air conditioning LAND ROVER DEFENDER 1996 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 62 of 455

ENGINE

3

REPAIR ENGINE

Service repair no - 12.41.01

Remove

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

remove and refit procedures are required, it may

be necessary to remove the undertray and/or

integral access panels.

See CHASSIS AND BODY, Repair, Front

undertray

orSee CHASSIS AND BODY, Repair,

Rear undertray

CAUTION: Seal all exposed pipe ends

against ingress of dirt after disconnection.

1.Ensure vehicle is level and apply park brake.

2.Disconnect battery.

NOTE: The vehicle may be fitted with an

alarm and immobilisation system using a

battery backed-up alarm sounder.

See ELECTRICAL, Repair, battery

3.Remove bonnet.

4.Remove cable ties securing gearbox harness to

breather pipes.

5.Disconnect harness from diff lock and reverse

light switches.

6.Manouvre harness into engine bay.

7.Remove air cleaner.

See FUEL SYSTEM,

Repair, Air cleaner

8.Remove radiator assembly.See COOLING

SYSTEM, Repair, Radiator

If air conditioning is fitted the condenser will

have to be removed, compressor pipes and

heater matrix hoses disconnected.

See AIR CONDITIONING, Repair, Condenser

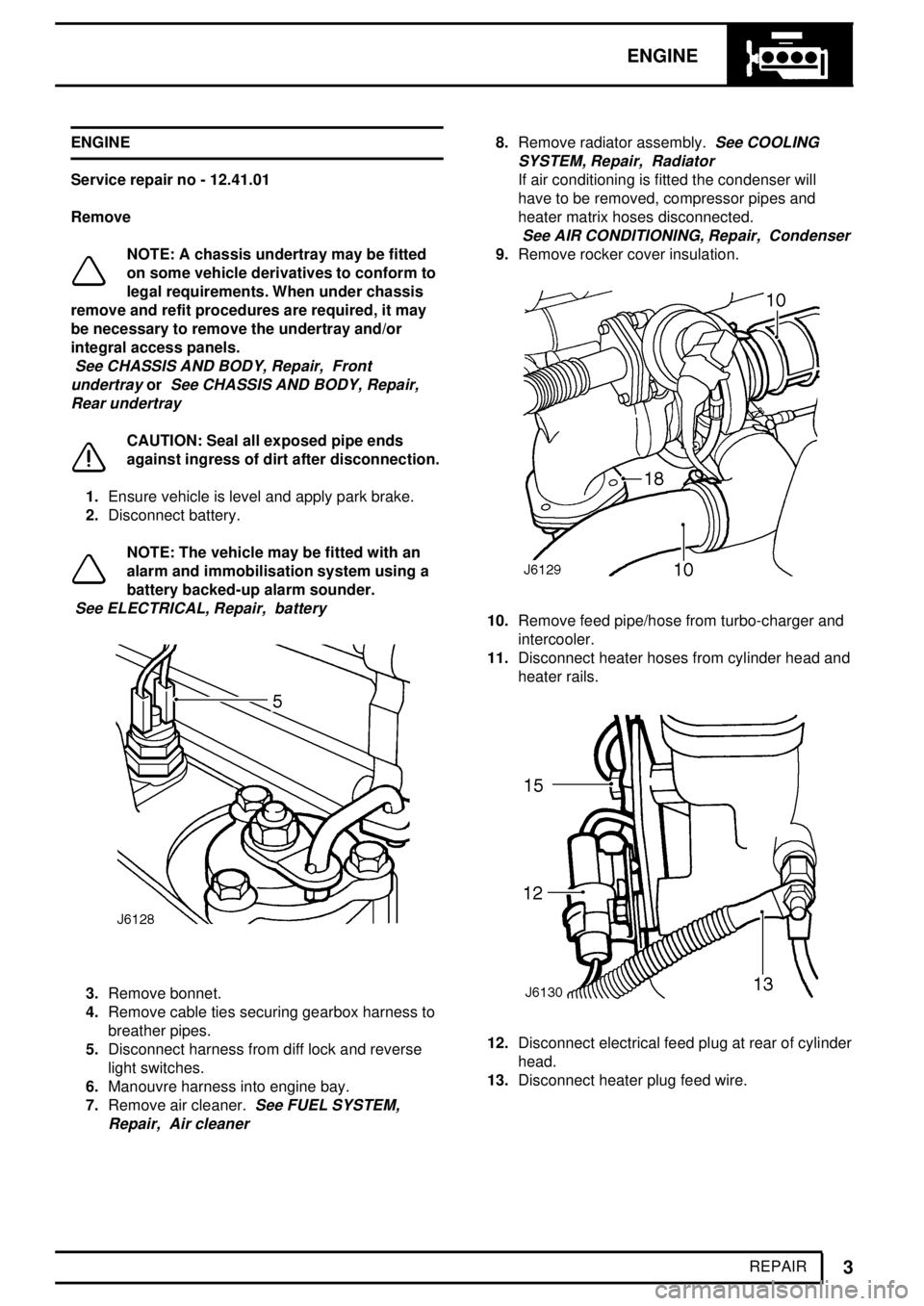

9.Remove rocker cover insulation.

10.Remove feed pipe/hose from turbo-charger and

intercooler.

11.Disconnect heater hoses from cylinder head and

heater rails.

12.Disconnect electrical feed plug at rear of cylinder

head.

13.Disconnect heater plug feed wire.

Page 65 of 455

12ENGINE

6

REPAIR 42.Raise engine, and locate front engine mountings

to chassis.

43.Remove gearbox support and lower engine.

44.Tighten front engine mounting to chassis fixings

to

45 Nm (33 lbf/ft).

45.Release chains from engine lifting brackets and

remove hoist.

46.Connect oil cooler pipes to oil filter adaptor.

47.Fit vacuum hose to brake servo adaptor.

48.Secure fuel feed pipe in retaining clip on air

cleaner bracket.

49.Fit fuel lift pump pipes.

50.Connect feed and spill return pipes to injector

pump.

51.If fitted, reconnect hand throttle cable to

mounting bracket and injector pump.

52.Fit outer cable adjusting nut into injector pump

mounting bracket.

53.Fit inner throttle cable to injector pump and

secure with clevis and split pin.

54.Secure bleed hose in retaining clips on front

timing cover.

55.Fit bleed hose to thermostat housing.

56.Connect inlet and outlet hoses to power steering

pump.

57.Fit down pipe to exhaust manifold and secure

with 3 nuts.

58.Connect starter motor battery and fuse box

leads.

59.If fitted, connect EGR valve multi-plug and

vacuum pipe.

60.Secure breather pipe clip to cylinder head.

61.Connect engine harness multi-plug.

62.Fit heater plug feed wire.

63.Connect electrical feed plug at rear of cylinder

head.

64.Fit heater hoses to cylinder head and heater

rails.

65.Fit feed pipe/hose to turbo-charger and

intercooler.

66.Fit rocker cover insulation.

67.Fit radiator assembly.

See COOLING SYSTEM,

Repair, Radiator

If applicable, fit air

conditioning condenser, compressor pipes and

heater matrix hoses.

See AIR CONDITIONING,

Repair, Condenser

68.Fit bonnet.

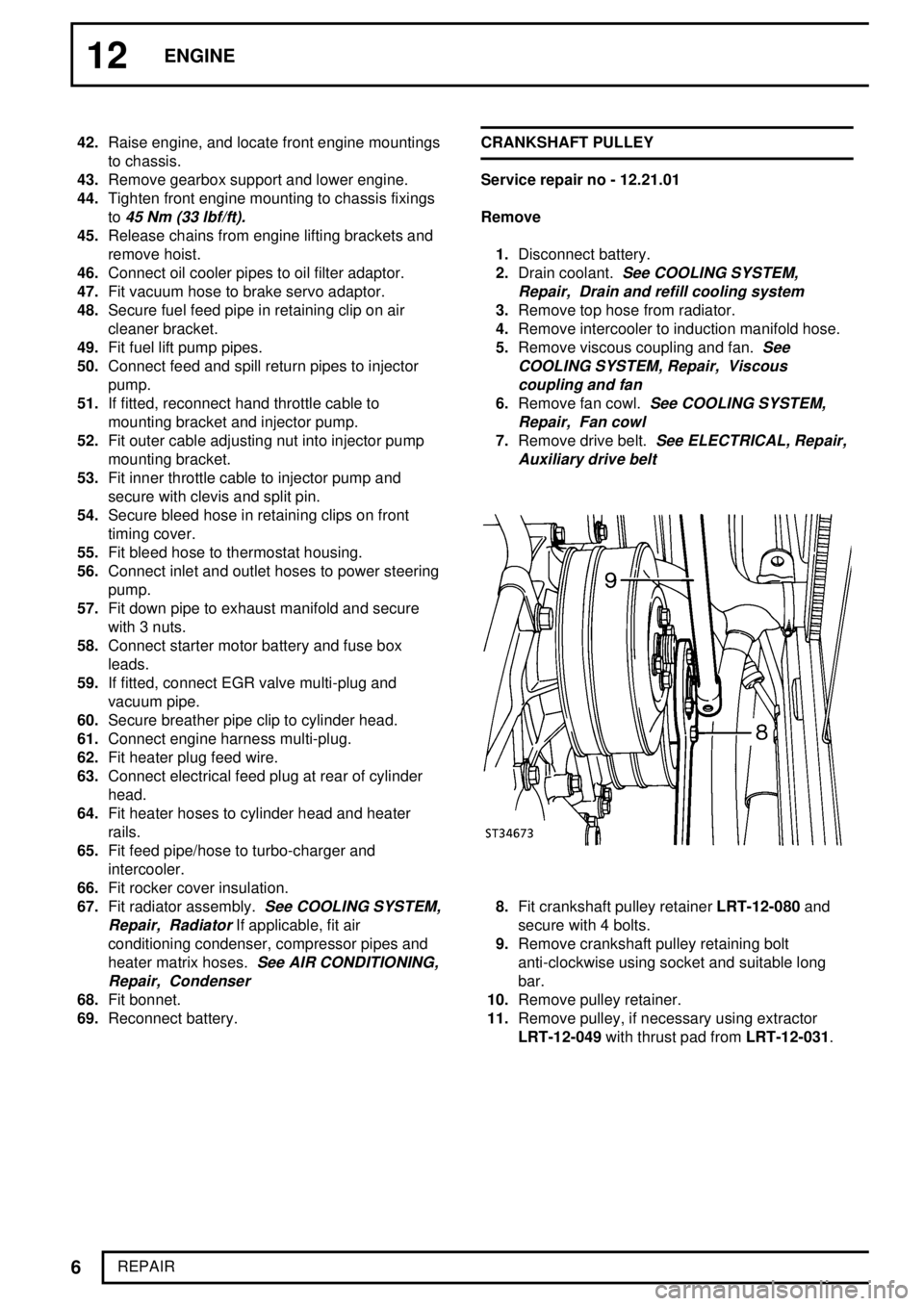

69.Reconnect battery.CRANKSHAFT PULLEY

Service repair no - 12.21.01

Remove

1.Disconnect battery.

2.Drain coolant.

See COOLING SYSTEM,

Repair, Drain and refill cooling system

3.Remove top hose from radiator.

4.Remove intercooler to induction manifold hose.

5.Remove viscous coupling and fan.

See

COOLING SYSTEM, Repair, Viscous

coupling and fan

6.Remove fan cowl.See COOLING SYSTEM,

Repair, Fan cowl

7.Remove drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

8.Fit crankshaft pulley retainerLRT-12-080and

secure with 4 bolts.

9.Remove crankshaft pulley retaining bolt

anti-clockwise using socket and suitable long

bar.

10.Remove pulley retainer.

11.Remove pulley, if necessary using extractor

LRT-12-049with thrust pad fromLRT-12-031.

Page 86 of 455

ENGINE

3

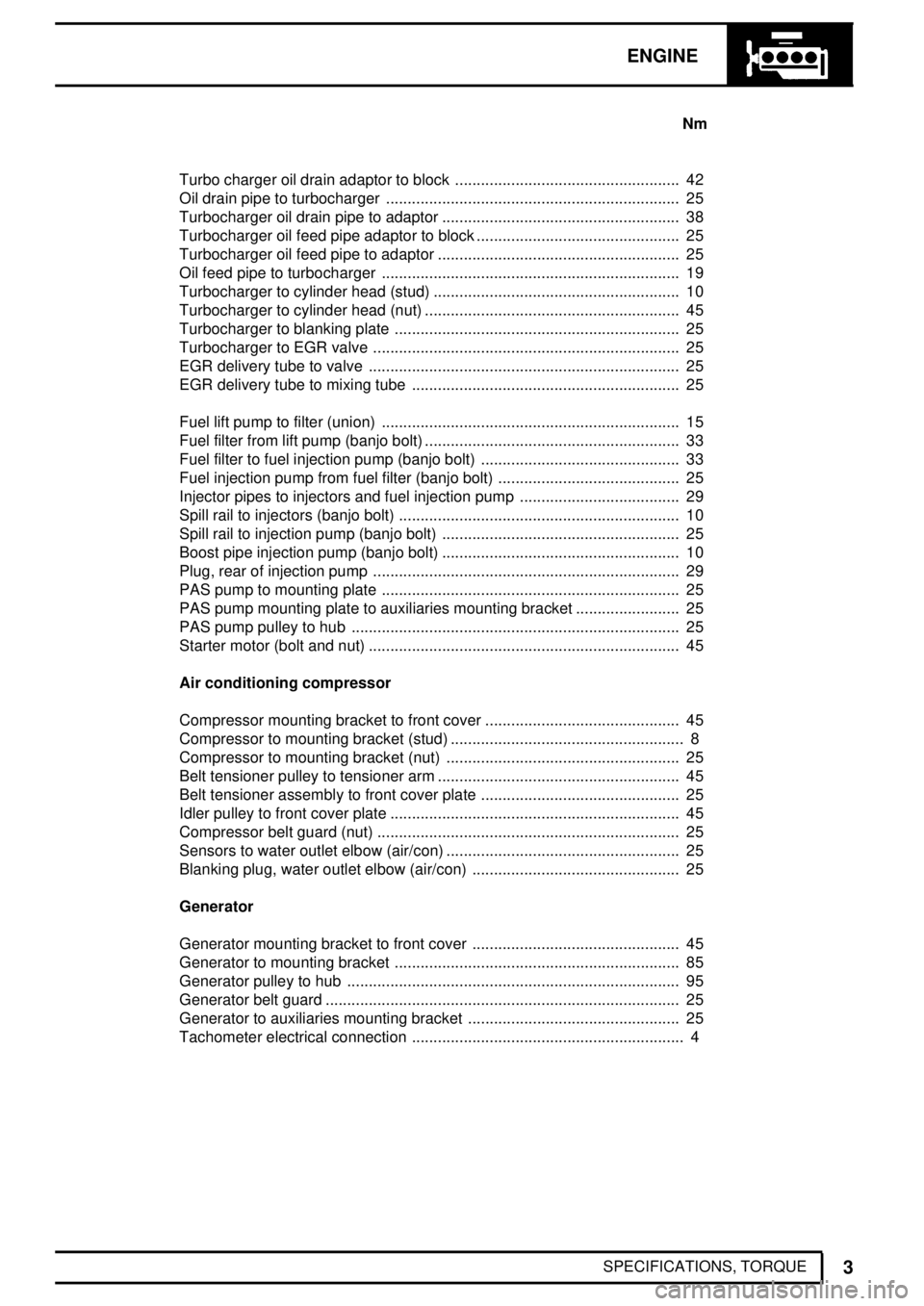

SPECIFICATIONS, TORQUENm

Turbo charger oil drain adaptor to block 42....................................................

Oil drain pipe to turbocharger 25....................................................................

Turbocharger oil drain pipe to adaptor 38.......................................................

Turbocharger oil feed pipe adaptor to block 25...............................................

Turbocharger oil feed pipe to adaptor 25........................................................

Oil feed pipe to turbocharger 19.....................................................................

Turbocharger to cylinder head (stud) 10.........................................................

Turbocharger to cylinder head (nut) 45...........................................................

Turbocharger to blanking plate 25..................................................................

Turbocharger to EGR valve 25.......................................................................

EGR delivery tube to valve 25........................................................................

EGR delivery tube to mixing tube 25..............................................................

Fuel lift pump to filter (union) 15.....................................................................

Fuel filter from lift pump (banjo bolt) 33...........................................................

Fuel filter to fuel injection pump (banjo bolt) 33..............................................

Fuel injection pump from fuel filter (banjo bolt) 25..........................................

Injector pipes to injectors and fuel injection pump 29.....................................

Spill rail to injectors (banjo bolt) 10.................................................................

Spill rail to injection pump (banjo bolt) 25.......................................................

Boost pipe injection pump (banjo bolt) 10.......................................................

Plug, rear of injection pump 29.......................................................................

PAS pump to mounting plate 25.....................................................................

PAS pump mounting plate to auxiliaries mounting bracket 25........................

PAS pump pulley to hub 25............................................................................

Starter motor (bolt and nut) 45........................................................................

Air conditioning compressor

Compressor mounting bracket to front cover 45.............................................

Compressor to mounting bracket (stud) 8......................................................

Compressor to mounting bracket (nut) 25......................................................

Belt tensioner pulley to tensioner arm 45........................................................

Belt tensioner assembly to front cover plate 25..............................................

Idler pulley to front cover plate 45...................................................................

Compressor belt guard (nut) 25......................................................................

Sensors to water outlet elbow (air/con) 25......................................................

Blanking plug, water outlet elbow (air/con) 25................................................

Generator

Generator mounting bracket to front cover 45................................................

Generator to mounting bracket 85..................................................................

Generator pulley to hub 95.............................................................................

Generator belt guard 25..................................................................................

Generator to auxiliaries mounting bracket 25.................................................

Tachometer electrical connection 4...............................................................

Page 113 of 455

FUEL SYSTEM

11

REPAIR HEATER PLUGS

Service repair no - 19.60.31

Remove

1.Disconnect battery.

No.1 heater plug - air conditioning models:

2.Release drive belt from compressor pulley.See

AIR CONDITIONING, Repair, Compressor

drive belt

3.Remove 4 bolts securing compressor to front

cover, move compressor aside.

No.3 heater plug:

4.Remove retaining bolt and withdraw breather

valve from rocker cover. Remove and discard 'O'

ring.

All heater plugs:

5.Remove terminal nut and disconnect wire from

heater plug terminal.

6.Unscrew heater plug.

Refit

7.Clean heater plug and seating.

8.Coat threads of heater plug with suitable

anti-seize compound operational to a

temperature of 1000°C.

9.Fit heater plug, tighten to

23 Nm (17 lbf/ft).

10.Connect wire to heater plug terminal and secure

with nut.

NOTE: Feed wire must be connected to

No. 4 heater plug terminal.

No. 3 heater plug:

11.Lubricate new 'O' ring with engine oil and fit to

breather valve.

12.Fit valve to rocker cover, tighten to bolt to

15 Nm

(11 lbf/ft).

No. 1 heater plug - air conditioning models

13.Position compressor to front cover, fit bolts and

tighten to

25 Nm (18 lbf/ft).

14.Fit drive belt to compressor pulley and adjust

tension.

See AIR CONDITIONING, Repair,

Compressor drive belt

All models:

15.Reconnect battery.

Page 126 of 455

COOLING SYSTEM

1

REPAIR VISCOUS COUPLING AND FAN

Service repair no - 26.25.19 - Viscous coupling

Service repair no - 26.25.05 - Fan

Remove

NOTE: The viscous coupling has a LH

thread.

1.Disconnect battery.

2.Using special pulley restraining toolLRT-12-094

and special spannerLRT-12-093unscrew

viscous coupling from pulley hub adaptor thread.

3.Remove viscous coupling and fan from vehicle.

NOTE: If air conditioning is fitted, the fan

cowl will also need removing,

See Fan

cowl

, with the viscous fan unit.

4.If required, remove 4 screws and release

viscous unit from fan blade.

Refit

5.Fit viscous unit to fan blades.

6.If applicable, fit fan cowl.

See Fan cowl

7.Carefully position viscous coupling and fit onto

pulley hub adaptor thread.

8.Using special pulley retaining tool, spanner and

a suitable torque wrench, tighten assembly to

45

Nm (33 lbf/ft).

Page 127 of 455

26COOLING SYSTEM

2

REPAIR FAN COWL

Service repair no - 26.25.11

Remove

1.Disconnect battery.

2.Drain coolant.

See Adjustment, Drain and

refill cooling system.

3.Slacken retaining clips and remove radiator top

hose.

4.Slacken retaining clip and remove top hose from

intercooler.

NOTE: On vehicles fitted with EGR system,

remove complete intercooler top hose

assembly.

5.Remove viscous coupling and fan

See Viscous coupling and fan.

6.Remove 2 nuts securing top of fan cowl.

7.Release expansion tank hose from clips at base

of fan cowl.

8.Lift and remove cowl .

NOTE: On vehicles fitted with air

conditioning, it will be necessary to

remove the cowl and viscous fan unit

together to enable clearance of the compressor.Refit

9.Position fan cowl.

10.Fit viscous fan unit.

See Viscous coupling

and fan

11.Fit expansion tank hose into fan cowl clips.

12.Secure top of fan cowl to radiator top cover.

13.Fit intercooler top hose.

14.Fit radiator top hose.

15.Refill cooling system.

See Adjustment, Drain

and refill cooling system

16.Reconnect battery.

FAN PULLEY

Service repair no - 26.25.04.

Remove

1.Disconnect battery.

2.Remove viscous fan unit.

See Viscous

coupling and fan

3.Remove drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

4.Unscrew 4 bolts and remove pulley from adaptor

boss.

Refit

5.Fit fan pulley to adaptor boss. Tighten bolts to

25

Nm (18 lbf/ft).

6.Fit drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

7.Fit viscous fan unit.See Viscous coupling

and fan

8.Reconnect battery.

Page 361 of 455

HEATING AND VENTILATION

1

DESCRIPTION AND OPERATION HEATING AND VENTILATION SYSTEM

Description

The heating and ventilation system is standard on all

models. Air conditioning is an optional system which

provides fully integrated climate control for the vehicle

interior.The heater assembly, comprising a matrix housed in a

distribution unit and a variable speed blower motor, is

located on one side of the engine compartment and

attached directly to the fascia bulkhead.

The heating controls are positioned on the outside of

the instrument binnacle and cable linked to

mechanical flaps in the distribution unit.

Heater assembly

1.Heater distribution unit

2.Fixings, heater to fascia bulkhead

3.Heater matrix

4.Blower motor housing

5.Circlip, impeller to blower motor

6.Impeller

7.Resistor unit and harness connector8.Fixings, blower motor mounting plate

9.Mounting plate, blower motor

10.Blower motor

11.Fixings, blower motor to mounting bracket

12.Temperature flap, air flow to heater matrix

13.Air flap, air supply to plenum chamber (heater

duct)

Page 372 of 455

AIR CONDITIONING

1

DESCRIPTION AND OPERATION AIR CONDITIONING SYSTEM

Description

Air conditioning is an optional system which provides

fully integrated climate control for the vehicle interior.

The air conditioning system comprises four major

units as follows:- An evaporator matrix and expansion

valve (1), housed in the heater/ cooler unit (3), an

engine mounted compressor (4), a condenser (5),mounted in front of the radiator, and a receiver/drier

(7) located to the right of the condenser.

Ancillary components in the system comprise a blower

motor (2), also housed in the heater/cooler unit, and

condenser cooling fan motors (6), mounted on a

support frame. The four major units are interconnectd

by preformed metal and flexible refrigerant pipes as

illustrated below (RH drive installation shown).

Coolant flow to a heater matrix, housed in the heater

cooler unit, is controlled by a water valve (8) from a

combined air conditioning panel on the vehicle fascia.

1.Evaporator matrix and expansion valve

2.Blower motor

3.Heater/cooler unit

4.Compressor

5.Condenser6.Condenser fan motors

7.Receiver/drier

8.Water valve

9.Heater matrix feed and return hoses

Page 373 of 455

82AIR CONDITIONING

2

DESCRIPTION AND OPERATION Operation

Evaporator unit and expansion valve

High pressure liquid refrigerant is delivered to the

expansion valve which is the controlling device for the

air conditioning system. A severe pressure drop

occurs across the valve and as the refrigerant flows

through the evaporator it picks up heat from the

ambient air, boils and vaporizes. As this change of

state occurs, a large amount of latent heat is

absorbed. The evaporator is therefore cooled and as

a result heat is extracted from the air flowing across

the evaporator. The refrigerant leaves the evaporator,

on its way to the compressor, as a low pressure gas.

An evaporator sensor measures the air temperature at

the evaporator and engages or disengages the

compressor clutch to prevent icing of the air ways.

Compressor

The compressor, a pump specially designed to raise

the pressure of the refrigerant, is mounted on the front

of the engine and is driven by an independent drive

belt from the crankshaft pulley. The compressor draws

vaporized refrigerant from the evaporator. It is

compressed with a resulting rise in temperature and

passed on to the condenser as a hot, high pressure

vapour.

Condenser

The condenser is mounted directly in front of the

radiator and consists of a refrigerant coil mounted in a

series of thin cooling fins to provide the maximum

heat transfer. Air flow across the condenser is induced

by vehicle movement and assisted by two electric fans

attached to the frame of the condenser. The

refrigerant high pressure vapour enters the condenser

inlet on the RH side. As the vapour passes through

the condenser coils the air flow, assisted by the two

fans, carries the latent heat away from the condenser.

This induces a change of state resulting in the

refrigerant condensing into a high pressure warm

liquid. From the condenser, the refrigerant continues

to the receiver/ drier.

Receiver/drier

This component acts as a reservoir and is used to

hold extra refrigerant until it is needed by the

evaporator. The drier within the receiver unit contains

a filter and dessicant (drying material) which absorb

moisture and prevent dessicant dust from being

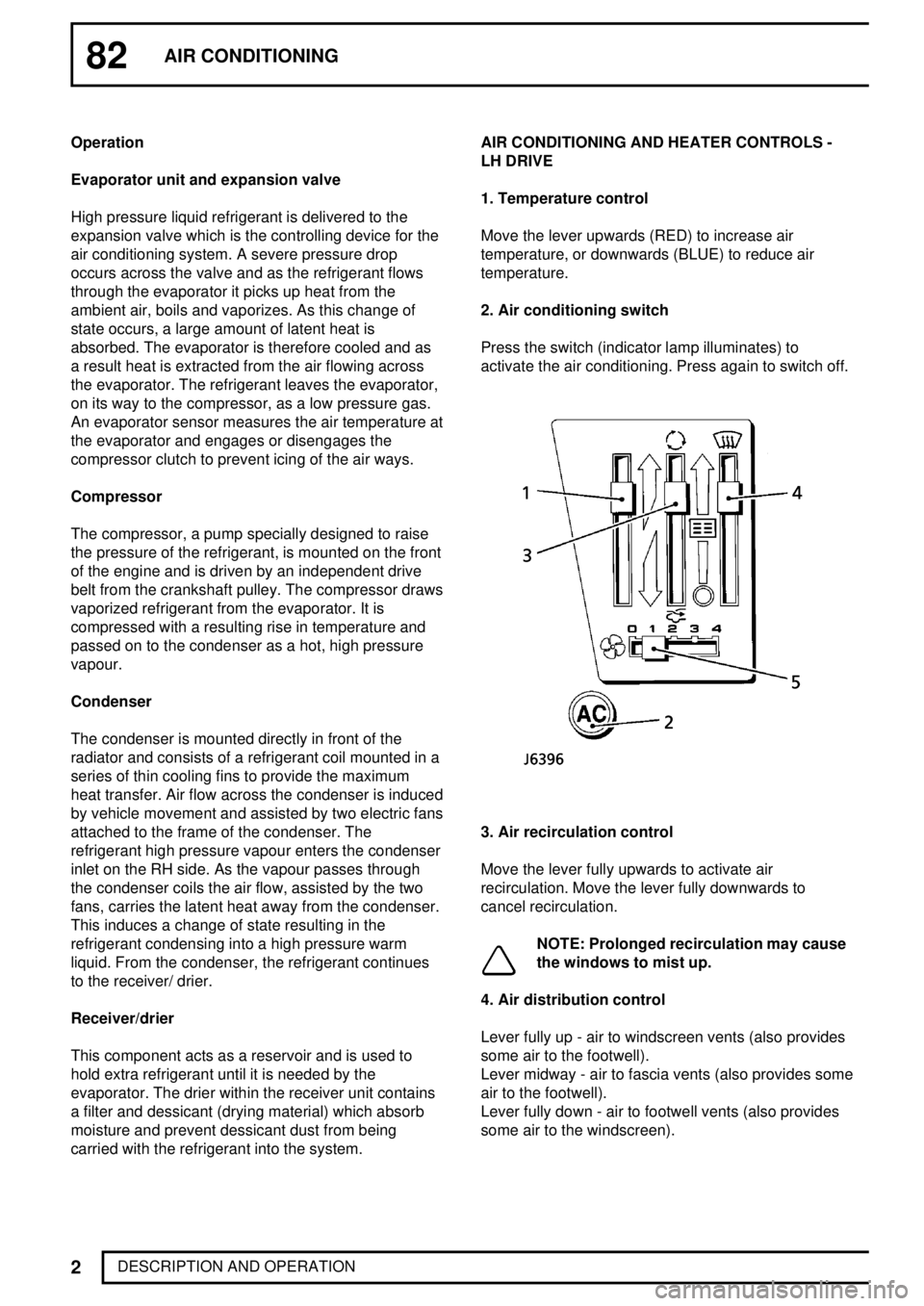

carried with the refrigerant into the system.AIR CONDITIONING AND HEATER CONTROLS -

LH DRIVE

1. Temperature control

Move the lever upwards (RED) to increase air

temperature, or downwards (BLUE) to reduce air

temperature.

2. Air conditioning switch

Press the switch (indicator lamp illuminates) to

activate the air conditioning. Press again to switch off.

3. Air recirculation control

Move the lever fully upwards to activate air

recirculation. Move the lever fully downwards to

cancel recirculation.

NOTE: Prolonged recirculation may cause

the windows to mist up.

4. Air distribution control

Lever fully up - air to windscreen vents (also provides

some air to the footwell).

Lever midway - air to fascia vents (also provides some

air to the footwell).

Lever fully down - air to footwell vents (also provides

some air to the windscreen).

Page 374 of 455

AIR CONDITIONING

3

DESCRIPTION AND OPERATION 5. Blower motor fan speed control

Move the lever to the right to progressively increase

fan speed.

Location of air vents - LH drive

AIR CONDITIONING AND HEATER CONTROLS -

RH DRIVE

1. Temperature control

Move the lever to the right (RED) to increase air

temperature, or to the left (BLUE) to reduce air

temperature.

2. Air conditioning indicator lamp

Illuminates when the air conditioning system is

operating.3. Air conditioning switch

Press the RH portion of the switch to activate the air

conditioning (indicator lamp illuminates). Press the LH

portion to switch off.

NOTE: Air conditioning should only be

activated when the engine is running.

4. Blower motor fan speed control

Move the lever upwards to progressively increase fan

speed.