tire type Lancia Flavia 2012 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2012, Model line: Flavia, Model: Lancia Flavia 2012Pages: 233, PDF Size: 2.61 MB

Page 33 of 233

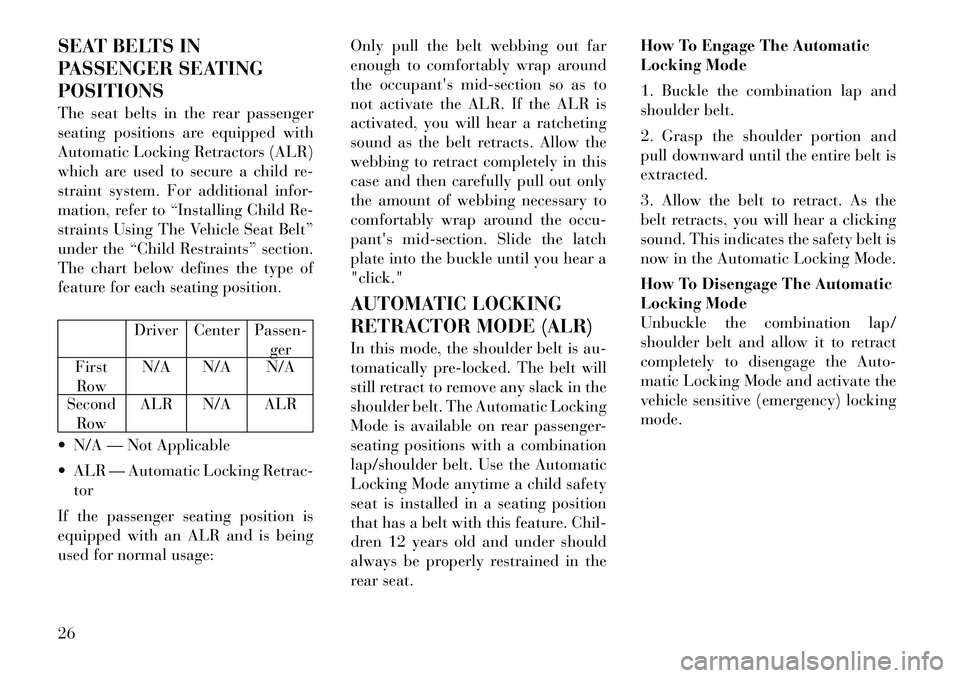

SEAT BELTS IN

PASSENGER SEATING

POSITIONS

The seat belts in the rear passenger

seating positions are equipped with

Automatic Locking Retractors (ALR)

which are used to secure a child re-

straint system. For additional infor-

mation, refer to “Installing Child Re-

straints Using The Vehicle Seat Belt”

under the “Child Restraints” section.

The chart below defines the type of

feature for each seating position.

Driver Center Passen-ger

First

Row N/A N/A N/A

Second Row ALR N/A ALR

N/A — Not Applicable

ALR — Automatic Locking Retrac- tor

If the passenger seating position is

equipped with an ALR and is being

used for normal usage: Only pull the belt webbing out far

enough to comfortably wrap around

the occupant's mid-section so as to

not activate the ALR. If the ALR is

activated, you will hear a ratcheting

sound as the belt retracts. Allow the

webbing to retract completely in this

case and then carefully pull out only

the amount of webbing necessary to

comfortably wrap around the occu-

pant's mid-section. Slide the latch

plate into the buckle until you hear a

"click."

AUTOMATIC LOCKING

RETRACTOR MODE (ALR)

In this mode, the shoulder belt is au-

tomatically pre-locked. The belt will

still retract to remove any slack in the

shoulder belt. The Automatic Locking

Mode is available on rear passenger-

seating positions with a combination

lap/shoulder belt. Use the Automatic

Locking Mode anytime a child safety

seat is installed in a seating position

that has a belt with this feature. Chil-

dren 12 years old and under should

always be properly restrained in the

rear seat.How To Engage The Automatic

Locking Mode

1. Buckle the combination lap and

shoulder belt.

2. Grasp the shoulder portion and

pull downward until the entire belt is

extracted.

3. Allow the belt to retract. As the

belt retracts, you will hear a clicking

sound. This indicates the safety belt is

now in the Automatic Locking Mode.

How To Disengage The Automatic

Locking Mode

Unbuckle the combination lap/

shoulder belt and allow it to retract

completely to disengage the Auto-

matic Locking Mode and activate the

vehicle sensitive (emergency) locking

mode.

26

Page 50 of 233

WARNING!Improper installation of a child re-

straint to the ISOFIX anchorages can

lead to failure of an infant or child

restraint. The child could be badly

injured or killed. Follow the manu-

facturer's directions exactly when in-

stalling an infant or child restraint.Installing Child Restraints Using

The Vehicle Seat Belts

The seat belts in the rear passenger

seating positions are equipped with

an Automatic Locking Retractor

(ALR) to secure a Child Restraint

System (CRS). These types of seat

belts are designed to keep the lap por-

tion of the seat belt tight around the

child restraint so that it is not neces-

sary to use a locking clip. The ALR

will make a ratcheting noise if you

extract the entire belt from the retrac-

tor and then allow the belt to retract

into the retractor. For additional in-

formation on ALR, refer to “Auto-

matic Locking Mode”. The chart be-

low defines the seating positions with

an Automatic Locking Retractor

(ALR) or a cinching latch plate.

Driver Center Passen-ger

First

Row N/A N/A N/A

Second Row ALR N/A ALR

N/A — Not Applicable

ALR — Automatic Locking Retrac- tor

Installing a Child Restraint with an

ALR:

1. To install a child restraint with

ALR, first, pull enough of the seat belt

webbing from the retractor to route it

through the belt path of the child re-

straint. Slide the latch plate into the

buckle until you hear a “click.” Next,

extract all the seat belt webbing out of

the retractor and then allow the belt to

retract into the retractor. As the belt

retracts, you will hear a ratcheting

sound. This indicates the safety belt is

now in the Automatic Locking mode.

2.

Finally, pull on any excess webbing

to tighten the lap portion around the

child restraint. Any seat belt system will

loosen with time, so check the belt oc-

casionally, and pull it tight if necessary.

In the rear seat, you may have trouble tightening the lap/shoulder

belt on the child restraint because

the buckle or latch plate is too close

to the belt path opening on the re-

straint. Disconnect the latch plate

from the buckle and twist the short

buckle-end belt several times to

shorten it. Insert the latch plate into

the buckle with the release button

facing out.

If the belt still can’t be tightened, or if pulling and pushing on the re-

straint loosens the belt, disconnect

the latch plate from the buckle,

turn the buckle around, and insert

the latch plate into the buckle

again. If you still can’t make the

child restraint secure, try a differ-

ent seating position.

To attach a child restraint tether

strap:

1. If lowered, raise the convertible

top.

NOTE:

The convertible top must be in the

UP position to access the tether

anchor.

43

Page 120 of 233

bel. (If your vehicle has tires of a

different size than the size indicated

on the vehicle placard or tire inflation

pressure label, you should determine

the proper tire inflation pressure for

those tires.)

As an added safety feature, your ve-

hicle has been equipped with a Tire

Pressure Monitoring System (TPMS)

that illuminates a low tire pressure

telltale when one or more of your tires

is significantly under-inflated. Ac-

cordingly, when the low tire pressure

telltale illuminates, you should stop

and check your tires as soon as pos-

sible, and inflate them to the proper

pressure. Driving on a significantly

under-inflated tire causes the tire to

overheat and can lead to tire failure.

Under-inflation also reduces fuel effi-

ciency and tire tread life, and may

affect the vehicle’s handling and stop-

ping ability.Please note that the TPMS is not a

substitute for proper tire maintenance,

and it is the driver’s responsibility to

maintain correct tire pressure, even if

under-inflation has not reached thelevel to trigger illumination of the

TPMS low tire pressure telltale.

Your vehicle has also been equipped

with a TPMS malfunction indicator to

indicate when the system is not oper-

ating properly. The TPMS malfunc-

tion indicator is combined with the

low tire pressure telltale. When the

system detects a malfunction, the tell-

tale will flash for approximately one

minute and then remain continuously

illuminated. This sequence will con-

tinue upon subsequent vehicle start-

ups as long as the malfunction exists.

When the malfunction indicator is il-

luminated, the system may not be

able to detect or signal low tire pres-

sure as intended. TPMS malfunctions

may occur for a variety of reasons,

including the installation of replace-

ment or alternate tires or wheels on

the vehicle that prevent the TPMS

from functioning properly. Always

check the TPMS malfunction telltale

after replacing one or more tires or

wheels on your vehicle, to ensure that

the replacement or alternate tires and

wheels allow the TPMS to continue to

function properly.

CAUTION!

The TPMS has been optimized for

the original equipment tires and

wheels. TPMS pressures and warn-

ing have been established for the tire

size equipped on your vehicle. Un-

desirable system operation or sensor

damage may result when using re-

placement equipment that is not of

the same size, type, and/or style.

Aftermarket wheels can cause sensor

damage. Do not use tire sealant from

a can or balance beads if your ve-

hicle is equipped with a TPMS, as

damage to the sensors may result.

26. Malfunction Indicator Light

(MIL) The Malfunction Indicator

Light (MIL) is part of an on-

board diagnostic system

called OBD that monitors

emissions, engine, and automatic

transmission control systems. The

light will illuminate when the key is in

the ON/RUN position before engine

start. If the bulb does not come on

when turning the key from LOCK to

ON/RUN, have the condition checked

promptly.

113

Page 154 of 233

Brake (ABS) and Electronic Brake

Force Distribution (EBD) Systems are

not functioning. Immediate repair to

the ABS system is required. See your

authorized dealer.

When the vehicle is driven over

11 km/h, you may hear a slight click-

ing sound as well as some related mo-

tor noises. These noises are the system

performing its self-check cycle to en-

sure that the ABS system is working

properly. This self check occurs each

time the vehicle is started and accel-

erated past 11 km/h.

ABS is activated during braking un-

der certain road or stopping condi-

tions. ABS-inducing conditions can

include ice, snow, gravel, bumps, rail-

road tracks, loose debris, or panic

stops.

You also may experience the following

when the brake system goes into anti-

lock:

The ABS motor running (it maycontinue to run for a short time

after the stop),

the clicking sound of solenoid valves, brake pedal pulsations,

and a slight drop or fall away of the

brake pedal at the end of the stop.

These are all normal characteristics of

ABS.

WARNING!

The Anti-Lock Brake System con-

tains sophisticated electronic equip-

ment that may be susceptible to in-

terference caused by improperly

installed or high output radio trans-

mitting equipment. This interfer-

ence can cause possible loss of anti-

lock braking capability. Installation

of such equipment should be per-

formed by qualified professionals.

All vehicle wheels and tires must be

the same size and type, and tires must

be properly inflated to produce accu-

rate signals for the computer. ELECTRONIC BRAKE

CONTROL SYSTEM

Your vehicle may be equipped with an

optional advanced electronic brake

control system that includes Anti-

Lock Brake System (ABS), Traction

Control System (TCS), Brake Assist

System (BAS), and Electronic Stabil-

ity Control (ESC). All systems work

together to enhance vehicle stability

and control in various driving condi-

tions and are commonly referred to as

ESC.

ANTI-LOCK BRAKE

SYSTEM (ABS)

This system aids the driver in main-

taining vehicle control under adverse

braking conditions. The system con-

trols hydraulic brake pressure to pre-

vent wheel lock-up and help avoid

skidding on slippery surfaces during

braking. Refer to “Anti-Lock Brake

System” in “Starting and Operating”

for further information.

147

Page 159 of 233

The pressure should be checked and

adjusted as well as inspecting for signs

of tire wear or visible damage at least

once a month. Use a good quality

pocket-type gauge to check tire pres-

sure. Do not make a visual judgement

when determining proper inflation.

Radial tires may look properly in-

flated even when they are under-

inflated.CAUTION!

After inspecting or adjusting the tire

pressure, always reinstall the valve

stem cap. This will prevent moisture

and dirt from entering the valve

stem, which could damage the valve

stem.

Inflation pressures specified on the

placard are always “cold tire inflation

pressure.” Cold tire inflation pressure

is defined as the tire pressure after the

vehicle has not been driven for at least

three hours, or driven less than

1.6 km after a three hour period. The

cold tire inflation pressure must not

exceed the maximum inflation pres-

sure molded into the tire sidewall. Check tire pressures more often if

subject to a wide range of outdoor

temperatures, as tire pressures vary

with temperature changes.

Tire pressures change by approxi-

mately 7 kPa per 7°C of air tempera-

ture change. Keep this in mind when

checking tire pressure inside a garage,

especially in the winter.

Example: If garage temperature =

20°C and the outside temperature =

0°C then the cold tire inflation pres-

sure should be increased by 21 kPa,

which equals 7 kPa for every 7°C for

this outside temperature condition.

Tire pressure may increase from 13 to

40 kPa during operation. DO NOT

reduce this normal pressure build up

or your tire pressure will be too low.

Tire Pressures For High Speed

Operation

The manufacturer advocates driving

at safe speeds within posted speed

limits. Where speed limits or condi-

tions are such that the vehicle can be

driven at high speeds, maintaining

correct tire inflation pressure is very

important. Increased tire pressureand reduced vehicle loading may be

required for high-speed vehicle op-

eration. Refer to original equipment

or an authorized tire dealer for recom-

mended safe operating speeds, load-

ing and cold tire inflation pressures.

WARNING!

High speed driving with your vehicle

under maximum load is dangerous.

The added strain on your tires could

cause them to fail. You could have a

serious collision. Do not drive a ve-

hicle loaded to the maximum capac-

ity at continuous speeds above

120 km/h.

RADIAL-PLY TIRESWARNING!

Combining radial ply tires with

other types of tires on your vehicle

will cause your vehicle to handle

poorly. The instability could cause a

collision. Always use radial ply tires

in sets of four. Never combine them

with other types of tires.

152

Page 162 of 233

CAUTION!

To avoid damage to your vehicle or

tires, observe the following precau-

tions:

Because of restricted chain clear-ance between tires and other sus-

pension components, it is impor-

tant that only chains in good

condition are used. Broken chains

can cause serious damage. Stop

the vehicle immediately if noise

occurs that could indicate chain

breakage. Remove the damaged

parts of the chain before further

use.

Do not exceed 70 km/h.

Drive cautiously and avoid severe

turns and large bumps, especially

with a loaded vehicle.

Install chains on the front wheels

as tightly as possible and then re-

tighten after driving about

0.8 km.

Do not drive for prolonged periods

of time on dry pavement.

(Continued)

CAUTION!(Continued)

Observe the tire chain manufac-

tur er's instructions on the method

of installation, operating speed,

and conditions for use. Always use

the lower suggested operating

speed of the chain manufacturer,

if different from the speed r ecom-

mended by the vehicle manufac-

turer.

This notice applies to all chain trac-

tion devices, including link and cable

(radial) chains.

TIRE ROTATION

RECOMMENDATIONS

Tires on the front and rear axles of

vehicles operate at different loads and

perform different steering, driving,

and braking functions. For these rea-

sons, they wear at unequal rates.

These effects can be reduced by

timely rotation of tires. The benefits

of rotation are especially worthwhile

with aggressive tread designs such as

those on all season type tires. Rotation

will increase tread life, help to main- tain mud, snow and wet traction lev-

els, and contribute to a smooth, quiet

ride.

Refer to the “Maintenance Schedule”

for the proper maintenance intervals.

The reasons for any rapid or unusual

wear should be corrected prior to ro-

tation being performed.

TIRE PRESSURE

MONITOR SYSTEM

(TPMS)

The Tire Pressure Monitor System

(TPMS) will warn the driver of a low

tire pressure based on the vehicle rec-

ommended cold placard pressure.

The tire pressure will vary with tem-

perature by about 7 kPa for every

7°C. This means that when the out-

side temperature decreases, the tire

pressure will decrease. Tire pressure

should always be set based on cold

inflation tire pressure. This is defined

as the tire pressure after the vehicle

has not been driven for at least three

hours, or driven less than 1.6 km after

a three hour period. The cold tire in-

flation pressure must not exceed the

maximum inflation pressure molded

155

Page 163 of 233

into the tire sidewall. Refer to “Tires –

General Information” in “Starting

and Operating” for information on

how to properly inflate the vehicle’s

tires. The tire pressure will also in-

crease as the vehicle is driven - this is

normal and there should be no adjust-

ment for this increased pressure.

The TPM System will warn the driver

of a low tire pressure if the tire pres-

sure falls below the low-pressure

warning limit for any reason, includ-

ing low temperature effects and natu-

ral pressure loss through the tire.

The TPM System will continue to

warn the driver of low tire pressure as

long as the condition exists, and will

not turn off until the tire pressure is at

or above the recommended cold plac-

ard pressure. Once the low tire pres-

sure warning (Tire Pressure Monitor-

ing Telltale Light) illuminates, you

must increase the tire pressure to the

recommended cold placard pressure

in order for the “Tire Pressure Moni-

toring Telltale Light” to turn off. The

system will automatically update and

the “Tire Pressure Monitoring Telltale

Light” will turn off once the systemreceives the updated tire pressures.

The vehicle may need to be driven for

up to 20 minutes above 24 km/h in

order for the TPMS to receive this

information.

For example, your vehicle may have a

recommended cold (parked for more

than three hours) placard pressure of

207 kPa. If the ambient temperature

is 20°C and the measured tire pres-

sure is 186 kPa, a temperature drop to

7°C will decrease the tire pressure to

approximately 158 kPa. This tire

pressure is sufficiently low enough to

turn ON the “Tire Pressure Monitor-

ing Telltale Light.” Driving the ve-

hicle may cause the tire pressure to

rise to approximately 186 kPa, but

the “Tire Pressure Monitoring Telltale

Light” will still be ON. In this situa-

tion, the “Tire Pressure Monitoring

Telltale Light” will turn OFF only

after the tires are inflated to the vehi-

cle’s recommended cold placard pres-

sure value.

CAUTION!

The TPMS has been optimized for

the original equipment tires and

wheels. TPMS pressures and

warning have been established for

the tire size equipped on your ve-

hicle. Undesirable system opera-

tion or sensor damage may result

when using replacement equip-

ment that is not of the same size,

type, and/or style. Aftermarket

wheels can cause sensor damage.

Do not use aftermarket tire seal-

ants or balance beads if your ve-

hicle is equipped with a TPMS, as

damage to the sensors may result.

After inspecting or adjusting the

tire pressure, always reinstall the

valve stem cap. This will prevent

moisture and dirt from entering

the valve stem, which could dam-

age the Tire Pressure Monitoring

Sensor.

156

Page 169 of 233

Gross Vehicle Weight Rating(GVWR)

Gross Axle Weight Rating (GAWR) front

Gross Axle Weight Rating (GAWR) rear

Vehicle Identification Number (VIN)

Type of Vehicle

Month Day and Hour of Manufac- ture (MDH)

The bar code allows a computer scan-

ner to read the Vehicle Identification

Number (VIN).

GROSS VEHICLE WEIGHT

RATING (GVWR)

The GVWR is the total allowable

weight of your vehicle. This includes

driver, passengers, and cargo. The to-

tal load must be limited so that you do

not exceed the GVWR.

GROSS AXLE WEIGHT

RATING (GAWR)

The GAWR is the maximum capacity

of the front and rear axles. Distribute

the load over the front and rear axles evenly. Make sure that you do not

exceed either front or rear GAWR.

WARNING!

Because the front wheels steer the

vehicle, it is important that you do

not exceed the maximum front or

rear GAWR. A dangerous driving

condition can result if either rating is

exceeded. You could lose control of

the vehicle and have a collision.

OVERLOADING

The load carrying components (axle,

springs, tires, wheels, etc.) of your

vehicle will provide satisfactory ser-

vice as long as you do not exceed the

GVWR and front and rear GAWR.

The best way to figure out the total

weight of your vehicle is to weigh it

when it is fully loaded and ready for

operation. Weigh it on a commercial

scale to ensure that it is not over the

GVWR.

Figure out the weight on the front and

rear of the vehicle separately. It is

important that you distribute the load

evenly over the front and rear axles. Overloading can cause potential

safety hazards and shorten useful ser-

vice life. Heavier axles or suspension

components do not necessarily in-

crease the

vehicle's GVWR.

LOADING

To load your vehicle properly, first

figure out its empty weight, axle by

axle and side by side. Store heavier

items down low and be sure you dis-

tribute their weight as evenly as pos-

sible. Stow all loose items securely

before driving. If weighing the loaded

vehicle shows that you have exceeded

either GAWR, but the total load is

within the specified GVWR, you must

redistribute the weight. Improper

weight distribution can have an ad-

verse effect on the way your vehicle

steers and handles and the way the

brakes operate.

TRAILER TOWING

Trailer towing with this vehicle is not

recommended.

162

Page 206 of 233

Immediate removal of any contami-

nant is recommended. Regular wash-

ing of the top will enhance its life and

appearance, and make successive

cleanings easier. Do not subject the

top to excessive heat. Frequently

vacuum the top and storage compart-

ment.

Washing

Hand washing is highly recom-

mended. Automatic car washing

equipment can damage the top mate-

rial. If you must use an automatic car

wash, soft cloth systems are preferred.CAUTION!

Avoid high-pressure car washes, as

they can damage the top material.

Also, increased water pressure may

force water past the weather strips.

General Cleaning

Careful vacuuming of the top before

washing is helpful in removing dust

and other foreign particles. Wash in

partial shade instead of direct sun.

Wet the entire vehicle before washing

the top. The top should be washed

with a soft, natural bristle scrub brush, and a mild soap solution such

as liquid dishwashing soap. Do not

use detergent.

CAUTION!

Never use an abrasive type cleaner

or bleaches. Cleaners should not

contain silicones, organic solvents,

petroleum distillates, or plasticizers.

Always wait until the top is thor-

oughly dry before lowering it into

the storage area.

Scrub in all directions, covering an

area of about two square feet at a

time. Avoid heavy scrubbing. Rinse

the entire vehicle with water to re-

move all soap and dirt from the top

fabric and to prevent streaking on

painted and chrome surfaces. Allow

the top to dry before lowering. Vacu-

uming the top with a wet/dry shop

vacuum will decrease the top's drying

time, ensure removal of all dirt, and

delete streaks in the material. Mul-

tiple cleanings may be necessary to

remove stubborn stains. If stains per-

sist, contact your local dealership for

further suggestions. Additional Cleaning Procedure

For additional cleaning assistance in

removing stubborn stains, apply ap-

propriate cleaners to the complete

stain, extending 50 mm beyond the

stain. With a soft bristle brush, scrub

in all directions over the stain. Avoid

heavy scrubbing. Rinse the area with

warm water. If the stain is still appar-

ent, repeat the cleaning procedure.

When the stain is no longer showing,

rinse the complete top with warm wa-

ter. Let the top dry before lowering it.

Protection

For appearance purposes, you may

wish to protect your cloth top periodi-

cally. A fabric protectant is suggested.

The top should be clean and dry be-

fore application of the protectant.

CAUTION!

Avoid getting the fabric protectant

on the surrounding weather strips,

moldings, paint, or glass. Damage to

these items might occur.

199

Page 223 of 233

About Your Brakes . . . . . . . . . 145

ABS

(Anti-Lock Brake System) . . . 146

Adding Engine Coolant

(Antifreeze) . . . . . . . . . . . . . . 191

Adding Washer Fluid . . . . . . . 188

Additives, Fuel . . . . . . . . . . . 160

Air Cleaner, Engine

(Engine Air Cleaner Filter) . . . 184

Air Conditioner

Maintenance . . . . . . . . . . . . . 186

Air Conditioning Filter . . . 128,186

Air Conditioning Refrigerant . . 186

Air Conditioning

System . . . . . . . . . . . . . . 124,186

Air Conditioning, Operating

Tips . . . . . . . . . . . . . . . . . . . 129

Air Pressure, Tires . . . . . . . . . 151

Airbag . . . . . . . . . . . . . . . . . . 30

Airbag Deployment . . . . . . . . . 34

Airbag Light . . . . 32,33,36,46,108

Airbag Maintenance . . . . . . . . . 35

Airbag, Side . . . . . . . . . . 31,32,33

Airbag, Window

(Side Curtain) . . . . . . . . . . . . . 32

Alarm (Security Alarm) . . . . . . 14

Alarm System

(Security Alarm) . . . . . . . . 14,112Alterations/Modifications,

Vehicle . . . . . . . . . . . . . . . . . . . 7

Anti-Lock Brake System

(ABS) . . . . . . . . . . . . . . . . . . 146

Anti-Lock Warning Light . . . . 146

Anti-Theft Security Alarm

(Theft Alarm) . . . . . . . . . . . . . 14

Antifreeze

(Engine Coolant) . . . . . . . 191,206

Disposal . . . . . . . . . . . . . . 192

Appearance Care . . . . . . . . . . 196

Ashtray . . . . . . . . . . . . . . . . . 100

Auto Down Power Windows . . . 19

Auto Unlock, Doors . . . . . . . . . 18

Automatic Door Locks . . . . . . . 18

Automatic Headlights . . . . . . . 91

Automatic Oil Change

Indicator . . . . . . . . . . . . 110,117

Automatic Temperature

Control (ATC) . . . . . . . . . . . . 124

Automatic Transaxle . . . . . 12,134 Adding Fluid . . . . . . . . . . . 207

Selection Of Lubricant . . . . 207

Automatic Transmission . . 135,194 Adding Fluid . . . . . . . . . . . 195

Fluid and Filter Changes . . . 195

Fluid Level Check . . . . . . . 195

Fluid Type . . . . . . . . . . . . . 195

Gear Ranges . . . . . . . . . . . 137 Special Additives . . . . . . . . 195

Autostick . . . . . . . . . . . . . . . 141

Battery . . . . . . . . . . . . . . . . . 185

Keyless Transmitter

Replacement (RKE) . . . . . . . 17

Location . . . . . . . . . . . . . . 185

Belts, Seat . . . . . . . . . . . . . 23,45

Body Mechanism

Lubrication . . . . . . . . . . . . . . 187

Brake Assist System . . . . . . . . 148

Brake Fluid . . . . . . . . . . . . . . 207

Brake System . . . . . . . . . . . . 193 Anti-Lock (ABS) . . . . . . . . 146

Fluid Check . . . . . . . . 194,207

Master Cylinder . . . . . . . . . 194

Parking . . . . . . . . . . . . . . . 145

Warning Light . . . . . . . . . . 108

Brake, Parking . . . . . . . . . . . 145

Brake/Transmission

Interlock . . . . . . . . . . . . . . . . 136

Brakes . . . . . . . . . . . . . . . . . 193

Break-In Recommendations,

New Vehicle . . . . . . . . . . . . . . 44

Bulb Replacement . . . . . . . . . 203

Bulbs, Light . . . . . . . . . . . 47,203

Calibration, Compass . . . . . . . 118

216