steering LAND ROVER DEFENDER 1996 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 58 of 455

MAINTENANCE

15

MAINTENANCE ADDITIONAL MAINTENANCE SCHEDULES

Camshaft drive belt

The engine timing gears are driven by a toothed

rubber belt which must be renewed at intervals

determined by the severity of operating conditions. In

reasonable, temperate climate operation, the belt

should be renewed every 120,000 km (72,000 miles)

or every six years whichever occurs earlier.

In adverse operating conditions, such as work in dusty

atmospheres, high ambient temperatures, desert and

tropical zones, renew the belt every 60,000 km

(36,000 miles) or every three years, whichever occurs

earlier.

CAUTION: If the drive belt is not renewed

at the correct interval, it could fail,

resulting in serious engine damage.

Oil change diesel engines

If the vehicle is operated on fuel with a high sulpher

content (over 1%) the oil change intervals must not

exceed 5000 km (3000 miles).

Anti-freeze

At two yearly intervals or at the onset of the second

winter, the cooling system should be drained, flushed

and refilled with the required water and anti-freeze

solution.

Hydraulic brake fluid.

It is recommended that at 40,000 km (24,000 miles)

intervals or every two years, whichever is the earlier,

the hydraulic brake fluid should be completely

renewed.

At 80,000 km (48,000 miles) intervals or every four

years, whichever is the earlier, all hydraulic brake fluid

seals and flexible hoses should be renewed. All

working surfaces of the master cylinder and caliper

cylinders should be examined and renewed where

necessary.Air cleaner

When the vehicle is used in dusty or field conditions or

deep wading, frequent attention to the air cleaner may

be required.

Dampers

At 60,000 km (36,000 miles) intervals remove all

suspension dampers, test for correct operation, refit or

renew as necessary.

SPECIAL OPERATING CONDITIONS

When the vehicle is operated in extremely arduous

conditions or on dusty, wet or muddy terrain, more

frequent attention should be paid to all servicing

requirements.

Additional daily or weekly attention depending on

operating conditions:

Check/top-up transfer box oil.

Check steering rubber boots for security and

condition. Renew if damaged.

Check brake fluid level: Investigate cause if any fluid

loss is suspected.

Clean brake discs and calipers.

Lubricate front and rear propeller shaft

universal/sliding joints. Under tropical or severe

conditions, particularly where sand is encountered,

the sliding joints must be lubricated very frequently to

prevent ingress of abrasive material.

Every week and every maintenance inspection check

tyre pressures and inspect tyre treads and side walls.

Under arduous cross-country conditions the tyre

pressures should be checked much more frequently,

even to the extent of a daily check.

Monthly

Renew gearbox oil.

Renew transfer box oil.

Check air cleaner element and renew every 6 months

or as necessary.

Page 63 of 455

12ENGINE

4

REPAIR

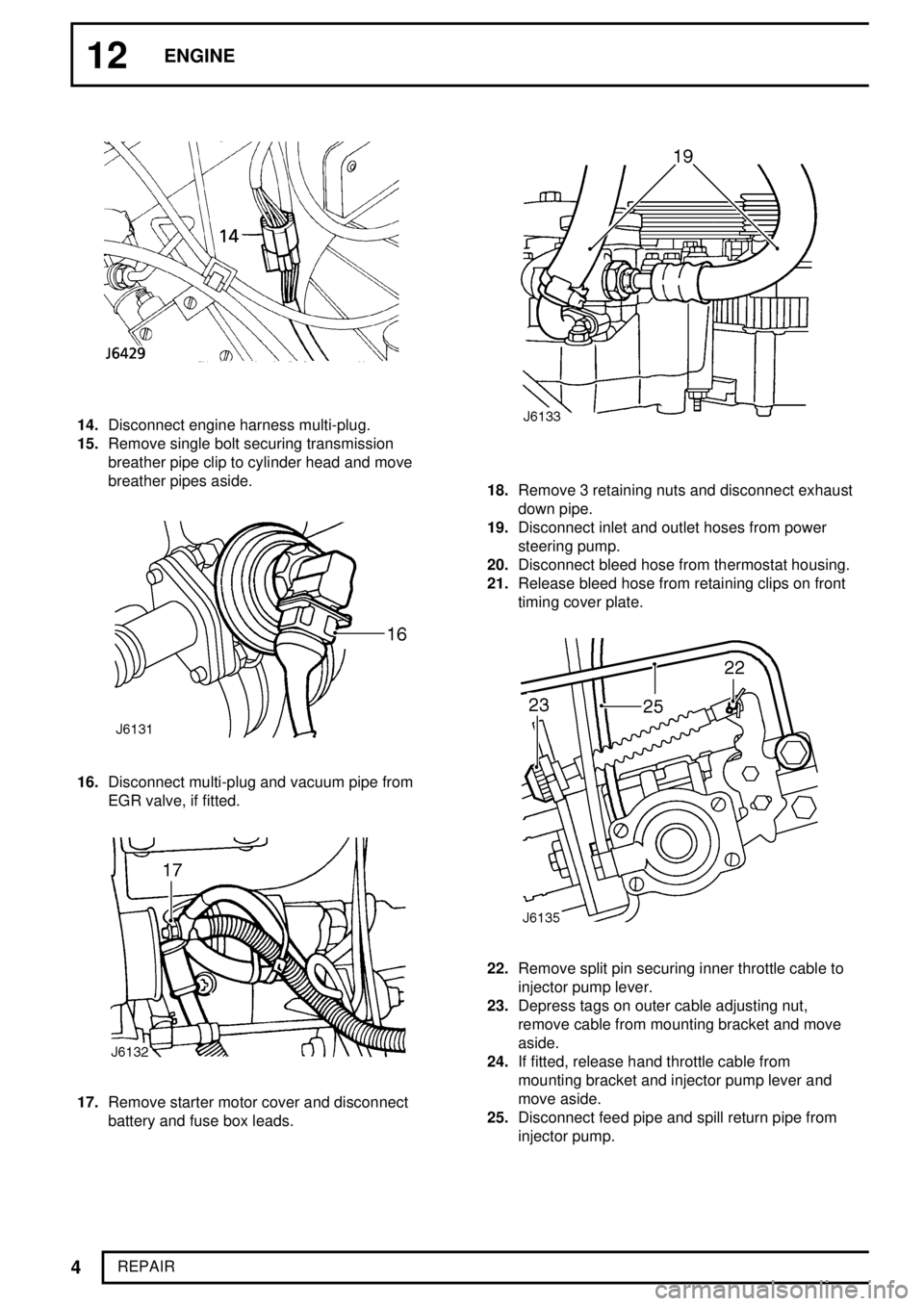

14.Disconnect engine harness multi-plug.

15.Remove single bolt securing transmission

breather pipe clip to cylinder head and move

breather pipes aside.

16.Disconnect multi-plug and vacuum pipe from

EGR valve, if fitted.

17.Remove starter motor cover and disconnect

battery and fuse box leads.

18.Remove 3 retaining nuts and disconnect exhaust

down pipe.

19.Disconnect inlet and outlet hoses from power

steering pump.

20.Disconnect bleed hose from thermostat housing.

21.Release bleed hose from retaining clips on front

timing cover plate.

22.Remove split pin securing inner throttle cable to

injector pump lever.

23.Depress tags on outer cable adjusting nut,

remove cable from mounting bracket and move

aside.

24.If fitted, release hand throttle cable from

mounting bracket and injector pump lever and

move aside.

25.Disconnect feed pipe and spill return pipe from

injector pump.

Page 65 of 455

12ENGINE

6

REPAIR 42.Raise engine, and locate front engine mountings

to chassis.

43.Remove gearbox support and lower engine.

44.Tighten front engine mounting to chassis fixings

to

45 Nm (33 lbf/ft).

45.Release chains from engine lifting brackets and

remove hoist.

46.Connect oil cooler pipes to oil filter adaptor.

47.Fit vacuum hose to brake servo adaptor.

48.Secure fuel feed pipe in retaining clip on air

cleaner bracket.

49.Fit fuel lift pump pipes.

50.Connect feed and spill return pipes to injector

pump.

51.If fitted, reconnect hand throttle cable to

mounting bracket and injector pump.

52.Fit outer cable adjusting nut into injector pump

mounting bracket.

53.Fit inner throttle cable to injector pump and

secure with clevis and split pin.

54.Secure bleed hose in retaining clips on front

timing cover.

55.Fit bleed hose to thermostat housing.

56.Connect inlet and outlet hoses to power steering

pump.

57.Fit down pipe to exhaust manifold and secure

with 3 nuts.

58.Connect starter motor battery and fuse box

leads.

59.If fitted, connect EGR valve multi-plug and

vacuum pipe.

60.Secure breather pipe clip to cylinder head.

61.Connect engine harness multi-plug.

62.Fit heater plug feed wire.

63.Connect electrical feed plug at rear of cylinder

head.

64.Fit heater hoses to cylinder head and heater

rails.

65.Fit feed pipe/hose to turbo-charger and

intercooler.

66.Fit rocker cover insulation.

67.Fit radiator assembly.

See COOLING SYSTEM,

Repair, Radiator

If applicable, fit air

conditioning condenser, compressor pipes and

heater matrix hoses.

See AIR CONDITIONING,

Repair, Condenser

68.Fit bonnet.

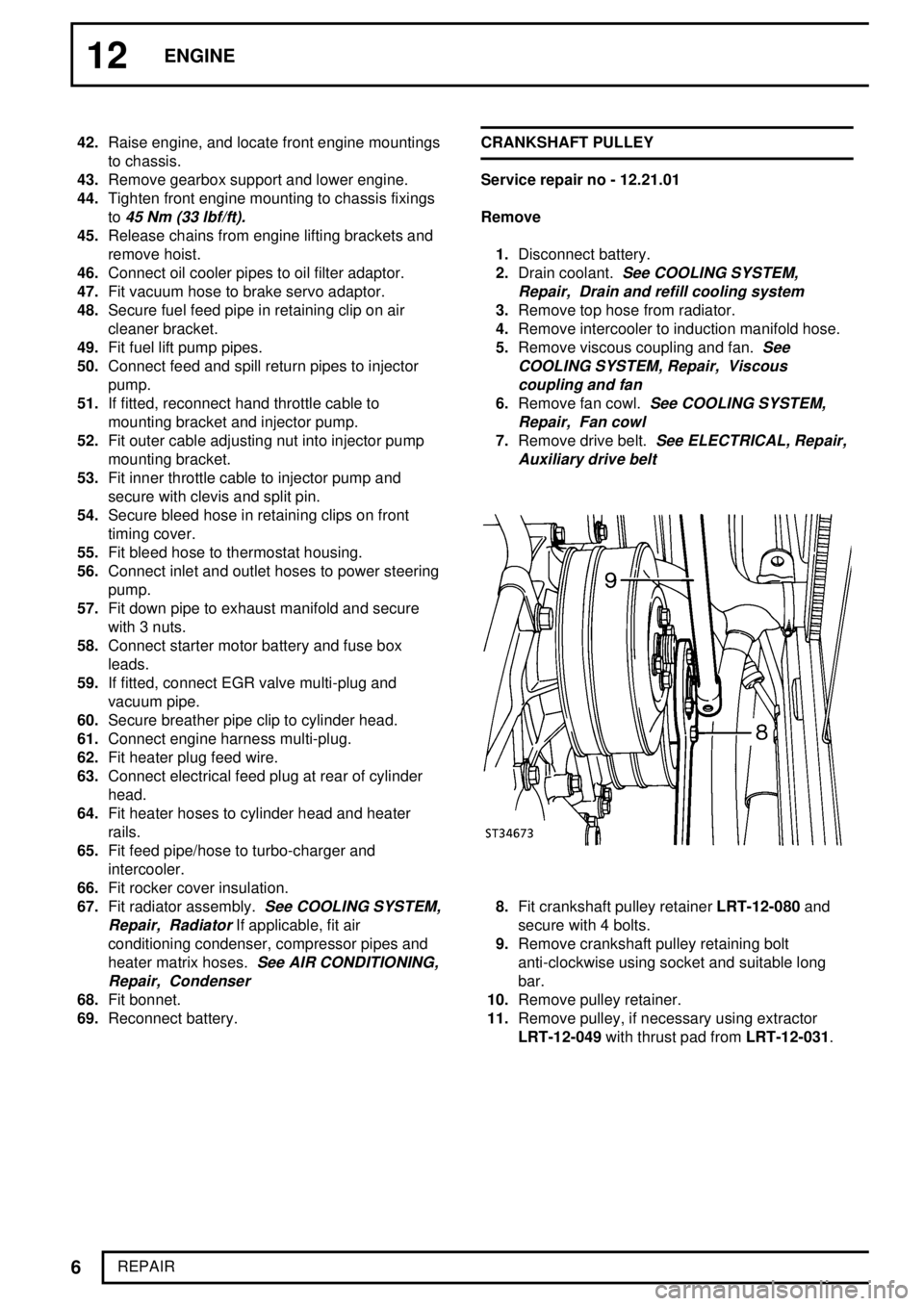

69.Reconnect battery.CRANKSHAFT PULLEY

Service repair no - 12.21.01

Remove

1.Disconnect battery.

2.Drain coolant.

See COOLING SYSTEM,

Repair, Drain and refill cooling system

3.Remove top hose from radiator.

4.Remove intercooler to induction manifold hose.

5.Remove viscous coupling and fan.

See

COOLING SYSTEM, Repair, Viscous

coupling and fan

6.Remove fan cowl.See COOLING SYSTEM,

Repair, Fan cowl

7.Remove drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

8.Fit crankshaft pulley retainerLRT-12-080and

secure with 4 bolts.

9.Remove crankshaft pulley retaining bolt

anti-clockwise using socket and suitable long

bar.

10.Remove pulley retainer.

11.Remove pulley, if necessary using extractor

LRT-12-049with thrust pad fromLRT-12-031.

Page 128 of 455

COOLING SYSTEM

3

REPAIR WATER PUMP

Service repair no - 26.50.01

Remove

1.Disconnect battery.

2.Drain cooling system.

See Adjustment, Drain

and refill cooling system

3.Remove radiator top hose.

4.Remove intercooler top hose.

5.Slacken water pump and power steering pump

pulley retaining bolts.

6.Remove drive belt.

See ELECTRICAL, Repair,

Auxiliary drive belt

7.Unscrew flange nut and remove belt tensioner.

8.Remove oil filler cap and remove rocker cover

insulation.

9.Slacken retaining clip and disconnect hose at

heater rail.

10.Unscrew 3 bolts and remove water pump pulley.

11.Unscrew 3 bolts and remove power steering

pump pulley.

12.Remove 8 bolts securing water pump, noting

location of 3 through bolts into cylinder block.

13.Withdraw pump and gasket from auxiliary

mounting bracket.

14.Clean all gasket material from mating faces.

Refit

15.Using new gasket, fit water pump to mounting

bracket. Tighten bolts to

25 Nm (18 lbf/ft).

16.Fit power steering pump pulley.

17.Fit water pump pulley. Tighten bolts of both

pulleys to

25 Nm (18 lbf/ft).

18.Fit drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

19.Fit hose at heater rail.

20.Fit rocker cover insulation and oil filler cap.

21.Fit drive belt tensioner. Tighten retaining nut to

45 Nm (33 lbf/ft).

22.Fit intercooler top hose.

23.Fit radiator top hose.

24.Refill cooling system.

See Adjustment, Drain

and refill cooling system

25.Reconnect battery.

Page 129 of 455

26COOLING SYSTEM

4

REPAIRREV: 05/99 AUXILIARY MOUNTING BRACKET AND GASKET

Service repair no - 26.50.04

Remove

1.Disconnect battery.

2.Drain cooling system

See Adjustment, Drain

and refill cooling system

.

3.Remove radiator top hose.

4.Remove intercooler top hose.

5.Remove viscous fan unit.

See Viscous

coupling and fan

6.Remove fan cowl.See Fan cowl

7.Slacken power steering pump pulley retaining

bolts.

8.Remove drive belt.

See ELECTRICAL, Repair,

Auxiliary Drive belt

9.Unscrew 3 bolts and remove power steering

pump pulley.

10.Remove 4 bolts securing power steering pump

mounting bracket.

11.Lower pump and bracket. Do not disconnect fluid

pipes.

12.Remove generator.

See ELECTRICAL, Repair,

Generator

13.Unscrew retaining nut and remove drive belt

tensioner.

14.Release hose clip from bracket above water

pump.15.Disconnect bottom hose/heater return hose at

water pump and heater rail.

16.Disconnect by-pass hose from water pump and

thermostat housing.

17.Remove 5 bolts (one with nut) and single

retaining nut, securing auxiliary mounting

bracket to cylinder block.

18.Withdraw mounting bracket, complete with water

pump.

19.Remove gasket and clean mating faces.

Refit

20.Using 2 slave studs, fit new gasket.

NOTE: All fixing bolts and nuts should be

tightened to

25 Nm (18 lbf/ft)unless

otherwise stated.

21.Locate mounting bracket, complete with water

pump on slave studs and secure with 4 other

fixings.

22.Remove slave studs and fit remaining bolts/nuts.

23.Fit by-pass hose to thermostat housing and

water pump.

24.Fit bottom hose/heater return hose to water

pump and heater rail.

25.Fit heater hose clip to mounting bracket.

26.Fit drive belt tensioner. Tighten nut to

45 Nm (33

lbf/ft).

27.Fit generator.See ELECTRICAL, Repair,

Generator

Do not fit drive belt at this stage.

Page 130 of 455

COOLING SYSTEM

5

REPAIR 28.Secure steering pump and bracket to auxiliary

mounting bracket.

29.Fit steering pump pulley.

30.Fit drive belt

See ELECTRICAL, Repair,

Auxiliary drive belt

.

31.Fit fan cowl

See Fan cowl.

32.Fit viscous fan unit

See Viscous coupling and

fan

.

33.Fit intercooler top hose.

34.Fit radiator top hose.

35.Refill cooling system.

See Adjustment, Drain

and refill cooling system

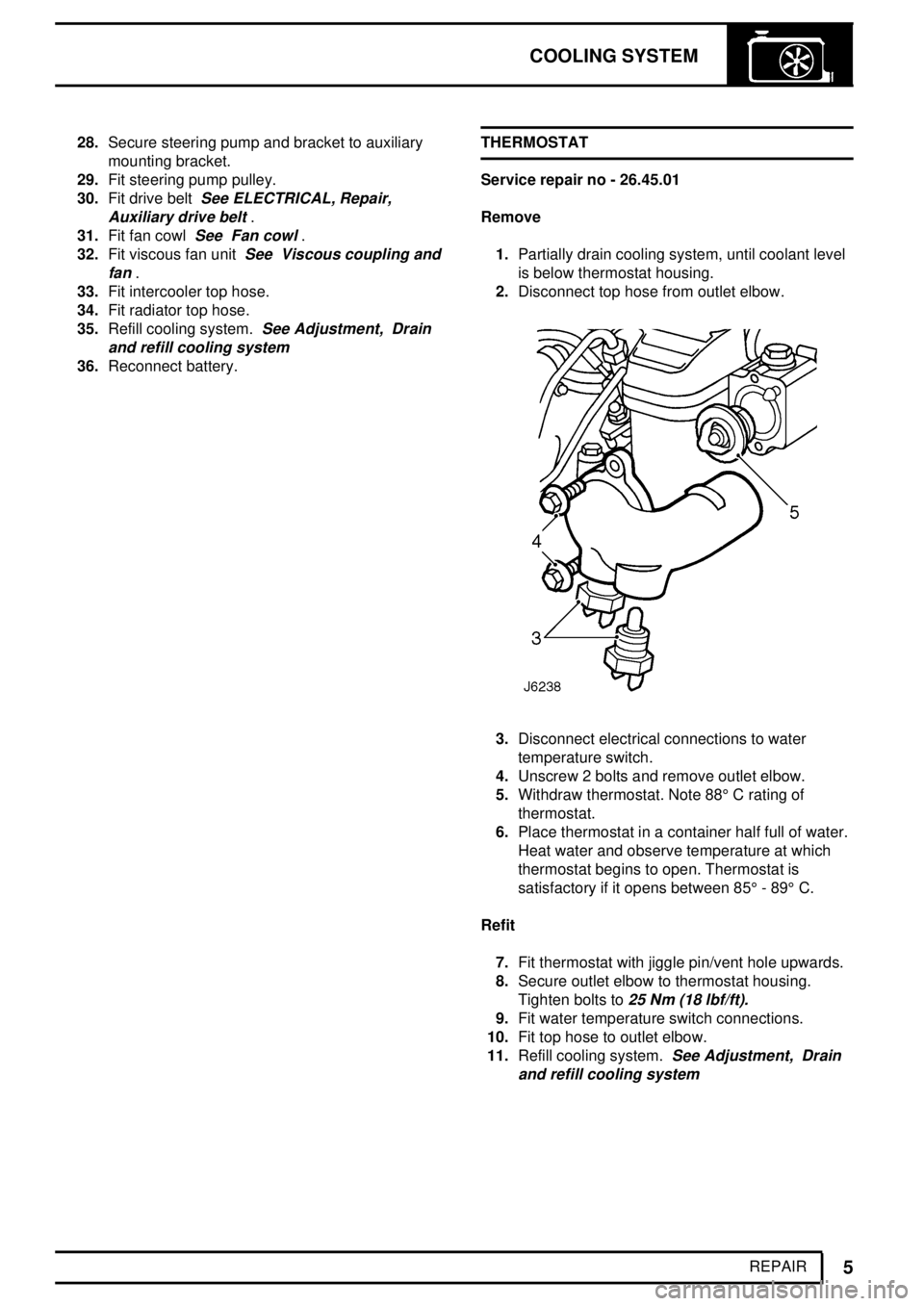

36.Reconnect battery.THERMOSTAT

Service repair no - 26.45.01

Remove

1.Partially drain cooling system, until coolant level

is below thermostat housing.

2.Disconnect top hose from outlet elbow.

3.Disconnect electrical connections to water

temperature switch.

4.Unscrew 2 bolts and remove outlet elbow.

5.Withdraw thermostat. Note 88°C rating of

thermostat.

6.Place thermostat in a container half full of water.

Heat water and observe temperature at which

thermostat begins to open. Thermostat is

satisfactory if it opens between 85°-89°C.

Refit

7.Fit thermostat with jiggle pin/vent hole upwards.

8.Secure outlet elbow to thermostat housing.

Tighten bolts to

25 Nm (18 lbf/ft).

9.Fit water temperature switch connections.

10.Fit top hose to outlet elbow.

11.Refill cooling system.

See Adjustment, Drain

and refill cooling system

Page 209 of 455

FRONT AXLE AND FINAL DRIVE

1

REPAIR REV: 05/99 FRONT AXLE ASSEMBLY

Service repair no - 54.10.01

Remove

WARNING: Remove and refit of axle

requires a further two persons to steady

axle when lowering or repositioning axle.

1.Support chassis front.

2.Remove road wheels.

3.Support axle weight with hydraulic jack.

4.Remove radius arms to chassis frame nuts.

5.Disconnect steering damper from track rod.

Using a extractor remove track rod links from

swivel pin arms.

6.Remove four nuts and bolts securing radius

arms to axle bracket.

7.Remove radius arms.

8.Remove bolts securing brake hose brackets .

Refit bolts to prevent oil leakage.

9.Remove bolts from brake calipers and tie to one

side.

10.Remove nuts and washers securing shock

absorbers to axle.

11.Disconnect drag link from swivel pin housing

arm.

12.Remove two nuts and bolts securing panhard

rod to axle bracket. Lift rod clear of axle.

13.Mark for reassembly drive shaft flanges.

Remove four nuts and bolts, tie propeller shaft to

one side.

14.Release axle ventilation pipe banjo and lower

axle assembly. Remove road springs.

15.Disconnect anti-roll bar link

See FRONT

SUSPENSION, Repair, Anti-roll bar ball

.

16.Remove axle assembly.

Refit

17.Position axle under vehicle, supporting left side

of axle, and fit anti-roll bar links

See FRONT

SUSPENSION, Repair, Anti-roll bar links

.

18.Fit propeller shaft. Tighten bolts to

47 Nm (35

lbf/ft).

19.Fit panhard rod to axle bracket. Tighten bolts to

88 Nm (65 lbf/ft).

20.Fit drag link to swivel pin arm. Tighten fixings to

40 Nm (30 lbf/ft).

21.Fit shock absorbers to axle.

22.Fit brake calipers. Tighten bolts to

82 Nm (60

lbf/ft).

23.Tighten upper swivel pin bolts to78 Nm (58

lbf/ft).

24.Fit radius arms to axle brackets. Tighten bolts to

197 Nm (145 lbf/ft).

25.Fit steering damper to track rod.

26.Fit radius arms to chassis side member. Tighten

fixings to

197 Nm (145 lbf/ft).

27.Tighten track rod end to40 Nm (30 lbf/ft)and fit

new split pin.

28.Remove chassis supports, fit road wheels and

tighten to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

Page 216 of 455

FRONT AXLE AND FINAL DRIVE

5

OVERHAUL 38.Place retaining plate, joint washer and oil seal

over axle flange ready for assembly.

39.Fit swivel bearing housing to axle flange with 7

bolts. Tighten to

73 Nm (54 lbf/ft).

40.Grease and fit upper and lower swivel pin taper

roller bearings.

41.Position swivel pin housing over swivel bearing

housing.

42.Coat joint washer both sides with sealing

compound and position on lower swivel pin.

43.Loosely fit brake shield bracket plus lower swivel

pin with lug outboard to swivel pin housing.

44.Loosely fit top swivel pin plus existing shims and

brake hose bracket to swivel pin housing.

45.Apply Loctite 270 or equivalent to lower swivel

pin bolts.

78 Nm (58 lbf/ft),bend over lock tabs.

46.Tighten top swivel pin bolts to

78 Nm (58 lbf/ft).

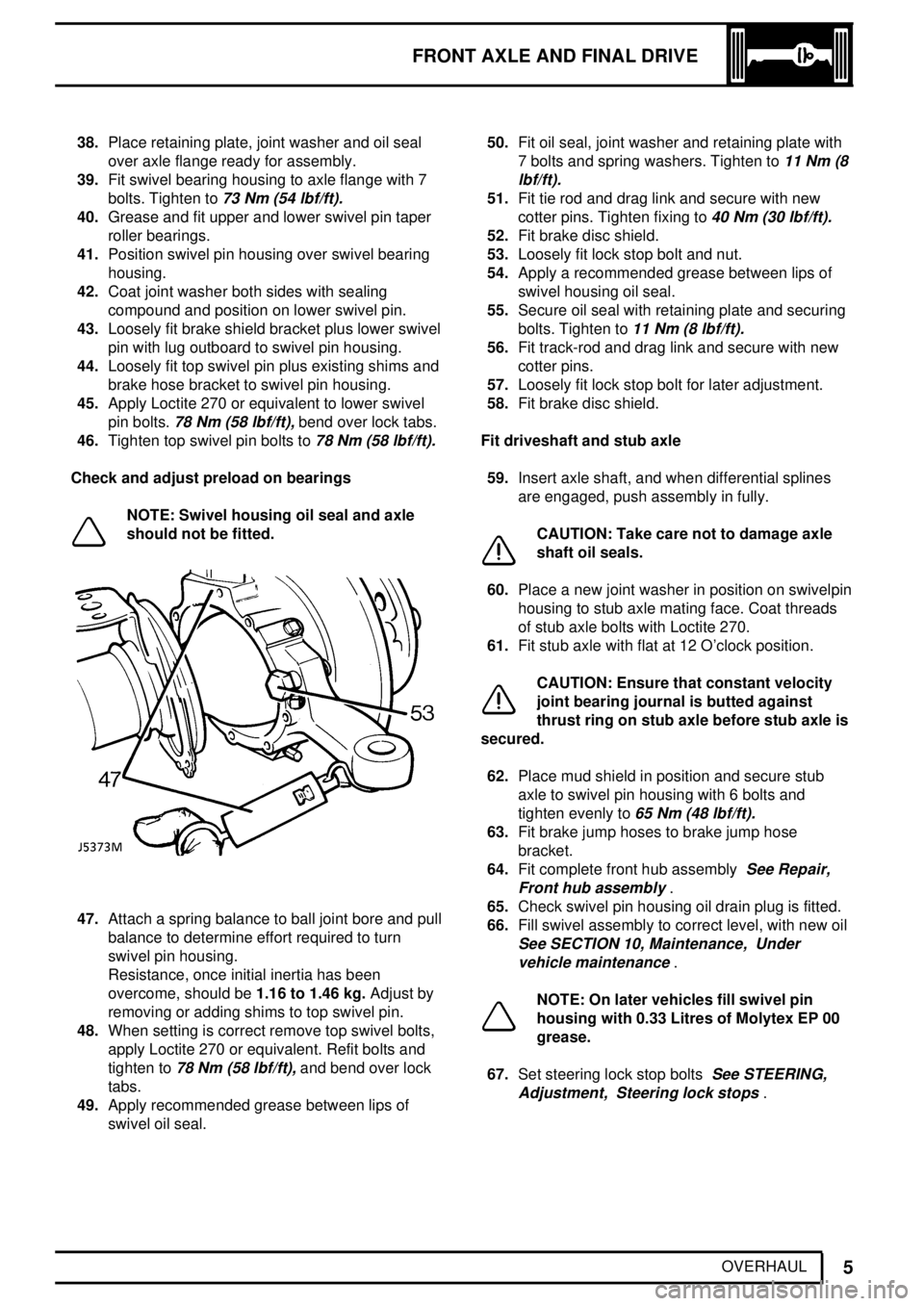

Check and adjust preload on bearings

NOTE: Swivel housing oil seal and axle

should not be fitted.

47.Attach a spring balance to ball joint bore and pull

balance to determine effort required to turn

swivel pin housing.

Resistance, once initial inertia has been

overcome, should be1.16 to 1.46 kg.Adjust by

removing or adding shims to top swivel pin.

48.When setting is correct remove top swivel bolts,

apply Loctite 270 or equivalent. Refit bolts and

tighten to

78 Nm (58 lbf/ft),and bend over lock

tabs.

49.Apply recommended grease between lips of

swivel oil seal.50.Fit oil seal, joint washer and retaining plate with

7 bolts and spring washers. Tighten to

11 Nm (8

lbf/ft).

51.Fit tie rod and drag link and secure with new

cotter pins. Tighten fixing to

40 Nm (30 lbf/ft).

52.Fit brake disc shield.

53.Loosely fit lock stop bolt and nut.

54.Apply a recommended grease between lips of

swivel housing oil seal.

55.Secure oil seal with retaining plate and securing

bolts. Tighten to

11 Nm (8 lbf/ft).

56.Fit track-rod and drag link and secure with new

cotter pins.

57.Loosely fit lock stop bolt for later adjustment.

58.Fit brake disc shield.

Fit driveshaft and stub axle

59.Insert axle shaft, and when differential splines

are engaged, push assembly in fully.

CAUTION: Take care not to damage axle

shaft oil seals.

60.Place a new joint washer in position on swivelpin

housing to stub axle mating face. Coat threads

of stub axle bolts with Loctite 270.

61.Fit stub axle with flat at 12 O'clock position.

CAUTION: Ensure that constant velocity

joint bearing journal is butted against

thrust ring on stub axle before stub axle is

secured.

62.Place mud shield in position and secure stub

axle to swivel pin housing with 6 bolts and

tighten evenly to

65 Nm (48 lbf/ft).

63.Fit brake jump hoses to brake jump hose

bracket.

64.Fit complete front hub assembly

See Repair,

Front hub assembly

.

65.Check swivel pin housing oil drain plug is fitted.

66.Fill swivel assembly to correct level, with new oil

See SECTION 10, Maintenance, Under

vehicle maintenance

.

NOTE: On later vehicles fill swivel pin

housing with 0.33 Litres of Molytex EP 00

grease.

67.Set steering lock stop bolts

See STEERING,

Adjustment, Steering lock stops

.

Page 218 of 455

STEERING

1

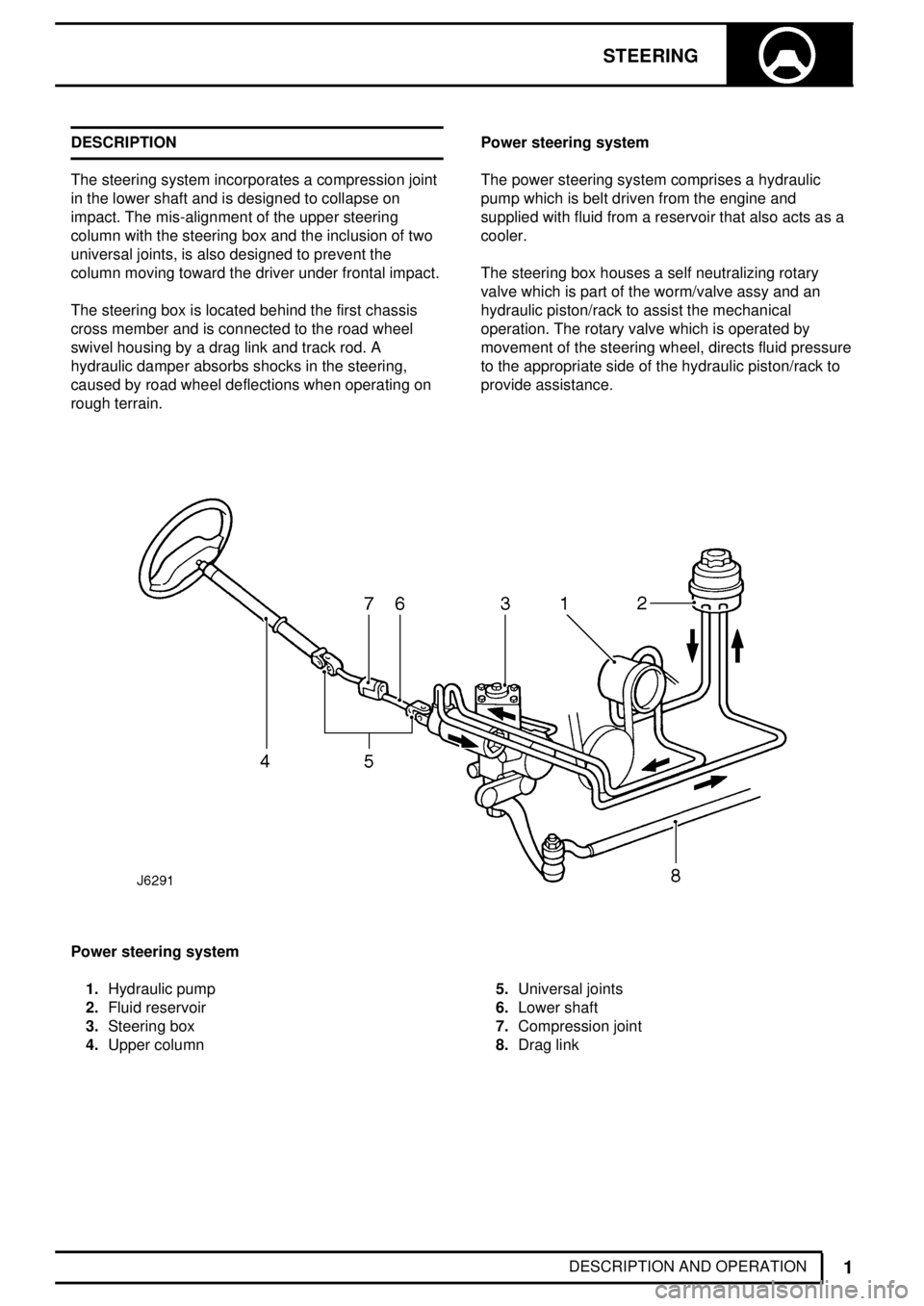

DESCRIPTION AND OPERATION DESCRIPTION

The steering system incorporates a compression joint

in the lower shaft and is designed to collapse on

impact. The mis-alignment of the upper steering

column with the steering box and the inclusion of two

universal joints, is also designed to prevent the

column moving toward the driver under frontal impact.

The steering box is located behind the first chassis

cross member and is connected to the road wheel

swivel housing by a drag link and track rod. A

hydraulic damper absorbs shocks in the steering,

caused by road wheel deflections when operating on

rough terrain.Power steering system

The power steering system comprises a hydraulic

pump which is belt driven from the engine and

supplied with fluid from a reservoir that also acts as a

cooler.

The steering box houses a self neutralizing rotary

valve which is part of the worm/valve assy and an

hydraulic piston/rack to assist the mechanical

operation. The rotary valve which is operated by

movement of the steering wheel, directs fluid pressure

to the appropriate side of the hydraulic piston/rack to

provide assistance.

Power steering system

1.Hydraulic pump

2.Fluid reservoir

3.Steering box

4.Upper column5.Universal joints

6.Lower shaft

7.Compression joint

8.Drag link

Page 219 of 455

57STEERING

2

DESCRIPTION AND OPERATION

Power steering box components

1.Housing complete with sector shaft bearings

2.Cover plate complete with bearing

3.Sector shaft

4.Hydraulic piston/rack

5.Worm/valve and torsion bar assembly

6.Shims for centralizing worm/valve

7.Ball race

8.'Teflon' seals for valve sleeve

9.Bearing adjuster, locknut and seal

10.Worm shaft pressure seal, circlip and dirt

excluder11.'Teflon' and rubber seal for piston

12.End cover seal and snap ring

13.Adjustment components for piston/rack

14.Hydraulic pipe

15.Bleed screw

16.Sector shaft adjustment lock nut with seal

17.Cover plate bolts

18.Cover plate seal

19.Seal, washer and backup seal

20.Circlip and dust cover