brake LAND ROVER DEFENDER 1996 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 119 of 455

FUEL SYSTEM

17

REPAIR EGR VALVE

Service repair no - 17.45.01

Remove

1.Disconnect multi-plug from EGR valve.

2.Disconnect vacuum pipe from EGR valve.

3.Remove 2 Allen screws securing EGR valve to

exhaust manifold.

4.Remove 2 bolts securing air inlet delivery tube to

EGR valve.

5.Remove EGR valve and discard gaskets.

Refit

6.Clean mating faces of EGR valve and exhaust

manifold.

7.Position new gaskets and fit EGR valve to

delivery tube and exhaust manifold. Tighten

bolts to

25 Nm (18 lbf/ft).

8.Fit vacuum pipe and multi-plug to EGR valve.EGR VALVE MODULATOR

Service repair no - 17.45.04

Remove

1.Disconnect multi-plug from modulator.

2.Disconnect spill pipe (green), modulator to air

cleaner hose.

3.Disconnect vacuum pipe (blue), modulator to

EGR valve.

4.Disconnect vacuum pipe (white), modulator to

brake servo pipe.

5.Unscrew 2 nuts securing modulator to flexible

mountings.

6.Remove modulator.

Refit

7.Fit modulator to flexible mountings and tighten

nuts to

8 Nm (6 lbf/ft).

8.Fit modulator pipes, ensuring they are connected

to correct ports.

9.Connect modulator multi-plug.

Page 156 of 455

37MANUAL GEARBOX

2

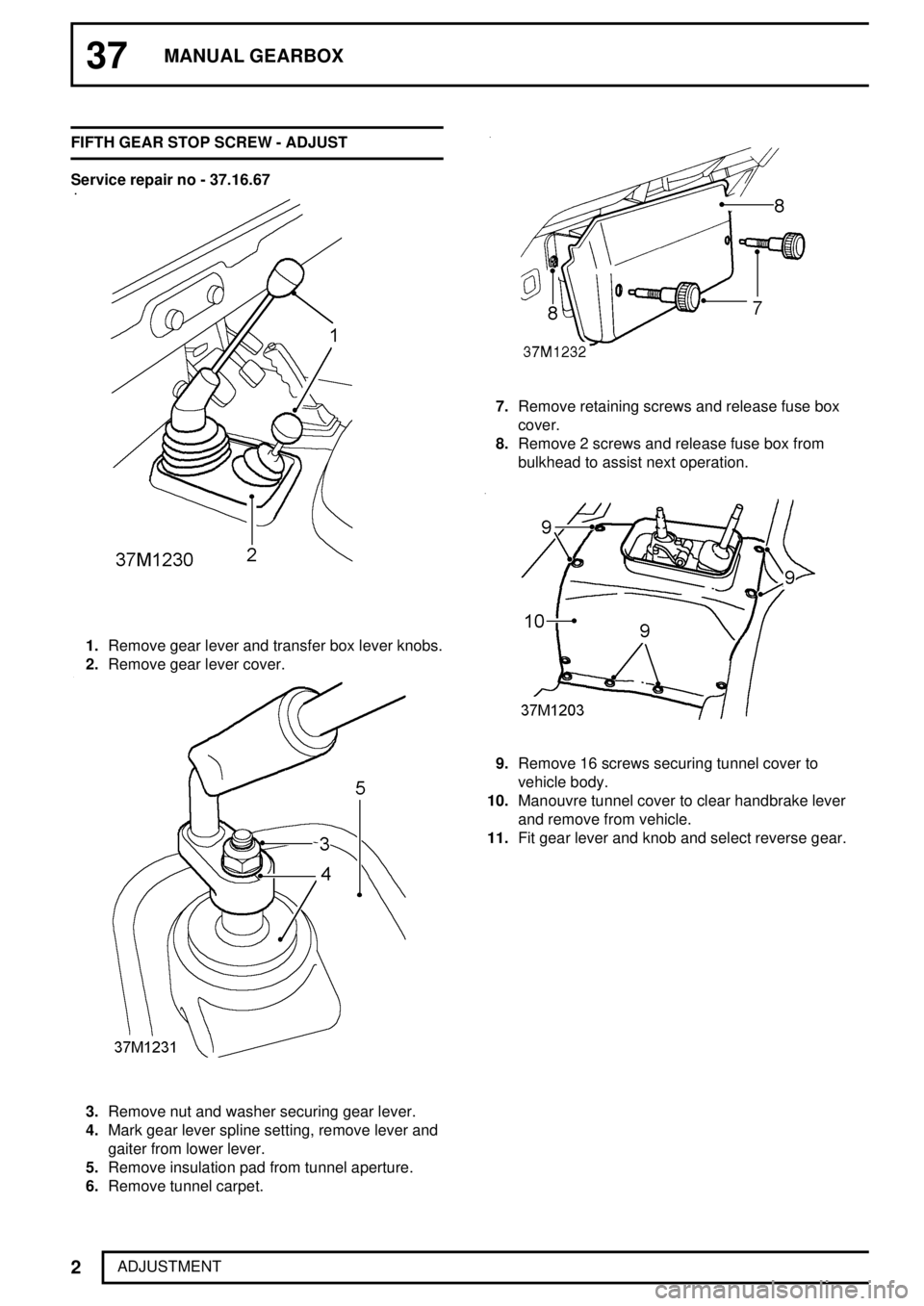

ADJUSTMENT FIFTH GEAR STOP SCREW - ADJUST

Service repair no - 37.16.67

1.Remove gear lever and transfer box lever knobs.

2.Remove gear lever cover.

3.Remove nut and washer securing gear lever.

4.Mark gear lever spline setting, remove lever and

gaiter from lower lever.

5.Remove insulation pad from tunnel aperture.

6.Remove tunnel carpet.

7.Remove retaining screws and release fuse box

cover.

8.Remove 2 screws and release fuse box from

bulkhead to assist next operation.

9.Remove 16 screws securing tunnel cover to

vehicle body.

10.Manouvre tunnel cover to clear handbrake lever

and remove from vehicle.

11.Fit gear lever and knob and select reverse gear.

Page 159 of 455

37MANUAL GEARBOX

2

REPAIR

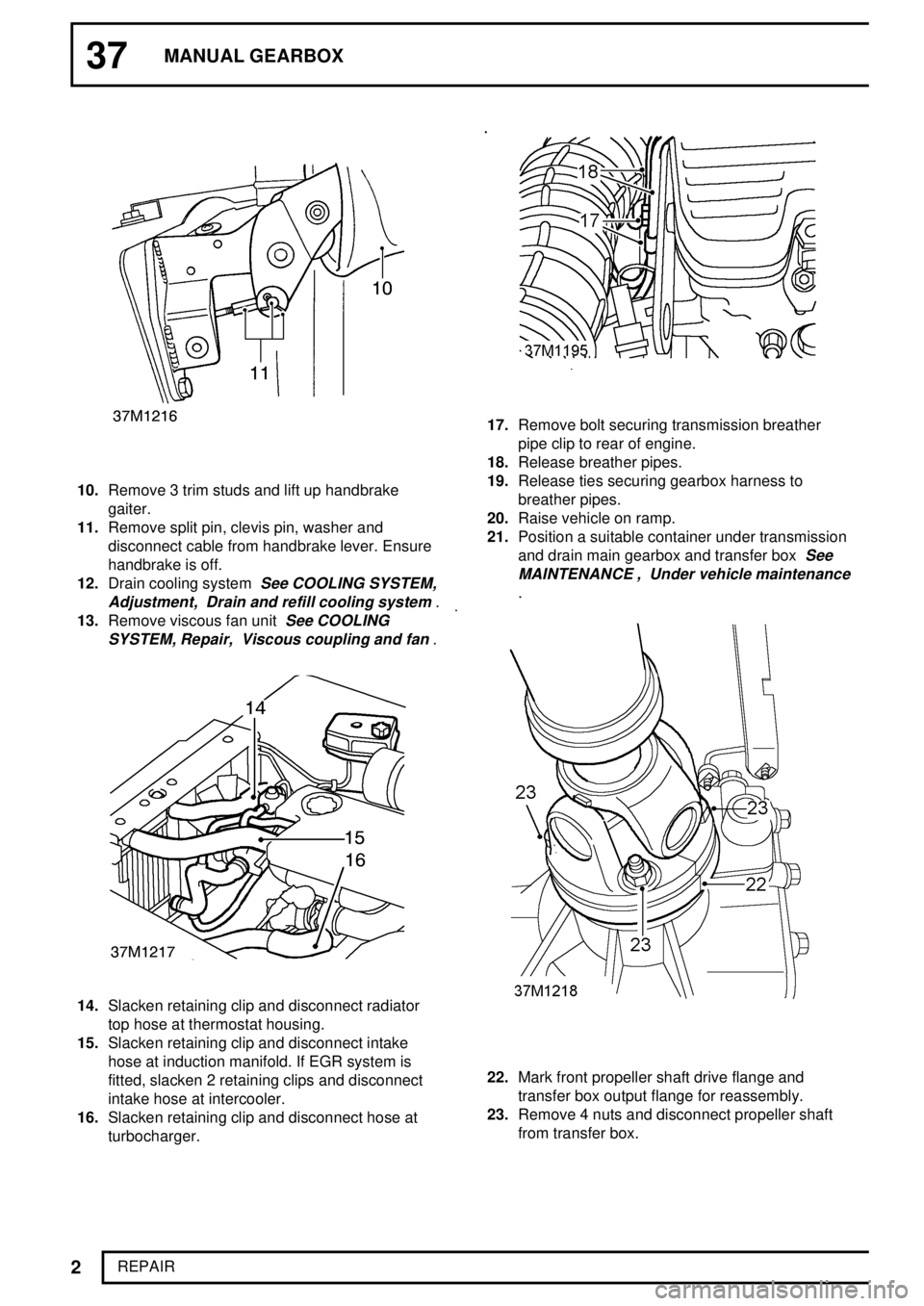

10.Remove 3 trim studs and lift up handbrake

gaiter.

11.Remove split pin, clevis pin, washer and

disconnect cable from handbrake lever. Ensure

handbrake is off.

12.Drain cooling system

See COOLING SYSTEM,

Adjustment, Drain and refill cooling system

.

13.Remove viscous fan unit

See COOLING

SYSTEM, Repair, Viscous coupling and fan

.

14.Slacken retaining clip and disconnect radiator

top hose at thermostat housing.

15.Slacken retaining clip and disconnect intake

hose at induction manifold. If EGR system is

fitted, slacken 2 retaining clips and disconnect

intake hose at intercooler.

16.Slacken retaining clip and disconnect hose at

turbocharger.

17.Remove bolt securing transmission breather

pipe clip to rear of engine.

18.Release breather pipes.

19.Release ties securing gearbox harness to

breather pipes.

20.Raise vehicle on ramp.

21.Position a suitable container under transmission

and drain main gearbox and transfer box

See

MAINTENANCE , Under vehicle maintenance

.

22.Mark front propeller shaft drive flange and

transfer box output flange for reassembly.

23.Remove 4 nuts and disconnect propeller shaft

from transfer box.

Page 160 of 455

MANUAL GEARBOX

3

REPAIR

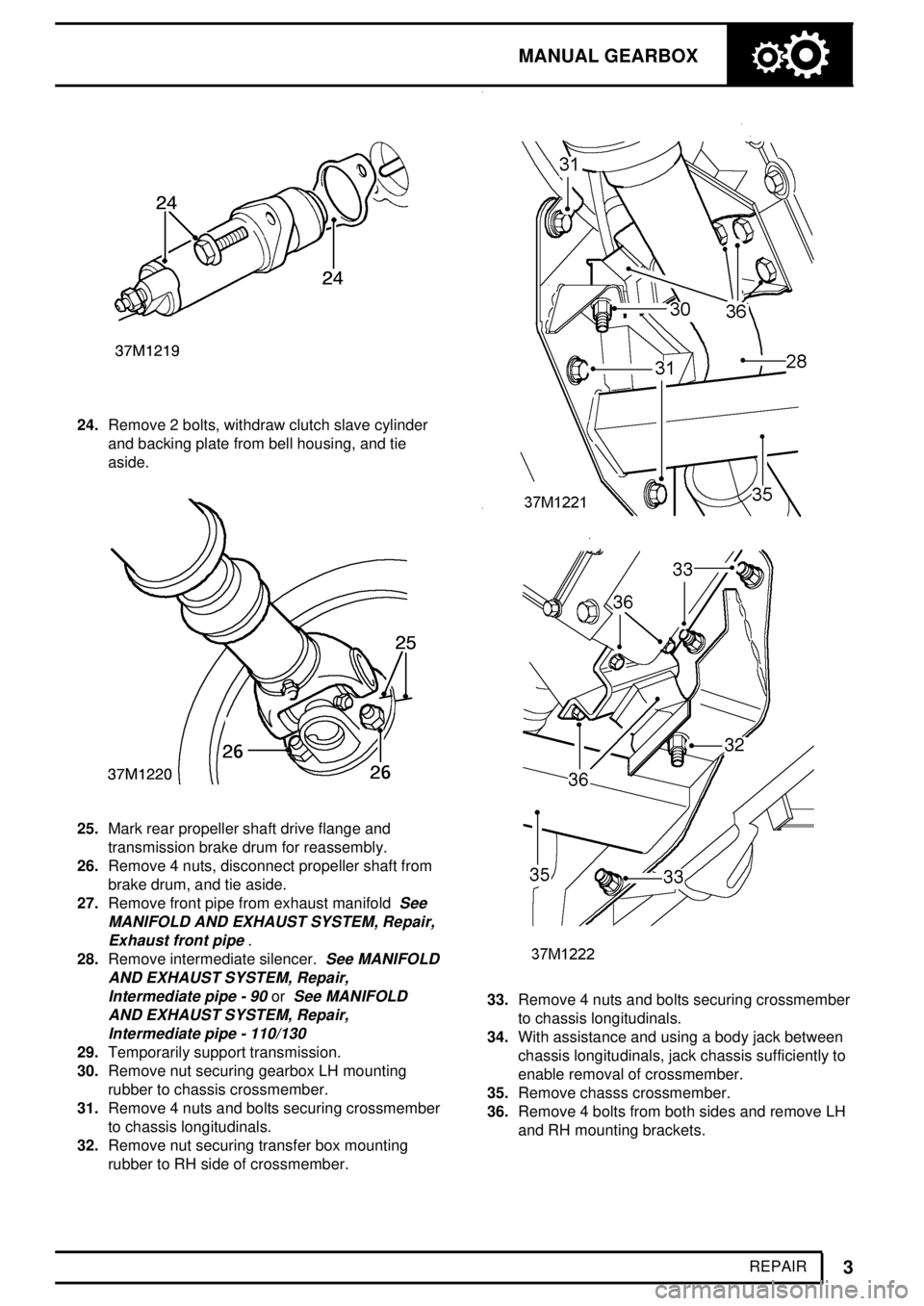

24.Remove 2 bolts, withdraw clutch slave cylinder

and backing plate from bell housing, and tie

aside.

25.Mark rear propeller shaft drive flange and

transmission brake drum for reassembly.

26.Remove 4 nuts, disconnect propeller shaft from

brake drum, and tie aside.

27.Remove front pipe from exhaust manifold

See

MANIFOLD AND EXHAUST SYSTEM, Repair,

Exhaust front pipe

.

28.Remove intermediate silencer.

See MANIFOLD

AND EXHAUST SYSTEM, Repair,

Intermediate pipe - 90

orSee MANIFOLD

AND EXHAUST SYSTEM, Repair,

Intermediate pipe - 110/130

29.Temporarily support transmission.

30.Remove nut securing gearbox LH mounting

rubber to chassis crossmember.

31.Remove 4 nuts and bolts securing crossmember

to chassis longitudinals.

32.Remove nut securing transfer box mounting

rubber to RH side of crossmember.

33.Remove 4 nuts and bolts securing crossmember

to chassis longitudinals.

34.With assistance and using a body jack between

chassis longitudinals, jack chassis sufficiently to

enable removal of crossmember.

35.Remove chasss crossmember.

36.Remove 4 bolts from both sides and remove LH

and RH mounting brackets.

Page 161 of 455

37MANUAL GEARBOX

4

REPAIR

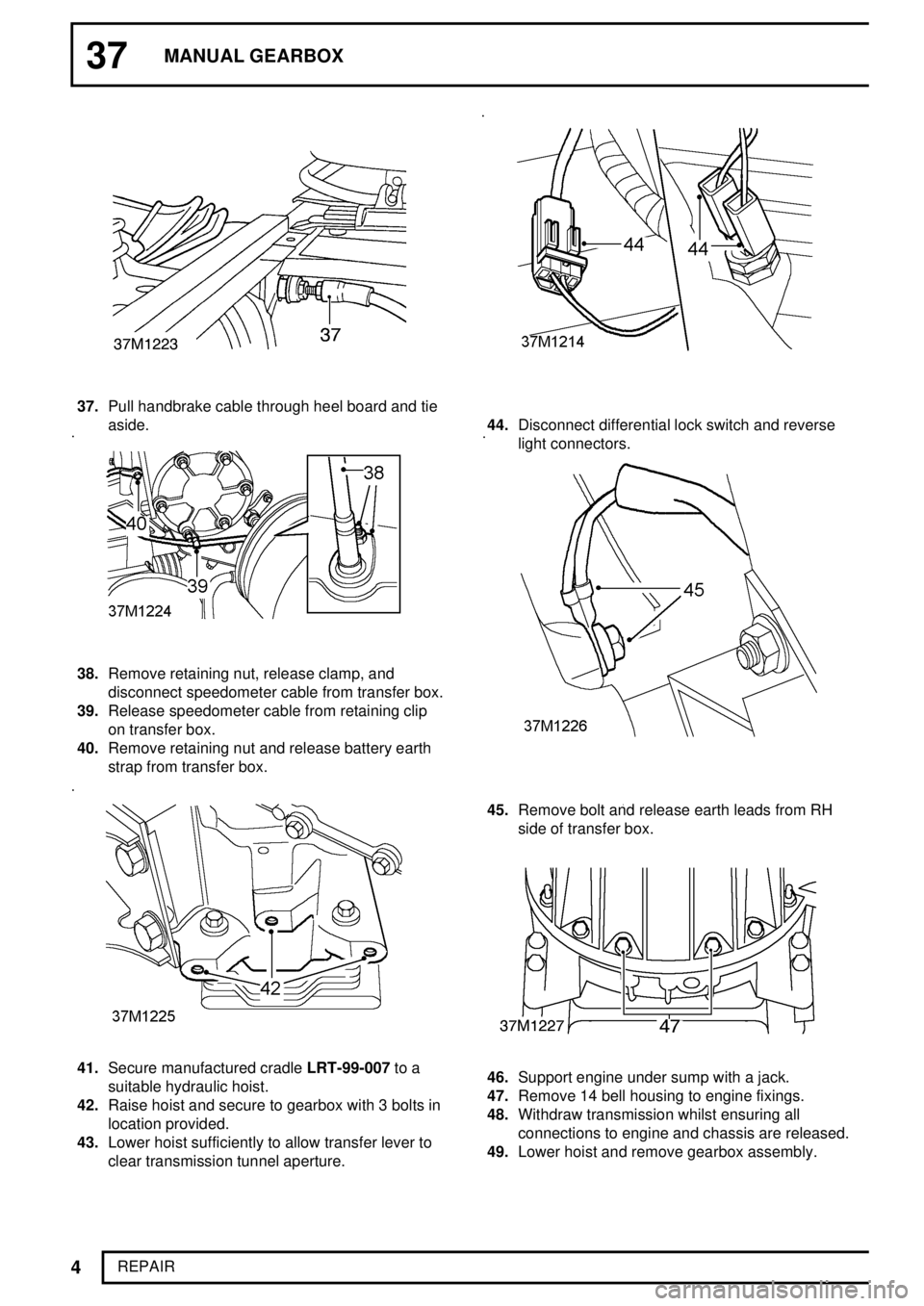

37.Pull handbrake cable through heel board and tie

aside.

38.Remove retaining nut, release clamp, and

disconnect speedometer cable from transfer box.

39.Release speedometer cable from retaining clip

on transfer box.

40.Remove retaining nut and release battery earth

strap from transfer box.

41.Secure manufactured cradleLRT-99-007to a

suitable hydraulic hoist.

42.Raise hoist and secure to gearbox with 3 bolts in

location provided.

43.Lower hoist sufficiently to allow transfer lever to

clear transmission tunnel aperture.

44.Disconnect differential lock switch and reverse

light connectors.

45.Remove bolt and release earth leads from RH

side of transfer box.

46.Support engine under sump with a jack.

47.Remove 14 bell housing to engine fixings.

48.Withdraw transmission whilst ensuring all

connections to engine and chassis are released.

49.Lower hoist and remove gearbox assembly.

Page 163 of 455

37MANUAL GEARBOX

6

REPAIRREV: 05/99 78.Position crossmember and locate over fixing

studs of LH and RH gearbox mounting rubbers.

79.Align crossmember and secure to chassis with 4

nuts and bolts on each side.

NOTE: Fit battery earth strap retaining clip

to LH top bolt.

80.Fit intermediate silencer.

See MANIFOLD AND

EXHAUST SYSTEM, Repair, Intermediate

pipe - 90

orSee MANIFOLD AND EXHAUST

SYSTEM, Repair, Intermediate pipe - 110/130

.

81.Fit front pipe to exhaust manifold

See

MANIFOLD AND EXHAUST SYSTEM, Repair,

Exhaust front pipe

.

82.Fit rear propeller shaft to transmission brake

drum. Tighten nuts to

47 Nm (33 lbf/ft).

83.Remove 3 bolts securing support cradle to

transmission and remove hoist.

84.Reconnect battery earth strap to transfer box

fixing.

85.Connect speedometer cable to transfer box and

secure with retaining clip.

86.Coat both sides of clutch slave clinder backing

plate with Hylomar P232M waterproof sealant.

87.Locate backing plate on slave cylinder.

88.Fit slave cylinder to bell housing, engaging

push-rod through centre of dust cover, and with

bleed screw uppermost. Tighten bolts to

25 Nm

(18 lbf/ft).

89.Fit front propeller shaft to transfer box. Tighten

nuts to

47 Nm (33 lbf/ft).

90.Refill main gearbox and transfer boxSee

MAINTENANCE , Under vehicle maintenance

.

91.Feed transmission brake cable through heel

board and ensure grommet is correctly located.

NOTE: Apply a soap solution to aid fitment

of cable.

92.Lower vehicle on ramp.

93.Fit ties to secure gearbox harness to

transmission breather pipes.

94.Fit breather pipe retaining clip to rear of engine.

95.Reconnect charge air hose at turbocharger.

96.Reconnect intake hose at induction manifold. If

EGR system is fitted, reconnect intake hose at

intercooler.

97.Reconnect radiator top hose at thermostat

housing.

98.Fit viscous fan unit

See COOLING SYSTEM,

Repair, Viscous coupling and fan

.

99.Reconnect battery.100.Refill cooling system

See COOLING SYSTEM,

Adjustment, Drain and refill cooling system

.

101.Connect cable clevis to handbrake lever and fit

handbrake gaiter.

102.Locate insulation pad over gear levers and fit to

tunnel cover.

103.Fit gear lever with gaiter to lower lever spline

and secure with retaining nut.

104.Fit gear lever cover.

105.Fit gear lever and transfer box lever knobs.

106.Fit gearbox cover carpet.

107.Check operation of handbrake and adjust as

necessary

See MAINTENANCE , Under

vehicle maintenance

.

Page 165 of 455

TRANSFER GEARBOX

1

DESCRIPTION AND OPERATION TRANSFER GEARBOX

Description

The transfer gearbox is a permanent 4 wheel drive,

two speed ratio reducing gearbox, incorporating high

and low range outputs with mechanically lockable

centre differential (diff-lock). High/low range and

diff-lock selection are made via a single lever located

forward of the main gear lever.

The transfer gearbox is mounted at the rear of the

main gearbox, the mainshaft of which extends into the

transfer casing. A transfer gear, supported on taper

roller bearings and splined to the gearbox mainshaft,

passes the drive to an intermediate gear cluster

supported on a single shaft and rotating on taper roller

bearings.The intermediate gears pass the drive to high and low

speed gears on the rear output shaft. The rear output

shaft passes through the speedo drive housing, which

also forms the mounting for the transmission brake. A

worm gear fitted to the rear output shaft drives a

pinion fitted in the speedo housing.

Integral with the output shafts is a differential

assembly which compensates for speed differences

between the front and rear prop shafts. To prevent all

the power being transmitted to the axle offering the

least resistance, a diff-lock is provided. The differential

lock should only be engaged during severe off-road

conditions and should be disengaged as soon as

conditions permit. Selection of differential lock

engages, through mechanical linkage, a dog clutch

with the front output shaft, this action locks the centre

differential and provides a fixed drive, giving equal

power to the front and rear output shafts.

Page 169 of 455

41TRANSFER GEARBOX

2

REPAIR

11.Remove 3 trim studs and lift up handbrake

gaiter.

12.Remove split pin, clevis pin, washer and

disconnect cable from handbrake lever. Ensure

handbrake is off.

13.Release handbrake outer cable from heelboard.

14.Remove fan cowl

See COOLING SYSTEM,

Repair, Fan cowl

.

15.Raise vehicle on ramp.

16.Drain transfer box oil

See SECTION 10,

Maintenance, Under vehicle maintenance

.

17.Remove intermediate silencer.

See MANIFOLD

AND EXHAUST SYSTEM, Repair,

Intermediate pipe - 90

orSee MANIFOLD

AND EXHAUST SYSTEM, Repair,

Intermediate pipe - 110/130

.

18.Mark rear propeller shaft drive flange and

transmission brake drum for reassembly.

19.Remove 4 nuts, disconnect propeller shaft from

brake drum, and tie aside.

20.Mark front propeller shaft drive flange and

transfer box output flange for reassembly.

21.Remove 4 nuts, disconnect propeller shaft from

transfer box, and tie aside.

22.Remove retaining clip at lower end of pivot arm

and disconnect differential lock control operating

rod.

Page 172 of 455

TRANSFER GEARBOX

5

REPAIR REV: 05/9963.Feed transmission brake cable through heel

board. Ensure cable grommet is correctly

located.

NOTE: Apply a soap solution to aid fitment

of cable.

64.Lower vehicle ramp.

65.Connect cable clevis to handbrake lever and fit

handbrake gaiter.

66.Connect high/low lever to operating rod.

67.Fit breather pipe banjo union to high/low

cross-shaft housing.

68.Fit centre access panel to seat base. If fitted,

secure EGR and alarm system diagnostic

connector mounting bracket to front of access

panel.

69.If fitted, reconnect multi-plug to EGR control unit

on base of centre seat cushion or cubby box.

70.Fit seat cushion or cubby box

See CHASSIS

AND BODY, Repair, Cubby box

.

71.Reconnect battery.

72.Check operation of handbrake and adjust as

necessary

See MAINTENANCE , Handbrake

cable

.

Page 173 of 455

TRANSFER GEARBOX

1

SPECIFICATIONS, TORQUE REV: 05/99 TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Transfer gearbox

Pinch bolt - operating arm to crank arm 9......................................................

End cover gear change housing 9.................................................................

Bottom cover to transfer case 25....................................................................

Front output housing to transfer case 25........................................................

Cross shaft housing to front output housing 25...............................................

Gear change housing 25.................................................................................

Pivot shaft to link arm 25.................................................................................

Connecting rod to adjustable clevis 25...........................................................

Anti-rotation plate intermediate shaft 25.........................................................

Front output housing cover 25........................................................................

Pivot bracket to extension housing 25............................................................

Finger housing to front output housing 25......................................................

Bearing housing to transfer case 25...............................................................

Brake drum to coupling flange 25...................................................................

Bearing housing cover to transfer gearbox 45................................................

Rear output speedometer housing to transfer gearbox 45..............................

Selector finger to cross shaft high/low 25.......................................................

Selector fork, high/low to shaft 25...................................................................

Transmission brake to speedometer housing 72............................................

Gate plate to grommet plate 9.......................................................................

Gearbox to transfer case 45...........................................................................

Oil drain plug 30..............................................................................................

Oil filler/level plug 30.......................................................................................

Differential case (front to rear) 60...................................................................

Output flanges 162...........................................................................................

Differential case rear stake nut 72..................................................................

Transfer breather 15.......................................................................................

Transfer box front drive flange to drive shaft 45..............................................

Transfer box rear drive flange to drive shaft 45..............................................

Transfer gearbox mounting brackets to chassis 30........................................

Mounting brackets to transfer gearbox 55......................................................

Mounting rubbers to mounting brackets 21.....................................................