fuel KIA VENGA 2016 Service Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2016, Model line: VENGA, Model: KIA VENGA 2016Pages: 404, PDF Size: 21.96 MB

Page 324 of 404

721

Maintenance

Timing belt (if equipped)

Inspect all parts related to the timing belt

for damage and deformation. Replace

any damaged parts immediately.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap iscorrectly replaced.Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in contact with

any heat source, sharp edges or movingcomponent which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.Air cleaner filter

We recommend that you use air cleaner

filter for replacement from an authorized

Kia dealer.

Spark plugs (for gasoline engine)

Make sure to install new spark plugs of

the correct heat range.

Valve clearance (if equipped)

Inspect for excessive valve noise and/or

engine vibration and adjust if necessary.

We recommend that the system be serv-

iced by an authorized Kia dealer.

YN ENG 7.QXP 9/5/2016 4:35 PM Page 21

Page 333 of 404

Maintenance

30

7

FUEL FILTER (FOR DIESEL)

Draining water from the fuel filter

The fuel filter for diesel engine plays an

important role of separating water from

fuel and accumulating the water in itsbottom.

If water accumulates in the fuel filter, the

warning light comes on when the ignition

switch is in the ON position. If this warning light illuminates,

we recommend that you con-

tact an authorized Kia dealer.

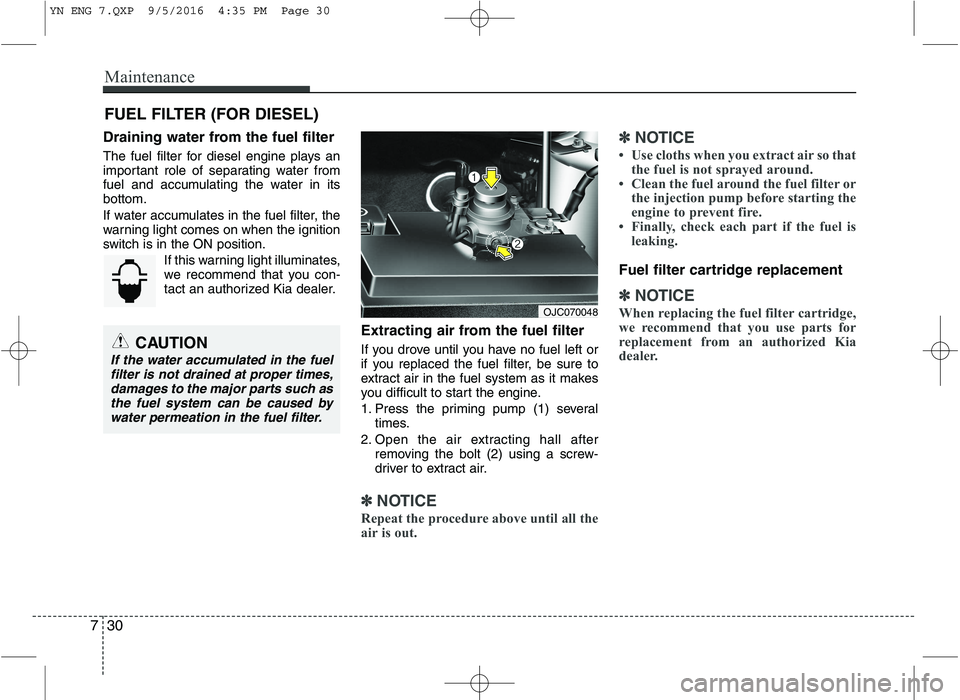

Extracting air from the fuel filter

If you drove until you have no fuel left or

if you replaced the fuel filter, be sure to

extract air in the fuel system as it makes

you difficult to start the engine.

1. Press the priming pump (1) severaltimes.

2. Open the air extracting hall after removing the bolt (2) using a screw-

driver to extract air.

✽✽ NOTICE

Repeat the procedure above until all the

air is out. ✽

✽

NOTICE

Use cloths when you extract air so that the fuel is not sprayed around.

Clean the fuel around the fuel filter or

the injection pump before starting the

engine to prevent fire.

Finally, check each part if the fuel is leaking.

Fuel filter cartridge replacement

✽✽ NOTICE

When replacing the fuel filter cartridge,

we recommend that you use parts for

replacement from an authorized Kia

dealer.

CAUTION

If the water accumulated in the fuel filter is not drained at proper times,damages to the major parts such as

the fuel system can be caused bywater permeation in the fuel filter.

OJC070048

YN ENG 7.QXP 9/5/2016 4:35 PM Page 30

Page 343 of 404

Maintenance

40

7

TIRES AND WHEELS

Tire care

For proper maintenance, safety, and

maximum fuel economy, you must

always maintain recommended tire

inflation pressures and stay within

the load limits and weight distribution

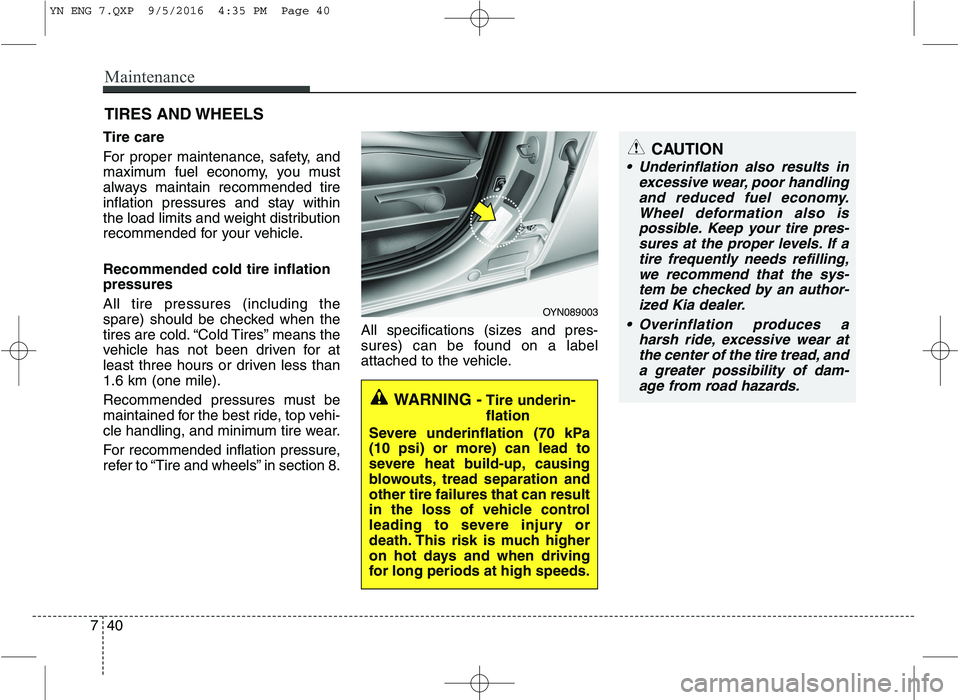

recommended for your vehicle. Recommended cold tire inflation pressures All tire pressures (including the

spare) should be checked when the

tires are cold. “Cold Tires” means the

vehicle has not been driven for at

least three hours or driven less than1.6 km (one mile).

Recommended pressures must be

maintained for the best ride, top vehi-

cle handling, and minimum tire wear.

For recommended inflation pressure,

refer to “Tire and wheels” in section 8. All specifications (sizes and pres-

sures) can be found on a label

attached to the vehicle.

WARNING -

Tire underin- flation

Severe underinflation (70 kPa(10 psi) or more) can lead to

severe heat build-up, causing

blowouts, tread separation andother tire failures that can result

in the loss of vehicle control

leading to severe injury or

death. This risk is much higher

on hot days and when driving

for long periods at high speeds.

OYN089003

CAUTION

Underinflation also results in excessive wear, poor handlingand reduced fuel economy. Wheel deformation also ispossible. Keep your tire pres-sures at the proper levels. If a tire frequently needs refilling,we recommend that the sys-tem be checked by an author- ized Kia dealer.

Overinflation produces a harsh ride, excessive wear atthe center of the tire tread, anda greater possibility of dam- age from road hazards.

YN ENG 7.QXP 9/5/2016 4:35 PM Page 40

Page 359 of 404

Maintenance

56

7

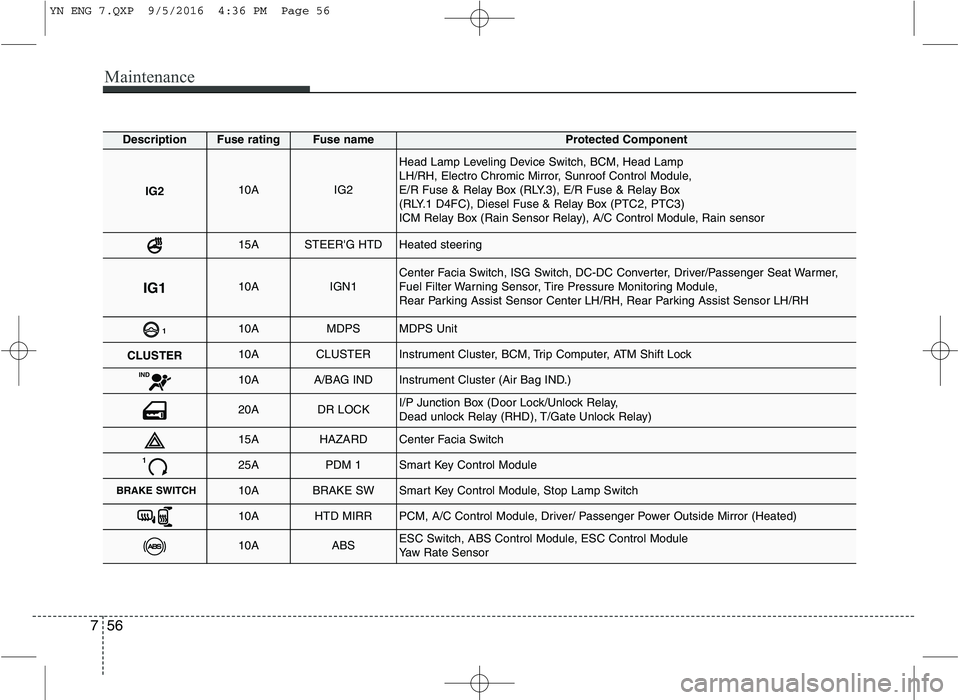

DescriptionFuse ratingFuse nameProtected Component

IG210AIG2

Head Lamp Leveling Device Switch, BCM, Head Lamp

LH/RH, Electro Chromic Mirror, Sunroof Control Module,

E/R Fuse & Relay Box (RLY.3), E/R Fuse & Relay Box

(RLY.1 D4FC), Diesel Fuse & Relay Box (PTC2, PTC3)

ICM Relay Box (Rain Sensor Relay), A/C Control Module, Rain sensor

15ASTEER'G HTDHeated steering

IG110AIGN1Center Facia Switch, ISG Switch, DC-DC Converter, Driver/Passenger Seat Warmer,

Fuel Filter Warning Sensor, Tire Pressure Monitoring Module,

Rear Parking Assist Sensor Center LH/RH, Rear Parking Assist Sensor LH/RH

110AMDPSMDPS Unit

CLU STER10ACLUSTERInstrument Cluster, BCM, Trip Computer, ATM Shift Lock

IND10AA/BAG INDInstrument Cluster (Air Bag IND.)

20ADR LOCKI/P Junction Box (Door Lock/Unlock Relay,

Dead unlock Relay (RHD), T/Gate Unlock Relay)

15AHAZARDCenter Facia Switch

125APDM 1Smart Key Control Module

BRAKE SWITCH10ABRAKE SWSmart Key Control Module, Stop Lamp Switch

10AHTD MIRRPCM, A/C Control Module, Driver/ Passenger Power Outside Mirror (Heated)

10AABSESC Switch, ABS Control Module, ESC Control Module

Yaw Rate Sensor

YN ENG 7.QXP 9/5/2016 4:36 PM Page 56

Page 362 of 404

759

Maintenance

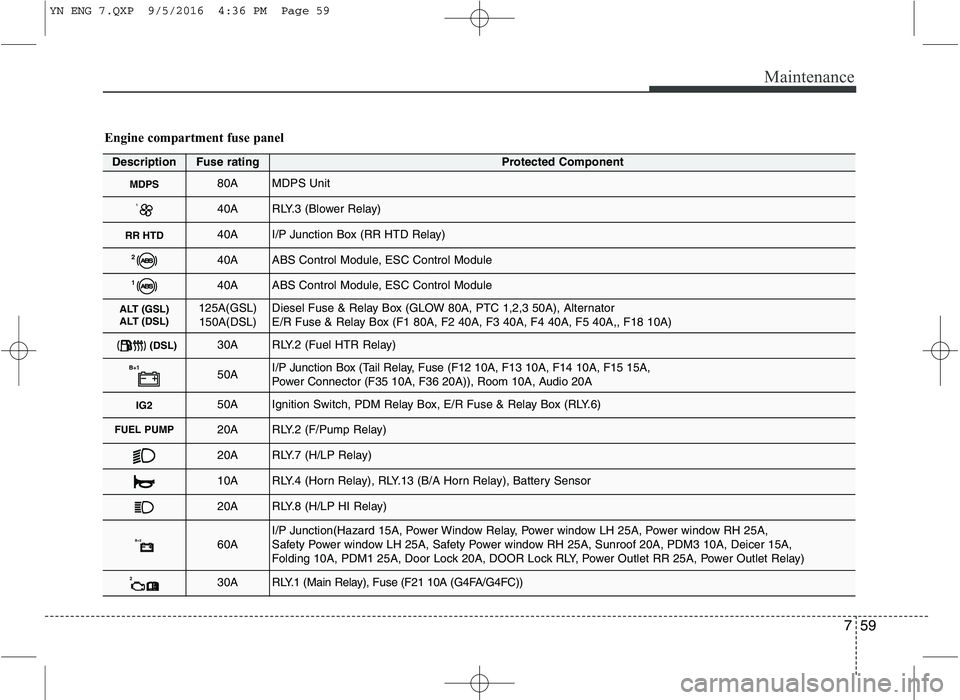

Engine compartment fuse panel

DescriptionFuse ratingProtected Component

MDPS80AMDPS Unit

140ARLY.3 (Blower Relay)

RR HTD40AI/P Junction Box (RR HTD Relay)

240AABS Control Module, ESC Control Module

140AABS Control Module, ESC Control Module

ALT (GSL)

ALT (DSL)125A(GSL)

150A(DSL)Diesel Fuse & Relay Box (GLOW 80A, PTC 1,2,3 50A), Alternator

E/R Fuse & Relay Box (F1 80A, F2 40A, F3 40A, F4 40A, F5 40A,, F18 10A)

30ARLY.2 (Fuel HTR Relay)

B+150AI/P Junction Box (Tail Relay, Fuse (F12 10A, F13 10A, F14 10A, F15 15A,

Power Connector (F35 10A, F36 20A)), Room 10A, Audio 20A

IG250AIgnition Switch, PDM Relay Box, E/R Fuse & Relay Box (RLY.6)

FUEL PUMP20ARLY.2 (F/Pump Relay)

20ARLY.7 (H/LP Relay)

10ARLY.4 (Horn Relay), RLY.13 (B/A Horn Relay), Battery Sensor

20ARLY.8 (H/LP HI Relay)

B+260AI/P Junction(Hazard 15A, Power Window Relay, Power window LH 25A, Power window RH 25A,

Safety Power window LH 25A, Safety Power window RH 25A, Sunroof 20A, PDM3 10A, Deicer 15A,

Folding 10A, PDM1 25A, Door Lock 20A, DOOR Lock RLY, Power Outlet RR 25A, Power Outlet Relay)

230ARLY.1 (Main Relay), Fuse (F21 10A (G4FA/G4FC))

(DSL)

YN ENG 7.QXP 9/5/2016 4:36 PM Page 59

Page 363 of 404

Maintenance

60

7

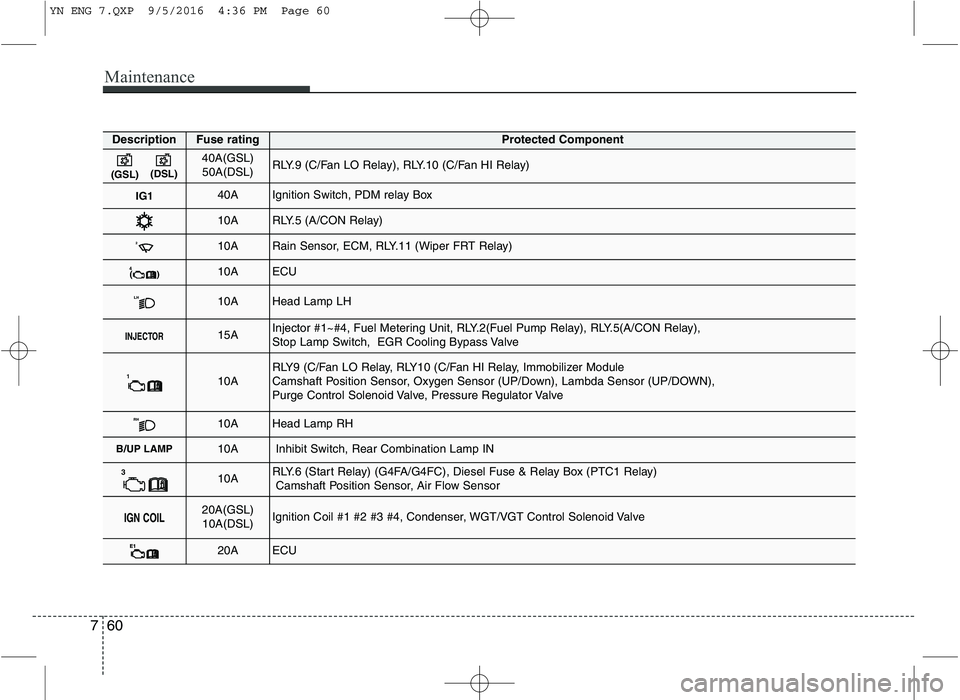

DescriptionFuse ratingProtected Component

40A(GSL)

50A(DSL)RLY.9 (C/Fan LO Relay), RLY.10 (C/Fan HI Relay)

IG140AIgnition Switch, PDM relay Box

10ARLY.5 (A/CON Relay)

210ARain Sensor, ECM, RLY.11 (Wiper FRT Relay)

4( )10AECU

LH10AHead Lamp LH

INJECTOR15AInjector #1~#4, Fuel Metering Unit, RLY.2(Fuel Pump Relay), RLY.5(A/CON Relay),

Stop Lamp Switch, EGR Cooling Bypass Valve

110ARLY9 (C/Fan LO Relay, RLY10 (C/Fan HI Relay, Immobilizer Module

Camshaft Position Sensor, Oxygen Sensor (UP/Down), Lambda Sensor (UP/DOWN),

Purge Control Solenoid Valve, Pressure Regulator Valve

RH10AHead Lamp RH

B/UP LAMP10AInhibit Switch, Rear Combination Lamp IN

310ARLY.6 (Start Relay) (G4FA/G4FC), Diesel Fuse & Relay Box (PTC1 Relay) Camshaft Position Sensor, Air Flow Sensor

IGN COIL20A(GSL)10A(DSL)Ignition Coil #1 #2 #3 #4, Condenser, WGT/VGT Control Solenoid Valve

20AECU

(GSL) (DSL)

YN ENG 7.QXP 9/5/2016 4:36 PM Page 60

Page 376 of 404

773

Maintenance

Bright-metal maintenance

To remove road tar and insects, use atar remover, not a scraper or other

sharp object.

To protect the surfaces of bright-metal parts from corrosion, apply a coating of

wax or chrome preservative and rub to

a high luster.

During winter weather or in coastal areas, cover the bright metal parts with

a heavier coating of wax or preserva-

tive. If necessary, coat the parts with

non-corrosive petroleum jelly or other

protective compound.

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may col-

lect on the underbody. If these materials

are not removed, accelerated rusting can

occur on the underbody parts such as

the fuel lines, frame, floor pan and

exhaust system, even though they have

been treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month, after off-road

driving and at the end of each winter. Payspecial attention to these areas because

it is difficult to see all the mud and dirt. It

will do more harm than good to wet down

the road grime without removing it. The

lower edges of the doors, rocker panels,

and frame members have drain holes

that should not clog with dirt; trapped

water in these areas can cause rusting.

Aluminum wheel maintenance

The aluminum wheels are coated with a

clear protective finish.

Do not use any abrasive cleaner, pol-ishing compound, solvent, or wire

brushes on aluminum wheels. They

may scratch or damage the finish.

Clean the wheel when it has cooled.

Use only a mild soap or neutral deter- gent, and rinse thoroughly with water.

Also, be sure to clean the wheels after

driving on salted roads. This helps pre-

vent corrosion.

Avoid washing the wheels with high- speed car wash brushes.

Do not use any alkaline or acid deter- gent. It may damage and corrode the

aluminum wheels coated with a clear

protective finish.

WARNING

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

YN ENG 7.QXP 9/5/2016 4:37 PM Page 73

Page 381 of 404

Maintenance

78

7

EMISSION CONTROL SYSTEM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Warranty &

Maintenance booklet in your vehicle.

Your vehicle is equipped with an emis- sion control system to meet all emission

regulations. There are three emission control sys-

tems which are as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system(3) Exhaust emission control system In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your vehicle

inspected and maintained by an author-

ized Kia dealer in accordance with the

maintenance schedule in this manual. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability Control

(ESC) system off by pressing the

ESC switch.

After dynamometer testing is com- pleted, turn the ESC system back on

by pressing the ESC switch again. 1. Crankcase emission control

system

The positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valveinto the induction system.

2. Evaporative emission control system

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

YN ENG 7.QXP 9/5/2016 4:37 PM Page 78

Page 382 of 404

779

Maintenance

Canister

Fuel vapors generated inside the fuel tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.

Purge Control Solenoid Valve (PCSV)

The purge control solenoid valve is con-

trolled by the Engine Control Module

(ECM); when the engine coolant temper-

ature is low during idling, the PCSV clos-

es so that evaporated fuel is not taken

into the engine. After the engine warms

up during ordinary driving, the PCSV

opens to introduce evaporated fuel to the

engine.3. Exhaust emission control

system

The Exhaust Emission Control System is

a highly effective system which controls

exhaust emissions while maintaining

good vehicle performance.

Vehicle modifications

This vehicle should not be modified. Modification of your vehicle could

affect its performance, safety or dura-

bility and may even violate governmen-

tal safety and emissions regulations.

In addition, damage or performance

problems resulting from any modification

may not be covered under warranty.

If you use unauthorized electric devices, it may cause the vehicle to

operate abnormally, wire damage, bat-

tery discharge and fire. For your safety,

do not use unauthorized electric

devices.

Engine exhaust gas precautions (car-

bon monoxide)

Carbon monoxide can be present with other exhaust fumes. Therefore, if you

smell exhaust fumes of any kind inside

your vehicle, have it inspected and

repaired immediately. If you ever sus-

pect exhaust fumes are coming into

your vehicle, drive it only with all the

windows fully open. Have your vehicle

checked and repaired immediately.

WARNING - Exhaust

Engine exhaust gases contain car-

bon monoxide (CO). Though color-

less and odorless, it is dangerousand could be lethal if inhaled.

Follow the instructions on this

page to avoid CO poisoning.

YN ENG 7.QXP 9/5/2016 4:37 PM Page 79

Page 383 of 404

Maintenance

80

7

Do not operate the engine in confined

or closed areas (such as garages) any

more than what is necessary to move

the vehicle in or out of the area.

When the vehicle is stopped in an open area for more than a short time

with the engine running, adjust the

ventilation system (as needed) to draw

outside air into the vehicle.

Never sit in a parked or stopped vehi- cle for any extended time with the

engine running.

When the engine stalls or fails to start, excessive attempts to restart the

engine may cause damage to theemission control system.Operating precautions for catalytic

converters (if equipped)Your vehicle is equipped with a catalytic

converter emission control device.

Therefore, the following precautions

must be observed:

Use only UNLEADED FUEL for gaso- line engine.

Do not operate the vehicle when there are signs of engine malfunction, such

as misfire or a noticeable loss of per-

formance.

Do not misuse or abuse the engine. Examples of misuse are coasting withthe ignition off and descending steep

grades in gear with the ignition off.

Do not operate the engine at high idle speed for extended periods (5 minutesor more).

Do not modify or tamper with any part of the engine or emission control sys-

tem. We recommend that the system

be inspected by an authorized Kia

dealer.

Avoid driving with an extremely low fuel level. Running out of fuel could cause

the engine to misfire, damaging the

catalytic converter.

Failure to observe these precautionscould result in damage to the catalytic

converter and to your vehicle.

Additionally, such actions could void your

warranties.

WARNING - Fire

A hot exhaust system can ignite flammable items under your vehi-

cle. Do not park, idle, or drive the

vehicle over or near flammable

objects, such as grass, vegeta-

tion, paper, leaves, etc.

The exhaust system and catalytic system are very hot while the

engine is running or immediately

after the engine is turned off. Keep

away from the exhaust system

and catalytic, you may get burned.

Also, do not remove the heat sink

around the exhaust system, do

not seal the bottom of the vehicle

or do not coat the vehicle for cor-

rosion control. It may present a

fire risk under certain conditions.

YN ENG 7.QXP 9/5/2016 4:37 PM Page 80