engine oil LAND ROVER DEFENDER 1996 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 414 of 455

86ELECTRICAL

2

DESCRIPTION AND OPERATION VEHICLE IMMOBILISATION AND ALARM SYSTEM

A sophisticated engine immobilisation and anti-theft

alarm system is offered on the Land Rover Defender

300 Tdi vehicle range, which incorporates the

following features:

Perimeter protection

This part of the alarm system protects side doors,

bonnet and rear door against unauthorised entry -

alarm sounding if any one of these apertures is

opened without alarm first being disarmed.

Interior protection

Also known as volumetric protection, this part of the

system protects space inside the vehicle. Once

armed, the alarm will sound if a door is opened, or if

movement is detected inside the vehicle.

Engine immobilisation

The engine is immobilised electronically whenever the

alarm system is armed. Even if the alarm has not

been armed, engine immobilisation will occur

automatically thirty seconds after the driver's door is

opened, or five minutes after the starter switch is

turned to position '0'.

ALARM SYSTEM COMPONENTS

Electronic control unit (ECU)

The ECU is the alarm system brain and controls all

vehicle immobilisation and alarm functions. It

responds to the inputs received, by supplying suitable

outputs to indicate status of the alarm system or

activating relevant warning devices. unit is located

under fascia behind instrument binnacle.

Handset and key

The handset is the primary source of control for the

alarm system i.e. it arms and disarms the alarm

components. The key can be used to override engine

immoblisation if the handset is lost or fails to operate,

seeEngine immobilisation override.The handset battery should last for approximately

three years dependent upon use. The following

symptoms will be noticed when the battery requires

replacement:

1.The handset will only work every other operation

while disarming.

2.The direction indicator lamps will not flash when

the alarm is disarmed.

For battery replacement procedure, seeHandset

Battery.

Passive coil

The passive coil is fitted on the starter switch and

activates a receiving coil in the handset, causing it to

automatically transmit a remobilisation signal to the

ECU.

Aerial

The aerial is integral within the alarm system harness

and supplies the ECU with the signal received from

handset.

Immobilisation spider

The immobilisation spider provides an interface

between ECU and immobilised areas of the vehicle.

This is installed in a sealed (safe) box inside the

vehicle battery box.

Digital diesel shut-off valve - 97 MY

When fitted, the digital diesel shut-off valve

immobilises the fuel injection pump by preventing

power reaching the fuel shut-off solenoid,

See

Immobilisation and alarm system circuit diagram -

with DDS

.

Page 416 of 455

86ELECTRICAL

4

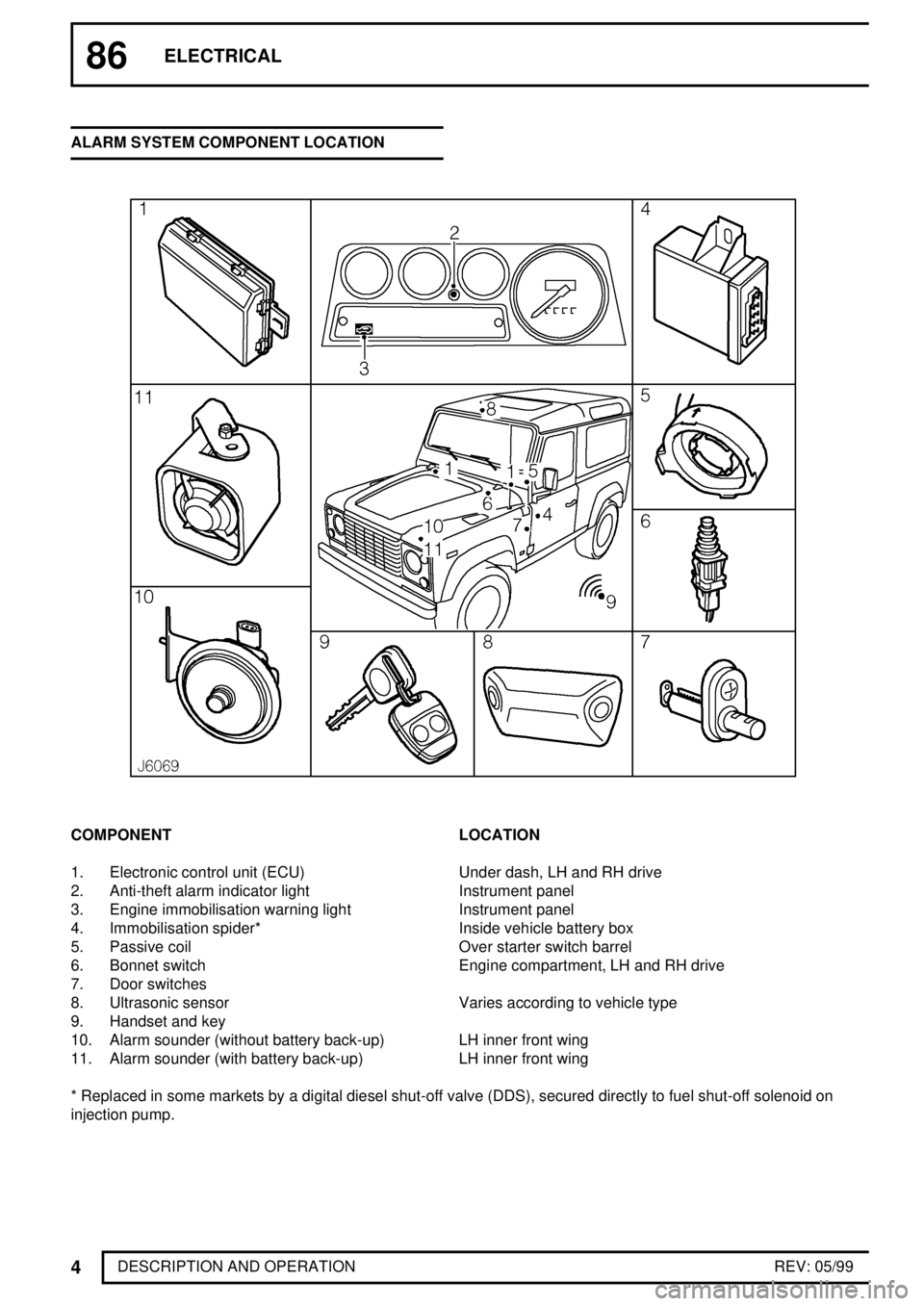

DESCRIPTION AND OPERATION REV: 05/99 ALARM SYSTEM COMPONENT LOCATION

COMPONENT LOCATION

1. Electronic control unit (ECU) Under dash, LH and RH drive

2. Anti-theft alarm indicator light Instrument panel

3. Engine immobilisation warning light Instrument panel

4. Immobilisation spider* Inside vehicle battery box

5. Passive coil Over starter switch barrel

6. Bonnet switch Engine compartment, LH and RH drive

7. Door switches

8. Ultrasonic sensor Varies according to vehicle type

9. Handset and key

10. Alarm sounder (without battery back-up) LH inner front wing

11. Alarm sounder (with battery back-up) LH inner front wing

* Replaced in some markets by a digital diesel shut-off valve (DDS), secured directly to fuel shut-off solenoid on

injection pump.

Page 421 of 455

ELECTRICAL

9

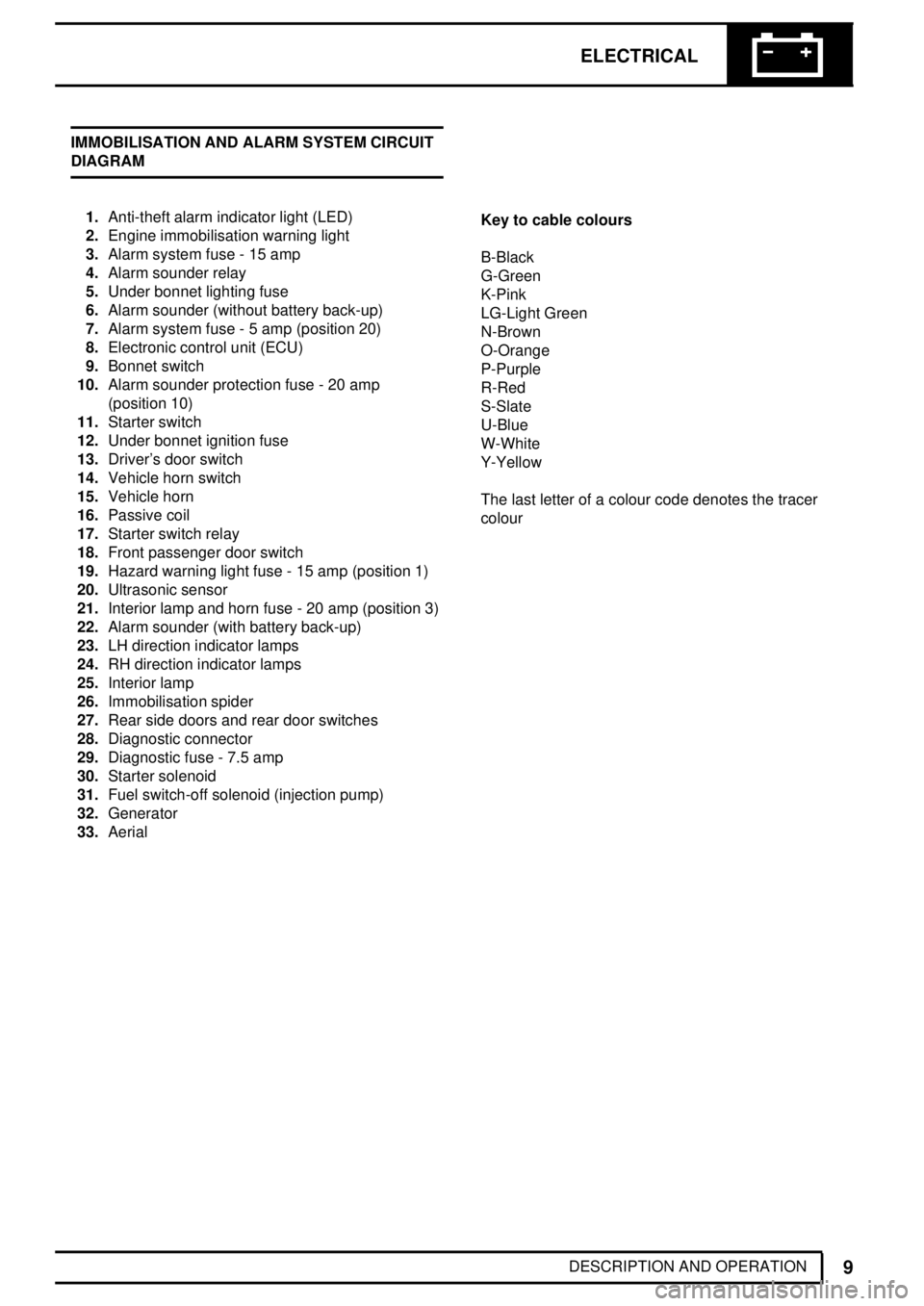

DESCRIPTION AND OPERATION IMMOBILISATION AND ALARM SYSTEM CIRCUIT

DIAGRAM

1.Anti-theft alarm indicator light (LED)

2.Engine immobilisation warning light

3.Alarm system fuse - 15 amp

4.Alarm sounder relay

5.Under bonnet lighting fuse

6.Alarm sounder (without battery back-up)

7.Alarm system fuse - 5 amp (position 20)

8.Electronic control unit (ECU)

9.Bonnet switch

10.Alarm sounder protection fuse - 20 amp

(position 10)

11.Starter switch

12.Under bonnet ignition fuse

13.Driver's door switch

14.Vehicle horn switch

15.Vehicle horn

16.Passive coil

17.Starter switch relay

18.Front passenger door switch

19.Hazard warning light fuse - 15 amp (position 1)

20.Ultrasonic sensor

21.Interior lamp and horn fuse - 20 amp (position 3)

22.Alarm sounder (with battery back-up)

23.LH direction indicator lamps

24.RH direction indicator lamps

25.Interior lamp

26.Immobilisation spider

27.Rear side doors and rear door switches

28.Diagnostic connector

29.Diagnostic fuse - 7.5 amp

30.Starter solenoid

31.Fuel switch-off solenoid (injection pump)

32.Generator

33.AerialKey to cable colours

B-Black

G-Green

K-Pink

LG-Light Green

N-Brown

O-Orange

P-Purple

R-Red

S-Slate

U-Blue

W-White

Y-Yellow

The last letter of a colour code denotes the tracer

colour

Page 423 of 455

ELECTRICAL

11

DESCRIPTION AND OPERATION IMMOBILISATION AND ALARM SYSTEM CIRCUIT

DIAGRAM - WITH DDS

1.Anti-theft alarm indicator light (LED)

2.Engine immobilisation warning light

3.Alarm system fuse - 15 amp

4.Alarm sounder relay

5.Under bonnet lighting fuse

6.Alarm sounder (without battery back-up)

7.Alarm system fuse - 5 amp (position 20)

8.Electronic control unit (ECU)

9.Bonnet switch

10.Alarm sounder protection fuse - 20 amp

(position 10)

11.Starter switch

12.Under bonnet ignition fuse

13.Driver's door switch

14.Vehicle horn switch

15.Vehicle horn

16.Passive coil

17.Starter switch relay

18.Front passenger door switch

19.Hazard warning light fuse - 15 amp (position 1)

20.Ultrasonic sensor

21.Interior lamp and horn fuse - 20 amp (position 3)

22.Alarm sounder (with battery back-up)

23.LH direction indicator lamps

24.RH direction indicator lamps

25.Interior lamp

26.Digital diesel shut-off valve (DDS)

27.Rear side doors and rear door switches

28.Diagnostic connector

29.Diagnostic fuse - 7.5 amp

30.Starter solenoid

31.Fuel shut-off solenoid (injection pump)

32.Generator

33.AerialKey to cable colours

B-Black

G-Green

K-Pink

LG-Light Green

N-Brown

O-Orange

P-Purple

R-Red

S-Slate

U-Blue

W-White

Y-Yellow

The last letter of a colour code denotes the tracer

colour

Page 426 of 455

ELECTRICAL

1

REPAIR ELECTRICAL PRECAUTIONS

The following guidelines are intended to ensure the

safety of the operator whilst preventing damage to

electrical and electronic components fitted to the

vehicle.

Polarity

Never reverse connect the vehicle battery and always

observe the correct polarity when connecting test

equipment.

High voltage circuits

WARNING: Before commencing work on

an ignition system, all high tension

terminals, adaptors and diagnostic

equipment for testing should be inspected to

ensure that they are adequately insulated and

shielded to prevent accidental personal contacts

and minimize the risk of shock. Wearers of

surgically implanted pacemaker devices should

not be in close proximity to ignition circuits or

diagnostic equipment.

Whenever disconnecting live high tension circuits

always use insulated pliers and never allow the open

end of a high tension lead to come into contact with

other components particularly electronic control units.

Exercise caution when measuring the voltage on the

coil terminals while the engine is running, since, high

voltage spikes can occur on these terminals.

Connectors and harness

Always ensure that these items are dry and oil free

before disconnecting and connecting test equipment.

Never force connectors apart either by using tools or

by pulling on the wiring harness. Always ensure

locking tabs are disengaged before removal and note

orientation to enable correct reconnection. Ensure that

any protective covers and substances are replaced if

disturbed. Having confirmed a component to be faulty

switch-off the ignition and disconnect the battery.

Remove the component and support the disconnected

harness. When replacing the component keep oily

hands away from electrical connection areas and

push connectors home until any locking tabs fully

engage.Battery disconnecting

Before disconnecting the battery, switch off all

electrical equipment.

Battery charging

Recharge the battery out of the vehicle and keep the

top well ventilated. While being charged or

discharged, and for approximately 15 minutes

afterwards, batteries emit hydrogen gas which is

flammable. Always ensure any battery charging area

is well ventilated and that every precaution is taken to

avoid naked flames and sparks.

GENERAL PRECAUTIONS

Switch-off ignition prior to making any connection or

disconnection in the system as electrical surge

caused by disconnecting 'live' connections can

damage electronic components.

Ensure hands and work surfaces are clean and free of

grease, swarf, etc. as grease collects dirt which can

cause tracking or high-resistance contacts.

When handling printed circuit boards, treat them as

you would a disc - hold by the edges only.

Prior to commencing a test, and periodically during a

test, touch a good earth, for instance, a cigar lighter

socket, to discharge body static as some electronic

components are vulnerable to static electricity.

Page 436 of 455

ELECTRICAL

11

REPAIR REV: 05/99 Refit

12.Fit new fuse.

13.Position instrument panel to fascia cowl area

and reconnect immobiliser warning light leads,

gearbox oil temperature lead, heated rear screen

leads, alarm LED plug lead, main harness

multi-plugs and speedometer cable,

14.Secure instrument panel to fascia cowl with 4

screws

See INSTRUMENTS, Repair,

Instrument panel.

15.Fit steering wheelSee STEERING, Repair,

Steering wheel.

16.Reconnect battery negative lead.

17.Fit battery access cover.

18.Fit LH front seat cushion.GENERATOR

Service repair no - 86.10.02

Remove

1.Disconnect battery.

2.Remove drive belt

See Auxiliary drive belt.

3.Unscrew 3 fixings, remove heat shield from rear

of generator, and disconnect electrical leads

from generator.

4.Remove generator bottom fixing bolt.

5.Remove long through bolt from top fixing and lift

generator from engine.

Refit

6.Fit generator to engine mounting bracket and

secure with top and bottom fixing bolts.

7.Connect electrical leads.

8.Fit heat shield.

9.Fit drive belt

See Auxiliary drive belt; Refit.

10.Reconnect battery.