cooling LAND ROVER DEFENDER 1996 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 66 of 455

ENGINE

7

REPAIR Refit

12.Lightly grease pulley spigot and locate pulley

onto cranshaft.

13.Fit pulley retaining bolt.

14.Fit pulley retainerLRT-12-080and secure with 4

bolts.

15.Tighten pulley nut to

80 Nm (59 lbf/ft)+90°.

16.Remove pulley retainer.

17.Fit drive belt.

See ELECTRICAL, Repair,

Auxiliary drive belt; Refit

18.Fit fan cowl.See COOLING SYSTEM, Repair,

Fan cowl

19.Fit viscous coupling and fan.See COOLING

SYSTEM, Repair, Viscous coupling and fan

20.Fit intercooler to induction manifold hose.

21.Fit radiator top hose.

22.Refill cooling system.

See COOLING SYSTEM,

Repair, Drain and refill cooling system

23.Reconnect battery.FRONT COVER PLATE AND SEAL

Service repair no - 12.65.01

Remove

1.Disconnect battery.

2.Drain coolant.

See COOLING SYSTEM,

Repair, Drain and refill cooling system

3.Remove top hose from radiator.

4.Remove intercooler to induction manifold hose.

5.Remove viscous coupling and fan.

See

COOLING SYSTEM, Repair, Viscous

coupling and fan

6.Remove fan cowl.See COOLING SYSTEM,

Repair, Fan cowl

7.Remove drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

8.Remove crankshaft pulley.See Crankshaft

pulley

9.Remove 14 bolts securing front cover plate. Note

that top 2 bolts also retain thermostat hose clips.

10.Remove cover plate complete with gasket.

11.Remove small gasket from centre bolt boss.

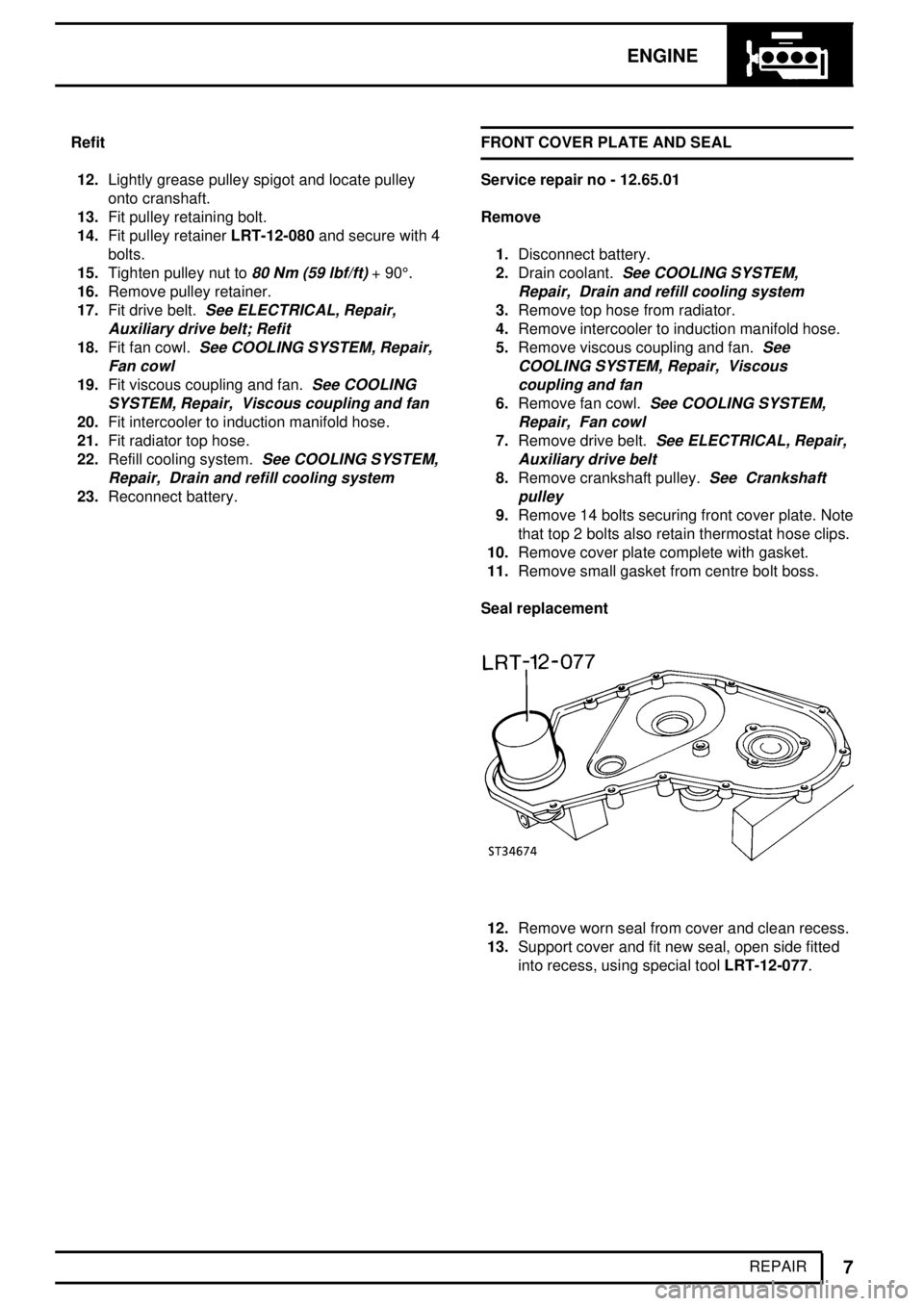

Seal replacement

12.Remove worn seal from cover and clean recess.

13.Support cover and fit new seal, open side fitted

into recess, using special toolLRT-12-077.

Page 67 of 455

12ENGINE

8

REPAIR Refit

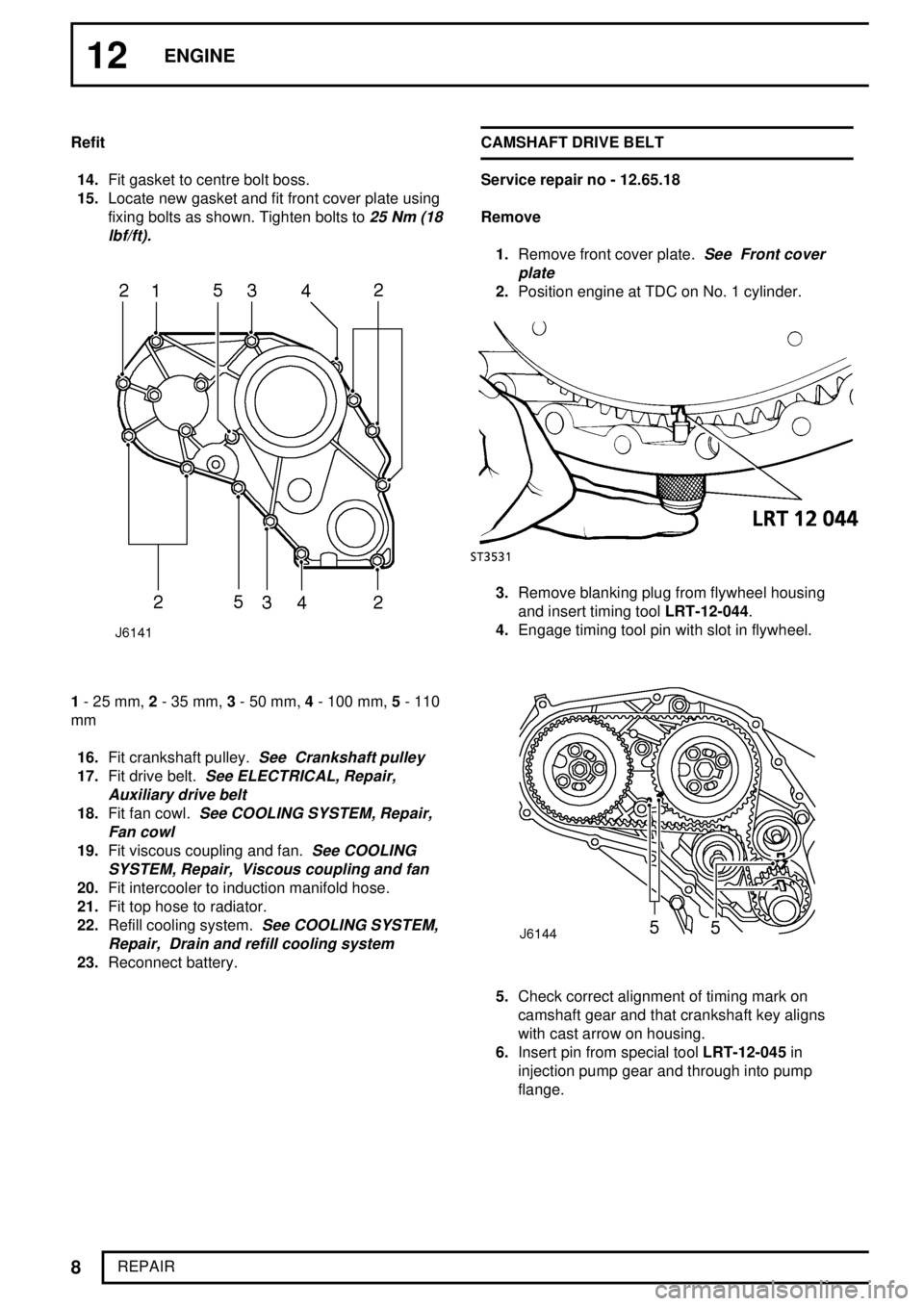

14.Fit gasket to centre bolt boss.

15.Locate new gasket and fit front cover plate using

fixing bolts as shown. Tighten bolts to

25 Nm (18

lbf/ft).

1- 25 mm,2- 35 mm,3- 50 mm,4- 100 mm,5- 110

mm

16.Fit crankshaft pulley.

See Crankshaft pulley

17.Fit drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

18.Fit fan cowl.See COOLING SYSTEM, Repair,

Fan cowl

19.Fit viscous coupling and fan.See COOLING

SYSTEM, Repair, Viscous coupling and fan

20.Fit intercooler to induction manifold hose.

21.Fit top hose to radiator.

22.Refill cooling system.

See COOLING SYSTEM,

Repair, Drain and refill cooling system

23.Reconnect battery.CAMSHAFT DRIVE BELT

Service repair no - 12.65.18

Remove

1.Remove front cover plate.

See Front cover

plate

2.Position engine at TDC on No. 1 cylinder.

3.Remove blanking plug from flywheel housing

and insert timing toolLRT-12-044.

4.Engage timing tool pin with slot in flywheel.

5.Check correct alignment of timing mark on

camshaft gear and that crankshaft key aligns

with cast arrow on housing.

6.Insert pin from special toolLRT-12-045in

injection pump gear and through into pump

flange.

Page 74 of 455

ENGINE

15

REPAIR FLYWHEEL

Service repair no - 12.53.07

Remove

1.Disconnect battery.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

assembly

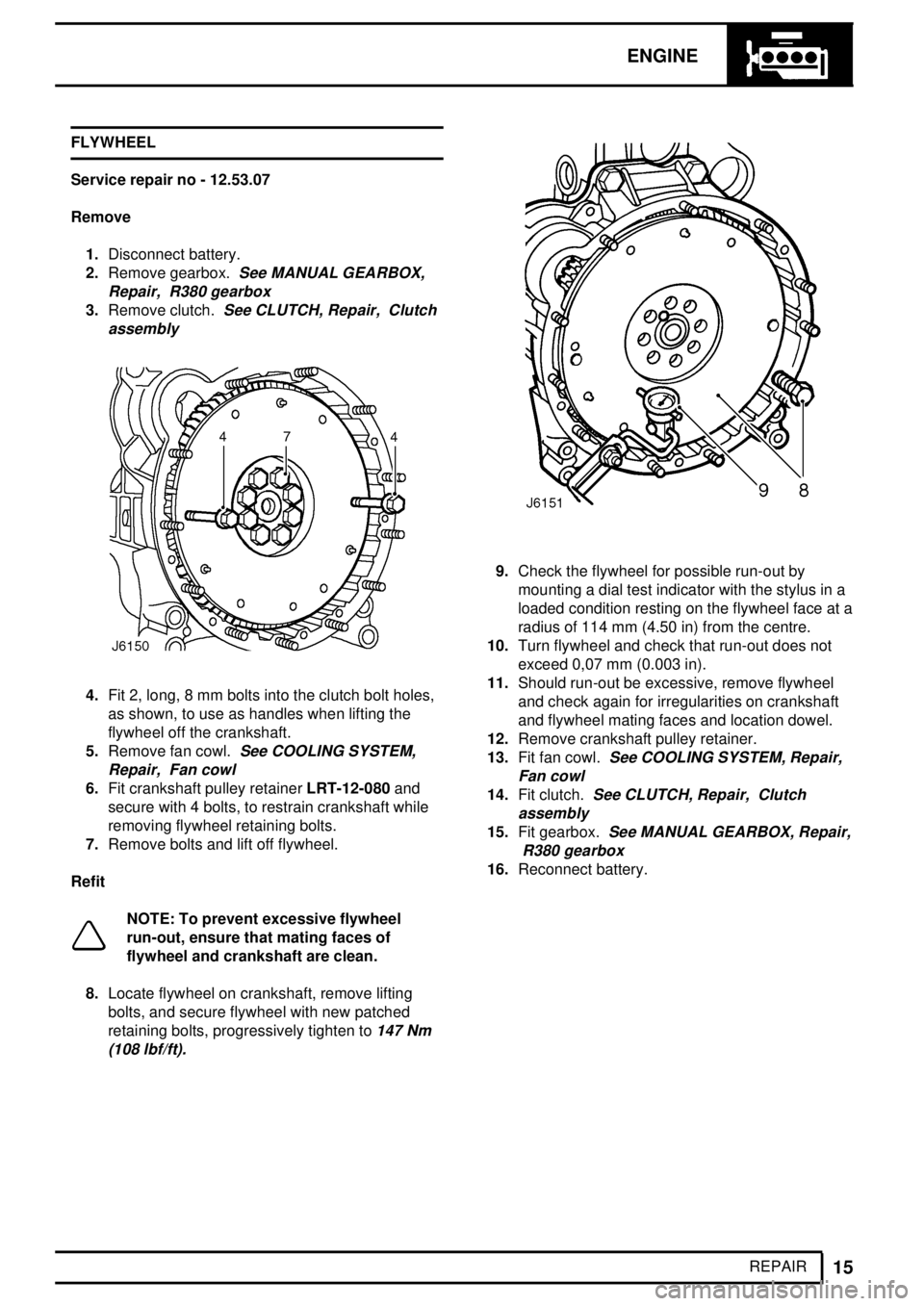

4.Fit 2, long, 8 mm bolts into the clutch bolt holes,

as shown, to use as handles when lifting the

flywheel off the crankshaft.

5.Remove fan cowl.

See COOLING SYSTEM,

Repair, Fan cowl

6.Fit crankshaft pulley retainerLRT-12-080and

secure with 4 bolts, to restrain crankshaft while

removing flywheel retaining bolts.

7.Remove bolts and lift off flywheel.

Refit

NOTE: To prevent excessive flywheel

run-out, ensure that mating faces of

flywheel and crankshaft are clean.

8.Locate flywheel on crankshaft, remove lifting

bolts, and secure flywheel with new patched

retaining bolts, progressively tighten to

147 Nm

(108 lbf/ft).

9.Check the flywheel for possible run-out by

mounting a dial test indicator with the stylus in a

loaded condition resting on the flywheel face at a

radius of 114 mm (4.50 in) from the centre.

10.Turn flywheel and check that run-out does not

exceed 0,07 mm (0.003 in).

11.Should run-out be excessive, remove flywheel

and check again for irregularities on crankshaft

and flywheel mating faces and location dowel.

12.Remove crankshaft pulley retainer.

13.Fit fan cowl.

See COOLING SYSTEM, Repair,

Fan cowl

14.Fit clutch.See CLUTCH, Repair, Clutch

assembly

15.Fit gearbox.See MANUAL GEARBOX, Repair,

R380 gearbox

16.Reconnect battery.

Page 79 of 455

12ENGINE

20

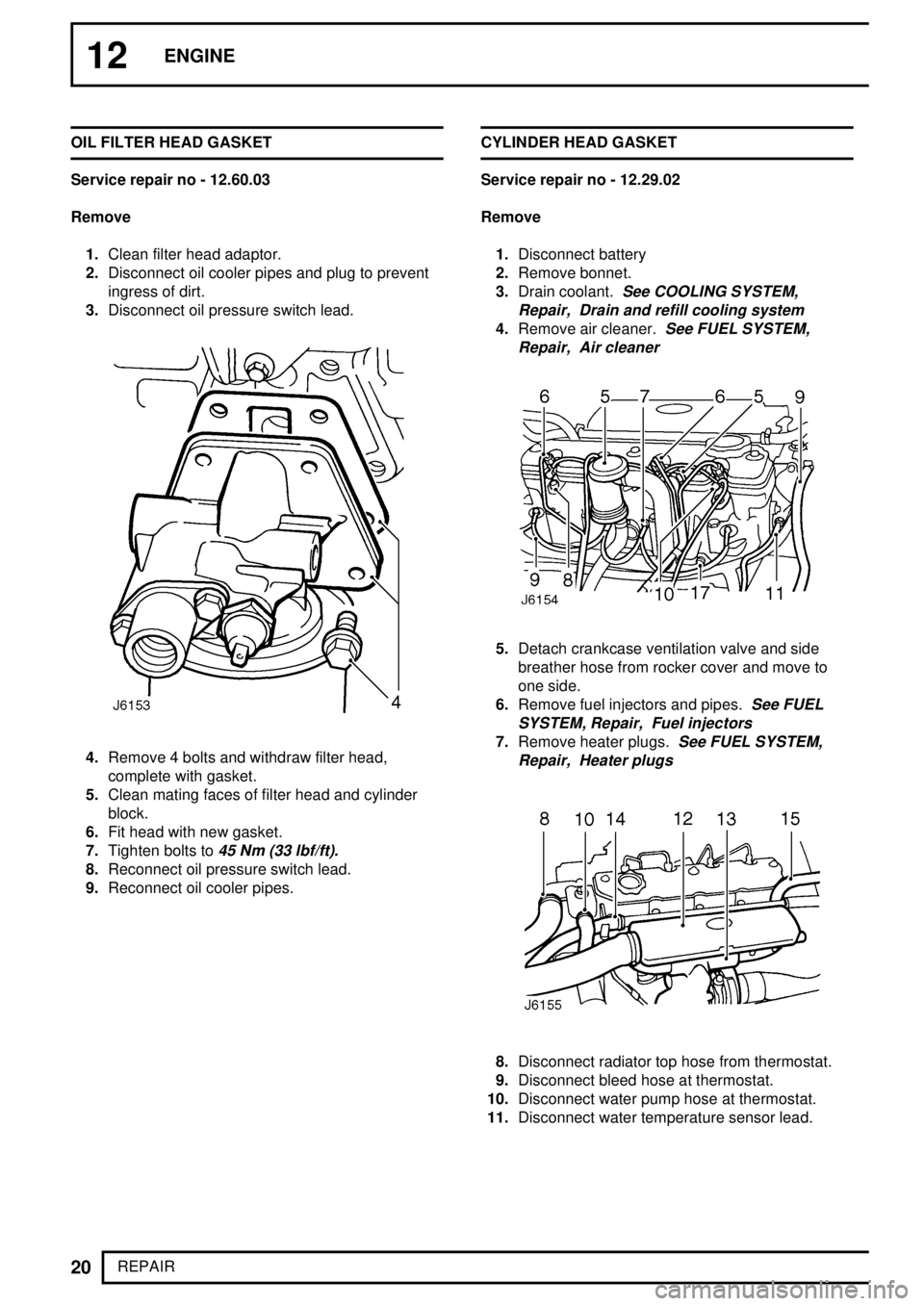

REPAIR OIL FILTER HEAD GASKET

Service repair no - 12.60.03

Remove

1.Clean filter head adaptor.

2.Disconnect oil cooler pipes and plug to prevent

ingress of dirt.

3.Disconnect oil pressure switch lead.

4.Remove 4 bolts and withdraw filter head,

complete with gasket.

5.Clean mating faces of filter head and cylinder

block.

6.Fit head with new gasket.

7.Tighten bolts to

45 Nm (33 lbf/ft).

8.Reconnect oil pressure switch lead.

9.Reconnect oil cooler pipes.CYLINDER HEAD GASKET

Service repair no - 12.29.02

Remove

1.Disconnect battery

2.Remove bonnet.

3.Drain coolant.

See COOLING SYSTEM,

Repair, Drain and refill cooling system

4.Remove air cleaner.See FUEL SYSTEM,

Repair, Air cleaner

5.Detach crankcase ventilation valve and side

breather hose from rocker cover and move to

one side.

6.Remove fuel injectors and pipes.

See FUEL

SYSTEM, Repair, Fuel injectors

7.Remove heater plugs.See FUEL SYSTEM,

Repair, Heater plugs

8.Disconnect radiator top hose from thermostat.

9.Disconnect bleed hose at thermostat.

10.Disconnect water pump hose at thermostat.

11.Disconnect water temperature sensor lead.

Page 82 of 455

ENGINE

23

REPAIR

43.Check and adjust valve clearances.

See Adjustment, Valve clearances - check

and adjust

44.Fit rocker cover, ensuring oil seal is satisfactory

for continued use, and renew if necessary.

45.Secure rocker cover with special seal washers

and nuts. Tighten to

10 Nm (7 lbf/ft).

46.Fit rear engine lifting bracket, securing breather

pipe and multi-plug retaining clips. Tighten fixing

bolts to

25 Nm (18 lbf/ft).

47.Fit engine harness bracket to cylinder head.

48.Secure air cleaner mounting bracket to support

strut.

49.Connect heater hose to rear of cylinder head.

50.Position heater rail and connect hose from water

pump.

51.Fit exhaust manifold and turbocharger assembly.

See MANIFOLD AND EXHAUST SYSTEM,

Repair, Exhaust manifold

52.Fit induction manifold.See MANIFOLD AND

EXHAUST SYSTEM, Repair, Induction

manifold

53.Connect water temperature sensor lead.

54.Connect water pump hose at thermostat.

55.Fit bleed hose at thermostat.

56.Connect radiator top hose at thermostat.

57.Fit heater plugs.

See FUEL SYSTEM, Repair,

Heater plugs

58.Fit fuel injectors.See FUEL SYSTEM, Repair,

Fuel injectors

59.Fit crankcase ventilation valve and side breather

hose.

60.Fit air cleaner.

See FUEL SYSTEM, Repair,

Air cleaner

61.Refill cooling system.See COOLING SYSTEM,

Repair, Drain and refill cooling system

62.Fit bonnet.

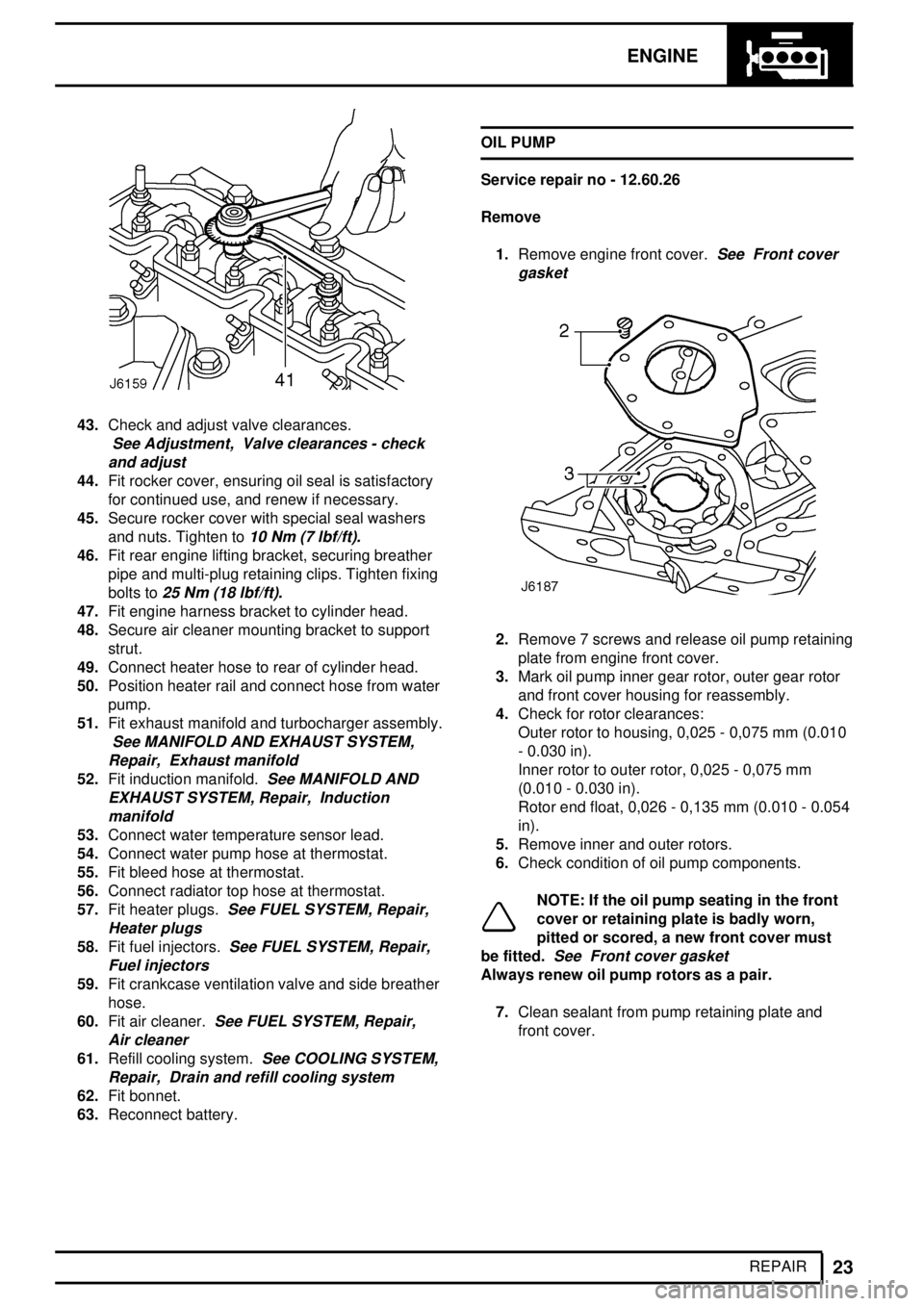

63.Reconnect battery.OIL PUMP

Service repair no - 12.60.26

Remove

1.Remove engine front cover.

See Front cover

gasket

2.Remove 7 screws and release oil pump retaining

plate from engine front cover.

3.Mark oil pump inner gear rotor, outer gear rotor

and front cover housing for reassembly.

4.Check for rotor clearances:

Outer rotor to housing, 0,025 - 0,075 mm (0.010

- 0.030 in).

Inner rotor to outer rotor, 0,025 - 0,075 mm

(0.010 - 0.030 in).

Rotor end float, 0,026 - 0,135 mm (0.010 - 0.054

in).

5.Remove inner and outer rotors.

6.Check condition of oil pump components.

NOTE: If the oil pump seating in the front

cover or retaining plate is badly worn,

pitted or scored, a new front cover must

be fitted.

See Front cover gasket

Always renew oil pump rotors as a pair.

7.Clean sealant from pump retaining plate and

front cover.

Page 96 of 455

FUEL SYSTEM

9

DESCRIPTION AND OPERATION OPERATION

Diesel engines operate by compression ignition. The

rapid compression of air in the cylinder during the

compression cycle heats the air and when fuel is

injected into the heated air, it ignites instantaneously.

During cold tarting, automatically controlled heater

plugs assist in raising the temperature of the

compressed air to ignition point.

A cold start advance unit advances the injection timing

to further assist starting. Idle quality is improved by

the high idle setting.

The engine is supplied with pre-compressed air by a

single stage turbocharger.

Exhaust gases passing over a turbine cause it to

rotate, driving a compressor mounted on the turbine

shaft. Air drawn from the cold air intake passes, via

the air cleaner, to the turbocharger where it is

compressed. Compression in the turbocharger warms

up the air considerably, so that it expands. As a result

the air mass per cylinder is reduced, having a

negative effect on power output. By fitting a charge-air

intercooler, located on the LH side of the radiator, the

air is cooled before reaching the cylinders. This

increases power output through increased mass of

oxygen in the combustion process, as well as

maximising engine durability, through maintaining

lower piston and head temperatures.

Fuel is drawn from the tank by a mechanical lift pump

and passes to the injection pump via a filter. In

addition to removing particle contamination from the

fuel, the filter incorporates a water separator, which

removes and stores water.

The sedimentor/s, when fitted, is located adjacent to

the fuel tank/s and separates contamination and water

particles in the fuel before reaching the fuel lift pump.

The injection pump meters a precisely timed, exact

quantity of fuel to the injectors in response to throttle

variations, injection timing varying with engine speed.

Any excess fuel delivered to the injection pump is

passed back to the tank via the spill return line.

Fuel is injected in a finely atomised form into the main

combustion chamber, the burning fuel expands

rapidly, creating extreme turbulence which mixes the

burning fuel thoroughly with the compressed air,

providing complete combustion.Cold Starting is assisted by heater plugs, a cold start

advance unit and a high idle setting.

Heater plugs

Heater plug operation is controlled by a timer unit,

start relay and resistor. When the ignition is turned on

the timer unit is energised, the heater plugs start to

operate and a warning light on the dashboard

illuminates, remaining on until the heater plugs are

automatically switched off.

The length of time the heater plugs will operate is

dependent on under bonnet temperature, which is

monitored by a sensor located in the timer unit.

Starting the engine results in the power supply to the

heater plugs passing through the resistor, which

reduces their operating temperature. The heater plugs

are cut out either by the temperature sensor in the

timer, or by a microswitch on the injection pump which

operates when the throttle is depressed.

Cold start advance

The cold start advance unit is connected to the engine

cooling system via hoses. It contains a temperature

sensitive element which is retracted when cold and

pulls the advance lever, via cable, towards the rear of

the pump against spring pressure. As coolant

temperature rises, the cold start element expands

releasing tension on the cable and allowing spring

pressure to move the advance lever forwards.

Exhaust gas recirculation (EGR), when fitted

Operation of the EGR system is dependent on the

following:

·Engine temperature - must be between 20°C and

100°C approx.

·Engine speed - must be between 630 and 2850

rev/min.

·Engine load - calculated by throttle position

sensor.

·EGR valve lift position.

·Duration of engine idling.

Page 121 of 455

COOLING SYSTEM

1

DESCRIPTION AND OPERATION ENGINE COOLING SYSTEM

Description

The complete cooling system of the 300Tdi engine

incorporates three independent functions:- Engine

(coolant) cooling; Turbo (charge air) intercooling;

Engine oil cooling.The intercooler is a separate aluminium unit, located

on the LH side of the engine compartment adjacent to

the radiator, sharing the same upper and lower

mountings. For details of turbo intercooling

See

FUEL SYSTEM, Description and operation,

Operation

. The oil cooler matrix is an integral part of

the radiator. Pre-formed pipes/hoses are used to link

the components within the separate systems as

shown below.

Engine cooling system

1.Radiator

2.Thermostat housing

3.Radiator bottom hose

4.Viscous fan

5.Water pump

6.Radiator top hose

7.Heater return hose

8.Coolant supply hose

9.By-pass hose

10.Radiator bleed (purge) hose

11.Bleed (purge) hose, thermostat housing

12.'Y' piece ejector

13.Expansion tank14.Heater rail

15.Heater unit

16.Heater feed hose

17.Intercooler

18.Air cleaner

19.Air feed hose

20.Turbocharger

21.Charge air supply pipe/hose

22.Cooled charge air supply hose

23.Exhaust manifold

24.Engine oil cooler

25.Feed pipe, engine oil cooler

26.Return pipe, engine oil cooler

27.Oil filter

Page 122 of 455

26COOLING SYSTEM

2

DESCRIPTION AND OPERATION ENGINE (COOLANT) COOLING

Description

The 300Tdi engine uses a pressurised cooling system

and cross flow radiator which is supplied with coolant

from an expansion tank mounted on the RH side of

the engine compartment. A belt driven centrifugal

water pump, fitted to an auxiliary mounting assembly,pumps coolant to the engine crankcase, cylinder head

and vehicle heater unit.

An eleven bladed fan, incorporating a viscous

coupling, is driven by an independent pulley secured

to the front cover plate. The thermostat housing,

bolted to the front of the cylinder head, is fitted with a

vent valve that purges excessive air pressure and

coolant back to the expansion tank.

Engine coolant circulation (engine warm - thermostat open).

1.Radiator

2.Thermostat/housing

3.Radiator bottom hose

4.Viscous fan

5.Water pump

6.Radiator top hose

7.Heater return hose

8.Coolant supply hose9.By-pass hose

10.Radiator bleed (purge) hose

11.Thermostat housing bleed (purge) hose

12.'Y' piece ejector

13.Expansion tank

14.Heater rail

15.Heater unit

16.Heater feed hose

Page 123 of 455

COOLING SYSTEM

3

DESCRIPTION AND OPERATION COOLANT CIRCULATION

Operation

When the engine is started from cold the thermostat

(2) prevents coolant circulation through the radiator by

closing off the top hose (6). During the engine warm

up period the water pump (5) circulates coolant to the

cylinders in the crankcase and through separate ports

to the cylinder head. At the rear of the cylinder head a

proportion of the flow is diverted through a heater feed

pipe (16) to the matrix of the heater unit (15). The

coolant is then carried, via a heater return rail (14) and

hoses (7), back to the water pump. The remaining

coolant flows through a by-pass hose (9) at the

thermostat housing and back to the water pump to

complete the first cycle.

When the normal engine running temperature is

reached, the thermostat opens, closing off the by-pass

hose (9). Coolant is then circulated via the top hose

(6) and through the radiator, where it is cooled and

drawn from the radiator bottom hose (3) by the water

pump (5). The coolant circulation through the

crankcase and cylinder head remains the same.

Two bleed pipes (10) and (11) help control the system

pressure by purging excess air and coolant to the

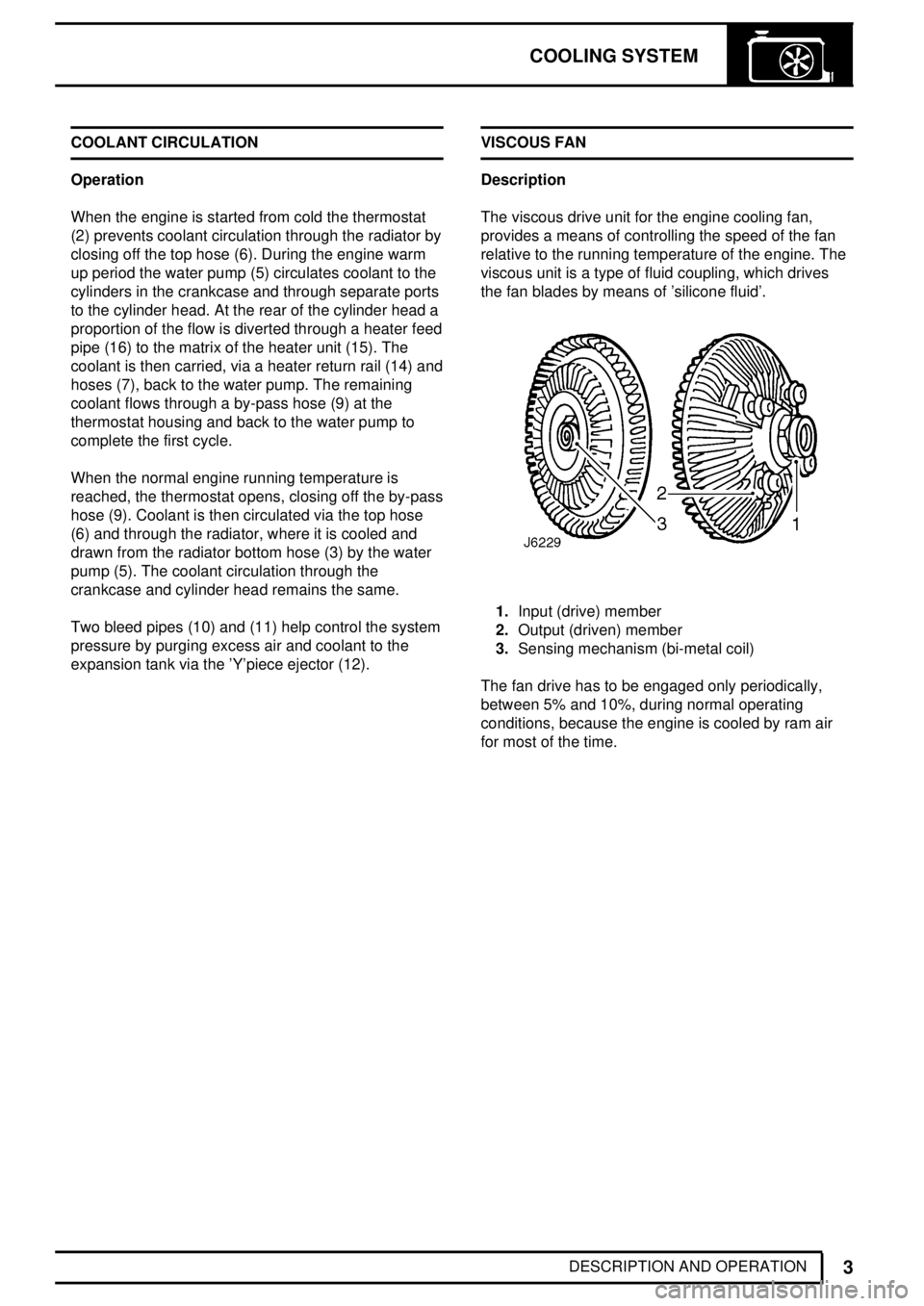

expansion tank via the 'Y'piece ejector (12).VISCOUS FAN

Description

The viscous drive unit for the engine cooling fan,

provides a means of controlling the speed of the fan

relative to the running temperature of the engine. The

viscous unit is a type of fluid coupling, which drives

the fan blades by means of 'silicone fluid'.

1.Input (drive) member

2.Output (driven) member

3.Sensing mechanism (bi-metal coil)

The fan drive has to be engaged only periodically,

between 5% and 10%, during normal operating

conditions, because the engine is cooled by ram air

for most of the time.

Page 124 of 455

26COOLING SYSTEM

4

DESCRIPTION AND OPERATION Operation

To engage and disengage the fan drive the bi-metal

coil senses air temperature behind the radiator. When

a pre-determined temperature is reached, the coil

opens a valve (5) which allows fluid to enter the drive

area and, due to centrifugal force, circulates to the

annular drive area.

There are two sets of annular grooves (3), one in the

drive clutch and the other in the drive body, a specific

clearance being provided between the two sets of

grooves.

Viscous unit disengaged (engine at normal

running temperature)

1.Input (drive) member

2.Output (driven) member

3.Running clearance

4.Pump plate

5.Valve (closed)

6.Sensing mechanism (bi-metal coil)

7.Fluid seal

8.Bearing, input member

9.Fluid chamber

10.Fluid reservoirWhen this clearance is filled with viscous fluid, a

shearing action, caused by the speed differential

between the two drive components, transmits torque

to the fan. The fluid is thrown to the outside of the unit

by centrifugal force from where it is recirculated to the

reservoir (10) via the pump plate (4) adjacent to the

drive member.

If the engine speed is increased the amount of slip will

also increase to limit the maximum fan speed.

When the air temperature from the radiator drops

sufficiently, the bi-metal coil closes the valve and

prevents fluid entering the drive area. The fluid that is

in the drive area will gradually pump out into the

reservoir (10) and the fan will return to an idle

condition.

Viscous unit engaged (hot running temperature)

Bi-metal coil (6) expanded, valve (5) open.