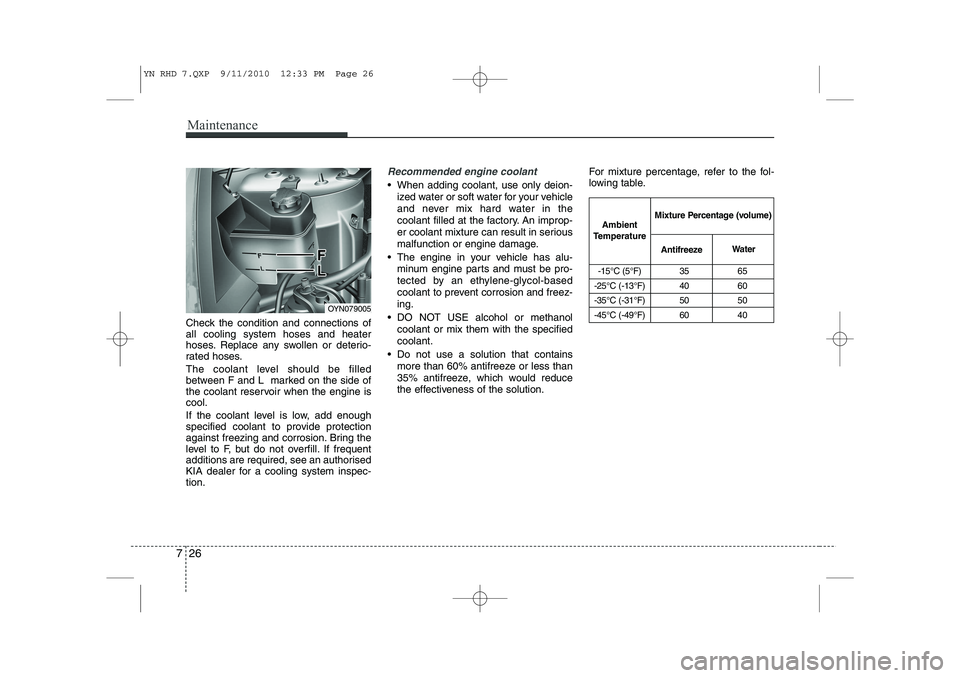

Check the condition and connections of all cooling system hoses and heater

hoses. Replace any swollen or deterio-

rated hoses.

The coolant level should be filled

between F and L marked on the side of

the coolant reservoir when the engine iscool.

If the coolant level is low, add enough

specified coolant to provide protection

against freezing and corrosion. Bring the

level to F, but do not overfill. If frequent

additions are required, see an authorised

KIA dealer for a cooling system inspec-tion.

Recommended engine coolant

When adding coolant, use only deion-

ized water or soft water for your vehicle

and never mix hard water in the

coolant filled at the factory. An improp-

er coolant mixture can result in serious

malfunction or engine damage.

The engine in your vehicle has alu- minum engine parts and must be pro-

tected by an ethylene-glycol-based

coolant to prevent corrosion and freez-ing.

DO NOT USE alcohol or methanol coolant or mix them with the specifiedcoolant.

Do not use a solution that contains more than 60% antifreeze or less than

35% antifreeze, which would reduce

the effectiveness of the solution. For mixture percentage, refer to the fol-

lowing table.

-15°C (5°F) 35 65

-25°C (-13°F) 40 60

-35°C (-31°F) 50 50

-45°C (-49°F) 60 40

Ambient

Temperature Mixture Percentage (volume)

Antifreeze Water

OYN079005

YN RHD 7.QXP 9/11/2010 12:33 PM Page 26

Page 697 of 761

757

Maintenance

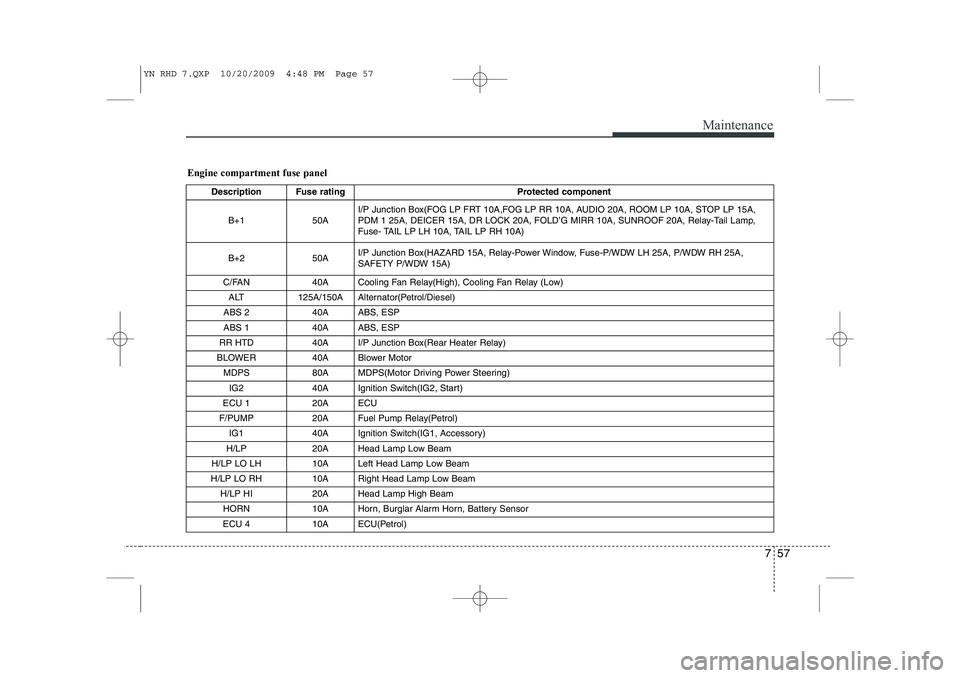

Engine compartment fuse panelDescription Fuse rating Protected component

B+1 50A I/P Junction Box(FOG LP FRT 10A,FOG LP RR 10A, AUDIO 20A, ROOM LP 10A, STOP LP 15A,

PDM 1 25A, DEICER 15A, DR LOCK 20A, FOLD’G MIRR 10A, SUNROOF 20A, Relay-Tail Lamp,

Fuse- TAIL LP LH 10A, TAIL LP RH 10A)

B+2 50A I/P Junction Box(HAZARD 15A, Relay-Power Window, Fuse-P/WDW LH 25A, P/WDW RH 25A,

SAFETY P/WDW 15A)

C/FAN 40A Cooling Fan Relay(High), Cooling Fan Relay (Low) ALT 125A/150A Alternator(Petrol/Diesel)

ABS 2 40A ABS, ESP

ABS 1 40A ABS, ESP

RR HTD 40A I/P Junction Box(Rear Heater Relay)

BLOWER 40A Blower Motor

MDPS 80A MDPS(Motor Driving Power Steering)IG2 40A Ignition Switch(IG2, Start)

ECU 1 20A ECU

F/PUMP 20A Fuel Pump Relay(Petrol) IG1 40A Ignition Switch(IG1, Accessory)

H/LP 20A Head Lamp Low Beam

H/LP LO LH 10A Left Head Lamp Low Beam

H/LP LO RH 10A Right Head Lamp Low Beam

H/LP HI 20A Head Lamp High BeamHORN 10A Horn, Burglar Alarm Horn, Battery Sensor

ECU 4 10A ECU(Petrol)

YN RHD 7.QXP 10/20/2009 4:48 PM Page 57

Page 698 of 761

Maintenance

58

7

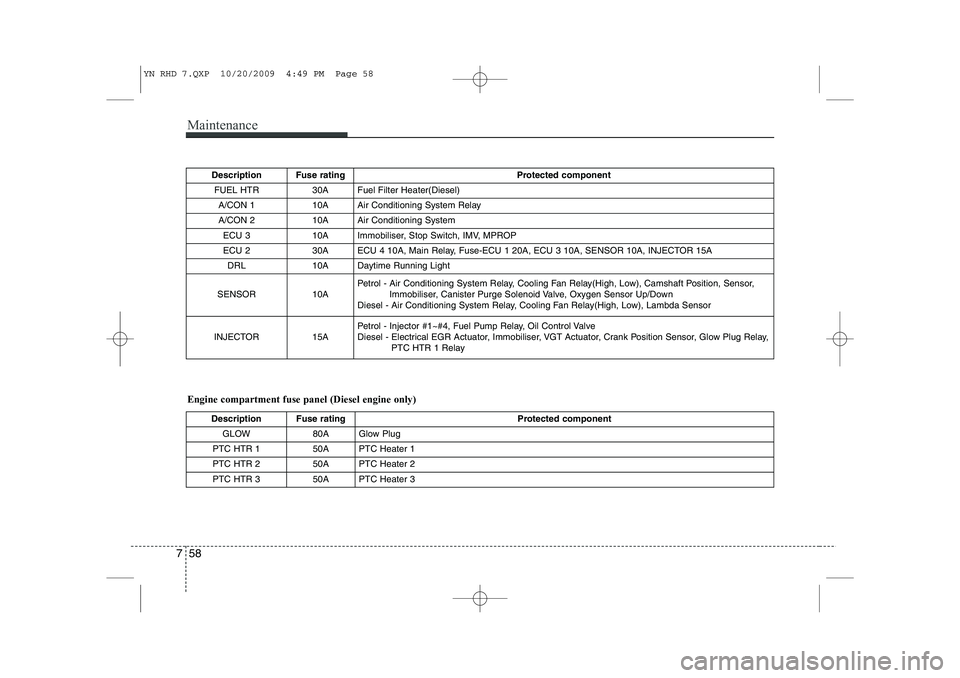

Engine compartment fuse panel (Diesel engine only) Description Fuse rating

Protected component

FUEL HTR30AFuel Filter Heater(Diesel)

A/CON 110AAir Conditioning System Relay

A/CON 210AAir Conditioning System

ECU 3 10A Immobiliser, Stop Switch, IMV, MPROP

ECU 2 30A ECU 4 10A, Main Relay, Fuse-ECU 1 20A, ECU 3 10A, SENSOR 10A, INJECTOR 15A

DRL 10A Daytime Running Light

SENSOR 10A Petrol - Air Conditioning System Relay, Cooling Fan Relay(High, Low), Camshaft Position, Sensor,

Immobiliser, Canister Purge Solenoid Valve, Oxygen Sensor Up/Down

Diesel - Air Conditioning System Relay, Cooling Fan Relay(High, Low), Lambda Sensor

INJECTOR 15A Petrol - Injector #1~#4, Fuel Pump Relay, Oil Control Valve

Diesel - Electrical EGR Actuator, Immobiliser, VGT Actuator, Crank Position Sensor, Glow Plug Relay,

PTC HTR 1 Relay

Description Fuse rating Protected component

GLOW 80A Glow Plug

PTC HTR 1 50A PTC Heater 1

PTC HTR 2 50A PTC Heater 2

PTC HTR 3 50A PTC Heater 3

YN RHD 7.QXP 10/20/2009 4:49 PM Page 58