gearbox Lancia Musa 2009 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2009, Model line: Musa, Model: Lancia Musa 2009Pages: 218, PDF Size: 3.7 MB

Page 114 of 218

113

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICALSPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

STARTING

AND

DRIVING

STARTING AND DRIVING

ENGINE STARTING ......................................... 114

PARKING THE CAR ......................................... 116

USING THE MECHANICAL GEARBOX............117

CONTAINING RUNNING COSTS ..................... 118

TOWING TRAILERS ........................................ 119

SNOW TYRES .................................................. 122

SNOW CHAINS ................................................ 123

CAR INACTIVITY ............................................ 124

113-124 MUSA 1ed GB 10-07-2008 9:37 Pagina 113

Page 118 of 218

117

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICALSPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

STARTING

AND

DRIVING

USING THE

MECHANICAL

GEARBOX

To engage the gears, press the clutch

pedal fully and shift the gear lever

into one of the required positions (the

diagram is shown on the knob).

IMPORTANT Reverse may only be

engaged when the car is at a stand-

still. With the engine running, wait for

at least 2 seconds with the clutch

pedal fully pressed before engaging

reverse to prevent damage to the gears

and grating.

To engage sixth gear (where pro-

vided), operate the lever by pressing

it towards the right in order to avoid

engaging fourth gear by mistake. The

same applies when shifting from sixth

to fifth gear.

To engage reverse Rfrom neutral, lift

the sliding collar A-fig. 2-3 under the

knob while shifting the lever towards

the right and then backwards (only

for petrol versions).

For Multijet versions, only shift the

lever towards the right and then back-

wards.

fig. 2L0D0150m

fig. 3L0D0360m

Do not drive with the hand

resting on the gear lever, be-

cause this pressure, even if

light, over time can wear

gear inner components.

Press the clutch pedal fully

to change gears correctly.

For this reason, there must be no

obstacles on the floor under the ped-

als: ensure that rubber mats (if any)

are correctly positioned, not inter-

fering with the pedals.

WARNING

113-124 MUSA 1ed GB 10-07-2008 9:37 Pagina 117

Page 138 of 218

WARNING

137

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICALSPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

STARTING

AND

DRIVING

IN AN

EMERGENCY

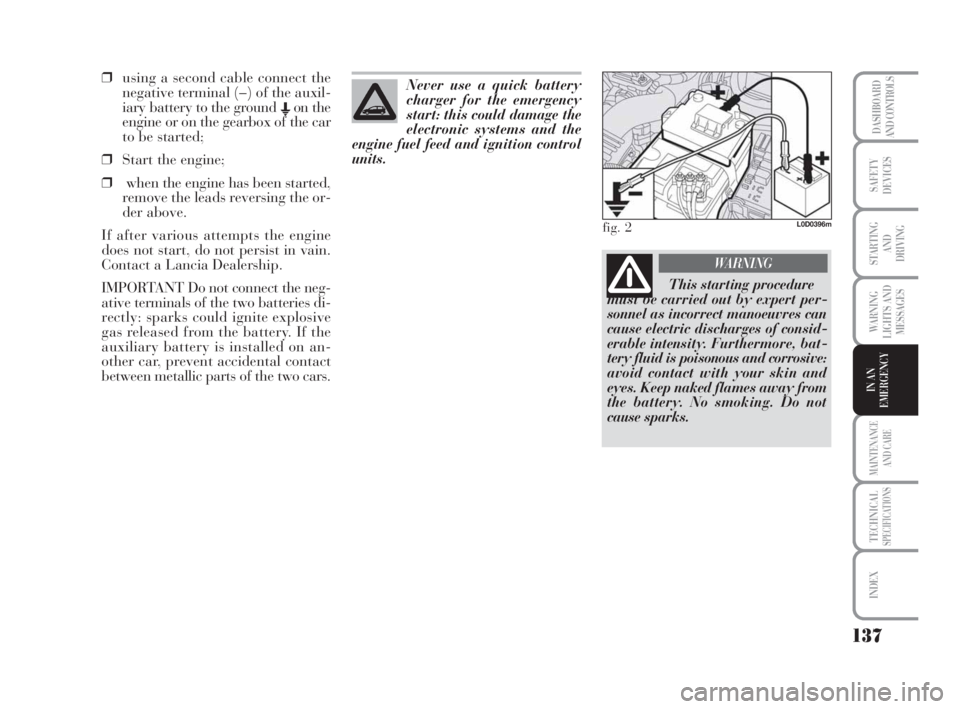

❒using a second cable connect the

negative terminal (–) of the auxil-

iary battery to the ground E

on the

engine or on the gearbox of the car

to be started;

❒Start the engine;

❒when the engine has been started,

remove the leads reversing the or-

der above.

If after various attempts the engine

does not start, do not persist in vain.

Contact a Lancia Dealership.

IMPORTANT Do not connect the neg-

ative terminals of the two batteries di-

rectly: sparks could ignite explosive

gas released from the battery. If the

auxiliary battery is installed on an-

other car, prevent accidental contact

between metallic parts of the two cars.Never use a quick battery

charger for the emergency

start: this could damage the

electronic systems and the

engine fuel feed and ignition control

units.

This starting procedure

must be carried out by expert per-

sonnel as incorrect manoeuvres can

cause electric discharges of consid-

erable intensity. Furthermore, bat-

tery fluid is poisonous and corrosive:

avoid contact with your skin and

eyes. Keep naked flames away from

the battery. No smoking. Do not

cause sparks.

fig. 2L0D0396m

135-164 MUSA 1ed GB 10-07-2008 9:38 Pagina 137

Page 161 of 218

160

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICALSPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

STARTING

AND

DRIVING

IN AN

EMERGENCY

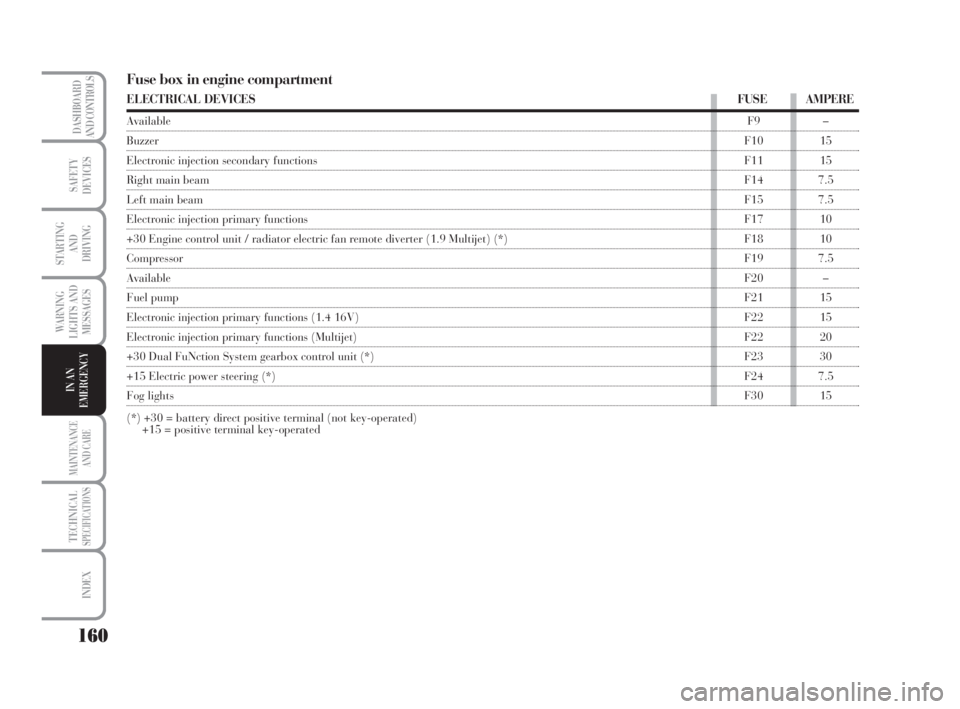

Fuse box in engine compartment

ELECTRICAL DEVICESFUSEAMPERE

AvailableF9 –

BuzzerF10 15

Electronic injection secondary functionsF11 15

Right main beam F14 7.5

Left main beam F15 7.5

Electronic injection primary functionsF17 10

+30 Engine control unit / radiator electric fan remote diverter (1.9 Multijet) (*) F18 10

CompressorF19 7.5

AvailableF20 –

Fuel pump F21 15

Electronic injection primary functions (1.4 16V)F22 15

Electronic injection primary functions (Multijet)F22 20

+30 Dual FuNction System gearbox control unit (*)F23 30

+15 Electric power steering (*)F24 7.5

Fog lightsF30 15

(*) +30 = battery direct positive terminal (not key-operated)

+15 = positive terminal key-operated

135-164 MUSA 1ed GB 10-07-2008 9:38 Pagina 160

Page 164 of 218

163

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICALSPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

STARTING

AND

DRIVING

IN AN

EMERGENCY

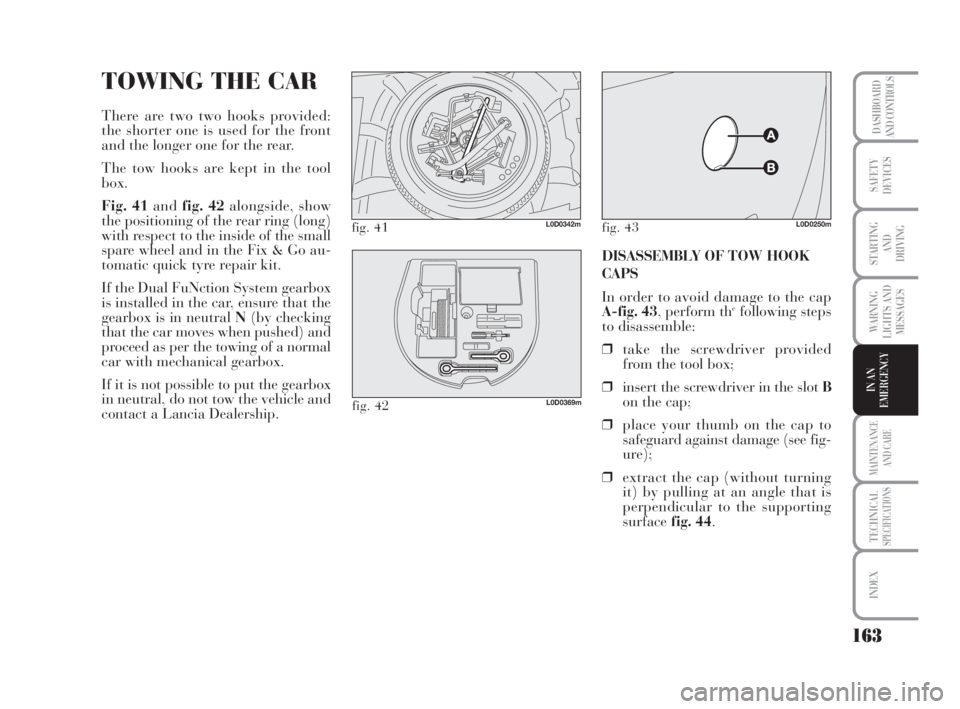

TOWING THE CAR

There are two two hooks provided:

the shorter one is used for the front

and the longer one for the rear.

The tow hooks are kept in the tool

box.

Fig. 41 andfig. 42 alongside, show

the positioning of the rear ring (long)

with respect to the inside of the small

spare wheel and in the Fix & Go au-

tomatic quick tyre repair kit.

If the Dual FuNction System gearbox

is installed in the car, ensure that the

gearbox is in neutral N(by checking

that the car moves when pushed) and

proceed as per the towing of a normal

car with mechanical gearbox.

If it is not possible to put the gearbox

in neutral, do not tow the vehicle and

contact a Lancia Dealership.

fig. 41L0D0342m

fig. 42L0D0369m

DISASSEMBLY OF TOW HOOK

CAPS

In order to avoid damage to the cap

A-fig. 43, perform th

efollowing steps

to disassemble:

❒take the screwdriver provided

from the tool box;

❒insert the screwdriver in the slot B

on the cap;

❒place your thumb on the cap to

safeguard against damage (see fig-

ure);

❒extract the cap (without turning

it) by pulling at an angle that is

perpendicular to the supporting

surfacefig. 44.

fig. 43L0D0250m

135-164 MUSA 1ed GB 10-07-2008 9:38 Pagina 163

Page 170 of 218

169

WARNING

LIGHTS AND

MESSAGES

TECHNICALSPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

STARTING

AND

DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

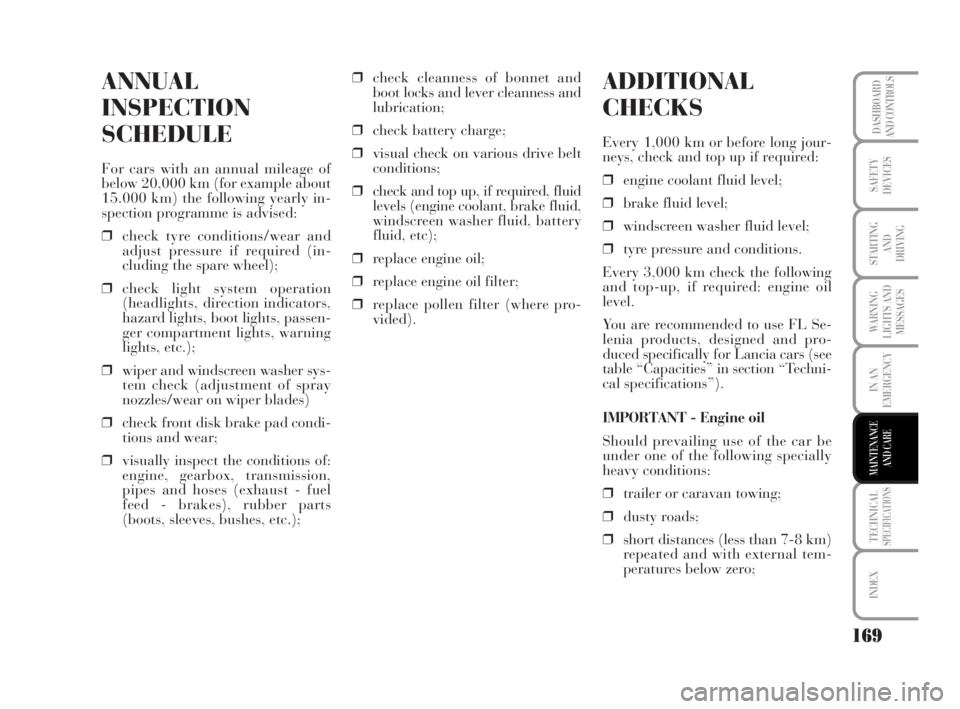

ANNUAL

INSPECTION

SCHEDULE

For cars with an annual mileage of

below 20,000 km (for example about

15.000 km) the following yearly in-

spection programme is advised:

❒check tyre conditions/wear and

adjust pressure if required (in-

cluding the spare wheel);

❒check light system operation

(headlights, direction indicators,

hazard lights, boot lights, passen-

ger compartment lights, warning

lights, etc.);

❒wiper and windscreen washer sys-

tem check (adjustment of spray

nozzles/wear on wiper blades)

❒check front disk brake pad condi-

tions and wear;

❒visually inspect the conditions of:

engine, gearbox, transmission,

pipes and hoses (exhaust - fuel

feed - brakes), rubber parts

(boots, sleeves, bushes, etc.);❒check cleanness of bonnet and

boot locks and lever cleanness and

lubrication;

❒check battery charge;

❒visual check on various drive belt

conditions;

❒check and top up, if required, fluid

levels (engine coolant, brake fluid,

windscreen washer fluid, battery

fluid, etc);

❒replace engine oil;

❒replace engine oil filter;

❒replace pollen filter (where pro-

vided).

ADDITIONAL

CHECKS

Every 1,000 km or before long jour-

neys, check and top up if required:

❒engine coolant fluid level;

❒brake fluid level;

❒windscreen washer fluid level;

❒tyre pressure and conditions.

Every 3,000 km check the following

and top-up, if required: engine oil

level.

You are recommended to use FL Se-

lenia products, designed and pro-

duced specifically for Lancia cars (see

table “Capacities” in section “Techni-

cal specifications”).

IMPORTANT - Engine oil

Should prevailing use of the car be

under one of the following specially

heavy conditions:

❒trailer or caravan towing;

❒dusty roads;

❒short distances (less than 7-8 km)

repeated and with external tem-

peratures below zero;

165-186 MUSA 1ed GB 10-07-2008 9:39 Pagina 169

Page 193 of 218

192

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

STARTING

AND

DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICALSPECIFICATIONS

Modifications or repairs to the fuel feed system that are not carried out properly or do not take the system’s

technical specifications into account can cause malfunctions leading to the risk of fire.

(▲) Engine provided for some versions/markets only

FUEL FEED/IGNITION

Fuel feed/ignition

1.48V(▲)-1.416V

Multipoint phased sequential electronic injection,

integrated with ignition,

returnless system1.3 Multijet - 1.6 Multijet

Electronically controlled Multijet “Common Rail”

direct injection, with turbo

and intercooler

TRANSMISSION

Gearbox

Clutch

Drive1.4

16V

Five or six forward gears plus reverse

with synchronisers for forward gears

Self-adjusting external hydraulic control

with pedal without loadless stroke

Fr

ont

1.48V(▲)-1.3 Multijet - 1.6 Multijet

Five forward gears plus reverse

with synchronisers for forward gears

Self-adjusting external hydraulic control

with pedal without loadless stroke

Fr

ont

187-205 MUSA 1ed GB 10-07-2008 9:40 Pagina 192

Page 200 of 218

199

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

STARTING

AND

DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICALSPECIFICATIONS

PERFORMANCE

With mechanical gearbox

Top speed after initial car use in km/h.

1.48V(▲)1.416V1.3 Multijet 70HP 1.3 Multijet 90HP1.6 Multijet

163 175 159 173 190

(

▲) Engine provided for some versions/markets only

187-205 MUSA 1ed GB 10-07-2008 9:40 Pagina 199

Page 202 of 218

201

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

STARTING

AND

DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICALSPECIFICATIONS

1.6 Multijet

litres

–

–

47

5 - 7

6.0

–

–

2.85

3.0

1.98

0.45

1.5kg

–

–

–

–

–

–

–

2.54

2.65

1.8

–

– 1.416V1.48V(▲)

litres

47

5 - 7

–

–

4.5

2.5

2.7

–

–

1.65

0.45

1.5 litres

47

5 - 7

–

–

4.5

2.4

2.6

–

–

1.65

0.45

1.5kg

–

–

–

–

–

2.2

2.35

–

–

1.5

–

– kg

–

–

–

–

–

2.1

2.25

–

–

1.5

–

–1.3 MultijetSpecified fuels

Original products

Unleaded petrol with no

less than 95 R.O.N.

(EN228 Specification)

Diesel fuel for motor vehicles

(EN590 specifications)

50-50 mixture of demineralised

water and PARAFLU UP

(❐)

SELENIA 20K

SELENIA WR

TUTELA CAR TECHNYX

TUTELA TOP 4

Mixture of water and

TUTELA PROFESSIONAL

SC 35

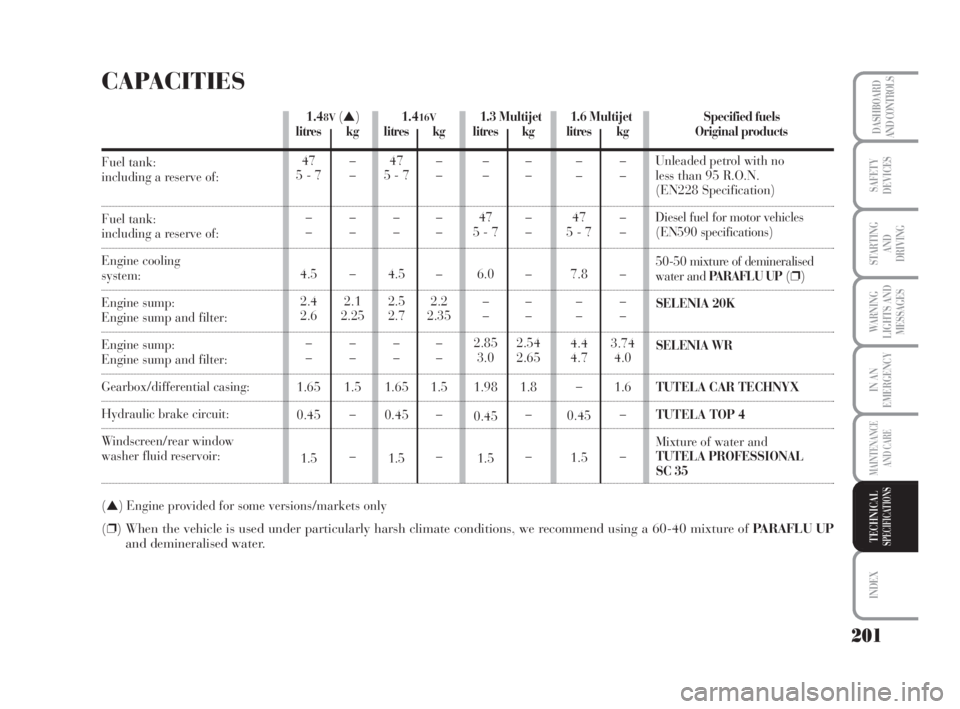

CAPACITIES

Fuel tank:

including a reserve of:

Fuel tank: including a reserve of:

Engine cooling

system:

Engine sump:

Engine sump and filter:

Engine sump:

Engine sump and filter:

Gearbox/differential casing:

Hydraulic brake circuit:

Windscreen/rear window

washer fluid reservoir:

(▲) Engine provided for some versions/markets only

(❐) When the vehicle is used under particularly harsh climate conditions, we recommend using a 60-40 mixture of PARAFLU UP

and demineralised water.

kg

–

–

–

–

–

–

–

3.74

4.0

1.6

–

– litres

–

–

47

5 - 7

7.8

–

–

4.4

4.7

–

0.45

1.5

187-205 MUSA 1ed GB 10-07-2008 9:40 Pagina 201

Page 204 of 218

203

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

STARTING

AND

DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICALSPECIFICATIONS

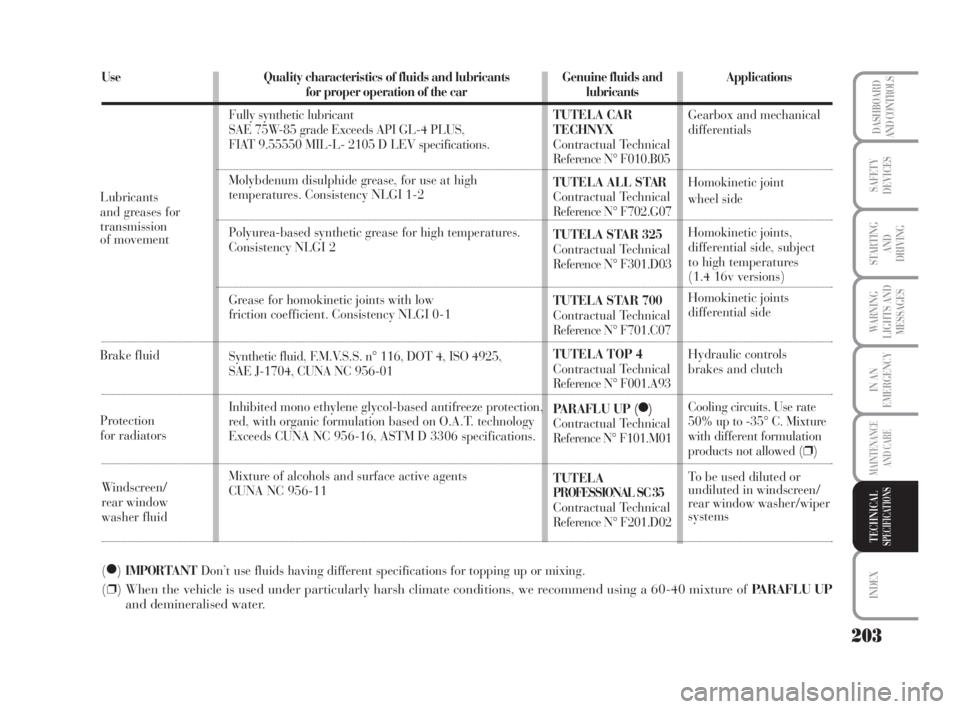

Use

(●)IMPORTA N TDon’t use fluids having different specifications for topping up or mixing.

(❐) When the vehicle is used under particularly harsh climate conditions, we recommend using a 60-40 mixture of PARAFLU UP

and demineralised water.

Quality characteristics of fluids and lubricants

for proper operation of the car

Fully synthetic lubricant

SAE 75W-85 grade Exceeds API GL-4 PLUS,

FIAT 9.55550 MIL-L- 2105 D LEV specifications.

Molybdenum disulphide grease, for use at high

temperatures. Consistency NLGI 1-2

Polyurea-based synthetic grease for high temperatures.

Consistency NLGI 2

Grease for homokinetic joints with low

friction coefficient. Consistency NLGI 0-1

Synthetic fluid, F.M.V.S.S. n° 116, DOT 4, ISO 4925,

SAE J-1704, CUNA NC 956-01

Inhibited mono ethylene glycol-based antifreeze protection,

red, with organic formulation based on O.A.T. technology

Exceeds CUNA NC 956-16, ASTM D 3306 specifications.

Mixture of alcohols and surface active agents

CUNA NC 956-11Genuine fluids and

lubricants

TUTELA CAR

TECHNYX

Contractual Technical

Reference N° F010.B05

TUTELA ALL STAR

Contractual Technical

Reference N° F702.G07

TUTELA STAR 325

Contractual Technical

Reference N° F301.D03

TUTELA STAR 700

Contractual Technical

Reference N° F701.C07

TUTELA TOP 4

Contractual Technical

Reference N° F001.A93

PARAFLU UP (

●)

Contractual Technical

Reference N° F101.M01

TUTELA

PROFESSIONAL SC 35Contractual Technical

Reference N° F201.D02Applications

Gearbox and mechanical

differentials

Homokinetic joint

wheel side

Homokinetic joints,

differential side, subject

to high temperatures

(1.4 16v versions)

Homokinetic joints

differential side

Hydraulic controls

brakes and clutch

Cooling circuits. Use rate

50% up to -35° C. Mixture

with different formulation

products not allowed

(❐)

To be used diluted or

undiluted in windscreen/

rear window washer/wiper

systems Lubricants

and greases for

transmission

of movement

Brake fluid

Protection

for radiators

Windscreen/

rear window

washer fluid

187-205 MUSA 1ed GB 10-07-2008 9:40 Pagina 203