Rear light Lancia Musa 2010 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2010, Model line: Musa, Model: Lancia Musa 2010Pages: 218, PDF Size: 3.71 MB

Page 181 of 218

180

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN

EMERGENZA

MAINTENANCE

AND CARE

❒a tyre will age even if it is not used

much. Cracks in the tread and on

the sidewalls are a sign of ageing.

Have the tyres checked by spe-

cialised personnel if they have been

fitted for longer than 6 years. Re-

member to check the spare wheel

very carefully;

❒In case of replacement, always fit

new tyres, avoiding those with an

unknown origin.

❒If a tyre is replaced, also change the

inflation valve.

❒to allow even wear between the

front and rear tyres, it is advisable

to change them over every 10-15

thousand kilometres, keeping them

on the same side of the car so as not

to reverse the direction of rotation.

Remember that the road

holding qualities of your

car also depends on the correct in-

flation pressure of the tyres.

WARNING

Excessively low pressure

will cause overheating of

the tyre and may cause severe tyre

damage.

WARNING

Do not exchange the tyres

from the left to the right of

the car and vice versa.

WARNING

Do not repaint alloy wheel

rims at temperatures

higher than 150°C. The mechani-

cal features of the wheels could be

compromised.

WARNING

RUBBER HOSES

Carefully follow the information con-

tained in the “Service schedule” in

this section for maintenance of brake

system and fuel feed rubber hoses.

Ozone, high temperatures and pro-

longed lack of fluid in the system may

cause hardening and cracking of the

hoses, with possible leaks. Careful in-

spections are therefore necessary.

Page 182 of 218

181

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

WINDSCREEN/REAR

WINDOW

WIPER/WASHER

BLADES

Periodically clean the rubber part us-

ing special products; TUTELA PRO-

FESSIONAL SC 35is recommended.

Replace the blades if the rubber edge

is deformed or worn. In all cases, it is

advisable to replace them approxi-

mately once a year.

A few simple precautions can reduce

the possibility of damage to the

blades:

❒make sure that the rubber part is

not stuck to the windscreen at sub-

zero temperatures. Use an an-

tifreeze product to release it if re-

quired.

❒remove the snow from the win-

dow: this will avoid overstressing

the electrical motor in addition to

protecting the blades;

❒do not operate the windscreen and

rear window wipers on dry glass.

Driving with worn wiper

blades is a serious hazard,

because visibility is reduced in bad

weather.

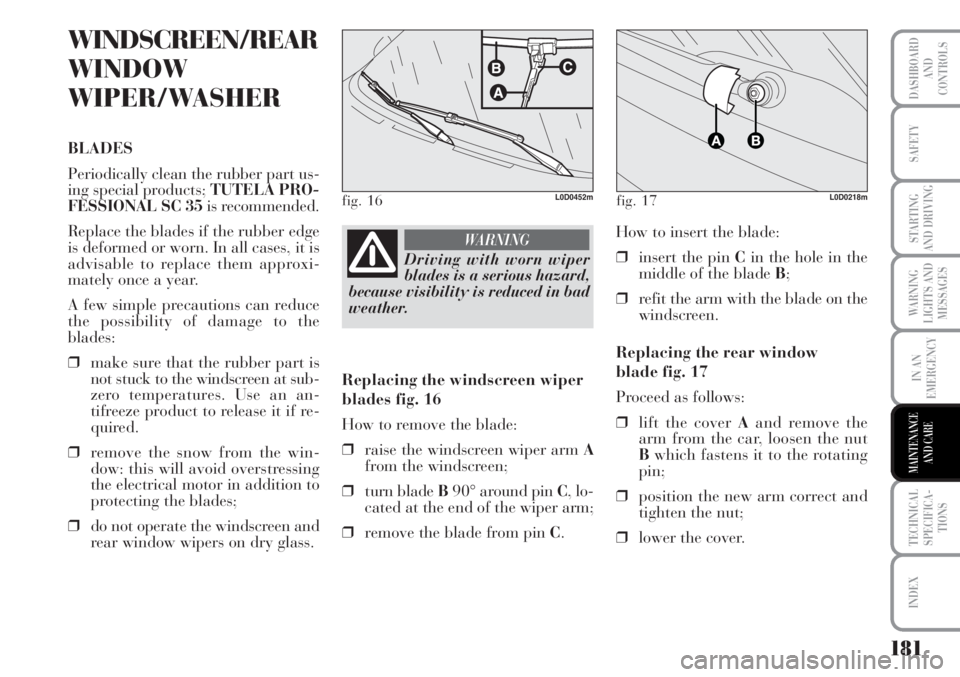

WARNINGHow to insert the blade:

❒insert the pin Cin the hole in the

middle of the blade B;

❒refit the arm with the blade on the

windscreen.

Replacing the rear window

blade fig. 17

Proceed as follows:

❒lift the cover Aand remove the

arm from the car, loosen the nut

Bwhich fastens it to the rotating

pin;

❒position the new arm correct and

tighten the nut;

❒lower the cover.

fig. 16L0D0452mfig. 17L0D0218m

Replacing the windscreen wiper

blades fig. 16

How to remove the blade:

❒raise the windscreen wiper arm A

from the windscreen;

❒turn blade B90° around pin C, lo-

cated at the end of the wiper arm;

❒remove the blade from pin C.

Page 183 of 218

182

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN

EMERGENZA

MAINTENANCE

AND CARE

SPRAY NOZZLES

Windscreen washer fig. 18

If there is no jet of fluid, firstly check

that there is fluid in the reservoir: see

“Checking fluid levels” in this sec-

tion).

Then check that the nozzle holes are

not clogged, if necessary using a nee-

dle.

The front window nozzle do not need

to be adjusted. The liquid is atomised

over a predetermined area of the

windscreen.Rear window washer fig. 19

The rear window nozzle do not need

to be adjusted. The liquid is atomised

over a predetermined area of the rear

window.

The nozzle is arranged on the upper

part of the tailgate.

BODYWORK

PROTECTION FROM

ATMOSPHERIC AGENTS

The main causes of corrosion are the

following:

❒atmospheric pollution;

❒salty air and humidity (coastal ar-

eas, or hot humid climates);

❒seasonal environment conditions.

Not to be underestimated is also the

abrasive action of wind-borne atmos-

pheric dust and sand and mud and

gravel raised by other cars.

On your vehicle, Lancia has imple-

mented the best manufacturing tech-

nologies to effectively protect the

bodywork against corrosion.

fig. 18L0D0219mfig. 19L0D0220m

Page 185 of 218

184

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN

EMERGENZA

MAINTENANCE

AND CARE

To correctly wash the car:

❒remove the aerial from the roof to

prevent damage to it if the car is

washed in an automatic system;

❒wash the body using a low pres-

sure jet of water;

❒wipe a sponge with a slightly soapy

solution over the bodywork, fre-

quently rinsing with the sponge;

❒rinse well with water and dry with

a jet of air or a chamois leather.

Dry the parts less in sight particularly

carefully, such as the door frames and

the headlight frames, where water

may stagnate more easily. It is a good

idea to leave the car in the open for a

while after washing it to give time for

the water to evaporate.

Do not wash the car after it has been

parked in the sun or when the engine

is bonnet is hot: this could take the

shine off the paint.Exterior plastic parts must be cleaned

in the same way as the rest of the car.

Where possible, do not park under

trees; the resinous substance many

species release give the paint a dull

appearance and increase the possibil-

ity of triggering rust processes.

IMPORTANT Bird droppings must be

washed off immediately and thor-

oughly as the acid they contain is par-

ticularly aggressive.Windows

Use specific window cleaner products.

Also use clean cloths to avoid scratch-

ing the glass or damaging the trans-

parency.

IMPORTANT Wipe the rear window

inside gently with a cloth in the di-

rection of the filaments to avoid dam-

aging the heating device.

Front headlights

IMPORTANT Never use aromatic

substances (e.g.: petrol) or ketenes

(e.g.: acetone) for cleaning front

headlight plastic lens.Detergents pollute the envi-

ronment. The vehicle

should be washed in areas

equipped for collecting and

purifying the liquid used in the

washing process.

Page 189 of 218

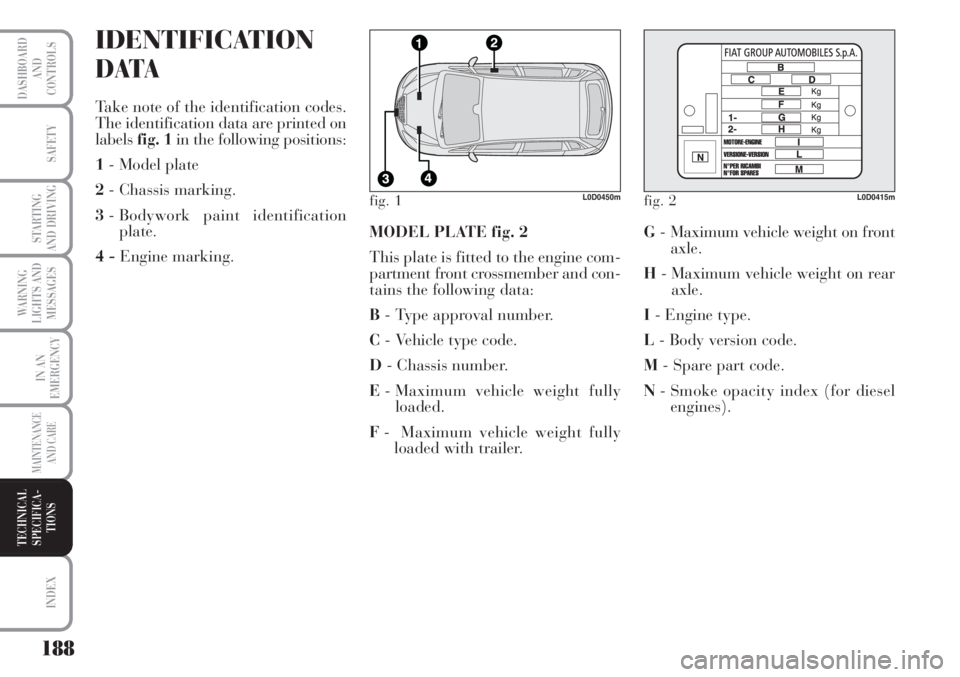

IDENTIFICATION

DATA

Take note of the identification codes.

The identification data are printed on

labelsfig. 1in the following positions:

1- Model plate

2- Chassis marking.

3- Bodywork paint identification

plate.

4 - Engine marking.MODEL PLATE fig. 2

This plate is fitted to the engine com-

partment front crossmember and con-

tains the following data:

B- Type approval number.

C- Vehicle type code.

D- Chassis number.

E- Maximum vehicle weight fully

loaded.

F- Maximum vehicle weight fully

loaded with trailer.G- Maximum vehicle weight on front

axle.

H- Maximum vehicle weight on rear

axle.

I- Engine type.

L- Body version code.

M- Spare part code.

N- Smoke opacity index (for diesel

engines).

fig. 1L0D0450mfig. 2L0D0415m

188

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

Page 194 of 218

BRAKES

Service brakes:

– front

– rear

Parking brake

IMPORTANT Water, ice and salt sprinkled on the roads may deposit on the brake disks reducing braking efficiency the first time the

brakes are applied.

(

▲) Engine version for some versions/markets only 1.4

8V(▲)-1.416V- 1.3 Multijet 70 HP

Self-ventilating discs (257 mm x 22 mm)

Drum (203 mm x 38 mm)

Operated by hand lever, acting on

rear brakes

SUSPENSIONS

Front

Rear

(

▲) Engine version for some versions/markets only 1.4

8V(▲)-1.416V- 1.3 Multijet - 1.6 Multijet

McPherson independent wheels

Semi-independent wheels interconnected by means of torque axle

STEERING SYSTEM

Type

Steering circle

(kerb to kerb) m

(

▲) Engine version for some versions/markets only 1.4

8V(▲)-1.416V- 1.3 Multijet - 1.6 Multijet

Rack and pinion with electric power steering

10,0

1.3 Multijet 90 HP - 1.3 Multijet 95 HP

1.6 Multijet

Self-ventilating discs (284 mm x 22 mm)

1.3 Multijet 90 HP -1.3 Multijet 95 HP: drum

(228 mm x 40 mm)

1.6 Multijet: disc (240 mm x 11 mm)

Operated by hand lever, acting on

rear brakes

193

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

Page 198 of 218

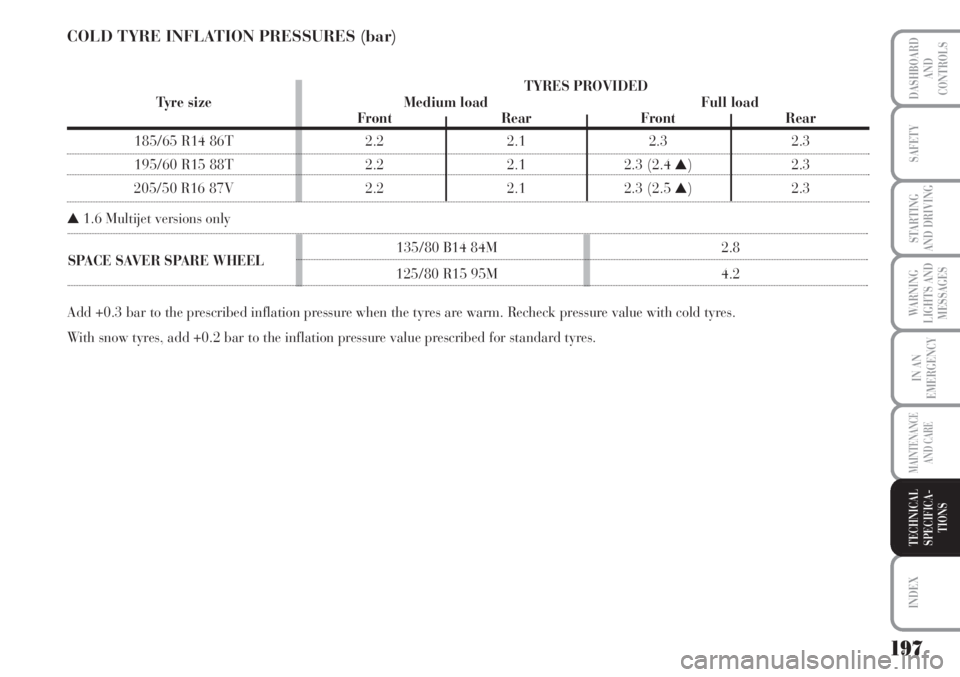

135/80 B14 84M 2.8SPACE SAVER SPARE WHEEL

125/80 R15 95M 4.2

TYRES PROVIDED

Tyre size Medium load Full load

Front Rear Front Rear

Add +0.3 bar to the prescribed inflation pressure when the tyres are warm. Recheck pressure value with cold tyres.

With snow tyres, add +0.2 bar to the inflation pressure value prescribed for standard tyres.

COLD TYRE INFLATION PRESSURES (bar)

185/65 R14 86T 2.2 2.1 2.3 2.3

195/60 R15 88T 2.2 2.1 2.3 (2.4 ▲)2.3

205/50 R16 87V 2.2 2.1 2.3 (2.5 ▲)2.3

▲1.6 Multijet versions only

197

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

Page 201 of 218

1.48V(▲)-1.416V

1155

500

940

805

1655

1000

400

75

601.3 Multijet

1200

500

940

805

1700

1000

400

75

601.6 Multijet

1275

500

1000

805

1775

1100

500

75

60

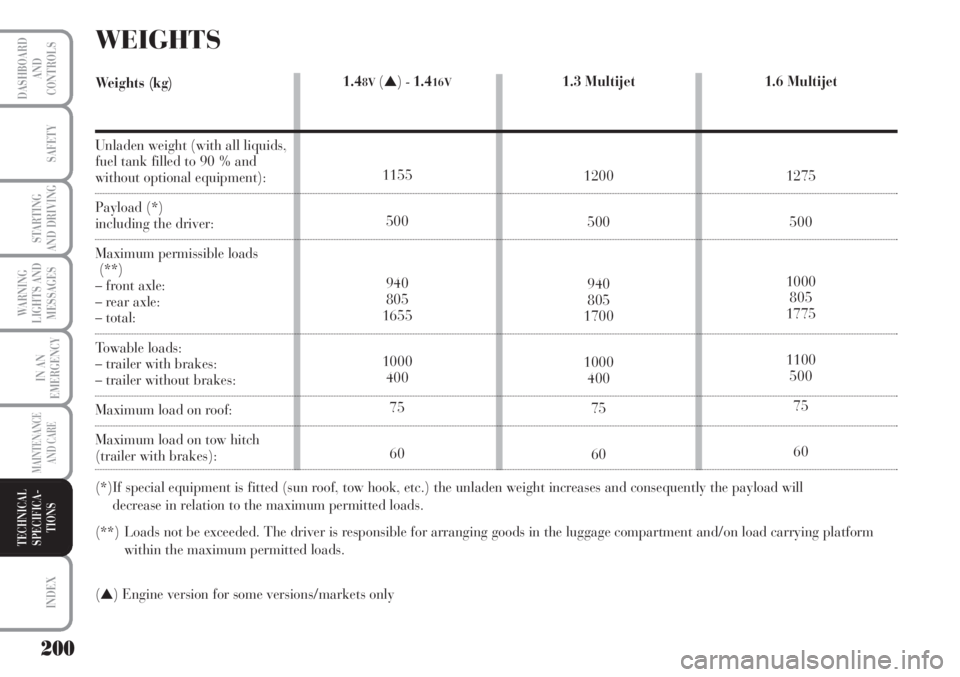

WEIGHTS

Weights (kg)

Unladen weight (with all liquids,

fuel tank filled to 90 % and

without optional equipment):

Payload (*)

including the driver:

Maximum permissible loads

(**)

– front axle:

– rear axle:

– total:

Towable loads:

– trailer with brakes:

– trailer without brakes:

Maximum load on roof:

Maximum load on tow hitch

(trailer with brakes):

(*)If special equipment is fitted (sun roof, tow hook, etc.) the unladen weight increases and consequently the payload will

decrease in relation to the maximum permitted loads.

(**) Loads not be exceeded. The driver is responsible for arranging goods in the luggage compartment and/on load carrying platform

within the maximum permitted loads.

(

▲) Engine version for some versions/markets only

200

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

Page 202 of 218

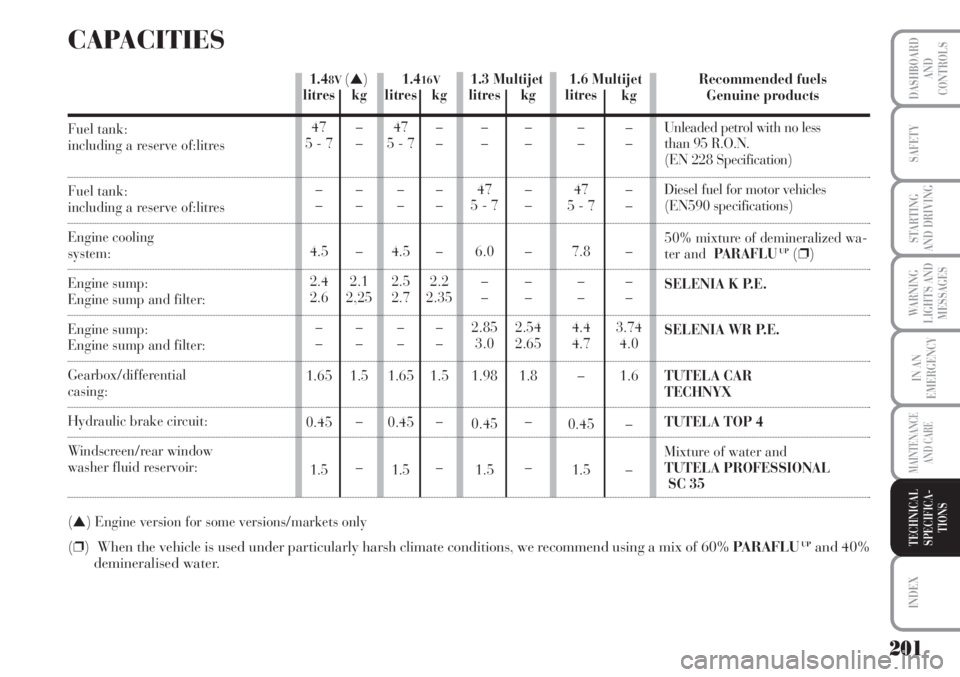

1.6 Multijet 1.416V1.48V(▲)1.3 Multijet

CAPACITIES

Fuel tank:

including a reserve of:litres

Fuel tank: including a reserve of:litres

Engine cooling

system:

Engine sump:

Engine sump and filter:

Engine sump:

Engine sump and filter:

Gearbox/differential

casing:

Hydraulic brake circuit:

Windscreen/rear window

washer fluid reservoir:

(▲) Engine version for some versions/markets only

(❐) When the vehicle is used under particularly harsh climate conditions, we recommend using a mix of 60% PA R A F L UUPand 40%

demineralised water.

kg

–

–

–

–

–

–

–

3.74

4.0

1.6

–

–Recommended fuels

Genuine products

Unleaded petrol with no less

than 95 R.O.N.

(EN 228 Specification)

Diesel fuel for motor vehicles

(EN590 specifications)

50% mixture of demineralized wa-

ter andPARAFLU

UP(❐)

SELENIA K P.E.

SELENIA WR P.E.

TUTELA CAR

TECHNYX

TUTELA TOP 4

Mixture of water and

TUTELA PROFESSIONAL

SC 35 litres

47

5 - 7

–

–

4.5

2.4

2.6

–

–

1.65

0.45

1.5kg

–

–

–

–

–

2.1

2,25

–

–

1.5

–

–litres

47

5 - 7

–

–

4.5

2.5

2.7

–

–

1.65

0.45

1.5kg

–

–

–

–

–

2.2

2.35

–

–

1.5

–

–litres

–

–

47

5 - 7

6.0

–

–

2.85

3.0

1.98

0.45

1.5kg

–

–

–

–

–

–

–

2.54

2.65

1.8

–

–litres

–

–

47

5 - 7

7.8

–

–

4.4

4.7

–

0.45

1.5

201

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

Page 204 of 218

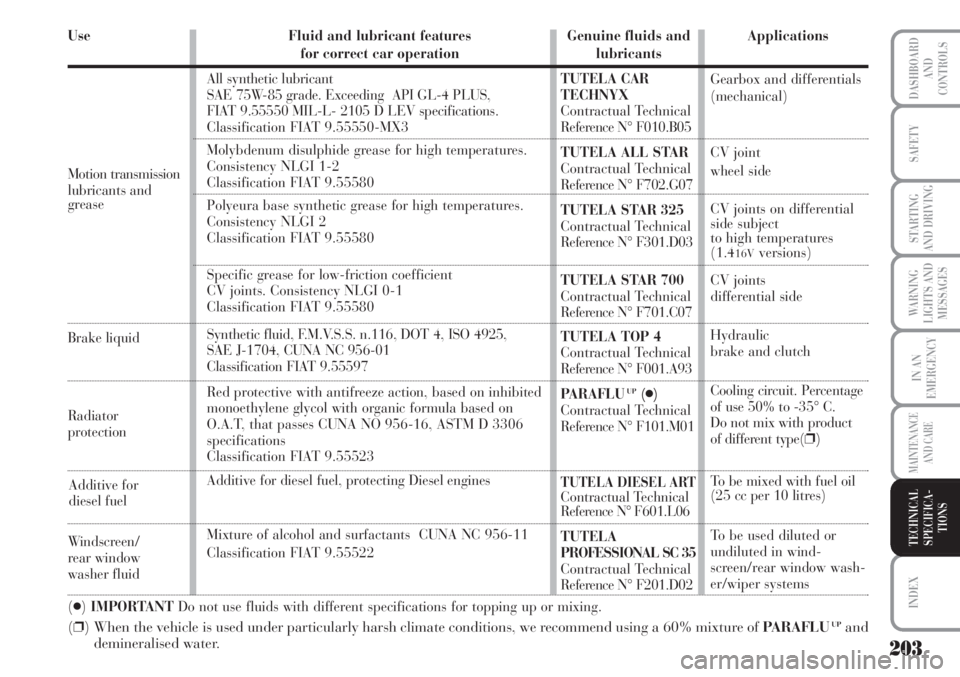

Use

(●)IMPORTANT Do not use fluids with different specifications for topping up or mixing.

(❐) When the vehicle is used under particularly harsh climate conditions, we recommend using a 60% mixture of PARAFLUUPand

demineralised water.

Fluid and lubricant features

for correct car operation

All synthetic lubricant

SAE 75W-85 grade. Exceeding API GL-4 PLUS,

FIAT 9.55550 MIL-L- 2105 D LEV specifications.

Classification FIAT 9.55550-MX3

Molybdenum disulphide grease for high temperatures.

Consistency NLGI 1-2

Classification FIAT 9.55580

Polyeura base synthetic grease for high temperatures.

Consistency NLGI 2

Classification FIAT 9.55580

Specific grease for low-friction coefficient

CV joints. Consistency NLGI 0-1

Classification FIAT 9.55580

Synthetic fluid, F.M.V.S.S. n.116, DOT 4, ISO 4925,

SAE J-1704, CUNA NC 956-01

Classification FIAT 9.55597

Red protective with antifreeze action, based on inhibited

monoethylene glycol with organic formula based on

O.A.T, that passes CUNA NO 956-16, ASTM D 3306

specifications

Classification FIAT 9.55523

Additive for diesel fuel, protecting Diesel engines

Mixture of alcohol and surfactants CUNA NC 956-11

Classification FIAT 9.55522Genuine fluids and

lubricants

TUTELA CAR

TECHNYX

Contractual Technical

Reference N° F010.B05

TUTELA ALL STAR

Contractual Technical

Reference N° F702.G07

TUTELA STAR 325

Contractual Technical

Reference N° F301.D03

TUTELA STAR 700

Contractual Technical

Reference N° F701.C07

TUTELA TOP 4

Contractual Technical

Reference N° F001.A93

PA R A F L U

UP(●)

Contractual Technical

Reference N° F101.M01

TUTELA DIESEL ARTContractual Technical

Reference N° F601.L06

TUTELA

PROFESSIONAL SC 35

Contractual Technical

Reference N° F201.D02Applications

Gearbox and differentials

(mechanical)

CV joint

wheel side

CV joints on differential

side subject

to high temperatures

(1.4

16Vversions)

CV joints

differential side

Hydraulic

brake and clutch

Cooling circuit. Percentage

of use 50% to -35° C.

Do not mix with product

of different type

(❐)

To be mixed with fuel oil

(25 cc per 10 litres)

To be used diluted or

undiluted in wind-

screen/rear window wash-

er/wiper systems Motion transmission

lubricants and

grease

Brake liquid

Radiator

protection

Windscreen/

rear window

washer fluid

203

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

Additive for

diesel fuel