Lancia Thesis 2007 Owner handbook (in English)

Manufacturer: LANCIA, Model Year: 2007, Model line: Thesis, Model: Lancia Thesis 2007Pages: 386, PDF Size: 8.69 MB

Page 271 of 386

270

– Reconnect the negative battery

terminal (-) after checking the bat-

tery charge.

IMPORTANT Before connecting

the battery again carefully read and

comply with instructions contained

in the paragraph “If battery is to be

disconnected” in the chapter “In an

emergency”.

– With the gear lever to neutral,

start the engine and let it idle a few

minutes, pressing the clutch pedal

repeatedly.

This operation must be

carried out outdoor.

Exhaust gas contains car-

bon monoxide, an extremely

toxic gas.USEFUL

ACCESSORIES

In addition to the legal require-

ments we recommend keeping the

following in the car (fig. 2):

– first-aid kit with non-alcoholic

base disinfectant, sterile gauze, a roll

of gauze bandage, plasters, etc.,

– torch,

– round-nosed scissors,

– work gloves,

- fire extinguisher.

These articles are all available from

Lineaccessori Lancia range.

fig. 2

L0A0170b

Page 272 of 386

271

EMERGENCY

START-UP

If the Lancia CODE system cannot

deactivate the engine immobilising

system, symbols Yand Uwill

remain lit on the multifunction dis-

play together with messages

“ELECTRONIC KEY NOT

RECOGNISED” and “ENGINE

CONTROL SYSTEM FAULT”, and

the engine will not start. Follow the

emergency start-up procedure to

start the engine.

Read the whole procedure care-

fully before trying to carry it out.

If you make a mistake in the emer-

gency procedure you must turn the

ignition key back to STOP and

repeat the whole operation from the

beginning (step 1).

1) Read the five-digit electronic

code on the CODE card.

2) Turn the ignition key to MAR.3) Press and hold down the accel-

erator pedal. The warning light U

on the instrument panel will light up

for about 8 seconds, and then go

out. At this point release the acceler-

ator pedal and get ready to count the

flashes of the warning light U.

4) Count the number of flashes

that corresponds to the first figure of

the code on the CODE card, then

press the accelerator pedal and keep

it down until the Uwarning light

comes on for four seconds and then

goes out. Release the accelerator

pedal.

5) The Uwarning light will start

flashing again: after it has flashed

the number of times that corre-

sponds to the second figure on the

CODE card, press the accelerator

pedal to the floor and keep it there.

6) Do the same for the remaining

digits on the CODE card.7) Once the final figure has been

entered, keep the accelerator pedal

pressed. The Uwarning light will

light up for 4 seconds and then go

out. Release the accelerator pedal.

8) The Uwarning light will flash

rapidly for about 4 seconds to indi-

cate that the operation has been

completed correctly.

9) Start the engine by turning the

ignition key from MARto AVV

(without turning it to STOP).

If, however, warning light Ustays

on, turn the ignition key to STOP

and repeat the procedure from step

1).

IMPORTANTAfter an emergency

start, you should contact a Lancia

Dealershipimmediately as you will

have to repeat the procedure

described each time you want to

start the engine.

IN AN EMERGENCY

Page 273 of 386

272

JUMP STARTING

If the battery is flat, you can use

another battery to start the engine.

Its capacity must be the same or

slightly greater than the flat battery

(see the “Technical Specification”

chapter).

The battery is placed on the left

side of the boot, protected by a

cover.Before opening the lug-

gage compartment bonnet

to reload the battery or to

connect an auxiliary battery,

carefully read and comply with

the instructions contained in the

paragraph “If battery is to be dis-

connected” in the chapter “In an

emergency”.

Jump starting does not damage the

Lancia CODE system. Proceed as

follows:

1) Disconnect all electrical devices

that are not strictly useful.

2) Lift the boot tailgate by turning

the key metal insert clockwise in the

latch.3) Loosen the knob A(fig. 1) and

remove the protective cover B.

4) Press flanges A(fig. 2) and

remove the cover B.

5) Connect the positive terminals

(+) A(fig. 3) and Bof the two bat-

teries with a jump lead.

6) With a second lead connect first

the negative terminal (–) Cof the

auxiliary battery and then the earth

braid Dof the car to be started.

fig. 1

L0A0030b

fig. 2

L0A0031b

fig. 3

L0A0032b

Page 274 of 386

273

7) Start the engine.

8) When the engine has started,

remove the leads in the reverse order

to before: D, C, Band finally A.

IMPORTANT If the engine fails to

start after a few attempts, do not keep

turning the key but have the car seen

to at a Lancia Dealership.

9) Put the cover back on the bat-

tery positive terminal by fitting the

lock flanges in.

10) Put the cover back and retight-

en the knob.

11) Close the boot tailgate.IMPORTANTWhen the tailgate is

closed, the boot latch is not locked.

To lock it, turn the metal insert of

the key anticlockwise in the latch.

Do not carry out this

procedure if you lack

experience: if it is not

done correctly it can cause very

intense electrical discharges and

the battery might even explode.

Do not to put naked flames or

lighted cigarettes near the battery

and do not cause sparks: risk of

explosion and fire.

Never use a battery

charger to jump start the

engine: you could damage

the electronic system, with spe-

cial reference to ignition and

injection control unit.

BUMP STARTING

Do not bump start by pushing,

towing or coasting downhill. This

way of starting could cause a rush of

fuel into the catalytic converter and

damage it beyond repair.

Remember that ifthe engine is not

running, the brake booster and the

power steering will not work. You

therefore have to use considerably

more effort on both the brake pedal

and the steering wheel.

Never connect the nega-

tive terminals of the two

batteries directly: sparks

could ignite the flammable gas

from the battery. If the auxiliary

battery is installed on another

car, prevent accidental contact

between the metal parts of the

two vehicles.

Page 275 of 386

274

Signal the presence of

the stopped car according

to the laws in force: haz-

ard lights, reflecting triangle, etc.

Passengers should get out of the

car and stay clear from oncoming

traffic while the wheel is being

changed.

IF A TYRE

IS PUNCTURED

Follow the instructions on this and

the following pages to use the jack

and the spare wheel correctly.If the wheel is being

changed on a steep or

badly surfaced road,

place wedges or other suitable

material under the wheels to stop

the car from moving.

Have the punctured tyre

repaired and fitted back as soon

as possible. Do not lubricate the

bolt threads before fitting them

back: they could come loose.

Wheel bolts are specific

for the type of rim (alloy

or steel) fitted. Never use,

also if in an emergency, wheel

bolts for another type of rim.

When changing rims (alloy rims

instead of steel ones or vice

versa), also the whole wheel bolt

set shall be changed with other

bolts specific for the new type of

rim adopted.The jack should only be

used to change a wheel on

the car for which it was

designed. It should not be put to

other uses or employed to raise

other models of car. Under no

circumstances should it be used

when carrying out repairs under

the car.

An incorrectly positioned jack

may cause the car to fall.

Do not use the jack to lift loads

exceeding those indicated on the

label attached to the jack itself.

The wheel cap may fly off when

the car is moving if it is not fas-

tened correctly. Never tamper

with the inflation valve. Do not

insert tools between the rim and

the tyre.

Check the tyre and spare wheel

pressure regularly. Tyre pressure

is shown in the “Technical

Specifications” chapter.

Page 276 of 386

275

CHANGING

A WHEEL

Please note:

– the jack weighs 2.100 kg;

– the jack requires no adjustments;

– the jack cannot be repaired. If it

breaks, it must be replaced with a

genuine spare part;

– no other tool, part from the

ratchet wrench, can be fitted to the

jack.Change the wheel as follows:

1) Stop the car so that it is not a

hazard for other road users or your-

self when changing the wheel. The

ground should be as flat and firm as

possible.

2) Turn engine off and engage the

electric parking brake.

3) Engage first gear or reverse. On

versions with automatic gearbox

shift the lever to P.4) Open the boot.

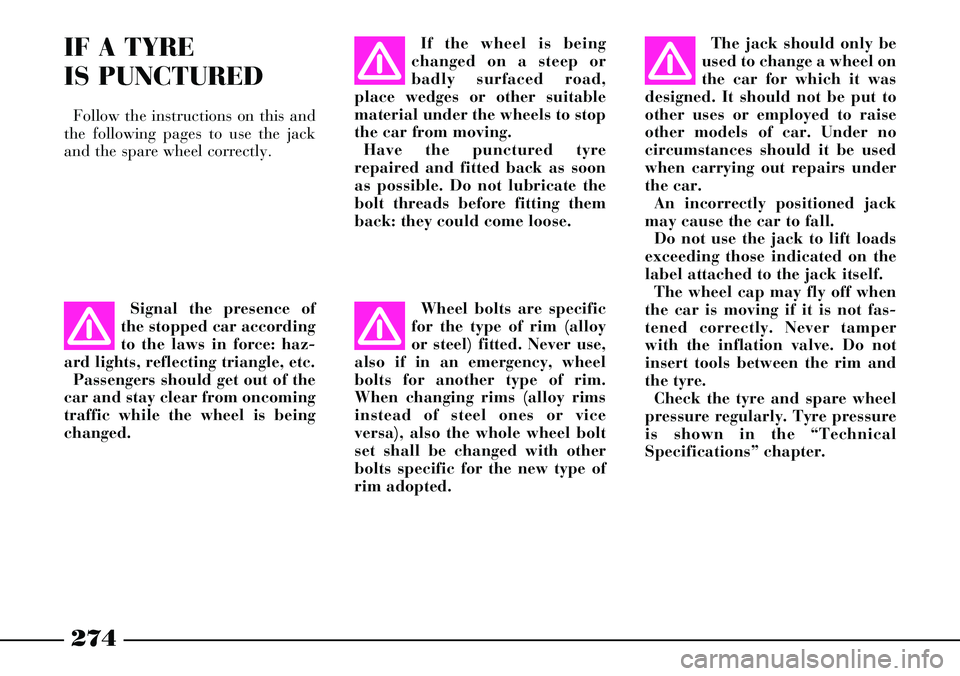

5) Fold the boot carpet A(fig. 4).

6) Take out the warning triangle A

(fig. 5) and the tool kit B.

7) Release the locking device A

(fig. 6) and take out the jack holder

Band the spare wheel C, then place

them next to the wheel to be

changed.

fig. 4

L0A0033b

fig. 5

L0A0034b

fig. 6

L0A0035b

Page 277 of 386

276

8) Unscrew manually the jack han-

dle A(fig. 7) and remove it from the

container B.9) Open the tool bag and take out

the tools to be used (fig. 8):

1 – tow ring

2 – flat/cross-head screwdriver

3 – ratchet wrench

4 – ratchet wrench bush

5 – wheel bolt (for versions with

alloy rims)

6 – tool for removing the hub cap

(for versions with alloy rims)

7 – bush for unscrewing/screwing

the wheel bolts by hand8 – wrench for power steering re-

servoir cap screws

9 – wrench for actuating the sun-

roof in an emergency (where fitted)

10) On versions with alloy rims,

remove the press-fit wheel hub cap

A(fig. 9), pulling it by tool Bfitted

into C. On versions with steel rims,

remove the press-fit wheel cap A

(fig. 10).

fig. 8

L0A0326b

fig. 7

L0A0038b

fig. 9

L0A0327b

fig. 10

L0A0367b

Page 278 of 386

277

13) Position the jack under the car

near the wheel to be replaced in the

point shown on the panelling at

approximately 20 cm from the fend-

er edge, as shown in (fig. 12). 11) Place the bushing A(fig. 11)

for the wheel bolts on the ratchet

wrench B.

IMPORTANTThe ratchet wrench

must be used on one side to unscrew

and on the other side to screw.

12) Loosen the wheel bolts by

about one turn, then rock the car to

make it easier to remove the rim

from the wheel hub.Warn anyone nearby

that the car is about to be

lifted. They must stay

clear and not touch the car until

it is back on the ground.

fig. 12

L0A0039b

fig. 11

L0A0037b

Page 279 of 386

278

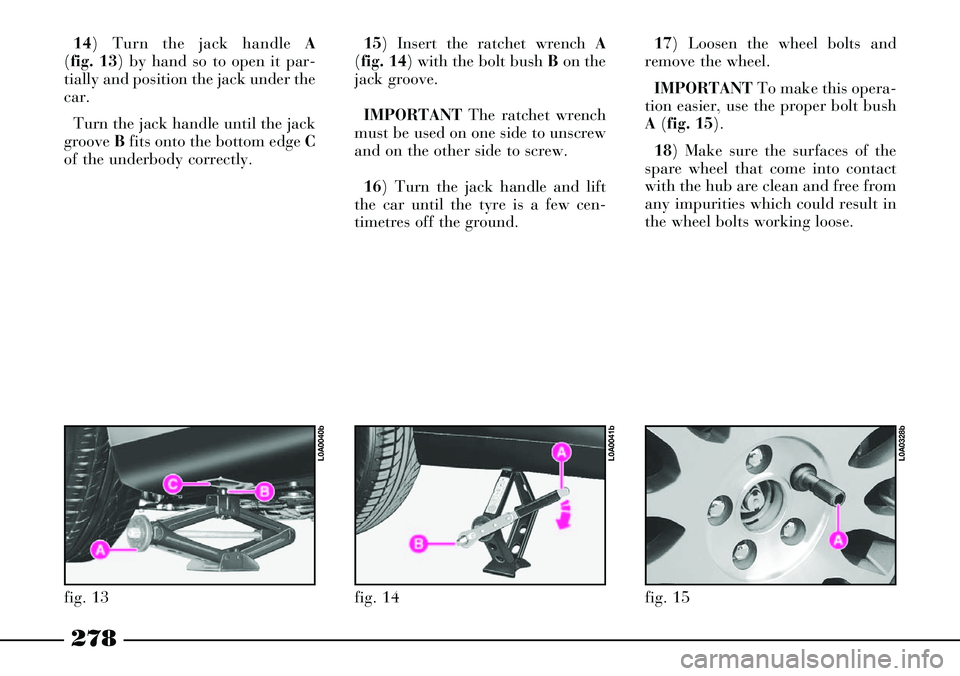

15) Insert the ratchet wrench A

(fig. 14) with the bolt bush Bon the

jack groove.

IMPORTANTThe ratchet wrench

must be used on one side to unscrew

and on the other side to screw.

16) Turn the jack handle and lift

the car until the tyre is a few cen-

timetres off the ground.17) Loosen the wheel bolts and

remove the wheel.

IMPORTANTTo make this opera-

tion easier, use the proper bolt bush

A(fig. 15).

18) Make sure the surfaces of the

spare wheel that come into contact

with the hub are clean and free from

any impurities which could result in

the wheel bolts working loose.

fig. 15

L0A0328b

fig. 13

L0A0040b

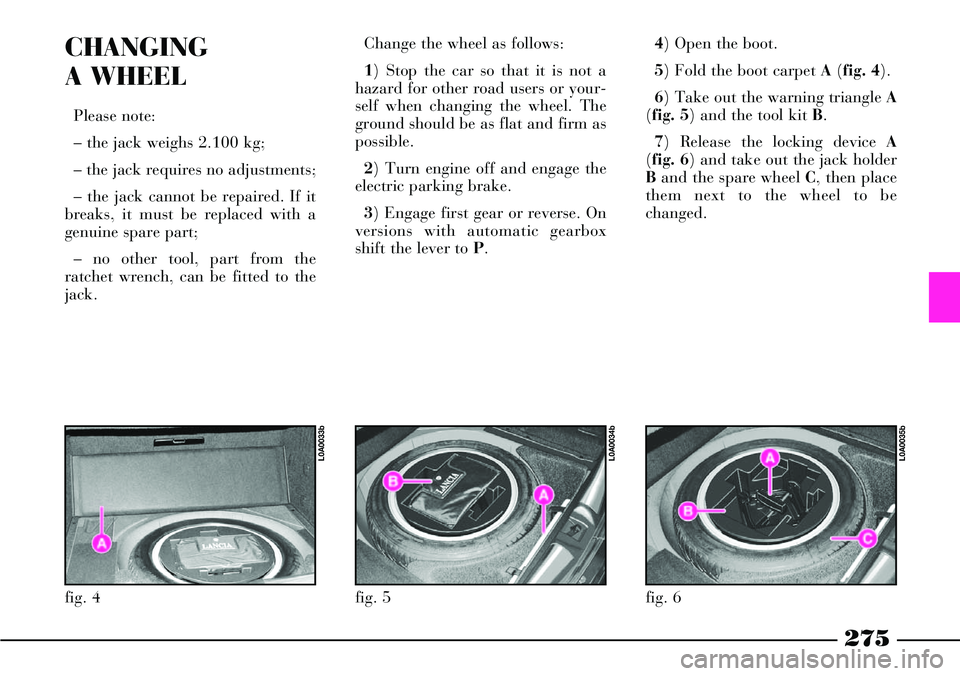

14) Turn the jack handle A

(fig. 13) by hand so to open it par-

tially and position the jack under the

car.

Turn the jack handle until the jack

groove Bfits onto the bottom edge C

of the underbody correctly.

fig. 14

L0A0041b

Page 280 of 386

279

19) On versions with alloy rims, to

make the wheel fitting easier, screw

the pin A(fig. 16), provided in the

tool kit, to the hub and then place

the wheel and tighten up the four

bolts in the free holes. Finally,

unscrew pin Aand screw the last

bolt.

On versions with steel rims, fit the

wheel making pin A(fig. 17) coin-

cide with one of the holes B.

IMPORTANTTo make bolt tight-

ening easier, use the proper bolt

bush A(fig. 15).Wheel bolts are specific

for the type of rim (alloy

or steel) fitted. Never use,

also if in an emergency, wheel

bolts for another type of rim.

When changing rims (alloy rims

instead of steel ones or vice

versa), also the whole wheel bolt

set shall be changed with other

bolts specific for the new type of

rim adopted.20) Lower the car and remove the

jack (fig. 18).

fig. 16

L0A0043b

fig. 17

L0A0366b

fig. 18

L0A0044b