run flat Lancia Delta 2012 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2012, Model line: Delta, Model: Lancia Delta 2012Pages: 295, PDF Size: 8.29 MB

Page 131 of 295

1

KNOWING YOUR CAR129

IMPORTANT The steering may become slightly stiff fol-

lowing parking manoeuvres involving a lot of steering.

This is normal and is caused by a system to prevent the

motor from overheating. No servicing is required. The

power steering system will start working normally again

the next time the car is used.T.P.M.S. SYSTEM

(Tyre Pressure Monitoring System)

(for versions/markets, where provided)

The car may be equipped with a tyre pressure monitor-

ing system. This system comprises a radio frequency

transmitter fitted to each wheel (on the wheel rim inside

the tyre), which is able to send information on the tyre

inflation pressure of each wheel to the control unit.

IMPORTANT NOTES ABOUT THE TPMS SYSTEM

The fault indications are not stored and will therefore

not be displayed after the engine has been switched off

and then on again. If the fault conditions persist, the

control unit will send the relative indications to the in-

strument panel only after the vehicle has been in motion

for a short time.

Before starting any servicing operation, stop

the engine and remove the key from the igni-

tion switch to operate the steering lock, par-

ticularly when the wheels do not touch the ground.

If this is not possible (e.g. if the key must be kept in

the MAR position or the engine must be kept run-

ning), remove the electric power steering system

main fuse.

Page 184 of 295

182STARTING AND DRIVING

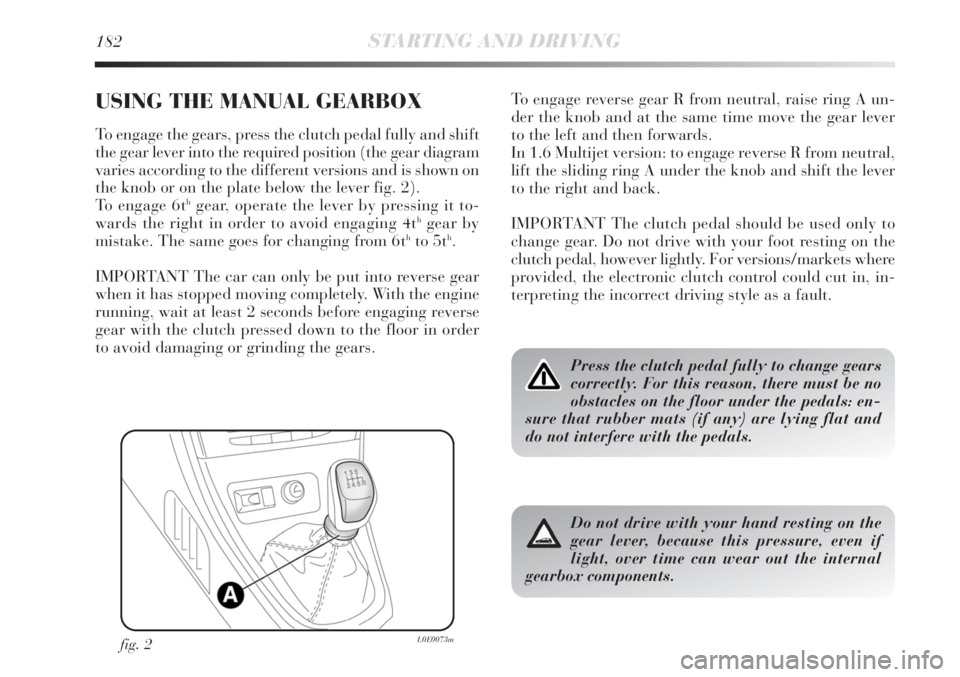

USING THE MANUAL GEARBOX

To engage the gears, press the clutch pedal fully and shift

the gear lever into the required position (the gear diagram

varies according to the different versions and is shown on

the knob or on the plate below the lever fig. 2).

To engage 6t

hgear, operate the lever by pressing it to-

wards the right in order to avoid engaging 4thgear by

mistake. The same goes for changing from 6thto 5th.

IMPORTANT The car can only be put into reverse gear

when it has stopped moving completely. With the engine

running, wait at least 2 seconds before engaging reverse

gear with the clutch pressed down to the floor in order

to avoid damaging or grinding the gears.

fig. 2L0E0073m

To engage reverse gear R from neutral, raise ring A un-

der the knob and at the same time move the gear lever

to the left and then forwards.

In 1.6 Multijet version: to engage reverse R from neutral,

lift the sliding ring A under the knob and shift the lever

to the right and back.

IMPORTANT The clutch pedal should be used only to

change gear. Do not drive with your foot resting on the

clutch pedal, however lightly. For versions/markets where

provided, the electronic clutch control could cut in, in-

terpreting the incorrect driving style as a fault.

Press the clutch pedal fully to change gears

correctly. For this reason, there must be no

obstacles on the floor under the pedals: en-

sure that rubber mats (if any) are lying flat and

do not interfere with the pedals.

Do not drive with your hand resting on the

gear lever, because this pressure, even if

light, over time can wear out the internal

gearbox components.

Page 195 of 295

IN AN EMERGENCY193

4

In the event of a puncture caused by foreign

bodies, the kit may be used to repair tyres

showing damages on the track or shoulder

up to max. 4 mm diameter.

Give the instruction booklet to the personnel

charged with handling the treated tyre.

The kit cannot be used to repair damage to

the tyre sidewall. Do not use the quick repair

kit if the tyre is damaged as the vehicle has

run on a flat tyre.

If the wheel rim is damaged (bad groove dis-

tortion causing air leakage) it cannot be re-

paired. Do not remove the foreign body

(screw or nail) from the tyre.

IMPORTANT INFORMATION:

The sealing fluid of the quick tyre repair kit is effective

with external temperatures between −20 °C and +50 °C.

The sealing fluid will expire.

Do not operate the compressor for longer

than 20 consecutive minutes. Risk of over-

heating. The quick repair kit is not suitable

for definitive repairs. Tyres may only be repaired

temporarily.

Page 202 of 295

200IN AN EMERGENCY

The driving characteristics of the car may

change when a space-saver wheel is fitted.

Avoid sudden acceleration and braking, sud-

den steering and fast cornering. The total life of

a space-saver wheel is approximately 3000 km,

after which it must be replaced by another wheel of

the same type. Never attempt to fit a conventional

tyre on a rim designed for use as a space-saver

wheel. Have the punctured wheel repaired and re-

placed as soon as possible. Two or more space-

saver wheels should never be used together. Do not

apply grease to the bolt threads before assembly:

they might spontaneously unscrew.The jack can only be used for changing

wheels on the car with which it is provided or

on cars of the same model Never use the jack

for other purposes, such as lifting other car models.

In no case should it be used for repairs under the

car. Incorrect positioning of the jack may cause the

jacked car to fall. Do not use the jack for loads

higher than those shown on the label. Snow chains

cannot be fitted to the space-saver wheel. So, if

a front (drive) wheel is punctured and chains are

needed, a rear wheel should be fitted to the front of

the car and the space-saver wheel should be fitted

to the rear. This way, with two normal front driving

wheels, you can install the snow chains on them,

thus resolving the emergency.

If the hub cap is not installed properly, it

may detach when the vehicle is running.

Never tamper with the inflation valve. Never

introduce tools of any kind between rim and tyre.

Regularly check tyre and space-saver wheel pres-

sure, complying with the data in the chapter “6”.

Tool box (versions with Bose HI-FI)

There is a tool box located in the luggage compartment

for versions with Bose HI-FI.

This box contains:

❍screwdriver;

❍tow hook;

❍wheel bolt spanner;

❍wheel bolt access spanner;

❍alloy wheel centring device;

❍jack.

Page 207 of 295

IN AN EMERGENCY205

4

REFITTING THE STANDARD WHEEL

Following the procedure described previously, raise the

car and remove the space saver spare wheel.

Versions with steel rims

Proceed as follows:

❍make sure the contact surfaces between standard

wheel and hub are clean so that the fastening bolts

will not come loose;

❍fit the standard wheel inserting the 4 bolts into the

holes;

❍using the wrench provided, tighten the fastening bolts;

❍press-fit the hub cap, aligning the special splining (on

the cap) with the inflation valve;

❍lower the car and remove the jack;

❍using the wrench provided, fully tighten the bolts in

the sequence shown previously.Versions with alloy wheels

❍Place the wheel onto the hub and tighten the bolts us-

ing the wrench provided;

❍lower the car and remove the jack;

❍using the spanner provided, fully tighten the bolts in

the sequence shown in fig. 8;

❍refit the press-fitted hub cap, making sure that the

reference hole on the wheel is aligned with the refer-

ence pin on the cap.

IMPORTANT If it is not fitted properly, the hub cap may

detach when the vehicle is running.