fuel pressure Lancia Ypsilon 2002 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2002, Model line: Ypsilon, Model: Lancia Ypsilon 2002Pages: 191, PDF Size: 2.45 MB

Page 70 of 191

67

G

Only change the fuel filler cap with

a genuine spare part in order not to

compromise the petrol fume recovery

system.FUEL TANK CAP

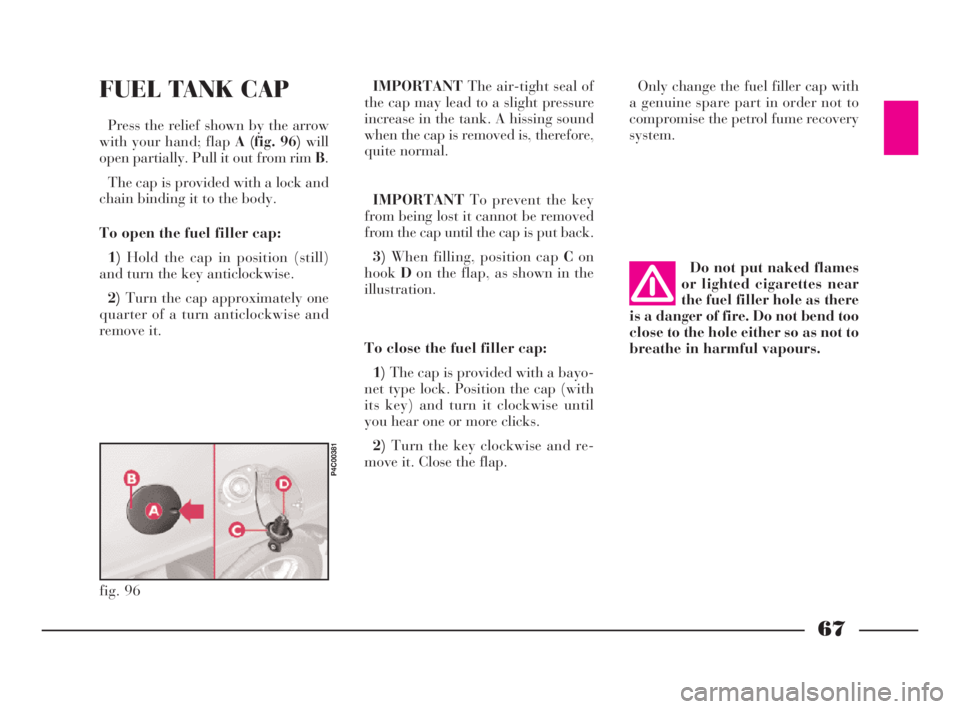

Press the relief shown by the arrow

with your hand; flapA (fig. 96)will

open partially. Pull it out from rim B.

The cap is provided with a lock and

chain binding it to the body.

To open the fuel filler cap:

1)Hold the cap in position (still)

and turn the key anticlockwise.

2)Turn the cap approximately one

quarter of a turn anticlockwise and

remove it.IMPORTANTThe air-tight seal of

the cap may lead to a slight pressure

increase in the tank. A hissing sound

when the cap is removed is, therefore,

quite normal.

IMPORTANTTo prevent the key

from being lost it cannot be removed

from the cap until the cap is put back.

3)When filling, position cap Con

hookDon the flap, as shown in the

illustration.

To close the fuel filler cap:

1)The cap is provided with a bayo-

net type lock. Position the cap (with

its key) and turn it clockwise until

you hear one or more clicks.

2)Turn the key clockwise and re-

move it. Close the flap.Do not put naked flames

or lighted cigarettes near

the fuel filler hole as there

is a danger of fire. Do not bend too

close to the hole either so as not to

breathe in harmful vapours.

fig. 96

P4C00381

4C001-067 ING 11-03-2008 11:57 Pagina 67

Page 84 of 191

81

G

CONTAINING

RUNNING COSTS

AND POLLUTION

Some suggestions which may help

you to keep the running costs of your

car down and lower the amount of

toxic emissions released into the at-

mosphere are given below.

GENERAL CONSIDERATIONS

Car maintenance

The overall state of the car is an im-

portant factor which has a marked in-

fluence over fuel consumption and

driving comfort and on the life span

of your car. For this reason care

should be taken to maintain your ve-

hicle by carrying out the necessary

checks and regulations in accordance

with the specifications given in the

Servize Schedule (see spark plugs,

idle, air filters, timing sections).Tyres

Tyres should be checked at least

every four weeks: if the pressure is too

low fuel consumption increases as the

resistance to the rolling movement of

the tyre is greater. In this state, tyre

wear is increased and car handling

suffers which will affect safety.

Unnecessary loads

Do not travel with too much luggage

stowed in the boot. The weight of the

car (especially when driving in town)

and its trim greatly affects consump-

tion and stability.

Roof/ski racks

Remove roof or ski racks from the

roof of the car as soon as they are no

longer needed. These accessories re-

duce the aerodynamic penetration of

the car and will increase consump-

tion. When transporting particularly

large objects, use a trailer where pos-

sible.Electrical devices

Use the electrical devices for the nec-

essary time only. The heated rear win-

dow, supplementary lights, wind-

screen wipers, heating system blower

require large amounts of energy and,

increasing the request for power also

increases fuel consumption (up to

+25% when driving in built-up areas).

Air conditioner

The air conditioner is an additional

load which greatly affects the engine

leading to higher consumption (on av-

erage up to +20%). When the tem-

perature outside the car permits it,

use the air vents where possible.

Spoilers

The use of aerodynamic optional ex-

tras which are not certified for specific

use on the car, may reduce the aero-

dynamic penetration of the car and

increase consumption.

4C068-089 ING 11-03-2008 11:59 Pagina 81

Page 125 of 191

122

G

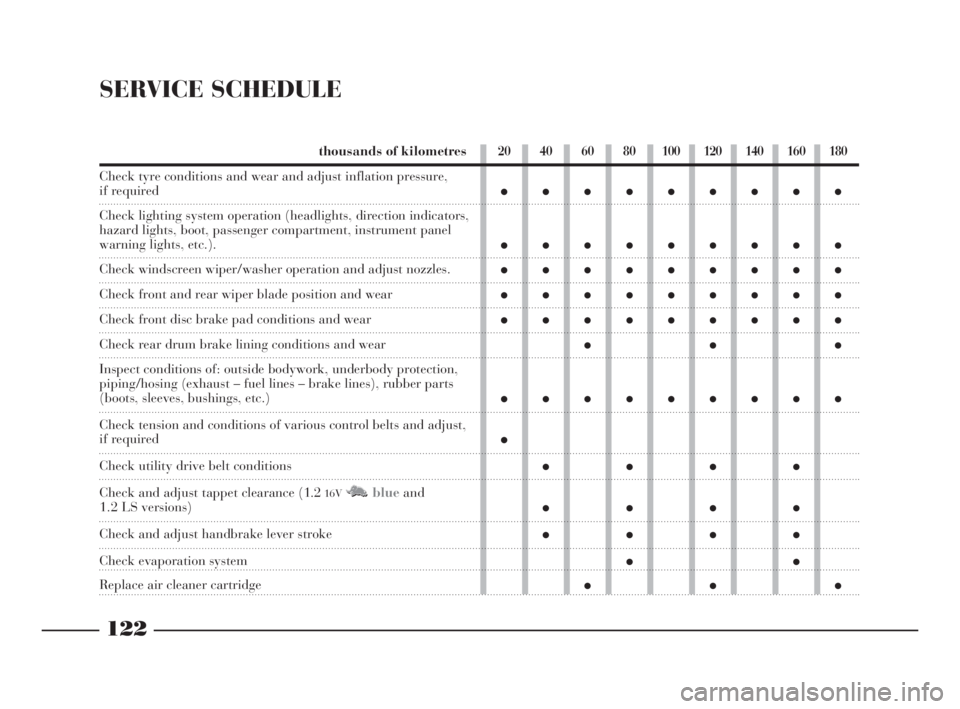

SERVICE SCHEDULE

thousands of kilometres

Check tyre conditions and wear and adjust inflation pressure,

if required

Check lighting system operation (headlights, direction indicators,

hazard lights, boot, passenger compartment, instrument panel

warning lights, etc.).

Check windscreen wiper/washer operation and adjust nozzles.

Check front and rear wiper blade position and wear

Check front disc brake pad conditions and wear

Check rear drum brake lining conditions and wear

Inspect conditions of: outside bodywork, underbody protection,

piping/hosing (exhaust – fuel lines – brake lines), rubber parts

(boots, sleeves, bushings, etc.)

Check tension and conditions of various control belts and adjust,

if required

Check utility drive belt conditions

Check and adjust tappet clearance (1.2

16VM Nblueand1.2 LS versions)

Check and adjust handbrake lever stroke

Check evaporation system

Replace air cleaner cartridge

20 40 60 80 100 120 140 160 180

●●●●●●●●●

●●●●●●●●●

●●●●●●●●●

●●●●●●●●●

●●●●●●●●●

●●●

●●●●●●●●●

●

●●●●

●●●●

●●●●

●●

●●●

4C120-143 ING 11-03-2008 12:01 Pagina 122

Page 127 of 191

124

G

ADDITIONAL

CHECKS

Every 1000 kilometres or before

long trips, check and top up as neces-

sary:

– coolant level

– brake fluid level

– power steering fluid level

– windscreen washer liquid level

– tyre pressure and condition.

Every 3,000 kmcheck and top up

as necessary: engine oil level.

You are recommended to use

FL Groupproducts designed and pro-

duced specially for Lancia cars (see

the “Capacities” table in the “Tech-

nical specifications” section).

ANNUAL

INSPECTION

SCHEDULE

The following annual inspection

schedule is recommended for cars

travelling less than 20,000 km a year

(e.g. approximately 10,000 km). The

schedule includes the following oper-

ations:

– Check tyre condition and wear and

adjust pressure, if required (including

spare wheel).

– Check operation of lights (head-

lights, direction indicators, hazard

lights, boot light, passenger compart-

ment ceiling light, glove compartment

light, instrument panel lights, etc.).

– Check windscreen wiper/washer

and adjust nozzles.

– Check position/wear of wind-

screen/rear window wiper blades.

– Check front brake pad conditions

and wear.– Inspect conditions of. engine, gear-

box, transmission, piping (exhaust -

fuel feed - brakes), rubber parts (boots

- sleeves - bushings - etc.), brake and

fuel line hoses.

– Check battery charge status.

– Check conditions of various con-

trol belts.

– Check and top up fluid levels (en-

gine coolant, brakes, windscreen

washer, battery, etc.).

– Change engine oil.

– Replace engine oil filter.

– Replace pollen filter (where fitted).

4C120-143 ING 11-03-2008 12:01 Pagina 124

Page 147 of 191

TECHNICAL SPECIFICATIONS

Motor and engineering enthusiasts as well as

those “in the trade” will probably start reading

from this point in the manual. This, in fact, is

where a section jam-packed with facts, figures,

formulae, measurements and tables begins. In a

sense, it is the Lancia Y’s identity card.

A document that introduces the car and explains

in technical jargon all the features that go together

to make it a model designed to give you superla-

tive driving satisfaction.VEHICLE IDENTIFICATION DATA ............... 145

ENGINE CODE - BODY VERSIONS............... 146

ENGINE......................................................... 147

TRANSMISSION............................................. 150

BRAKES......................................................... 151

SUSPENSION ................................................. 152

STEERING..................................................... 152

WHEELS........................................................ 153

WHEEL GEOMETRY ..................................... 155

ELECTRICAL SYSTEM ................................. 155

PERFORMANCE............................................ 156

WEIGHTS...................................................... 157

DIMENSIONS................................................. 158

CAPACITIES .................................................. 160

TYRE PRESSURE .......................................... 163

FLUIDS AND LUBRICANTS .......................... 164

FUEL CONSUMPTION -

CO

2EMISSIONS ............................................. 166

144

G

4C144-167 ING 11-03-2008 12:02 Pagina 144

Page 151 of 191

148

G

FUEL SUPPLY / IGNITION

1.2 versions

Integrated electronic injection and

ignition system: a single electronic

control unit controls both functions.

It processes both the time the injec-

tion lasts (for fuel metering) and the

spark advance angle.

– Type: ......................Multi-point.

– Method of measuring the amount

of aspirated air for petrol metering:

“Speed density” (*).

– “Closed loop”: information on

combustion for correct petrol meter-

ing achieved by means of two lambda

sensors (one upstream and the other

downstream with respect to the catal-

yser).– Electric petrol pump: in-tank.

– Injection pressure: ......... 3.5 bar.

– Air cleaner: dry-type with paper

filter element.

– Firing order: ................1-3-4-2.

– Engine idling speed: 750±50 rpm.

– Spark plugs:

Champion.................RC10YCC

NGK ........................... BKR5EZ1.216Vversions

Integrated electronic injection and

ignition system: a single electronic

control unit controls both functions.

It processes both the time the injec-

tion lasts (for fuel metering) and the

spark advance angle.

– Type: ......................Multi-point.

– Method of measuring the amount

of aspirated air for “Speed density”

petrol metering (*).

– “Closed loop”: information on

combustion for correct petrol meter-

ing achieved by means of two lambda

sensors (one upstream and the other

downstream with respect to the catal-

yser).

– Electric petrol pump: in-tank.

4C144-167 ING 11-03-2008 12:02 Pagina 148

Page 152 of 191

149

G

– Injection pressure: ......... 3.5 bar.

– Air cleaner: dry-type with paper

filter element.

– Firing order: ................1-3-4-2.

– Engine idling speed: 700±50 rpm.

– Spark plugs:

NGK ..........................DCPR8E-N

(*) Analytic method, by electronically process-

ing data from the engine rpm (speed) sensor

and from the air temperature and absolute pres-

sure sensors in the intake manifold (density).

LUBRICATION

Forced-fed with gear pump with

pressure relief valve incorporated.

Oil purification through full-flow

cartridge filter.

COOLING

Cooling system with radiator, cen-

trifugal pump and expansion tank.

“Fixed by-pass” thermostat(1.2 en-

gine)” on the secondary circuit for the

recirculation of water from the engine

to the radiator.

Electric fan for radiator cooling on

the radiator with switching on/off

controlled by thermostatic switch lo-

cated on the radiator. Modifications or repairs

to the fuel feed system that

are not carried out prop-

erly or do not take the system’s

technical specifications into ac-

count can cause malfunctions with

the risk of fire.

4C144-167 ING 11-03-2008 12:02 Pagina 149

Page 189 of 191

fdG

Stampato n. 603.45.362 - IV - 2001 - 3rdEdition - Printed by Satiz- Turin (Italy)

Coordinamento Editoriale Satiz - Torino

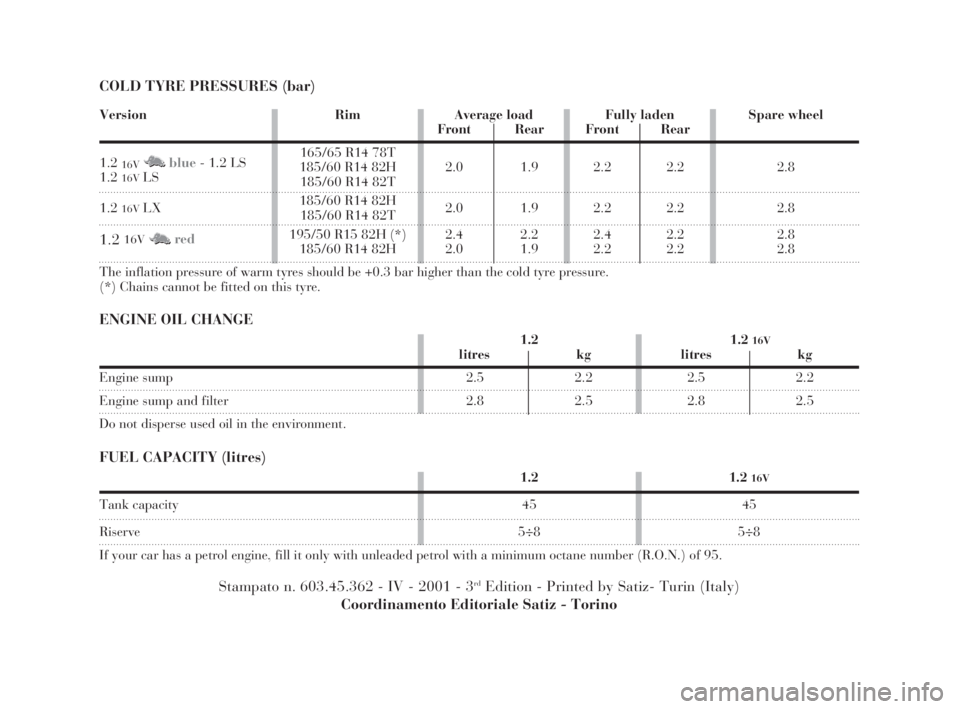

COLD TYRE PRESSURES (bar)

ENGINE OIL CHANGE

FUEL CAPACITY (litres)

Version Rim Average load Fully laden Spare wheelFront Rear Front Rear

165/65 R14 78T

1.2

16VM Nblue- 1.2 LS

185/60 R14 82H 2.0 1.9 2.2 2.2 2.81.216VLS

185/60 R14 82T

1.2

16VLX185/60 R14 82H

2.0 1.9 2.2 2.2 2.8185/60 R14 82T

1.216VM Nred195/50 R15 82H (*) 2.4 2.2 2.4 2.2 2.8185/60 R14 82H 2.0 1.9 2.2 2.2 2.8

The inflation pressure of warm tyres should be +0.3 bar higher than the cold tyre pressure.

(*) Chains cannot be fitted on this tyre.

1.2 1.2

16Vlitres kg litres kg

Engine sump 2.5 2.2 2.5 2.2

Engine sump and filter 2.8 2.5 2.8 2.5

Do not disperse used oil in the environment.

1.2 1.2 16V

Tank capacity 45 45

Riserve 5÷8 5÷8

If your car has a petrol engine, fill it only with unleaded petrol with a minimum octane number (R.O.N.) of 95.

4C177-184 Indice ING 13-03-2008 13:31 Pagina cop3