window LAND ROVER DEFENDER 1996 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 343 of 455

76CHASSIS AND BODY

22

REPAIR Refit

9.Fit new spring clips to the 3 brackets on top

edge of side trim panel.

10.Align trim panel, ensuring it is correctly

positioned around side window.

11.Locate trim panel spring clips on inner cant rail

and press firmly down to secure top edge of trim

panel.

12.Align bosses of trim panel with body side fixing

holes and secure with 4 bolts and washers. Do

not fully tighten at this stage.

13.Fit trim stud to secure bottom edge of trim panel

to 'B' post.

14.Secure seat belt guide to 'B' post, tighten bolt to

32 Nm (24 lbf/ft)and fit cap.

15.Fit rear end trim panel

See Rear end trim

panel

.

16.Fit rear seat squab

See Rear seat squab.SIDE TRIM PANEL - 110 STATION WAGON

Service repair no - 76.13.70

Remove

1.Remove rear inward facing seats

See Rear

seat squab - 90

,orSee Rear bench seat.

2.Remove rear end trim panel

See Rear end

trim panel

.

3.Prise finisher cap from rear seat belt upper guide

bracket retaining bolt.

4.Unscrew bolt and remove guide bracket from 'C'

post.

5.Remove bolt securing seat belt to wheel arch

mounting.

6.Prise trim panel cap fastener from 'C' post.

7.Remove seat belt aperture finisher from side trim

panel.

8.Remove screw and release seat belt clip from 'C'

post.

Page 344 of 455

CHASSIS AND BODY

23

REPAIR

9.Remove fixings securing bottom edge of trim

panel to body side.

10.Release top edge of trim panel by striking

upwards with the hand to disengage 3 spring

clips.

11.Lift trim panel from window surround and feed

seat belt through panel aperture.

12.Remove trim panel from vehicle.

Refit

13.Fit new spring clips to the 3 brackets on top

edge of side trim panel.

14.Feed seat belt through aperture in trim panel and

fit finisher.

15.Align trim panel, ensuring it is correctly

positioned around side window.

16.Locate trim panel spring clips on inner cant rail

and press firmly down to secure top edge of trim

panel.

17.Align bosses of trim panel with body side fixing

holes and secure with bolts or screws. If

individual type seats are fitted do not fully tighten

fixings at this stage.

18.Fit seat belt clip to 'C' post.

19.Fit trim panel cap fastener to 'C' post.

20.Fit seat belt to wheel arch. Tighten bolt to

32 Nm

(24 lbf/ft).

21.Fit seat belt guide bracket to 'C' post. Tighten

bolt to

32 Nm (24 lbf/ft)and fit finisher cap.

22.Fit rear end trim panel

See Rear end trim

panel

.

23.Fit inward facing seats

See Rear seat squab,

or

See Rear bench seat.REAR END TRIM PANEL - 90/110 STATION

WAGON

Service repair no - 76.13.71

Remove

1.Pull edge of rear end trim panel firmly to release

2 spring retaining clips from vertical rail at door

aperture.

2.Remove rear end trim panel.

Refit

3.Fit new spring clips to the 2 brackets on side of

trim panel.

4.Position outboard edge of trim panel in corner to

abut side trim panel and locate spring clips on

vertical rail.

5.Press edge of trim panel firmly to secure in

position.

Page 373 of 455

82AIR CONDITIONING

2

DESCRIPTION AND OPERATION Operation

Evaporator unit and expansion valve

High pressure liquid refrigerant is delivered to the

expansion valve which is the controlling device for the

air conditioning system. A severe pressure drop

occurs across the valve and as the refrigerant flows

through the evaporator it picks up heat from the

ambient air, boils and vaporizes. As this change of

state occurs, a large amount of latent heat is

absorbed. The evaporator is therefore cooled and as

a result heat is extracted from the air flowing across

the evaporator. The refrigerant leaves the evaporator,

on its way to the compressor, as a low pressure gas.

An evaporator sensor measures the air temperature at

the evaporator and engages or disengages the

compressor clutch to prevent icing of the air ways.

Compressor

The compressor, a pump specially designed to raise

the pressure of the refrigerant, is mounted on the front

of the engine and is driven by an independent drive

belt from the crankshaft pulley. The compressor draws

vaporized refrigerant from the evaporator. It is

compressed with a resulting rise in temperature and

passed on to the condenser as a hot, high pressure

vapour.

Condenser

The condenser is mounted directly in front of the

radiator and consists of a refrigerant coil mounted in a

series of thin cooling fins to provide the maximum

heat transfer. Air flow across the condenser is induced

by vehicle movement and assisted by two electric fans

attached to the frame of the condenser. The

refrigerant high pressure vapour enters the condenser

inlet on the RH side. As the vapour passes through

the condenser coils the air flow, assisted by the two

fans, carries the latent heat away from the condenser.

This induces a change of state resulting in the

refrigerant condensing into a high pressure warm

liquid. From the condenser, the refrigerant continues

to the receiver/ drier.

Receiver/drier

This component acts as a reservoir and is used to

hold extra refrigerant until it is needed by the

evaporator. The drier within the receiver unit contains

a filter and dessicant (drying material) which absorb

moisture and prevent dessicant dust from being

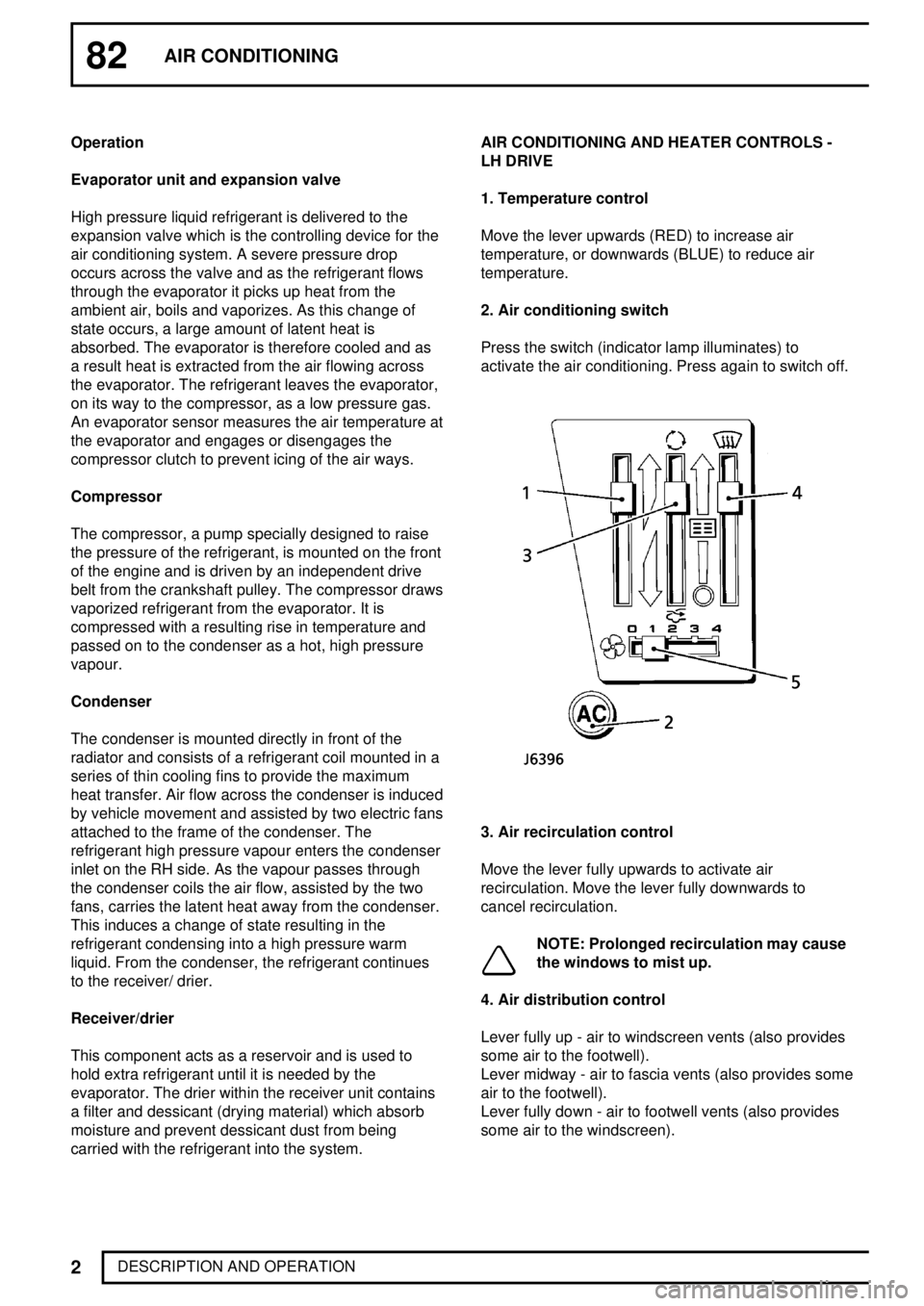

carried with the refrigerant into the system.AIR CONDITIONING AND HEATER CONTROLS -

LH DRIVE

1. Temperature control

Move the lever upwards (RED) to increase air

temperature, or downwards (BLUE) to reduce air

temperature.

2. Air conditioning switch

Press the switch (indicator lamp illuminates) to

activate the air conditioning. Press again to switch off.

3. Air recirculation control

Move the lever fully upwards to activate air

recirculation. Move the lever fully downwards to

cancel recirculation.

NOTE: Prolonged recirculation may cause

the windows to mist up.

4. Air distribution control

Lever fully up - air to windscreen vents (also provides

some air to the footwell).

Lever midway - air to fascia vents (also provides some

air to the footwell).

Lever fully down - air to footwell vents (also provides

some air to the windscreen).

Page 375 of 455

82AIR CONDITIONING

4

DESCRIPTION AND OPERATION 5. Air distribution control

Push LH button - air to windscreen vents (also

provides some air to the footwell).

Push middle button - air to fascia vents (also provides

some air to the footwell).

Push RH button - air to footwell vents (also provides

some air to the windscreen).

6. Air recirculation switch

Press the LH portion of the switch to activate air

recirculation. Press the RH portion for fresh air.

NOTE: Prolonged recirculation may cause

the windows to mist up.

Page 379 of 455

82AIR CONDITIONING

4

ADJUSTMENT 5.Operate the refrigerant recharging system

according to the manufactures instructions.

Refrigerant to charge system is 1.1 kg.

6.If the full charge has not been accepted by the

system, start the engine and run it at 1500

rev/min for a minimum of 2 minutes.

Switch on the air conditioning system, open the

vehicle windows, set the temperature control to

cold and switch the blower to maximum speed.

7.Consult Refrigerant Station Manual for correct

procedure to complete the charge.

8.Carry out the air conditioning system

performance test.LEAK TEST SYSTEM

The following instructions refer to an electronic type

Refrigerant Leak Detector for use with R134a, which

is the safest and most sensitive.

CAUTION: When a major repair has been

carried out, a leak test should be carried

out using an inert gas (see below).

1.Place the vehicle in a well ventilated area but

free from draughts, as leakage from the system

could be dissipated without detection.

2.Follow the instructions issued by the

manufacturer of the particular leak detector

being used.

3.Commence searching for leaks by passing the

detector probe around all joints and components,

refrigerant gas is heavier than air.

4.Insert the probe into an air outlet of the

evaporator or into the evaporator drain tube.

Switch the air conditioning blower on and off at

intervals of ten seconds. Any leaking refrigerant

will be gathered in by the blower and detected.

5.Insert the probe between the magnetic clutch

and compressor to check the shaft seal for

leaks.

6.Check all service valve connections, valve plate,

head and base plate joints and back seal plate.

7.Check the condenser for leaks at the pipe

unions.

8.If any leaks are found, the system must be

discharged before rectification.

9.Rectify any leaks and recheck for leaks during

evacuation prior to charging.

Leak test using inert gas

Use Nitrogen or Helium gas.

1.Connect gas line to recharging station.

2.Pressurise system to 3 bar.

3.Carry out leak test as above.

Page 380 of 455

AIR CONDITIONING

5

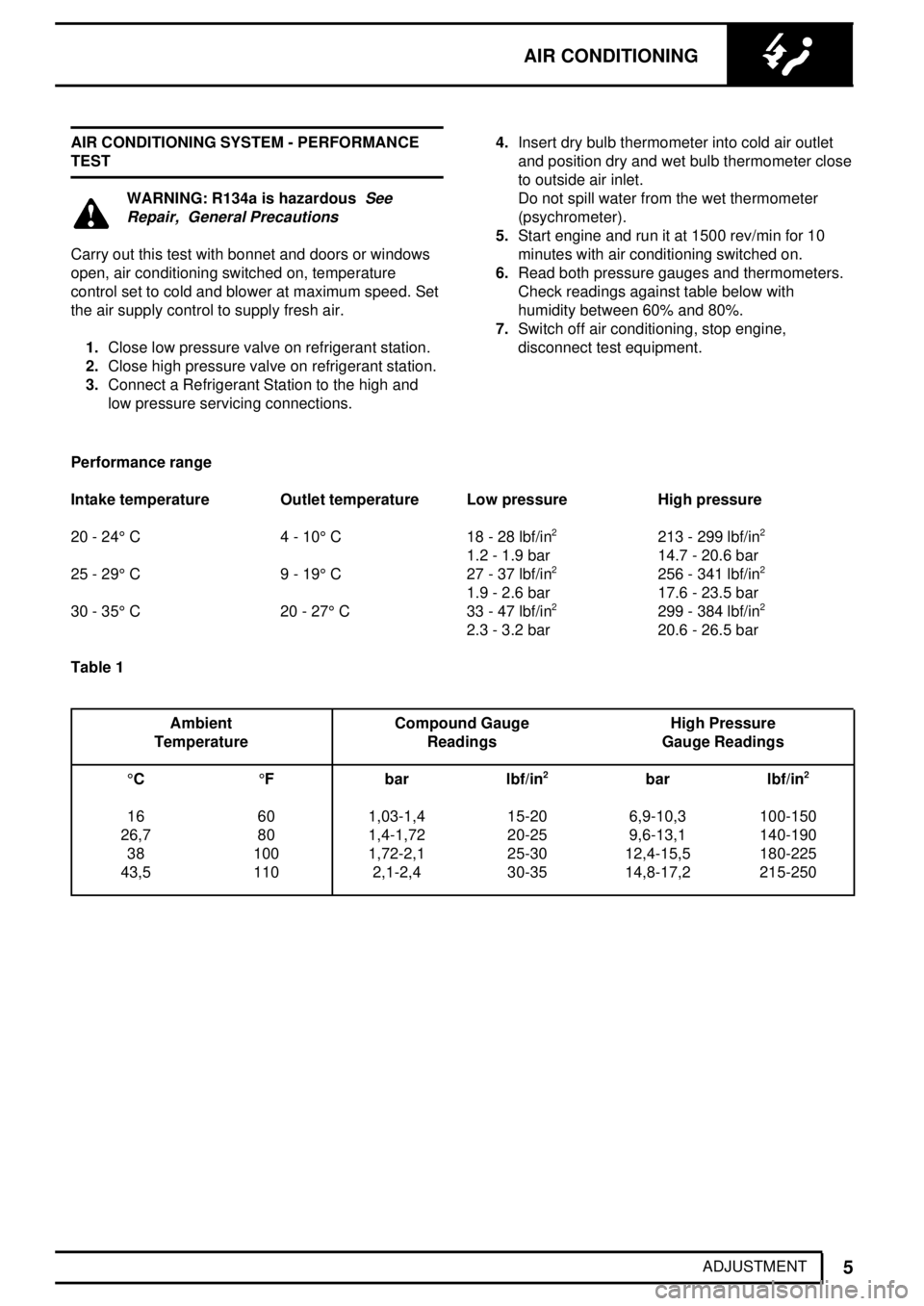

ADJUSTMENT AIR CONDITIONING SYSTEM - PERFORMANCE

TEST

WARNING: R134a is hazardousSee

Repair, General Precautions

Carry out this test with bonnet and doors or windows

open, air conditioning switched on, temperature

control set to cold and blower at maximum speed. Set

the air supply control to supply fresh air.

1.Close low pressure valve on refrigerant station.

2.Close high pressure valve on refrigerant station.

3.Connect a Refrigerant Station to the high and

low pressure servicing connections.4.Insert dry bulb thermometer into cold air outlet

and position dry and wet bulb thermometer close

to outside air inlet.

Do not spill water from the wet thermometer

(psychrometer).

5.Start engine and run it at 1500 rev/min for 10

minutes with air conditioning switched on.

6.Read both pressure gauges and thermometers.

Check readings against table below with

humidity between 60% and 80%.

7.Switch off air conditioning, stop engine,

disconnect test equipment.

Performance range

Intake temperature Outlet temperature Low pressure High pressure

20 - 24°C4-10°C 18 - 28 lbf/in

2213 - 299 lbf/in2

1.2 - 1.9 bar 14.7 - 20.6 bar

25 - 29°C9-19°C 27 - 37 lbf/in2256 - 341 lbf/in2

1.9 - 2.6 bar 17.6 - 23.5 bar

30 - 35°C20-27°C 33 - 47 lbf/in2299 - 384 lbf/in2

2.3 - 3.2 bar 20.6 - 26.5 bar

Table 1

Ambient Compound Gauge High Pressure

Temperature Readings Gauge Readings

°C°F bar lbf/in

2bar lbf/in2

16 60 1,03-1,4 15-20 6,9-10,3 100-150

26,7 80 1,4-1,72 20-25 9,6-13,1 140-190

38 100 1,72-2,1 25-30 12,4-15,5 180-225

43,5 110 2,1-2,4 30-35 14,8-17,2 215-250

Page 381 of 455

82AIR CONDITIONING

6

ADJUSTMENT SYSTEM TEST

1.Place the vehicle in a ventilated, shaded area

free from excessive draught, with the doors and

windows open.

2.Check that the surface of the condenser is not

restricted with dirt, leaves, flies, etc. Do not

neglect to check the surface between the

condenser and the radiator. Clean as necessary.

3.Switch on the ignition and the air conditioner air

flow control. Check that the blower is operating

efficiently at low, medium and high speeds.

Switch off the blower and the ignition.

4.Check that the evaporator condensate drain

tubes are open and clear.

5.Check the tension of the compressor driving belt,

and adjust if necessary.

6.Inspect all connections for the presence of

refrigerant oil. If oil is evident, check for leaks,

and repair as necessary.

NOTE: The compressor oil is soluble in

Refrigerant R134a and is deposited when

the refrigerant evaporates from a leak.

7.Start the engine.

8.Set the temperature controls to cold and switch

the air conditioner blower control on and off

several times, checking that the magnetic clutch

on the compressor engages and releases each

time.

9.With the temperature control at maximum

cooling and the blower control at high speed,

warm up the engine and fast idle at 1000

rev/min.

10.Repeat at 1800 rev/min.

11.Gradually increase the engine speed to the high

range and check the sight glass at intervals.

12.Check for frosting on the service valves.

13.Check the high pressure hoses and connections

by hand for varying temperature. Low

temperature indicates a restriction or blockage at

that point.

14.Switch off the air conditioning blower and stop

the engine.

15.If the air conditioning equipment is still not

satisfactory, carry out a pressure test as

previously described in this section.PRECAUTIONS IN HANDLING REFRIGERANT

LINES

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

1.When disconnecting any hose or pipe

connection the system must be discharged of all

pressure. Proceed cautiously, regardless of

gauge readings. Open connections slowly,

keeping hands and face well clear, so that no

injury occurs if there is liquid in the line. If

pressure is noticed, allow it to bleed off slowly.

2.Lines, flexible end connections and components

must be capped immediately they are opened to

prevent the entrance of moisture and dirt.

3.Any dirt or grease on fittings must be wiped off

with a clean alcohol dampened cloth. Do not use

chlorinated solvents such as trichloroethylene. If

dirt, grease or moisture cannot be removed from

inside the hoses, they must be replaced with

new hoses.

4.All replacement components and flexible end

connections must be sealed, and only opened

immediately prior to making the connection.

5.Ensure the components are at room temperature

before uncapping, to prevent condensation of

moisture from the air that enters.

6.Components must not remain uncapped for

longer than 15 minutes. In the event of delay, the

caps must be fitted.

7.Receiver/driers must never be left uncapped as

they contain Silica Gel crystals which will absorb

moisture from the atmosphere. A receiver/ drier

left uncapped must not be used, fit a new unit.

8.The compressor shaft must not be rotated until

the system is entirely assembled and contains a

charge of refrigerant.

9.A new compressor contains an initial charge of

refrigerant oil. The compressor also contains a

holding charge of gas when received which

should be retained by leaving the seals in place

until the pipes are re-connected.

10.The receiver/drier should be the last component

connected to the system to ensure optimum

dehydration and maximum moisture protection of

the system.

Page 417 of 455

ELECTRICAL

5

DESCRIPTION AND OPERATION REV: 05/99 ALARM SYSTEM OPERATION

Arming alarm

To arm the alarm, aim handset at vehicle and press

the RH button (Padlock symbol). Provided all doors

and or apertures are closed, the direction indicator

lamps will flash three times to confirm that the alarm is

armed. All security features previously described will

be active.

Once armed, the alarm will sound if a door or the

bonnet is opened, or if movement is detected inside

the vehicle.

Disarming alarm

Within range of the vehicle, briefly press the LH

(Plain) button on the handset; the direction indicator

lamps will flash once to indicate that the alarm has

been disarmed and the engine re-mobilised.

NOTE: In some territories, the interior

lamps will illuminate when the alarm is

disarmed.

If the direction indicators fail to flash when the

alarm is armed:

This indicates that a door or the bonnet is not fully

closed, in which case the alarm will be partially armed

and engine immobilised, but interior protection will not

be active.

Once the open door or bonnet is closed, the direction

indicators will flash three times and the alarm will fully

arm as described previously.

If the alarm sounds:

The vehicle horn and alarm sounder will operate

continuously for 30 seconds when the alarm is

triggered. The horn and alarm sounder can be

triggered up to three times.

To silence the alarm, press either handset button. If

the handset is inoperative, the alarm can only be

disarmed by entering the emergency key access

code, seeEngine immobilisation override.Anti-theft alarm indicator light

A RED indicator light on the instrument panel

indicates the status of the alarm system. When the

alarm is armed successfully, the light flashes rapidly.

After 10 seconds, the light adjusts to a slower

frequency and continues flashing as an anti-theft

deterrent.

If the light fails to illuminate during the rapid flash

phase, this indicates a 'mislock' (door or the bonnet

not fully closed or key in starter switch). If this occurs,

the indicator light will still flash at slower frequency as

an anti-theft deterrent.

The indicator light will illuminate continuously under

the following conditions:

1.Alarm system armed and immobilised with

ignition 'on' or driver's door open.

2.Engine immobilised with ignition 'on' or driver's

door open.

Interior protection

Interior protection is activated automatically when the

alarm system is armed; twin sensors inside the

vehicle monitor interior space and will activate the

alarm if an intrusion is detected.

However, if passengers or animals are to be left inside

the vehicle, or if a window or sunroof is to be left

open, the alarm must be armed with the interior

protection DISABLED as follows:

To disable interior protection:

1.Open the driver's door.

2.Use the handset to arm the alarm in normal way.

3.Close the driver's door (the direction indicator

lamps will flash three times and the anti-theft

indicator light commences flashing rapidly). The

alarm system is now armed with the interior

protection disabled.

NOTE: Interior protection will not operate

until 15 seconds after the alarm is set.

Page 419 of 455

ELECTRICAL

7

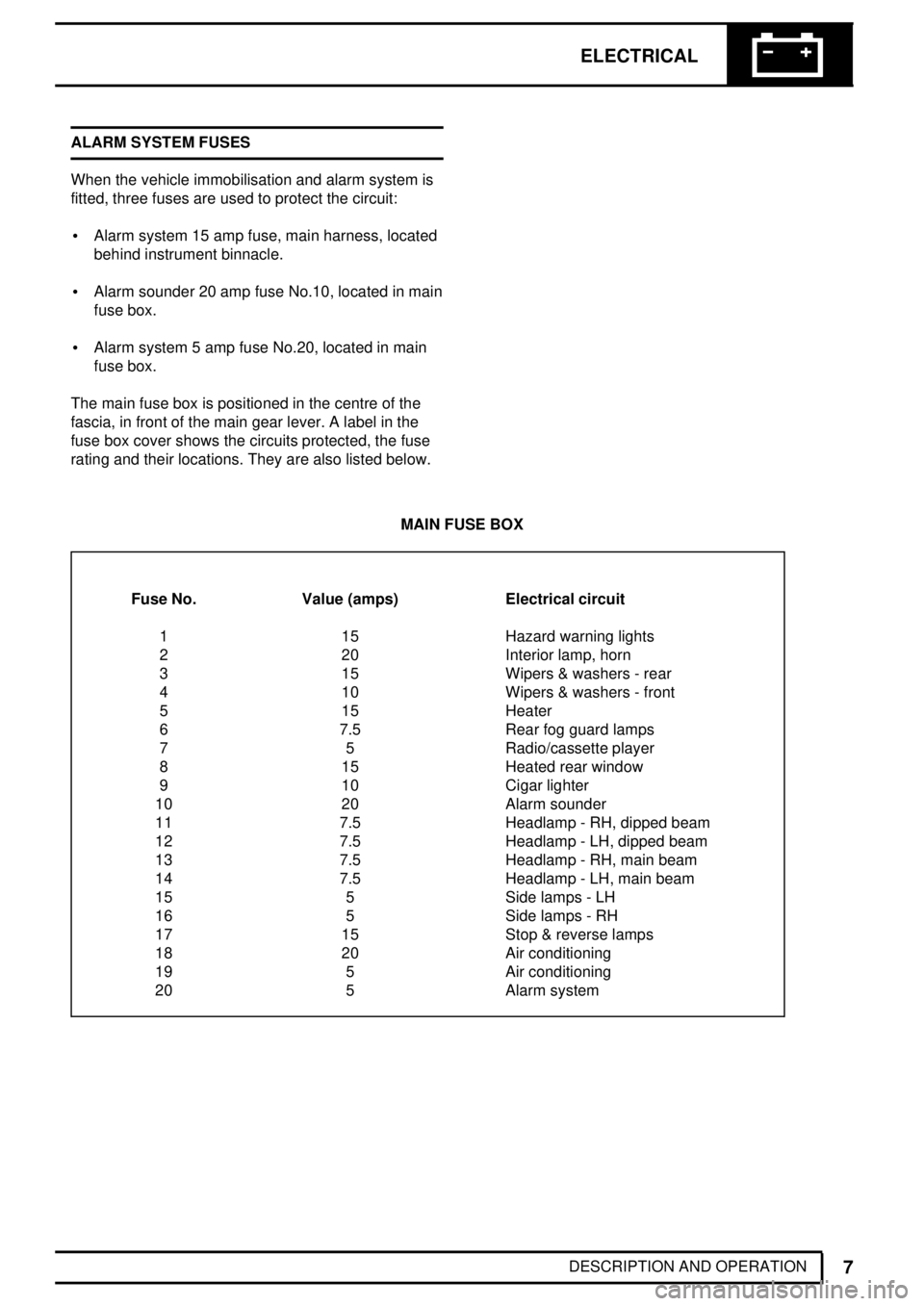

DESCRIPTION AND OPERATION ALARM SYSTEM FUSES

When the vehicle immobilisation and alarm system is

fitted, three fuses are used to protect the circuit:

·Alarm system 15 amp fuse, main harness, located

behind instrument binnacle.

·Alarm sounder 20 amp fuse No.10, located in main

fuse box.

·Alarm system 5 amp fuse No.20, located in main

fuse box.

The main fuse box is positioned in the centre of the

fascia, in front of the main gear lever. A label in the

fuse box cover shows the circuits protected, the fuse

rating and their locations. They are also listed below.

MAIN FUSE BOX

Fuse No. Value (amps) Electrical circuit

1 15 Hazard warning lights

2 20 Interior lamp, horn

3 15 Wipers & washers - rear

4 10 Wipers & washers - front

5 15 Heater

6 7.5 Rear fog guard lamps

7 5 Radio/cassette player

8 15 Heated rear window

9 10 Cigar lighter

10 20 Alarm sounder

11 7.5 Headlamp - RH, dipped beam

12 7.5 Headlamp - LH, dipped beam

13 7.5 Headlamp - RH, main beam

14 7.5 Headlamp - LH, main beam

15 5 Side lamps - LH

16 5 Side lamps - RH

17 15 Stop & reverse lamps

18 20 Air conditioning

19 5 Air conditioning

20 5 Alarm system