battery LAND ROVER DEFENDER 1996 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 355 of 455

76CHASSIS AND BODY

34

REPAIRREV: 05/99 LOWER FASCIA PANEL (HEATER DUCT)

ASSEMBLY

Service repair no - 76.46.05

Remove

1.Disconnect battery.

2.Remove steering wheel

See STEERING,

Repair, Steering wheel

.

3.Remove steering column nacelle

See

STEERING, Repair, Steering column nacelle

.

4.Remove instrument panel

See INSTRUMENTS,

Repair, instrument panel

.

5.Release heater cable at control lever

See

HEATING AND VENTILATION, Repair, Heater

control cable - air distribution

.

6.Remove 2 screws, withdraw switch panel from

lower fascia and disconnect switch multi-plugs.

7.Prise out Land Rover decal and remove screw

securing grab handle to crash pad.

8.Remove lower screw and lift grab handle from

lower fascia panel.

9.On RH drive vehicles only, remove screw

securing LH side of finisher to wiper motor cover.

10.Remove 4 screws and remove both demister

vents from crash pad.

11.Remove 3 screws securing crash pad to fascia

bulkhead.

12.Remove crash pad.

13.Remove radio, if fitted.

14.Remove 2 trim studs securing radio housing to

trim panel. Remove radio housing.

Page 358 of 455

CHASSIS AND BODY

37

REPAIR REV: 05/9947.Connect leads and plugs to auxiliary switches

and clock.

48.Secure switch panel to lower fascia panel and

switch cover.

49.Position radio housing, if applicable, and feed

radio multi- plug, aerial and speaker leads from

switch cover to radio housing.

50.Secure radio housing to trim panel.

51.Fit radio connections and secure radio in

housing.

52.Fit crash pad to fascia bulkhead.

53.Fit demister vents in crash pad.

54.Fit grab handle to lower fascia panel and secure

to crash pad. Refit Land Rover decal.

55.Connect multi-plugs to rear screen, hazard and

interior lamp switches and fit switch panel to

fascia panel.

56.Fit heater control cable

See HEATING AND

VENTILATION, Repair, Heater control cable -

air distribution

.

57.Fit instrument panel

See INSTRUMENTS,

Repair, instrument panel

.

58.Fit steering column nacelle

See STEERING,

Repair, Steering column nacelle

.

59.Fit steering wheel

See STEERING, Repair,

Steering wheel

.

60.Reconnect battery.FRONT UNDERTRAY

Service repair no - 76.11.81 - Front undertray

Service repair no - 76.11.85 - Acoustic pad

Remove

1.Raise vehicle on ramp.

2.Position support under chassis front

crossmember.

3.Lower ramp to give clearance between axle and

undertray.

4.Remove 4 nuts, disconnect propeller shaft from

front axle, and move aside.

5.Remove 2 bolts securing undertray to chassis

front crossmember.

6.Remove nut securing undertray to bump stop

front fixing bolt on both sides.

7.Remove 2 bolts securing sides of undertray to

rear undertray.

8.Pull front undertray forwards to release flanges

from rear undertray.

9.Lower undertray to clear steering box etc. and

manouvre rearwards over axle.

10.Remove front undertray.

11.If necessary, remove 8 fasteners to release

acoustic pad from undertray.

Page 364 of 455

HEATING AND VENTILATION

1

REPAIR HEATER UNIT

Service repair no - 80.20.01

Remove

1.Remove bonnet and disconnect battery.

2.Remove radiator bottom hose at radiator union

and drain cooling system

See COOLING

SYSTEM, Repair, Drain and refill cooling

system

.

3.Slacken clips and remove heater hoses at

heater box unions.

4.Remove outer cable securing clips.

5.Slacken trunnions and remove control cables

from heater vent flap levers.

6.Remove heater wiring harness securing loop.

7.Disconnect harness multi-plug.

8.Remove interior bulkhead trim.

9.Remove lower nuts and bolts securing the

heater unit to the bulkhead.

10.Slacken heater unit upper retaining bolts.

11.Manoeuvre heater unit, complete with blower

motor, clear of air inlet duct and remove from

engine compartment.

12.If existing heater unit is to be refitted, remove

sealing rubber.

For heater matrix removal

See Heater matrix.

For blower motor removal

See Blower motor.

Refit

13.Smear a new heater unit sealing rubber with a

suitable impact adhesive and fit to heater.

14.Manoevre heater unit into position in engine

compartment, fit blower motor to air inlet duct

and locate upper fixing bolts.

15.Loosely fit heater unit lower fixing bolts.

16.Fully tighten upper fixing bolts.

17.Fully tighten lower fixings and refit interior

bulkhead trim.

18.Secure wiring harness and reconnect multi-plug.

19.Fit control cables to vent flap trunnions and

secure with outer cable clips.

20.Connect heater hoses.

21.Fit radiator bottom hose and refill cooling system

See COOLING SYSTEM, Repair, Drain and

refill cooling system

.

22.Fit bonnet and reconnect battery.

Page 367 of 455

80HEATING AND VENTILATION

4

REPAIR HEATER CONTROL CABLE - TEMPERATURE

CONTROL

Service repair no - 80.10.05

Remove

1.Disconnect battery.

2.Remove 4 screws securing instrument panel to

fascia cowl.

3.Pull instrument panel away from fascia and

disconnect speedometer cable to give easier

access to control cable at bulkhead.

4.Remove retaining screws and pull off air

distribution and temperature control lever knobs.

5.Remove 3 screws and detach side cover,

complete with control lever assembly.

6.Remove 2 screws securing control lever

assembly to side cover and remove cover. Note

plastic screw spacers fitted between cover and

control lever assembly and retain.

7.Remove small bolt and release outer cable

retaining clip.

8.Slacken grub screw and release inner cable from

clevis.

9.From inside engine compartment, release outer

cable retaining clip at heater unit.

10.Slacken trunnion fixing and release inner cable

from heater unit flap lever.

11.Release 2 retaining clips securing control cables

to engine bulkhead and heater hoses.

12.Pull control cable through bulkhead grommet

and remove from vehicle.

Refit

13.Fit new control cable to heater flap lever trunnion

with approximately 10 mm of inner cable

protruding from trunnion. Fully tighten trunnion.

14.Secure outer cable with retaining clip.

15.Route control cable through sealing grommet

and along inside of engine bulkhead to fascia

panel.

Page 368 of 455

HEATING AND VENTILATION

5

REPAIR 16.Secure control cables to engine bulkhead and

heater hoses with retaining clips.

17.With control lever in closed position, fit inner

cable to lever clevis and fully tighten clevis grub

screw.

18.Fit outer cable retaining clip and fully tighten

securing bolt.

19.Fit side cover to control lever assembly. Ensure

fixing screw spacers are positioned between

cover and lever assembly.

20.Fit side cover to fascia.

21.Fit control lever knobs.

22.Reconnect speedometer cable and fit instrument

panel.

23.Reconnect battery.

Page 369 of 455

80HEATING AND VENTILATION

6

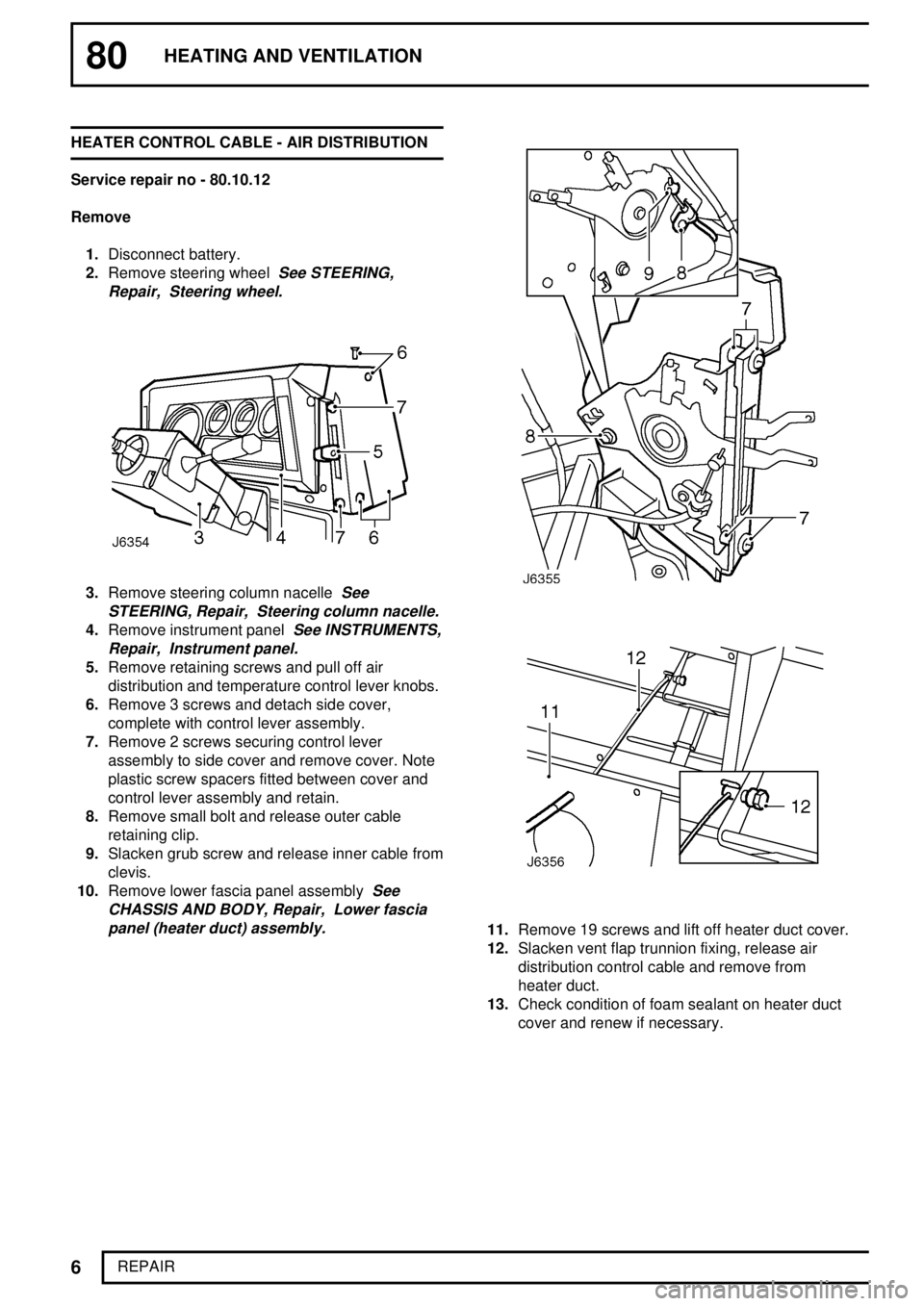

REPAIR HEATER CONTROL CABLE - AIR DISTRIBUTION

Service repair no - 80.10.12

Remove

1.Disconnect battery.

2.Remove steering wheel

See STEERING,

Repair, Steering wheel.

3.Remove steering column nacelleSee

STEERING, Repair, Steering column nacelle.

4.Remove instrument panelSee INSTRUMENTS,

Repair, Instrument panel.

5.Remove retaining screws and pull off air

distribution and temperature control lever knobs.

6.Remove 3 screws and detach side cover,

complete with control lever assembly.

7.Remove 2 screws securing control lever

assembly to side cover and remove cover. Note

plastic screw spacers fitted between cover and

control lever assembly and retain.

8.Remove small bolt and release outer cable

retaining clip.

9.Slacken grub screw and release inner cable from

clevis.

10.Remove lower fascia panel assembly

See

CHASSIS AND BODY, Repair, Lower fascia

panel (heater duct) assembly.

11.Remove 19 screws and lift off heater duct cover.

12.Slacken vent flap trunnion fixing, release air

distribution control cable and remove from

heater duct.

13.Check condition of foam sealant on heater duct

cover and renew if necessary.

Page 370 of 455

HEATING AND VENTILATION

7

REPAIR Refit

14.Fit new control cable through heater duct cover

and secure to vent flap trunnion. Bend over

cable end to fully secure.

15.Fit heater duct cover.

16.Fit lower fascia panel assembly to fascia

bulkhead

See CHASSIS AND BODY, Repair,

lower fascia panel (heater duct) assembly.

17.Route control cable along fascia bulkhead to

contol lever assembly.

18.With control lever in closed position, secure

cable to clevis.

19.Fit outer cable retaining clip to lever assembly.

20.Fit lever assembly to side cover. Ensure screw

spacers are fitted between cover and lever

assembly.

21.Fit side cover to fascia cowl.

22.Fit control lever knobs.

23.Fit instrument panel

See INSTRUMENTS,

Repair, Instrument panel.

24.Fit steering column nacelleSee STEERING,

Repair, Steering column nacelle.

CONTROL CABLE AND BLOWER MOTOR SWITCH

Service repair no - 80.10.17 - Control cable

Service repair no - 80.10.22 - Blower motor switch

Remove

1.Disconnect battery.

2.From inside engine compartment, release outer

cable retaining clip at heater unit.

3.Slacken trunnion fixing and release inner cable

from heater unit flap lever.

4.Release 2 retaining clips securing control cables

to engine bulkhead and heater hoses.

5.Remove 4 screws securing instrument panel to

fascia cowl.

6.Pull instrument panel away from fascia and

disconnect speedometer cable to ease access to

control cable.

7.Remove 2 screws securing control lever

assembly to side of fascia panel cowl. Note

plastic screw spacers fitted between cowl and

lever assembly and retain.

Page 371 of 455

80HEATING AND VENTILATION

8

REPAIR

8.Release lever assembly and disconnect 3

blower motor leads, noting their positions.

9.Pull control cable through bulkhead grommet

and out from instrument panel cowl.

10.Release retaining clip securing outer cable to

lever assembly.

11.Release inner cable from lever peg.

NOTE: If the blower motor switch is faulty

the complete lever assembly will have to

be renewed.

Refit

12.Fit new control cable to lever assembly peg.

13.Fit retaining clip to secure outer cable.

14.Reconnect blower motor leads.

15.Route cable to rear of instrument panel cowl,

along bulkhead and out through grommet into

engine compartment.

16.Fit lever assembly to panel cowl. Ensure screw

spacers are fitted between cowl and lever

assembly.

17.Fit instrument panel to fascia cowl.

18.With lever in closed position, fit control cable to

heater unit flap lever trunnion.

19.Secure outer cable with retaining clip.

20.Secure control cables to engine bulkhead and

heater hoses with retaining clips.

21.Reconnect battery.

Page 383 of 455

AIR CONDITIONING

1

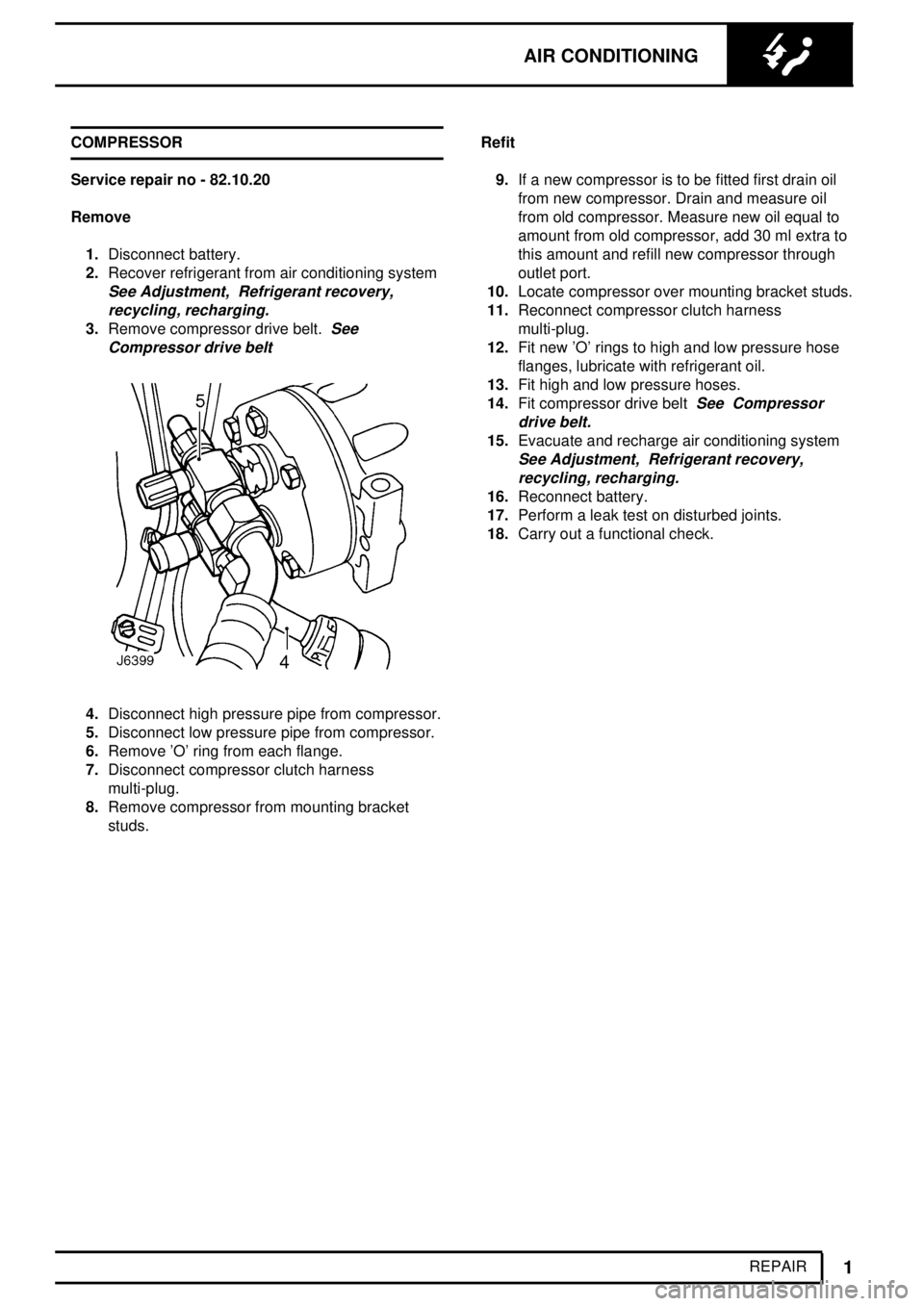

REPAIR COMPRESSOR

Service repair no - 82.10.20

Remove

1.Disconnect battery.

2.Recover refrigerant from air conditioning system

See Adjustment, Refrigerant recovery,

recycling, recharging.

3.Remove compressor drive belt.See

Compressor drive belt

4.Disconnect high pressure pipe from compressor.

5.Disconnect low pressure pipe from compressor.

6.Remove 'O' ring from each flange.

7.Disconnect compressor clutch harness

multi-plug.

8.Remove compressor from mounting bracket

studs.Refit

9.If a new compressor is to be fitted first drain oil

from new compressor. Drain and measure oil

from old compressor. Measure new oil equal to

amount from old compressor, add 30 ml extra to

this amount and refill new compressor through

outlet port.

10.Locate compressor over mounting bracket studs.

11.Reconnect compressor clutch harness

multi-plug.

12.Fit new 'O' rings to high and low pressure hose

flanges, lubricate with refrigerant oil.

13.Fit high and low pressure hoses.

14.Fit compressor drive belt

See Compressor

drive belt.

15.Evacuate and recharge air conditioning system

See Adjustment, Refrigerant recovery,

recycling, recharging.

16.Reconnect battery.

17.Perform a leak test on disturbed joints.

18.Carry out a functional check.

Page 384 of 455

82AIR CONDITIONING

2

REPAIR COMPRESSOR DRIVE BELT

Service repair no - 82.10.02

Remove

1.Disconnect battery.

2.Remove auxiliary drive belt

See ELECTRICAL,

Repair, Auxiliary drive belt.

3.Remove 3 nuts securing drive belt guard to

compressor retaining studs.

4.Slacken 3 belt tensioner retaining bolts.

5.Remove compressor drive belt. Mark direction

on belt if refitting.Refit

6.Fit compressor drive belt.

7.Fit drive belt guard.

8.Fit torque meter to centre of tensioner, apply and

hold a torque of

35 Nm (26 lbf/ft).

9.Tighten tensioner retaining bolts.

10.Rotate crankshaft 2 full turns.

11.Reapply and hold a torque of

35 Nm (26 lbf/ft)

to tensioner, then fully slacken and retighten

tensioner retaining bolts to

25 Nm (18 lbf/ft).

12.Fit auxiliary drive beltSee ELECTRICAL,

Repair, Auxiliary drive belt.

13.Reconnect battery.