suspension LAND ROVER DEFENDER 1996 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 143 of 455

33CLUTCH

2

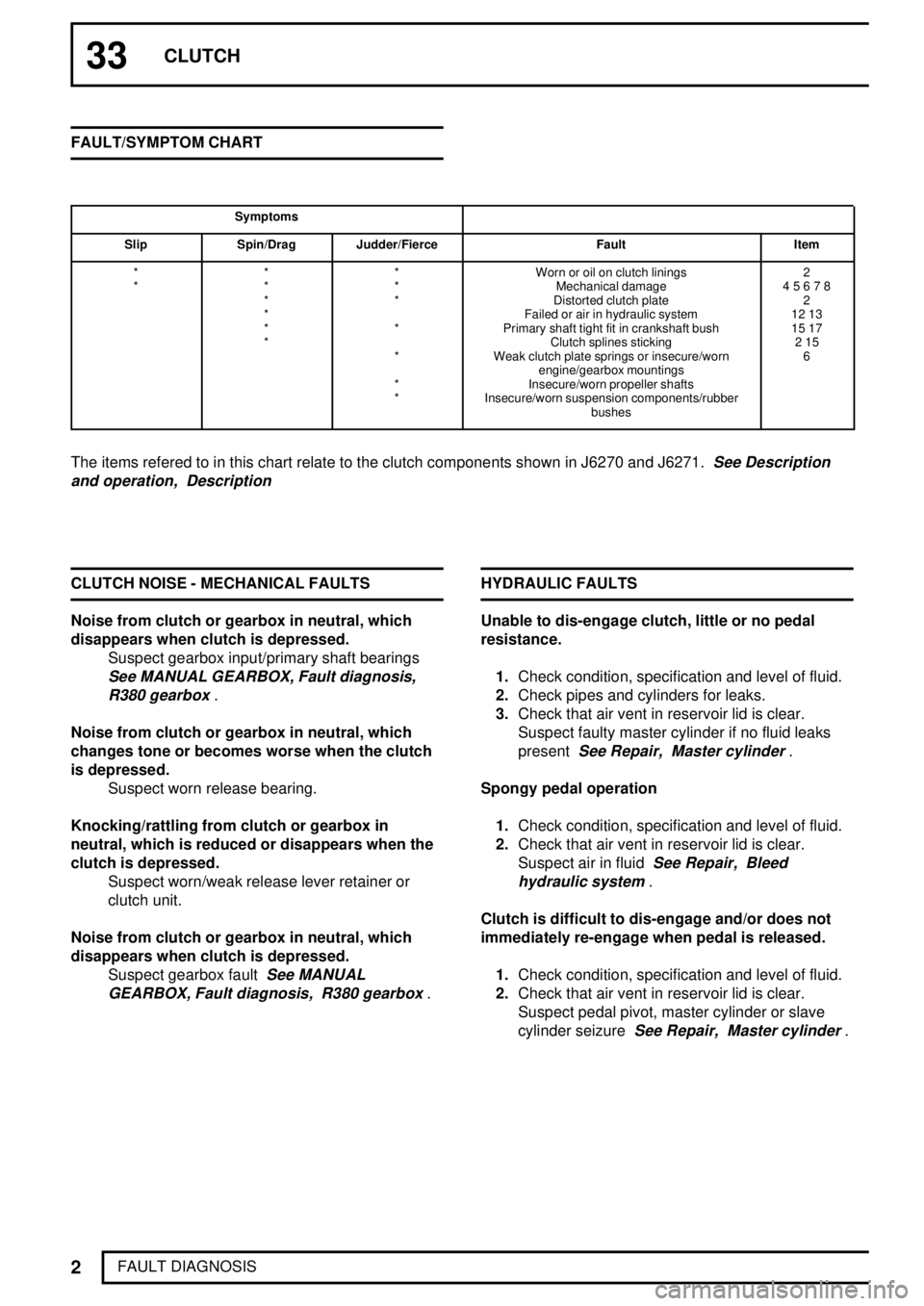

FAULT DIAGNOSIS FAULT/SYMPTOM CHART

Symptoms

Slip Spin/Drag Judder/Fierce Fault Item

* * * Worn or oil on clutch linings 2

* * * Mechanical damage45678

* * Distorted clutch plate 2

* Failed or air in hydraulic system 12 13

* * Primary shaft tight fit in crankshaft bush 15 17

* Clutch splines sticking 2 15

* Weak clutch plate springs or insecure/worn

engine/gearbox mountings6

* Insecure/worn propeller shafts

* Insecure/worn suspension components/rubber

bushes

The items refered to in this chart relate to the clutch components shown in J6270 and J6271.See Description

and operation, Description

CLUTCH NOISE - MECHANICAL FAULTS

Noise from clutch or gearbox in neutral, which

disappears when clutch is depressed.

Suspect gearbox input/primary shaft bearings

See MANUAL GEARBOX, Fault diagnosis,

R380 gearbox

.

Noise from clutch or gearbox in neutral, which

changes tone or becomes worse when the clutch

is depressed.

Suspect worn release bearing.

Knocking/rattling from clutch or gearbox in

neutral, which is reduced or disappears when the

clutch is depressed.

Suspect worn/weak release lever retainer or

clutch unit.

Noise from clutch or gearbox in neutral, which

disappears when clutch is depressed.

Suspect gearbox fault

See MANUAL

GEARBOX, Fault diagnosis, R380 gearbox

.HYDRAULIC FAULTS

Unable to dis-engage clutch, little or no pedal

resistance.

1.Check condition, specification and level of fluid.

2.Check pipes and cylinders for leaks.

3.Check that air vent in reservoir lid is clear.

Suspect faulty master cylinder if no fluid leaks

present

See Repair, Master cylinder.

Spongy pedal operation

1.Check condition, specification and level of fluid.

2.Check that air vent in reservoir lid is clear.

Suspect air in fluid

See Repair, Bleed

hydraulic system

.

Clutch is difficult to dis-engage and/or does not

immediately re-engage when pedal is released.

1.Check condition, specification and level of fluid.

2.Check that air vent in reservoir lid is clear.

Suspect pedal pivot, master cylinder or slave

cylinder seizure

See Repair, Master cylinder.

Page 183 of 455

REAR AXLE AND FINAL DRIVE

1

REPAIR REAR AXLE

Service repair no - 51.25.01

Remove

WARNING: Remove and refit of axle

requires a further two persons to steady

the axle when lowering or repositioning

axle.

1.Drain brake system.

2.Support chassis rear.

3.Remove road wheels.

4.Support axle weight with hydraulic jack.

5.Disconnect shock absorbers.

6.Disconnect flexible brake hose at RH chassis

side member and breather hose at banjo

connection on axle casing.

7.Disconnect lower links at axle.8.Mark differential and propeller shaft flanges with

identification marks for assembly.

9.Remove 4 nuts and bolts, lower propeller shaft

and tie to one side.

10.Disconnect pivot bracket ball joint at axle

bracket.

11.Release bolts and remove coil spring retaining

plates.

12.Lower axle and remove road springs.

13.If applicable, remove anti-roll bar links at axle

See REAR SUSPENSION, Repair, anti-roll

bar

.

14.Remove axle assembly.

Page 184 of 455

51REAR AXLE AND FINAL DRIVE

2

REPAIRREV: 05/99 Refit

15.Position axle and fit lower links. Tighten fixings

to

176 Nm (130 lbf/ft).

16.If applicable, fit anti-roll bar links to axleSee

REAR SUSPENSION, Repair, Anti-roll bar

links

.

17.Raise axle and locate road springs.

18.Fit coil spring retaining plates and secure with

fixing bolts.

19.Secure pivot bracket ball joint to axle bracket.

Tighten fixing to

176 Nm (130 lbf/ft).

20.Align propeller shaft to differential drive flange

and tighten fixings to

47 Nm (35 lbf/ft).

21.Reconnect flexible brake hose and axle breather

hose.

22.Refit shock absorbers.

23.Fit road wheels and tighten to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy Duty wheels -170 Nm (125 lbf/ft)

24.Remove rear chassis support.

25.Bleed brake system

See BRAKES, Repair,

brake system bleed

.

Page 209 of 455

FRONT AXLE AND FINAL DRIVE

1

REPAIR REV: 05/99 FRONT AXLE ASSEMBLY

Service repair no - 54.10.01

Remove

WARNING: Remove and refit of axle

requires a further two persons to steady

axle when lowering or repositioning axle.

1.Support chassis front.

2.Remove road wheels.

3.Support axle weight with hydraulic jack.

4.Remove radius arms to chassis frame nuts.

5.Disconnect steering damper from track rod.

Using a extractor remove track rod links from

swivel pin arms.

6.Remove four nuts and bolts securing radius

arms to axle bracket.

7.Remove radius arms.

8.Remove bolts securing brake hose brackets .

Refit bolts to prevent oil leakage.

9.Remove bolts from brake calipers and tie to one

side.

10.Remove nuts and washers securing shock

absorbers to axle.

11.Disconnect drag link from swivel pin housing

arm.

12.Remove two nuts and bolts securing panhard

rod to axle bracket. Lift rod clear of axle.

13.Mark for reassembly drive shaft flanges.

Remove four nuts and bolts, tie propeller shaft to

one side.

14.Release axle ventilation pipe banjo and lower

axle assembly. Remove road springs.

15.Disconnect anti-roll bar link

See FRONT

SUSPENSION, Repair, Anti-roll bar ball

.

16.Remove axle assembly.

Refit

17.Position axle under vehicle, supporting left side

of axle, and fit anti-roll bar links

See FRONT

SUSPENSION, Repair, Anti-roll bar links

.

18.Fit propeller shaft. Tighten bolts to

47 Nm (35

lbf/ft).

19.Fit panhard rod to axle bracket. Tighten bolts to

88 Nm (65 lbf/ft).

20.Fit drag link to swivel pin arm. Tighten fixings to

40 Nm (30 lbf/ft).

21.Fit shock absorbers to axle.

22.Fit brake calipers. Tighten bolts to

82 Nm (60

lbf/ft).

23.Tighten upper swivel pin bolts to78 Nm (58

lbf/ft).

24.Fit radius arms to axle brackets. Tighten bolts to

197 Nm (145 lbf/ft).

25.Fit steering damper to track rod.

26.Fit radius arms to chassis side member. Tighten

fixings to

197 Nm (145 lbf/ft).

27.Tighten track rod end to40 Nm (30 lbf/ft)and fit

new split pin.

28.Remove chassis supports, fit road wheels and

tighten to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

Page 225 of 455

STEERING

3

FAULT DIAGNOSIS STEERING DAMPER

The power steering system, as well as reducing the

effort required to manoeuvre the vehicle when

parking, also helps to dampen any deflections of the

road wheels, being transmitted back to the steering

wheel.

When operating the vehicle off road, the road wheels

are often deflected by ruts and boulders causing the

steering wheel to turn left and right. This phenomenon

is known as 'steering kickback'. To subdue the effects

of 'steering kickback', a hydraulic damper is fitted in

the steering linkage between the track rod and the

differential casing. The damper, which offers the same

resistance in extension and compression, is sealed for

life.

Steering damper check

Check the condition operation of the hydraulic

steering damper as follows:

Check procedure

1.Inspect damper for casing damage or leaks.

2.Clamp one end of the damper horizontally in a

vice using soft jaws. Compress and extend the

unit by hand. Resistance should be equal in both

directions.

3.If it is felt that the unit is outside acceptable

limits, fit a new steering damperSTEERING FAULTS

Symptom:-

Excessive kickback through steering wheel - when

driven on rough terrain.

1.Is the steering damper in good working order?

See Steering Damper.

NO - Renew unit

See Repair, Steering

Damper

.

YES - Continue.

2.Is there any looseness or free play in the

steering ball joints and linkage?

YES -

See Steering Linkage Inspect.

NO - Continue.

3.Is there any looseness or worn bushes in front

suspension?

YES -

See FRONT SUSPENSION, Repair,

Radius Arm

.

NOTE: When replacing suspension bushes

ALL bushes and fixings must be replaced.

NO - Continue.

4.Is the steering exceptionally light/sensitive when

driven on good road surface?

YES - See fault symptom -Steering

excessively light/sensitive and freeplay at

steering wheel.

NO - Suspect axle swivel resistance.

5.Check the resistance of the axle swivels

See

FRONT AXLE AND FINAL DRIVE, Overhaul,

Front Stub Axle, Constant Velocity Joint and

Swivel Pin Housing

.

Page 227 of 455

STEERING

5

FAULT DIAGNOSIS REV: 05/99 Symptom :-

Steering excessively light/sensitive. Excessive

freeplay at steering wheel.

1.Are steering box adjustments correct?

NO -

See Adjustment, Power Steering Box.

WARNING: Adjustments of steering box

should not be required while in warranty

period. If box is within warranty, it must be

returned to manufacturer. No attempt must be

made to introduce backlash.

YES - Suspect worn panhard rod or radius arm

bushes. Check condition of ball joints and the

lower steering column shaft universal joints for

wear

See Repair, Lower Steering Shaft and

Universal Joints

.

Symptom :-

Steering vibration, road wheel shimmy - wobble.

Vibration through the steering linkage powerful

enough to induce high frequency oscillation of the

steering wheel, is generally caused by out of balance

road wheels. However there are a number of other

possible causes of this symptom which if severe, may

be described as shimmy or wobble. Regardless of the

terminology used by the owner/driver to describe the

symptoms, the following diagnostic checks should be

carried out in the order presented.

1.Check the tyres and balance of the road wheels

See GENERAL SPECIFICATION DATA,

Information, Wheels and Tyres

,See

WHEELS AND TYRES, Fault diagnosis, Fault

- Symptoms See WHEELS AND TYRES,

Repair, Wheel Balancing .

2.Check the steering hydraulic damper function

See Steering Damper.

3.Check steering column universal joints for wear

and correct alignment

See Repair, Lower

Steering Shaft and Universal Joints

.4.Check steering linkage ball joints for wear,

correct alignment and security, including steering

box and tie rod

See Steering Linkage Inspect

.

5.Check all front suspension rubbers for wear.

Check all fixing torques, including radius arm

bushes, panhard rod and anti-roll bar

See

FRONT SUSPENSION, Repair, Panhard Rod

,

See FRONT SUSPENSION, Repair, Radius

Arm

,See FRONT SUSPENSION, Repair,

Anti-Roll Bar

,See FRONT SUSPENSION,

Repair, Front Shock Absorber

.

6.Fit new radius arm bushes using NTC 6781. Fit

new nuts, bolts and washers.

7.If problem persists fit damper kit STC 288 - 90,

STC 290 - 110/130 (2 off front) and STC 289 -

90, STC 291 - 110 levelled, STC 292 - 110

unlevelled, STC 293 - 130 (2 off rear). Road test

vehicle.

8.Check the power steering box adjustments and

operation

See Overhaul, Power Steering Box.

9.Check the hub bearing end floats and determine

the condition of the hub bearings as applicable

See FRONT AXLE AND FINAL DRIVE, Repair,

Front Hub Assembly

.

10.Check the resistance and condition of the

swivels

See FRONT AXLE AND FINAL DRIVE,

Description and operation, Description

.

If problem is not diagnosed: Repeat checks

starting at 1.

11.Carry out a full steering geometry check

See

GENERAL SPECIFICATION DATA,

Information, Steering

.

Page 228 of 455

57STEERING

6

FAULT DIAGNOSIS STEERING STABILITY AND VEER UNDER

BRAKING

Possible cause:

Incorrectly set, swivel pin bearing preload.

Remedy.

1.Follow instructions to overhaul front stub axle,

constant velocity joint and swivel pin

See

FRONT AXLE AND FINAL DRIVE, Overhaul,

Front Stub Axle, Constant Velocity Joint and

Swivel Pin Housing

.1. GENERAL STEERING

1.Carry out visual and safety checks

See Visual

and Safety Checks

.

2.Road test vehicle

See Road Test Procedure.

3.Is problem resolved?

YES - end

NO - continue

4.Is problem stiff steering?

YES -

See Stiff Steering Checklist.

NO-Goto6.

5.Is problem resolved?

YES - end

NO - go to 8.

6.Is problem steering niggle ?

YES - Replace radius arm bushes, arm and axle

See FRONT SUSPENSION, Repair, Radius

Arm

.

NO - go to 8.

7.Is problem resolved?

YES - end

NO - continue.

8.Centralise steering box

See Adjustment,

Centralise Steering Box

.

9.Is problem resolved?

YES - end

NO - continue.

10.Check, adjust if necessary, steering geometry.

11.Is problem resolved?

YES - end

NO - continue.

12.Categorise the remaining problems into one or

more of the following descriptions:

See 2. Steering Veer.

See 3. Veer Under Braking.

See 4. Directional Stability.

Page 231 of 455

STEERING

9

FAULT DIAGNOSIS POWER STEERING SYSTEM - EXCESSIVE NOISE

1.Is fluid level correct?

YES - go to 3.

NO - Refill or drain to correct level. Bleed

system, check for leaks

See Repair, Power

Steering System - Bleed

.

2.Is problem resolved?

YES - end

NO - continue.

3.Is pressure hose from pump to box touching

body in a hard foul condition?

YES - route hose away from body.

NO - go to 5.

4.Does noise remain?

YES - continue.

NO - end.

5.Is noise a whistle or hiss on full lock?

YES - noise is not a fault unless excessive.

Compare with other vehicles

NO - go to 8.

6.Is noise excessive?

YES - continue.

NO - end.

7.Change steering box and/or pump.

8.Is noise a squeal on full lock?

YES - check drive belt tension and remove belt if

necessary

See ELECTRICAL, Repair,

Auxiliary drive Belt

.

NO - go to 10.

9.Does squeal remain?

YES - drive belt contaminated, change belt.

NO - end.

10.Is noise a continuous moan?

YES - bleed PAS system

See Repair, Power

Steering System - Bleed

.

NO - go to 13.

11.Does moan remain?

YES - do figure 8 manoeuvres.

NO - end.

12.Does moan remain?

YES - continue

NO - end.13.Is noise an intermittent "grunt"?

YES -

See Power Steering System - Grunt.

NO - continue.

14.Is it a clunking noise?

YES - check drive belt tension and renew belt if

necessary

See ELECTRICAL, Repair,

Auxiliary drive Belt

.

NO - contact local technical office.

15.Does noise remain?

YES - Suspect suspension or drive train.

NO - end.

POWER STEERING SYSTEM - GRUNT

Steering box grunts intermittently when turning

from lock to lock:

1.Is fluid level correct?

YES - go to 3.

NO - refill or drain to correct level. Bleed system,

check for leaks

See Repair, Power Steering

System - Bleed

.

2.Does grunt remain?

YES - continue

NO - end.

3.Is correct low pressure hose, steering box to

reservoir, fitted?

YES - go to 5.

NO - Fit correct hose.

4.Does grunt remain?

YES - continue

NO - end.

5.Purge box by doing figure 8 manoeuvres e.g. on

car park, followed by 10 minutes normal road

use.

6.Does grunt remain?

YES - Contact local technical office

NO - end.

Page 234 of 455

57STEERING

12

FAULT DIAGNOSISREV: 05/99 VISUAL CHECK AND BASIC ADJUSTMENTS

NOTE: It is important that the following

instructions are carried out in the

sequence shown and the results recorded.

1.Road springs - check that road springs are

correctly seated and are to correct specification

for vehicle. For spring specification

See

GENERAL SPECIFICATION DATA,

Information, Road Spring Data

.

2.Ride height - measure trim height from wheel

centre to wheelarch eyebrow. Record results on

data sheet.

3.Check/top up power steering fluid

See Repair,

Power Steering Fluid Reservoir

.

4.Check tension and condition of drive belt

See

ELECTRICAL, Repair, Auxiliary drive belt

.

5.Track rod/drag link - check condition of track rod,

drag link and ball joints

See Repair, Drag Link

and Drag Link Ends

.

If either component is damaged, check operation

of steering damper and steering box for

smoothness. Replace all damaged or worn

components that impair the operation of the

steering system.

6.Suspension bushes - examine all steering and

suspension bushes for signs of wear and

deterioration. Also check all fixings for torque

relaxation. Tighten to correct torque value

See

FRONT SUSPENSION, Specifications, torque,

Torque Values

.

7.Oil leaks - check front and rear axle hubs for

leak and repair as necessary.

8.Brake system - check brake system for leaks,

pipe condition, pad wear/contamination, disc

wear/condition.

9.Hub end float - check movement in the hubs by

rocking the wheels.

10.Check front wheel alignment. Vehicles displaying

a tendency to veer more than considered

allowable, it is permissible to set the front track

to parallel.11.Having completed all the above checks and

adjustments, road test vehicle

See Road Test

Procedure

.

Attempt to reproduce the symptoms established

earlier. If symptoms still exist refer to relevant

Diagnostic Chart.

STEERING LINKAGE INSPECT

NOTE: When inspecting steering linkages

and ball joints for wear the following items

must be checked.

Steering ball joints

1.Check ball joint rubber boots for security, signs

of cracking or deterioration.

2.Check ball joint assemblies for seizure i.e. no

movement on ball joint and associated

assemblies.

3.Check for excessive wear. This will be evident

as extreme movement on track rod and steering

linkages. Renew parts as necessary

See

Repair, Track Rod and Linkage

,See Repair,

Drag Link and Drag Link Ends

.

Steering linkages

1.Check all linkages for wear, deterioration and

damage. Renew parts as necessary

See

Repair, Track Rod and Linkage

,See Repair,

Drag Link and Drag Link Ends

.

Page 241 of 455

57STEERING

4

REPAIR POWER STEERING BOX

Service repair no - 57.10.01

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

remove and refit procedures are required, it may

be necessary to remove the undertray

See

CHASSIS AND BODY, Repair, Front undertray

.

General precautions

·Whenever any part of system, is removed or

disconnected, utmost cleanliness must be

observed.

·Disconnected ports and hoses must be

plugged to prevent ingress of dirt. If metal

sediment is found in system, establish cause,

rectify and flush system.

·Do not start engine until reservoir is full as

pump will be damaged.

·Metric pipe fittings are used with 'O' ring pipe

ends on fittings to steering box.

·Follow normal 'O' ring replacement procedure

whenever pipes are disconnected.

·Ensure compatible metric components when

fitting replacement pipes.

CAUTION: After refitting steering linkage

parts follow correct procedure to ensure

that road wheels, steering box and

steering wheel are correctly positioned relative to

each other when in straight ahead condition.

NOTE: When drag link is disconnected

from steering box, travel available at

steering wheel to each full lock is not

equal.

Remove

1.Site vehicle on level surface.

2.Apply park brake, chock rear wheels, raise

vehicle and locate axle stands. Alternatively,

raise vehicle on a hoist.

3.Remove road wheel.

4.Remove panhard rod

See FRONT

SUSPENSION, Repair, Panhard rod

.

5.Disconnect steering damper from drag link.

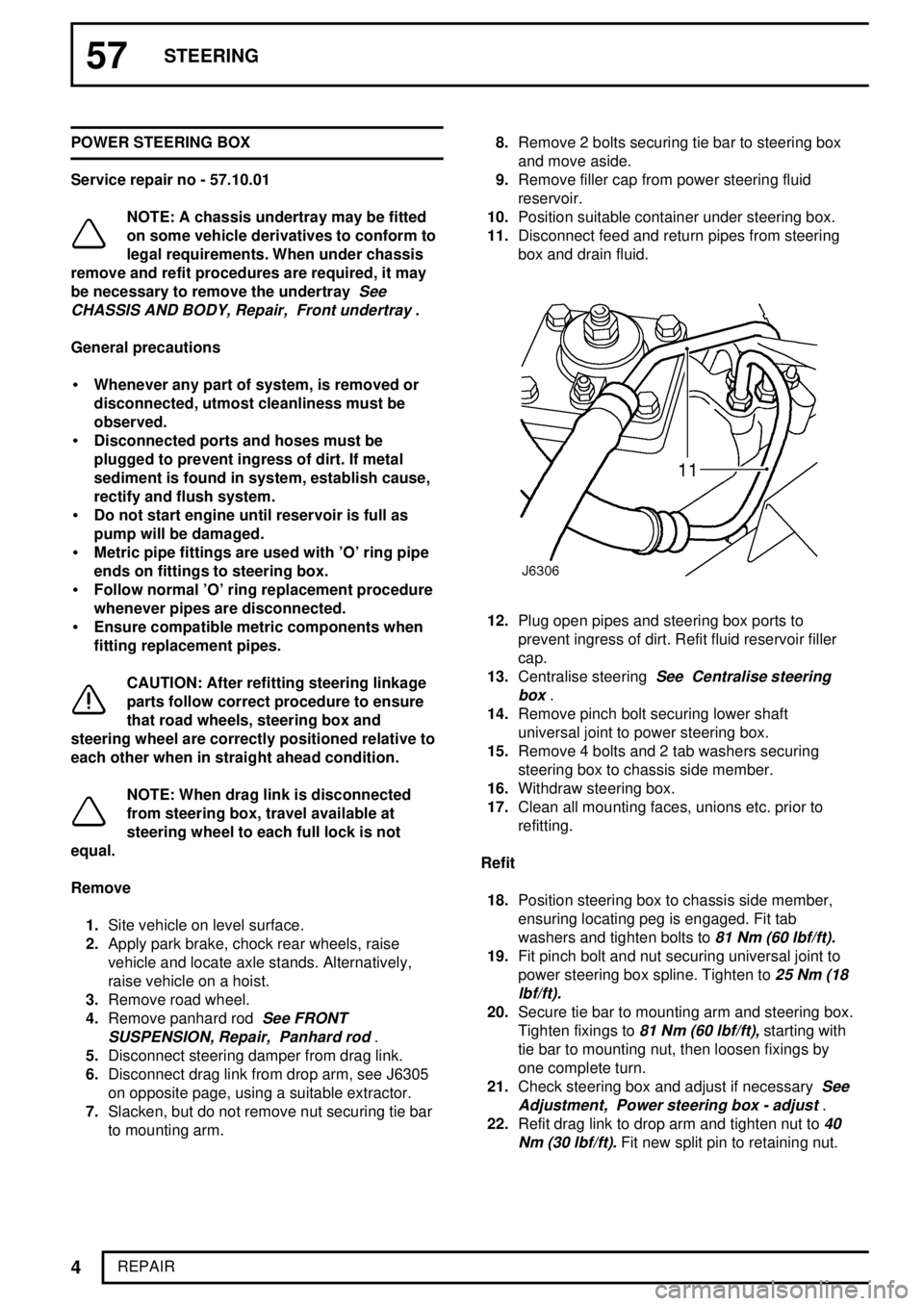

6.Disconnect drag link from drop arm, see J6305

on opposite page, using a suitable extractor.

7.Slacken, but do not remove nut securing tie bar

to mounting arm.8.Remove 2 bolts securing tie bar to steering box

and move aside.

9.Remove filler cap from power steering fluid

reservoir.

10.Position suitable container under steering box.

11.Disconnect feed and return pipes from steering

box and drain fluid.

12.Plug open pipes and steering box ports to

prevent ingress of dirt. Refit fluid reservoir filler

cap.

13.Centralise steering

See Centralise steering

box

.

14.Remove pinch bolt securing lower shaft

universal joint to power steering box.

15.Remove 4 bolts and 2 tab washers securing

steering box to chassis side member.

16.Withdraw steering box.

17.Clean all mounting faces, unions etc. prior to

refitting.

Refit

18.Position steering box to chassis side member,

ensuring locating peg is engaged. Fit tab

washers and tighten bolts to

81 Nm (60 lbf/ft).

19.Fit pinch bolt and nut securing universal joint to

power steering box spline. Tighten to

25 Nm (18

lbf/ft).

20.Secure tie bar to mounting arm and steering box.

Tighten fixings to

81 Nm (60 lbf/ft),starting with

tie bar to mounting nut, then loosen fixings by

one complete turn.

21.Check steering box and adjust if necessary

See

Adjustment, Power steering box - adjust

.

22.Refit drag link to drop arm and tighten nut to

40

Nm (30 lbf/ft).

Fit new split pin to retaining nut.