tow Lancia Musa 2011 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2011, Model line: Musa, Model: Lancia Musa 2011Pages: 218, PDF Size: 3.91 MB

Page 140 of 218

139

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

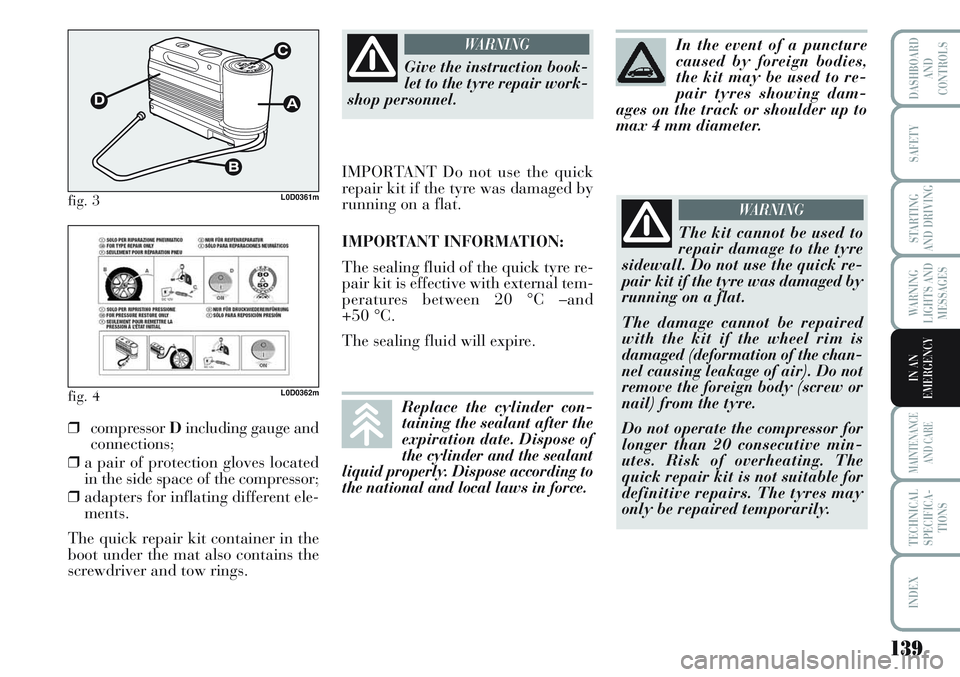

fig. 3L0D0361m

fig. 4L0D0362m

❒compressor Dincluding gauge and

connections;

❒a pair of protection gloves located

in the side space of the compressor;

❒adapters for inflating different ele-

ments.

The quick repair kit container in the

boot under the mat also contains the

screwdriver and tow rings.

Give the instruction book-

let to the tyre repair work-

shop personnel.

WARNING

IMPORTANT Do not use the quick

repair kit if the tyre was damaged by

running on a flat.

IMPORTANT INFORMATION:

The sealing fluid of the quick tyre re-

pair kit is effective with external tem-

peratures between 20 °C –and

+50 °C.

The sealing fluid will expire.

The kit cannot be used to

repair damage to the tyre

sidewall. Do not use the quick re-

pair kit if the tyre was damaged by

running on a flat.

The damage cannot be repaired

with the kit if the wheel rim is

damaged (deformation of the chan-

nel causing leakage of air). Do not

remove the foreign body (screw or

nail) from the tyre.

Do not operate the compressor for

longer than 20 consecutive min-

utes. Risk of overheating. The

quick repair kit is not suitable for

definitive repairs. The tyres may

only be repaired temporarily.

WARNING

In the event of a puncture

caused by foreign bodies,

the kit may be used to re-

pair tyres showing dam-

ages on the track or shoulder up to

max 4 mm diameter.

Replace the cylinder con-

taining the sealant after the

expiration date. Dispose of

the cylinder and the sealant

liquid properly. Dispose according to

the national and local laws in force.

Page 148 of 218

147

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

Versions with alloy rims

❒Check that the hub contact sur-

faces are clean;

❒fit the normal wheel centring it on

the pins, lead in the fastening

screws and tighten them using the

wrench provided;

❒lower the car and remove the jack;

❒using the wrench provided, fully

tighten the bolts in the sequence

shown in fig. 15.

❒snap fit the wheel cup on the hub.When you have finished

❒stow the spare wheel in the space

provided in the boot;

❒fit the jack partially open in its

box forcing it lightly to prevent it

from vibrating when travelling;

❒put the tools back into their places

in the container;

❒arrange the container and tools in

the spare wheel and secure the fas-

tening device;

❒rearrange the preformed boot

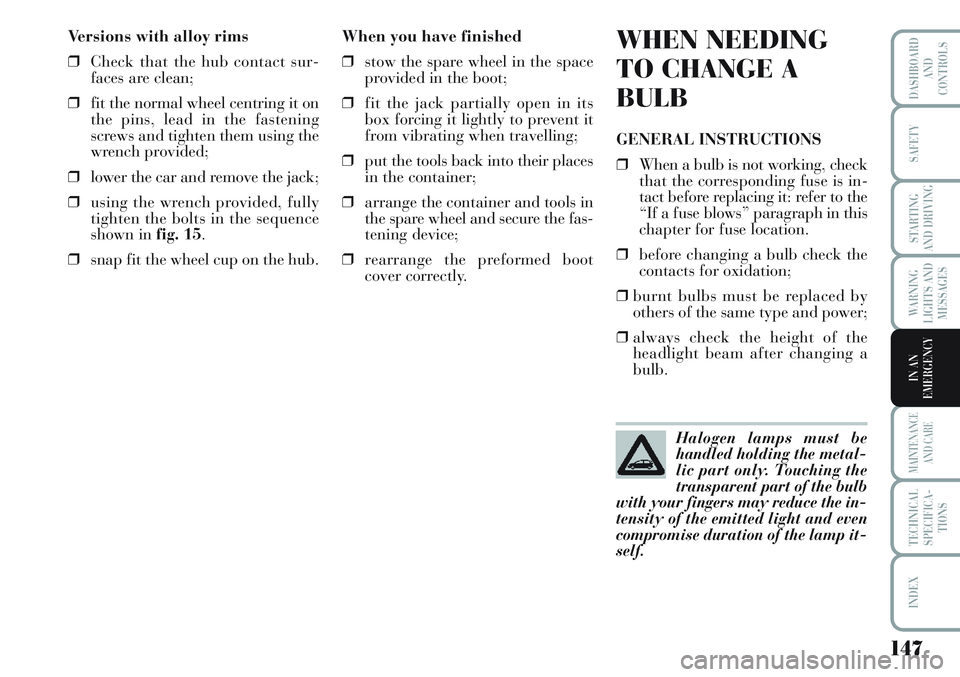

cover correctly. WHEN NEEDING

TO CHANGE A

BULB

GENERAL INSTRUCTIONS

❒When a bulb is not working, check

that the corresponding fuse is in-

tact before replacing it: refer to the

“If a fuse blows” paragraph in this

chapter for fuse location.

❒before changing a bulb check the

contacts for oxidation;

❒burnt bulbs must be replaced by

others of the same type and power;

❒always check the height of the

headlight beam after changing a

bulb.

Halogen lamps must be

handled holding the metal-

lic part only. Touching the

transparent part of the bulb

with your fingers may reduce the in-

tensity of the emitted light and even

compromise duration of the lamp it-

self.

Page 149 of 218

148

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

Modifications or repairs to

the fuel feed system that

are not carried out properly or do

not take the system’s technical

specifications into account can

cause malfunctions leading to the

risk of fire.

WARNING

Halogen bulbs contain

pressurised gas which, if

broken, may cause small frag-

ments of glass to be projected out-

wards.

WARNING

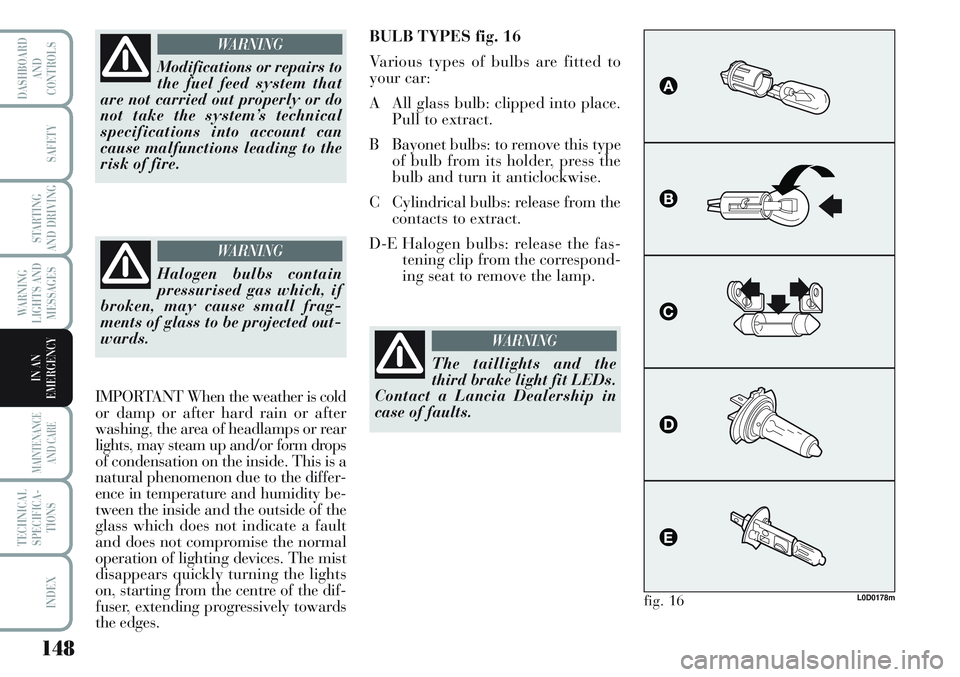

BULB TYPES fig. 16

Various types of bulbs are fitted to

your car:

A All glass bulb: clipped into place.

Pull to extract.

B Bayonet bulbs: to remove this type

of bulb from its holder, press the

bulb and turn it anticlockwise.

C Cylindrical bulbs: release from the

contacts to extract.

D-E Halogen bulbs: release the fas-

tening clip from the correspond-

ing seat to remove the lamp.

L0D0178mfig. 16

The taillights and the

third brake light fit LEDs.

Contact a Lancia Dealership in

case of faults.

WARNING

IMPORTANT When the weather is cold

or damp or after hard rain or after

washing, the area of headlamps or rear

lights, may steam up and/or form drops

of condensation on the inside. This is a

natural phenomenon due to the differ-

ence in temperature and humidity be-

tween the inside and the outside of the

glass which does not indicate a fault

and does not compromise the normal

operation of lighting devices. The mist

disappears quickly turning the lights

on, starting from the centre of the dif-

fuser, extending progressively towards

the edges.

Page 163 of 218

162

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

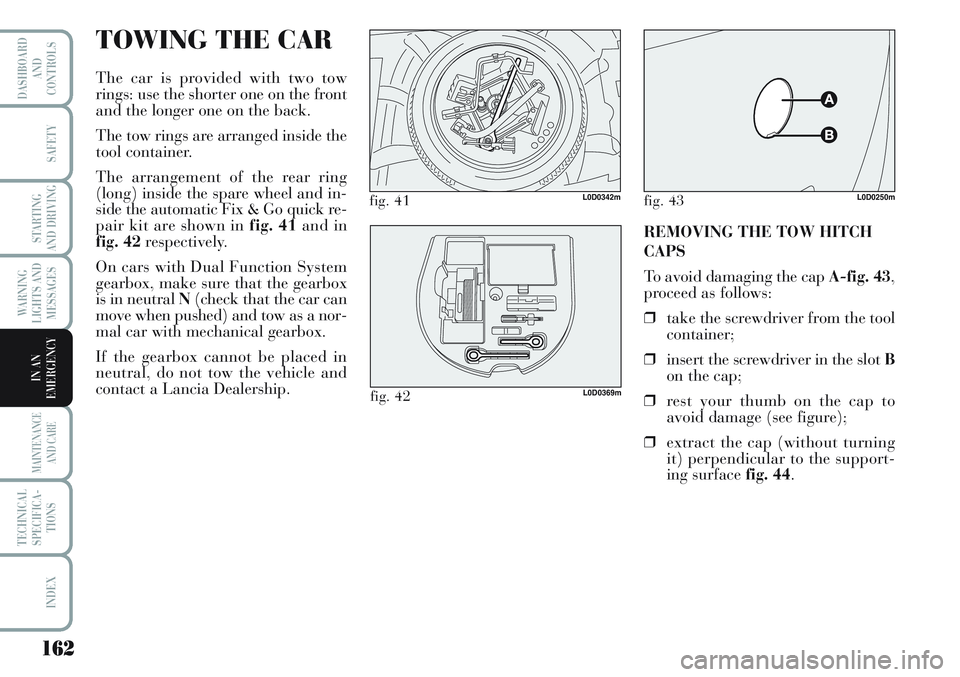

TOWING THE CAR

The car is provided with two tow

rings: use the shorter one on the front

and the longer one on the back.

The tow rings are arranged inside the

tool container.

The arrangement of the rear ring

(long) inside the spare wheel and in-

side the automatic Fix & Go quick re-

pair kit are shown in fig. 41 and in

fig. 42 respectively.

On cars with Dual Function System

gearbox, make sure that the gearbox

is in neutral N(check that the car can

move when pushed) and tow as a nor-

mal car with mechanical gearbox.

If the gearbox cannot be placed in

neutral, do not tow the vehicle and

contact a Lancia Dealership.

fig. 41L0D0342m

fig. 42L0D0369m

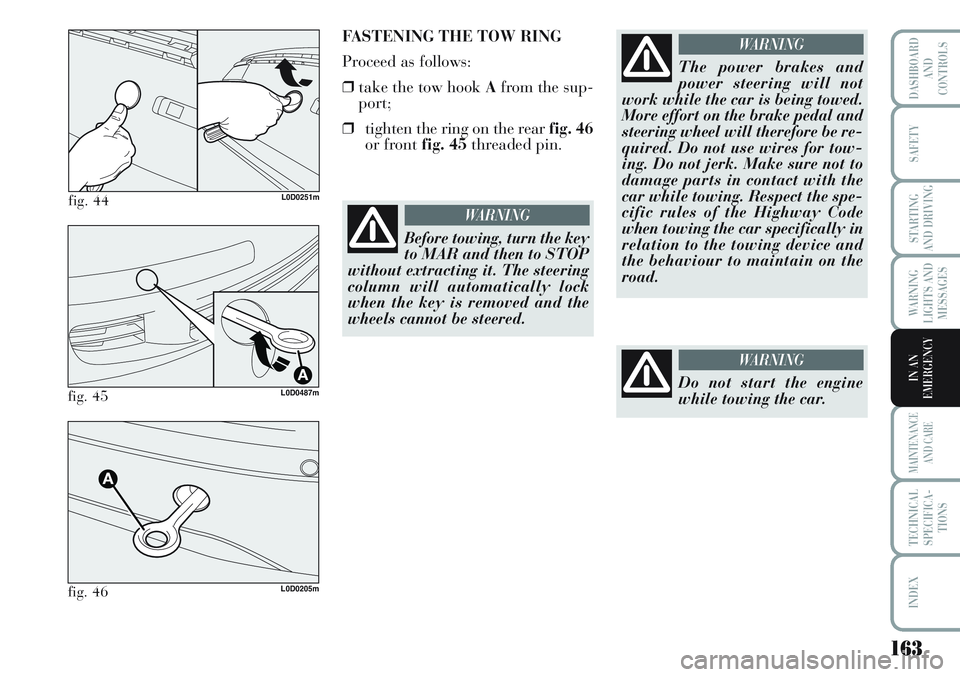

REMOVING THE TOW HITCH

CAPS

To avoid damaging the cap A-fig. 43,

proceed as follows:

❒take the screwdriver from the tool

container;

❒insert the screwdriver in the slot B

on the cap;

❒rest your thumb on the cap to

avoid damage (see figure);

❒extract the cap (without turning

it) perpendicular to the support-

ing surface fig. 44.

fig. 43L0D0250m

Page 164 of 218

163

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

fig. 44L0D0251m

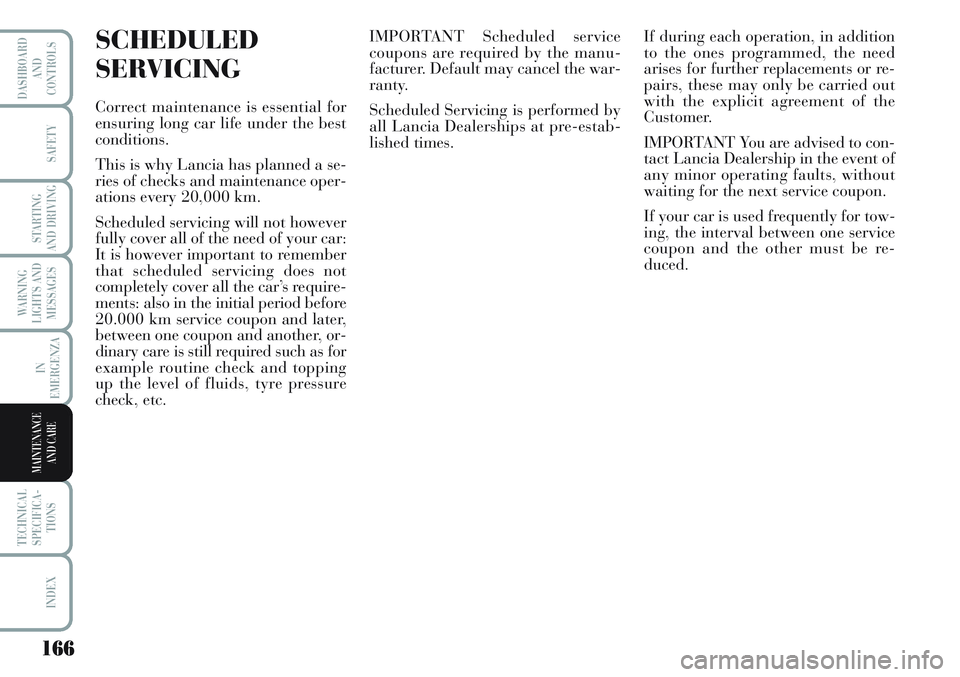

FASTENING THE TOW RING

Proceed as follows:

❒take the tow hook Afrom the sup-

port;

❒tighten the ring on the rear fig. 46

or front fig. 45threaded pin.

fig. 45L0D0487m

fig. 46L0D0205m

The power brakes and

power steering will not

work while the car is being towed.

More effort on the brake pedal and

steering wheel will therefore be re-

quired. Do not use wires for tow-

ing. Do not jerk. Make sure not to

damage parts in contact with the

car while towing. Respect the spe-

cific rules of the Highway Code

when towing the car specifically in

relation to the towing device and

the behaviour to maintain on the

road.

WARNING

Before towing, turn the key

to MAR and then to STOP

without extracting it. The steering

column will automatically lock

when the key is removed and the

wheels cannot be steered.

WARNING

Do not start the engine

while towing the car.

WARNING

Page 165 of 218

164

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

Before fitting the hook, clean

accurately its threaded seat.

Before starting to tow, make sure to

have tighten the hook.

WARNINGThe front and rear tow

hooks must only be used for

emergency situations on the

road. The vehicle may be

towed for short distances when a

dedicated device is used in compli-

ance with the Highway Code (rigid

bar), in order to move the vehicle on

the road in preparation for towing

by a tow truck Tow hooks MUST

NOT be used to tow vehicles off the

road or where there are obstacles

and/or for towing operations using

cables or other non-rigid devices.

Respecting the above conditions,

towing must only take place with

two vehicles (one towing, the other

towed) travelling as far as possible

in alignment along the same centre-

line.

Page 167 of 218

166

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN

EMERGENZA

MAINTENANCE

AND CARE

SCHEDULED

SERVICING

Correct maintenance is essential for

ensuring long car life under the best

conditions.

This is why Lancia has planned a se-

ries of checks and maintenance oper-

ations every 20,000 km.

Scheduled servicing will not however

fully cover all of the need of your car:

It is however important to remember

that scheduled servicing does not

completely cover all the car’s require-

ments: also in the initial period before

20.000 km service coupon and later,

between one coupon and another, or-

dinary care is still required such as for

example routine check and topping

up the level of fluids, tyre pressure

check, etc.IMPORTANT Scheduled service

coupons are required by the manu-

facturer. Default may cancel the war-

ranty.

Scheduled Servicing is performed by

all Lancia Dealerships at pre-estab-

lished times.If during each operation, in addition

to the ones programmed, the need

arises for further replacements or re-

pairs, these may only be carried out

with the explicit agreement of the

Customer.

IMPORTANT You are advised to con-

tact Lancia Dealership in the event of

any minor operating faults, without

waiting for the next service coupon.

If your car is used frequently for tow-

ing, the interval between one service

coupon and the other must be re-

duced.

Page 169 of 218

168

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN

EMERGENZA

MAINTENANCE

AND CARE

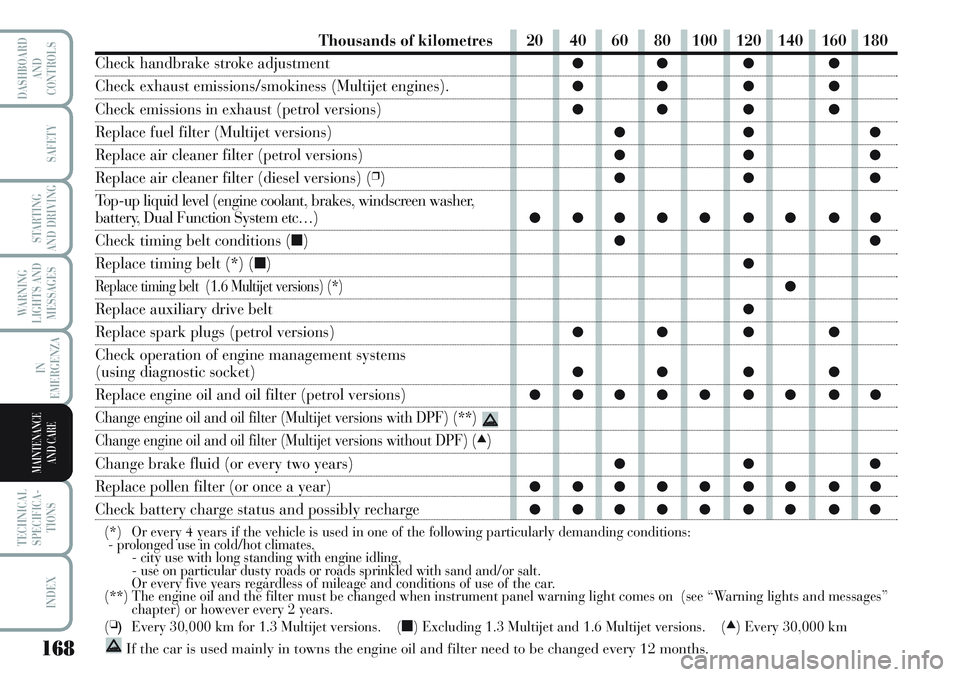

Thousands of kilometres

Check handbrake stroke adjustment

Check exhaust emissions/smokiness (Multijet engines).

Check emissions in exhaust (petrol versions)

Replace fuel filter (Multijet versions)

Replace air cleaner filter (petrol versions)

Replace air cleaner filter (diesel versions) (❒)

Top-up liquid level (engine coolant, brakes, windscreen washer,

battery, Dual Function System etc…)

Check timing belt conditions (■)

Replace timing belt (*) (■)

Replace timing belt (1.6 Multijet versions) (*)

Replace auxiliary drive belt

Replace spark plugs (petrol versions)

Check operation of engine management systems

(using diagnostic socket)

Replace engine oil and oil filter (petrol versions)

Change engine oil and oil filter (Multijet versions with DPF) (**)

Change engine oil and oil filter (Multijet versions without DPF) (▲)

Change brake fluid (or every two years)

Replace pollen filter (or once a year)

Check battery charge status and possibly recharge

(*) Or every 4 years if the vehicle is used in one of the following particularly demanding conditions:

- prolonged use in cold/hot climates,

- city use with long standing with engine idling,

- use on particular dusty roads or roads sprinkled with sand and/or salt.

Or every five years regardless of mileage and conditions of use of the car.

(**) The engine oil and the filter must be changed when instrument panel warning light comes on (see “Warning lights and messages”

chapter) or however every 2 years.

(

❏)Every 30,000 km for 1.3 Multijet versions. (■) Excluding 1.3 Multijet and 1.6 Multijet versions. (▲) Every 30,000 km

If the car is used mainly in towns the engine oil and filter need to be changed every 12 months.

20 40 60 80 100 120 140 160 180

●● ● ●

●● ● ●

●● ● ●

●●●

●●●

●●●

●●●●● ●●●●

●●

●

●

●

●● ● ●

●● ● ●

●●●●● ●●●●

●●●

●●●●● ●●●●

●●●●● ●●●●

Page 170 of 218

169

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

YEARLY

INSPECTION PLAN

The following yearly inspection plan

is recommended for cars clocking less

than 20,000 km a year (e.g. approx-

imately 15.000 km):

❒check tyre conditions/wear and

pressure (included spare wheel)

❒check lighting system operation

(headlights, direction indicators,

hazard lights, boot, passenger

compartment, instrument panel

warning lights, etc.)

❒check windscreen wiper/washer

(nozzle direction and blade wear)

❒check front disk brake pad condi-

tions and wear;

❒visually inspect: engine, gearbox,

transmission, flexible and stiff pip-

ing (exhaust, fuel feed, brakes),

rubber parts (boots, sleeves, bush-

ings, etc.);❒check cleanness of locks, bonnet

and boot and lever cleanness and

lubrication;

❒check battery charge;

❒visually inspect the accessory drive

belt conditions;

❒check and top up liquids if re-

quired (engine coolant, brakes,

windscreen washer, battery, etc.);

❒engine oil replacement;

❒replace engine oil filter;

❒replace pollen filter (for versions/

markets, where provided).

ADDITIONAL

INTERVENTIONS

Every 1,000 km or before long jour-

neys, check and, if necessary, top up:

❒engine coolant fluid level;

❒brake fluid level;

❒brake fluid level;

❒tyre pressure and conditions.

Every 3,000 km check the following

and top-up, if required: engine oil

level.

You are recommended to use

PETRONAS LUBRICANTS products,

designed and produced specifically for

Lancia cars (see table “Capacities” in

section “Technical specifications”).

IMPORTANT - Engine oil

Should prevailing use of the car be

under one of the following specially

heavy conditions:

❒trailer or caravan towing;

❒dusty roads;

Page 201 of 218

1.48V(▲)-1.416V

1155

500

940

805

1655

1000

400

75

601.3 Multijet

1200

500

940

805

1700

1000

400

75

601.6 Multijet

1275

500

1000

805

1775

1100

500

75

60

WEIGHTS

Weights (kg)

Unladen weight (with all liquids,

fuel tank filled to 90 % and

without optional equipment):

Payload (*)

including the driver:

Maximum permissible loads

(**)

– front axle:

– rear axle:

– total:

Towable loads:

– trailer with brakes:

– trailer without brakes:

Maximum load on roof:

Maximum load on tow hitch

(trailer with brakes):

(*)If special equipment is fitted (sun roof, tow hook, etc.) the unladen weight increases and consequently the payload will

decrease in relation to the maximum permitted loads.

(**) Loads not be exceeded. The driver is responsible for arranging goods in the luggage compartment and/on load carrying platform

within the maximum permitted loads.

(

▲) Engine version for some versions/markets only

200

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS