change wheel Lancia Thesis 2007 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2007, Model line: Thesis, Model: Lancia Thesis 2007Pages: 386, PDF Size: 8.69 MB

Page 14 of 386

13

1) Front door air outlets

2) Side window vents

3) Side vents

4) Instrument panel

5) Windscreen vent

6) Driver’s side vents

7) Central vents

8) Hazard light switch

9) Passenger’s side vent

10) Front passenger’s airbag

11) Front passenger’s airbag deactivation switch

12) Glove compartment/CD CHANGER compartment/

power socket

13) Glove compartment on/off button

14) CONNECT multifunction display (for control

description see the following pages)

15) Cassette player, CD and SIM telephone card slot flap

16) Automatic climate control and heated rear window

switch

17) Ashtray and cigar lighter

18) SOS button (for assistance services and functions)

19) Windscreen/headlight wiper/washer stalk 20) Trip meter reset button (long pressure)/Button for

deleting failure messages on the display (short pres-

sure)

21) Ignition switch

22) CONNECT controls on the steering wheel (for con-

trol description see the following pages)

23) Horn

24) Driver’s airbag

25) Steering wheel electric adjustment button

26) Radar Cruise Control controls/Cruise Control/direc-

tion indicator stalk and main/dipped beam head-

light switch

27) Glove compartment/fusebox cover

28) Bonnet opening lever

29) Outside light stalk knob - Front and rear fog light

buttons - Instrument panel dimmer and twilight sen-

sor sensitivity ring nuts

Page 100 of 386

99

Twilight sensor

It is composed by an infrared led

sensor installed on the windscreen in

order to detect the changes of the

external light intensity of the car , as

a function of the light sensitivity set;

greater is the sensitivity, smaller is

the amount of external light neces-

sary to control the switching-on of

the exterior headlights.

It consists of two sensors: a global

sensor for evaluating environment

light intensity and a directional one

for evaluating light intensity in run-

ning direction in order to recognize

tunnels, dark road sections, etc.When ring Ais turned to AUTO

(automatic light switching on), and

the twilight sensor is malfunction-

ing, side/taillights and dipped beam

headlights are switched on regard-

less of the light intensity and the dis-

play on the instrument panel shows

the message “TWILIGHT SENSOR

FAULT – GO TO DEALER”.

Failure indication will stay on as

long as ring Ais turned to AUTO. In

this case it is recommended to deac-

tivate the automatic function and

switch on the lights manually; con-

tact a Lancia Dealershipas soon as

possible.Delayed light switching off

(“Follow me home” device)

This device allows the illumination

of the space in front of the car for a

length of time of 30 seconds (or a

multiple of 30) and is activated with

the ignition key at STOPor

removed.

This device is activated by pulling

towards the steering wheel and then

releasing the left-hand stalk within 2

minutes from when the engine is

turned off. At each operation of the

stalk, the staying on of the lights is

extended by 30 seconds, up to a

maximum of 210 seconds that corre-

spond to 7 stalk operations, then the

lights are switched off automatical-

ly.

Total set time (in seconds) is

shown on the instrument panel dis-

play for about 20 seconds.

Page 102 of 386

101

IMPORTANTThis operation will

flash the main beam headlights.

Follow the Highway Code to prevent

being fined.

Direction indicators (fig. 96)

Move the stalk as follows:

up (position A) - to switch on the

right-hand indicators

down (position B) - to switch on

the left-hand indicators.

When direction indicators are on,

instrument panel warning light

Ÿor

∆will flash.

The direction indicators return

automatically to neutral position

when the car straightens up.

IMPORTANTIf you want the indi-

cator to flash briefly to show that

you are about to change lane, move

the stalk up or down without click-

ing into position. When you let it go

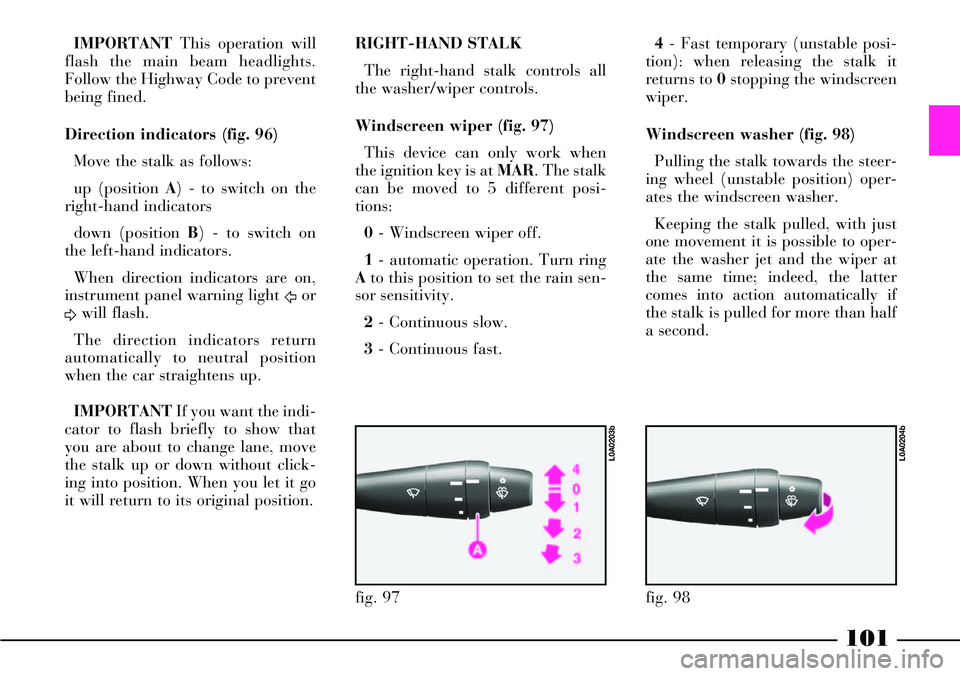

it will return to its original position.RIGHT-HAND STALK

The right-hand stalk controls all

the washer/wiper controls.

Windscreen wiper (fig. 97)

This device can only work when

the ignition key is at MAR. The stalk

can be moved to 5 different posi-

tions:

0- Windscreen wiper off.

1- automatic operation. Turn ring

Ato this position to set the rain sen-

sor sensitivity.

2- Continuous slow.

3- Continuous fast.4- Fast temporary (unstable posi-

tion): when releasing the stalk it

returns to 0stopping the windscreen

wiper.

Windscreen washer (fig. 98)

Pulling the stalk towards the steer-

ing wheel (unstable position) oper-

ates the windscreen washer.

Keeping the stalk pulled, with just

one movement it is possible to oper-

ate the washer jet and the wiper at

the same time; indeed, the latter

comes into action automatically if

the stalk is pulled for more than half

a second.

fig. 97

L0A0203b

fig. 98

L0A0204b

Page 120 of 386

119

ABS SYSTEM FAILURE

Turning the ignition key

to MAR, the instrument

panel warning light turns on but it

should go off after a few seconds.

When there is failure the warning

light stays on or comes on when

travelling together with message

“ABS SYSTEM FAULT” on the

multifunction display. In this case

the braking system keeps its effec-

tiveness unchanged, but without the

potential offered by the ABS system.

It is however recommended to con-

tact a Lancia Dealershipas soon

as possible.

In the event of instrument panel

warning light failure, the warning

light on the multifunction display

comes on together with message

“ABS INDICATOR FAULT”: con-

tact a Lancia Dealership as soon

as possible.In this case heavy brak-

ing may cause the rear

wheels to lock before

time, with the possibility of skid-

ding, stop the car immediately

and contact a Lancia Dealership.

>

EBD SYSTEM

FAULT

(ELECTRONIC

BRAKEFORCE DISTRIBUTOR)

The car is fitted with electronic

braking distributor (EBD). The

turning on at the same time of the

xand >warning lights on the

instrument panel together with mes-

sage “EBD SYSTEM FAULT” on

the multifunction display with the

engine running indicates an EBD

system failure.

x>

If the xwarning light

comes on when travelling,

stop immediately and

contact a Lancia Dealership.

In the event of instrument panel

warning light failure, the warning

light on the multifunction display

comes on together with message

“BRAKE FLUID INDICATOR

FAULT”: contact a Lancia

Dealership as soon as possible.

Page 192 of 386

191

To make ESP, ASR and

ABS systems work prop-

erly, the tyres must

absolutely be of the same brand

and type on all wheels, in perfect

conditions and, above all, of type,

brand and size specified. stantly changed and controlled in

the attempt to keep the driver’s

direction.

The ESP system considerably

increases the car safety in several

critical conditions and it is particu-

larly useful during overtaking, when

the grip conditions on the road bed

change.ASR FUNCTION (ANTISLIP

REGULATION)

General

The ASR function is part of the

ESP system and it checks the car

drive, taking action every time one

or both driving wheels slip, thus pre-

venting car instability and tyre wear.

On the basis of slipping conditions,

two different check systems are acti-

vated:

– if slipping affects both driving

wheels, as a result of the excessive

force transmitted, the ASR function

reduces the power supplied by the

engine;

– if slipping affects only one of the

driving wheels, the ASR function

automatically brakes the slipping

wheel, with an effect similar to the

self-locking differential.The action of the ASR function is

particularly useful in the following

conditions:

– internal wheel slipping when cor-

nering due to load dynamic varia-

tions and excessive acceleration;

– excessive power supplied to

wheels according to the road bed;

– acceleration on slippery ground,

covered with snow or ice;

– in case of grip loss on wet ground

(aquaplaning).

ASR function activation

The ASR function is activated

automatically whenever the engine

is started.

During driving it is possible to dis-

engage and engage this function by

pressing button A(fig. 142) on the

central console.

When the ASR function is on, sym-

bol Vis lighted on the multifunc-

tion display together with the mes-

sage “ASR ON”.

Page 258 of 386

257

– Keep a greater safety distance

from the cars in front of you than

during daylight hours: it is hard to

judge how fast other cars are going

when all you can see are their lights.

– Only use main beam headlights

when you are driving outside town

and when you are sure they do not

annoy other drivers.

– Dip your headlights as soon as

you see cars coming in the other

direction and pass them with the

headlights dipped.

– Keep all lights clean.

– Be careful of animals crossing the

road when driving in the country.

DRIVING IN THE RAIN

Rain and wet road surfaces spell

danger.

All manoeuvres are more difficult

on a wet road because the grip of the

wheels on the tarmac is greatly

reduced. This is why braking dis-

tances are much longer and road-

holding is lower.Here is some advice for driving in

the rain:

– Reduce speed and maintain a

greater safety distance from the cars

in front.

– If it is raining particularly heavi-

ly, visibility is also reduced. In these

cases, switch on the dipped head-

lights even if it is still daylight so you

can be seen more easily.

– Do not drive through puddles at

speed and hold on tightly to the

wheel if you do: a puddle taken at

high speed might cause you to lose

control of the car (“aquaplaning”).

– Move the ventilation controls to

the position for demisting the win-

dows (see the section “Getting to

know your car”), so to avoid visibil-

ity problems.

– Periodically check the condition

of the windscreen wiper blades. – Do not drive too many hours at a

time but stop at intervals to stretch

your legs and recoup your energy.

– Make sure the air in the car is

being changed continuously.

– Never coast downhill (i.e.: with

the engine off): if you do, you lose

the aid of engine braking and power

brakes so that braking requires

greater effort.

DRIVING AT NIGHT

There are the main rules to follow

when you are driving at night.

– Drive especially carefully: it is

harder to drive at night.

– Slow down especially if the road

is not lit.

– At the first signs of sleepiness,

stop: continuing would be a risk for

yourself and everybody else. Only

start driving again when you have

had enough rest.

Page 275 of 386

274

Signal the presence of

the stopped car according

to the laws in force: haz-

ard lights, reflecting triangle, etc.

Passengers should get out of the

car and stay clear from oncoming

traffic while the wheel is being

changed.

IF A TYRE

IS PUNCTURED

Follow the instructions on this and

the following pages to use the jack

and the spare wheel correctly.If the wheel is being

changed on a steep or

badly surfaced road,

place wedges or other suitable

material under the wheels to stop

the car from moving.

Have the punctured tyre

repaired and fitted back as soon

as possible. Do not lubricate the

bolt threads before fitting them

back: they could come loose.

Wheel bolts are specific

for the type of rim (alloy

or steel) fitted. Never use,

also if in an emergency, wheel

bolts for another type of rim.

When changing rims (alloy rims

instead of steel ones or vice

versa), also the whole wheel bolt

set shall be changed with other

bolts specific for the new type of

rim adopted.The jack should only be

used to change a wheel on

the car for which it was

designed. It should not be put to

other uses or employed to raise

other models of car. Under no

circumstances should it be used

when carrying out repairs under

the car.

An incorrectly positioned jack

may cause the car to fall.

Do not use the jack to lift loads

exceeding those indicated on the

label attached to the jack itself.

The wheel cap may fly off when

the car is moving if it is not fas-

tened correctly. Never tamper

with the inflation valve. Do not

insert tools between the rim and

the tyre.

Check the tyre and spare wheel

pressure regularly. Tyre pressure

is shown in the “Technical

Specifications” chapter.

Page 276 of 386

275

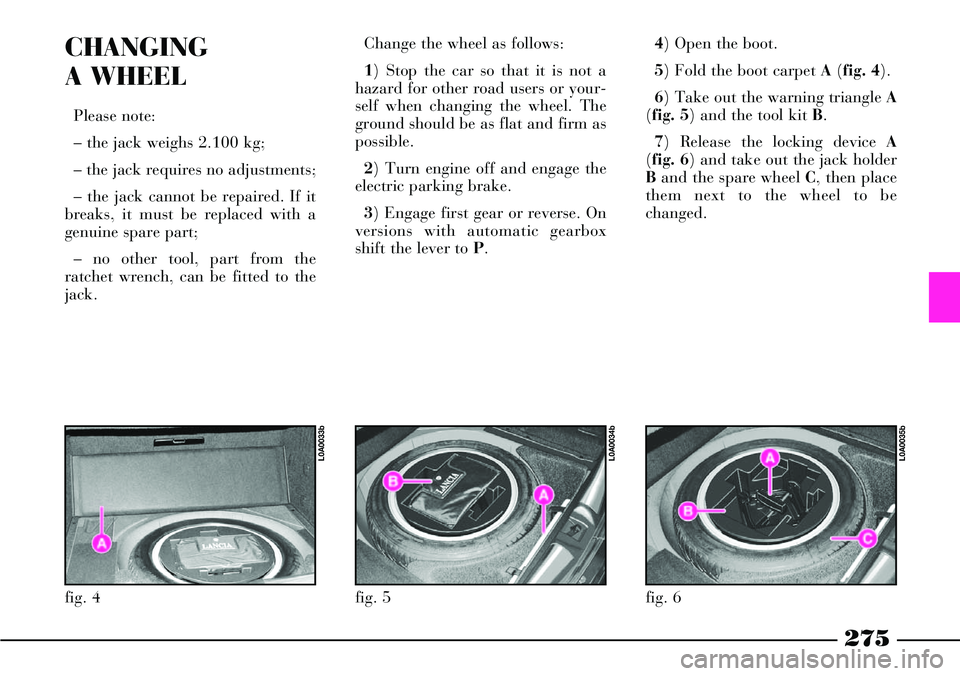

CHANGING

A WHEEL

Please note:

– the jack weighs 2.100 kg;

– the jack requires no adjustments;

– the jack cannot be repaired. If it

breaks, it must be replaced with a

genuine spare part;

– no other tool, part from the

ratchet wrench, can be fitted to the

jack.Change the wheel as follows:

1) Stop the car so that it is not a

hazard for other road users or your-

self when changing the wheel. The

ground should be as flat and firm as

possible.

2) Turn engine off and engage the

electric parking brake.

3) Engage first gear or reverse. On

versions with automatic gearbox

shift the lever to P.4) Open the boot.

5) Fold the boot carpet A(fig. 4).

6) Take out the warning triangle A

(fig. 5) and the tool kit B.

7) Release the locking device A

(fig. 6) and take out the jack holder

Band the spare wheel C, then place

them next to the wheel to be

changed.

fig. 4

L0A0033b

fig. 5

L0A0034b

fig. 6

L0A0035b

Page 280 of 386

279

19) On versions with alloy rims, to

make the wheel fitting easier, screw

the pin A(fig. 16), provided in the

tool kit, to the hub and then place

the wheel and tighten up the four

bolts in the free holes. Finally,

unscrew pin Aand screw the last

bolt.

On versions with steel rims, fit the

wheel making pin A(fig. 17) coin-

cide with one of the holes B.

IMPORTANTTo make bolt tight-

ening easier, use the proper bolt

bush A(fig. 15).Wheel bolts are specific

for the type of rim (alloy

or steel) fitted. Never use,

also if in an emergency, wheel

bolts for another type of rim.

When changing rims (alloy rims

instead of steel ones or vice

versa), also the whole wheel bolt

set shall be changed with other

bolts specific for the new type of

rim adopted.20) Lower the car and remove the

jack (fig. 18).

fig. 16

L0A0043b

fig. 17

L0A0366b

fig. 18

L0A0044b

Page 308 of 386

307

WITH AN ARM HOIST OR A

SHOP JACK

The car can only be jacked up by

positioning the jack arms or the shop

jack in the areas shown in fig. 84. An incorrectly posi-

tioned jack may cause the

car to fall. Do not use the

jack to lift loads exceeding those

indicated on the label attached to

the jack itself.

Be very careful not to

squeeze the brake pipes,

the fuel pipes or the side

member ribbing.

fig. 84

L0A0039b

JACKING THE CAR

WITH THE JACK

See “If a tyre is punctured”, in this

chapter.

Please note:

– the jack weighs 2.100 kg;

– the jack requires no adjustments;

– the jack cannot be repaired. If it

breaks, it must be replaced with a

new jack.

The jack should only be

used to change a wheel on

the car for which it was

designed. It should not be put to

other uses or employed to raise

other models. Under no circum-

stances should it be used when

carrying out repairs under the

car.