battery LAND ROVER DEFENDER 1996 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 238 of 455

STEERING

1

REPAIR STEERING COLUMN

Service repair no - 57.40.01

Remove

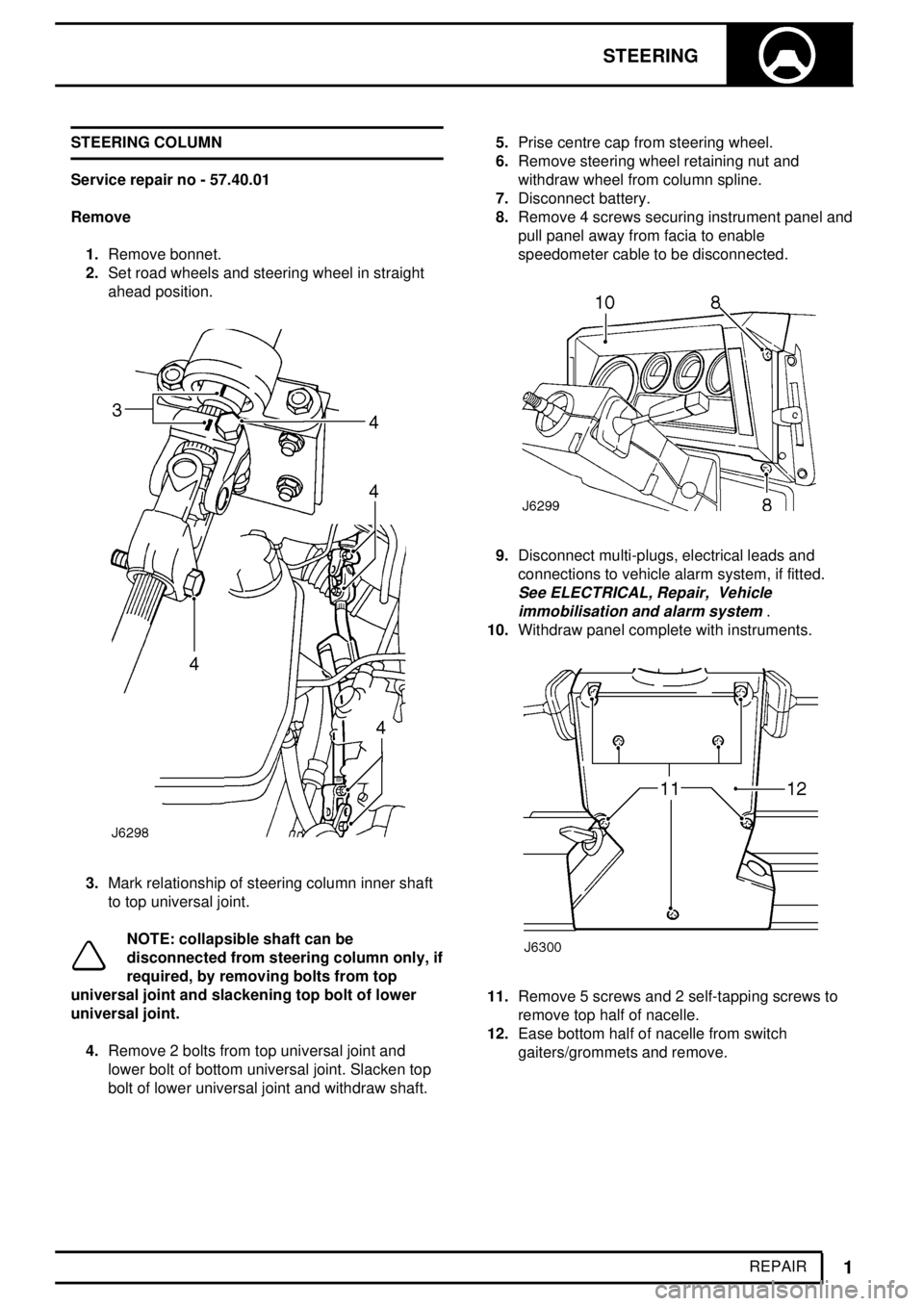

1.Remove bonnet.

2.Set road wheels and steering wheel in straight

ahead position.

3.Mark relationship of steering column inner shaft

to top universal joint.

NOTE: collapsible shaft can be

disconnected from steering column only, if

required, by removing bolts from top

universal joint and slackening top bolt of lower

universal joint.

4.Remove 2 bolts from top universal joint and

lower bolt of bottom universal joint. Slacken top

bolt of lower universal joint and withdraw shaft.5.Prise centre cap from steering wheel.

6.Remove steering wheel retaining nut and

withdraw wheel from column spline.

7.Disconnect battery.

8.Remove 4 screws securing instrument panel and

pull panel away from facia to enable

speedometer cable to be disconnected.

9.Disconnect multi-plugs, electrical leads and

connections to vehicle alarm system, if fitted.

See ELECTRICAL, Repair, Vehicle

immobilisation and alarm system

.

10.Withdraw panel complete with instruments.

11.Remove 5 screws and 2 self-tapping screws to

remove top half of nacelle.

12.Ease bottom half of nacelle from switch

gaiters/grommets and remove.

Page 244 of 455

STEERING

7

REPAIR POWER STEERING PUMP

Service repair no - 57.20.14

Remove

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

remove and refit procedures are required, it may

be necessary to remove the undertray

See

CHASSIS AND BODY, Repair, Front undertray

.

1.Disconnect battery.

2.Remove viscous fan unit

See COOLING

SYSTEM, Repair, Viscous coupling and fan

.

3.Restrain steering pump pulley, slacken but do

not remove 3 bolts securing pulley.

4.Remove drive belt

See ELECTRICAL, Repair,

Auxiliary drive belt

.

5.Remove bolts and remove pulley.

6.Position suitable container beneath steering

pump.

7.Slacken retaining clip and disconnect return

hose from steering pump.

8.Disconnect high pressure pipe from steering

pump.

9.Allow steering fluid to drain into container.

CAUTION: Plug all connections to prevent

ingress of dirt.

10.Remove 4 bolts securing steering pump bracket

to engine auxiliary mounting bracket.

11.Remove pump and bracket assembly.

12.Remove 3 bolts and detach mounting bracket

from pump.

Refit

13.Fit mounting bracket to replacement steering

pump. Tighten bolts to

9 Nm (7 lbf/ft).

14.Fit pump and bracket to auxiliary mounting

bracket. Tighten bolts to

35 Nm (26 lbf/ft).

15.Connect high pressure feed pipe to steering

pump and tighten to

20 Nm (15 lbf/ft).

16.Connect return hose to steering pump. Tighten

retaining clip to

3 Nm (2 lbf/ft).

17.Position pulley to steering pump, coat threads of

bolts with Loctite 242; fit but do not fully tighten

bolts.

18.Fit drive belt

See ELECTRICAL, Repair,

Auxiliary drive belt

.

19.Restrain steering pump pulley, tighten bolts to

10

Nm (7lbf/ft).

20.Fit viscous fan unitSee COOLING SYSTEM,

Repair, Viscous coupling and fan

.

21.Bleed power steering system

See Power

steering system - bleed

.

POWER STEERING PUMP DRIVE BELT

Service repair no - 57.20.02

NOTE: For details of drive belt remove and

refit

See ELECTRICAL, Repair, Auxiliary

drive belt

.

Page 246 of 455

STEERING

9

REPAIR REV: 05/99 STEERING COLUMN LOCK

Service repair no - 57.40.28

Remove

1.Disconnect battery.

2.Set road wheels in straight ahead position.

3.Remove steering wheel

See Steering wheel.

4.Remove instrument panel

See INSTRUMENTS,

Repair, Instrument panel

.

5.Remove steering column nacelle

See Steering

column nacelle

.

6.Note position of harness leads on back of starter

switch and disconnect lucars. If fitted, remove

alarm system passive coil from switch

See

ELECTRICAL, Repair, Vehicle immobilisation

and alarm system

.

7.Using a punch or stud extractor remove 2 shear

bolts securing steering lock/starter switch to

column.

8.Remove steering lock and collect 2 washers

between lock and clamp.

Refit

9.Fit steering lock/switch in position and line up

with switch plunger.

10.Secure lock to column with clamp and new shear

bolts. Evenly tighten bolts but do not shear them.

11.Temporarily fit steering wheel and operate lock

and switch mechanism to ensure it functions

correctly.

12.Fully tighten retaining bolts until heads shear.

13.Connect harness leads to rear of starter switch.

If applicable, fit alarm system passive coil

See

ELECTRICAL, Repair, Vehicle immobilisation

and alarm system

.14.Fit steering column nacelle

See Steering

column nacelle

.

15.Fit instrument panel

See INSTRUMENTS,

Repair, Instrument panel

.

16.Fit steering wheel

See Steering wheel.

17.Reconnect battery.

Page 247 of 455

57STEERING

10

REPAIR STEERING COLUMN NACELLE

Service repair no - 57.40.29

Remove

1.Disconnect battery.

2.Remove steering wheel

See Steering wheel.

3.Remove 5 screws and 2 self tapping screws and

lift top half of nacelle from steeering column

switch assembly.

4.Ease bottom half of nacelle from switch

gaiters/grommets. Remove lower nacelle.

Refit

5.Locate top half of nacelle in position and fit to

switch assembly gaiters/grommets.

6.Locate lower half of nacelle and loosely fit

retaining screws.

7.Ensure switch gaiters/grommets are correctly

located and nacelle is aligned with switch

assembly brackets.

8.Fully tighten screws.

9.Fit steering wheel

See Steering wheel.

10.Reconnect battery.DROP ARM

Service repair no - 57.50.14

Remove

1.Park vehicle on level surface and chock rear

wheels.

2.Raise vehicle and locate axle stands or use a

ramp.

3.Disconnect steering damper from drag link

See

Steering damper

.

4.Disconnect drag link ball joint from drop arm

using extractorLRT-57-018.

5.Mark drop arm and steering box for reassembly.

6.Bend back tabs on locking washer, slacken

retaining nut, but do not remove.

7.Fit extractorLRT-57-012and release drop arm

from steering box spline.

Page 283 of 455

70BRAKES

2

REPAIR BRAKE SYSTEM BLEED

Service repair no - 70.25.02

Preparation

WARNING: Before bleeding the brake

system refer to general brake service

practice.

See General Brake Service

Practice

.

·During bleed procedure, brake fluid level must

not be allowed to fall below the MIN level.

·To bleed the hydraulic circuits, four bleed

nipples are provided, one at each caliper.

·There are two methods by which air can be

removed from the braking system:-

1. MANUAL BLEED PROCEDURE.

2. PRESSURE BLEED PROCEDURE.

Pressure bleed procedure

Purpose designed equipment for pressure filling and

bleeding of hydraulic systems may be used on Land

Rover vehicles. The equipment manufacturer's

instructions must be followed and the pressure must

not exceed 4.5 bar, 65 lb/in

2.

Manual bleed procedure

Equipment required

·Clean glass receptacle

·Bleed hose

·Wrench

·Approx 2 litres (3 pints) brake fluid.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended lubricants and

fluids

Master cylinder bleed

1.Disconnect battery.

2.Depress brake pedal fully and slowly 5 times.

3.Release the pedal and wait for ten seconds.

4.Air bubbles will rise into the reservoir during

these instructions.

5.Repeat instructions until a firm resistance is felt

at the pedal.

Complete circuit bleed

1.Disconnect battery.

2.Bleed front calipers, driver's side first. Fit bleed

hose to bleed screw.

3.Dip free end of bleed hose into brake fluid in

bleed bottle.

4.Open bleed screw of caliper.

5.Depress brake pedal fully several times until fluid

is clear of air bubbles.

6.Keeping pedal fully depressed, tighten bleed

screw, then release pedal.

7.Repeat procedure on other front caliper followed

by rear calipers.

8.Fit all bleed screw protection caps.

9.Check/top-up fluid level when bleeding is

complete

See Fluid Level Check/Top-Up.

Page 284 of 455

BRAKES

3

REPAIR MASTER CYLINDER

Service repair no - 70.30.08

Before starting repair refer to general brake service

practice

See General Brake Service Practice.

Remove

1.Disconnect battery.

2.Place a container under the master cylinder to

catch escaping brake fluid.

3.Clean area round master cylinder ports.

4.Disconnect pipes from master cylinder ports.

Cover, not plug, the pipe ends to prevent entry of

dirt.

5.Disconnect electrical leads from reservoir cap.

6.Remove two nuts securing master cylinder to

servo and withdraw cylinder.

7.Remove reservoir cap and drain fluid into

suitable container for disposal.

8.The reservoir is a push fit in the master cylinder

and secured by seals. Carefully ease the

reservoir from the master cylinder by rolling it

from the seals. Note that the two seals are

different sizes.

Refit

9.Insert new reservoir seals in the master cylinder

ports and fit reservoir to master cylinder.

10.Ensuring that water ingress seal is in position, fit

master cylinder to servo. Tighten fixings to

26

Nm (19 lbf/ft).

11.Connect brake pipes to master cylinder ports

and tighten to

15 Nm (11 lbf/ft).

12.Fit electrical leads to reservoir cap

13.Fill reservoir with recommended brake fluid.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended lubricants and

fluids

14.Bleed the brake systemSee Brake system

bleed

.

15.Reconnect battery and road test vehicle.

Page 285 of 455

70BRAKES

4

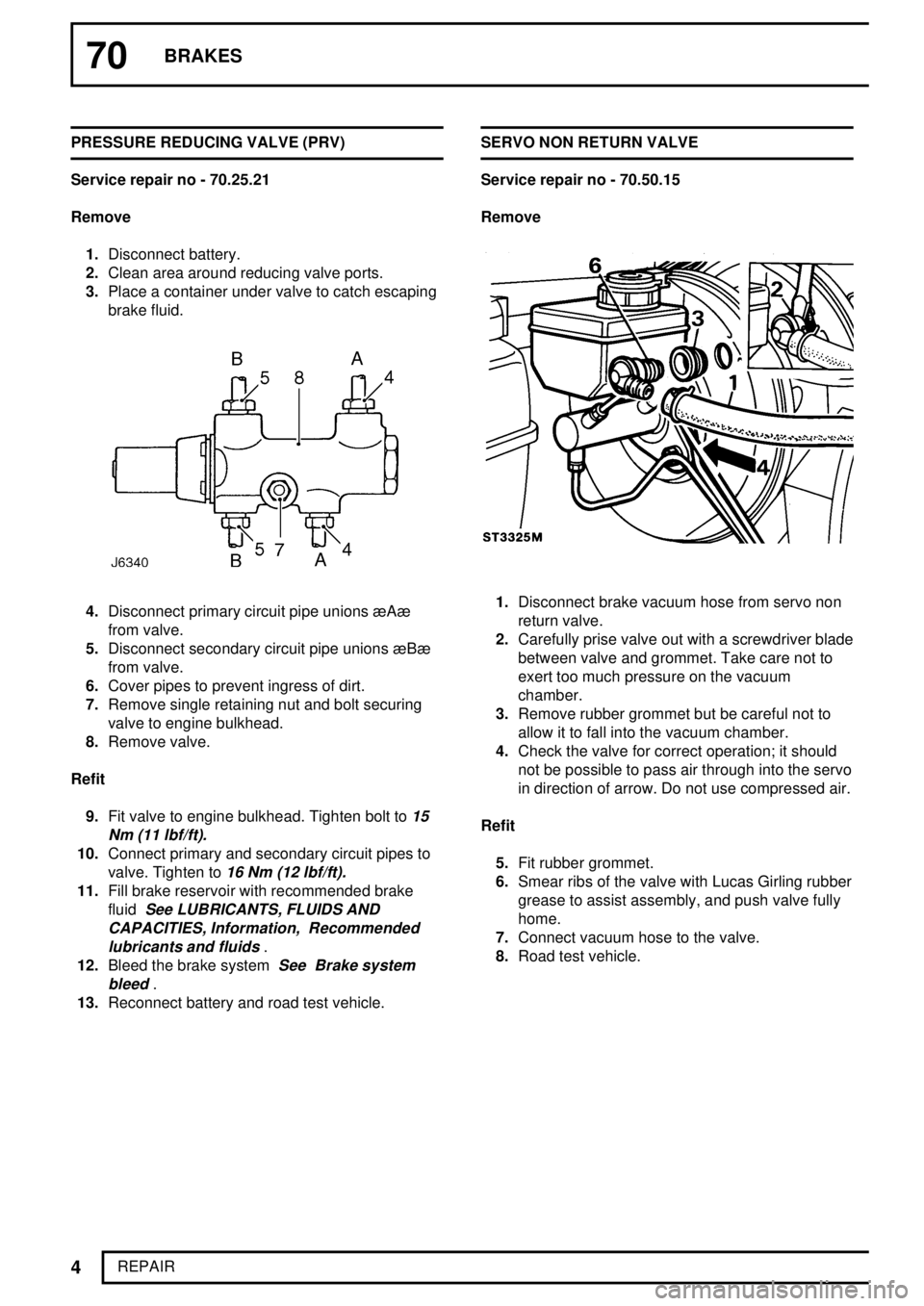

REPAIR PRESSURE REDUCING VALVE (PRV)

Service repair no - 70.25.21

Remove

1.Disconnect battery.

2.Clean area around reducing valve ports.

3.Place a container under valve to catch escaping

brake fluid.

4.Disconnect primary circuit pipe unions ñAñ

from valve.

5.Disconnect secondary circuit pipe unions ñBñ

from valve.

6.Cover pipes to prevent ingress of dirt.

7.Remove single retaining nut and bolt securing

valve to engine bulkhead.

8.Remove valve.

Refit

9.Fit valve to engine bulkhead. Tighten bolt to

15

Nm (11 lbf/ft).

10.Connect primary and secondary circuit pipes to

valve. Tighten to

16 Nm (12 lbf/ft).

11.Fill brake reservoir with recommended brake

fluid

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

lubricants and fluids

.

12.Bleed the brake system

See Brake system

bleed

.

13.Reconnect battery and road test vehicle.SERVO NON RETURN VALVE

Service repair no - 70.50.15

Remove

1.Disconnect brake vacuum hose from servo non

return valve.

2.Carefully prise valve out with a screwdriver blade

between valve and grommet. Take care not to

exert too much pressure on the vacuum

chamber.

3.Remove rubber grommet but be careful not to

allow it to fall into the vacuum chamber.

4.Check the valve for correct operation; it should

not be possible to pass air through into the servo

in direction of arrow. Do not use compressed air.

Refit

5.Fit rubber grommet.

6.Smear ribs of the valve with Lucas Girling rubber

grease to assist assembly, and push valve fully

home.

7.Connect vacuum hose to the valve.

8.Road test vehicle.

Page 299 of 455

70BRAKES

18

REPAIR VACUUM PUMP

Service repair no - 70.50.19

Remove

NOTE: To ease pump removal set engine

to T.D.C. on No.1 cylinder.

1.Disconnect battery.

2.Remove air cleaner

See FUEL SYSTEM,

Repair, Air cleaner

.

3.Detach servo hose from vacuum pump.

4.Remove bolt securing air cleaner support

bracket strut.

5.Remove 6 bolts securing vacuum pump.

6.Detach pump complete with strut and harness

bracket. Note location of strut and bracket for

Refit.

Refit

7.Clean mating faces of pump and block.

8.Loosely assemble pump to block with a new

gasket and with air cleaner strut and harness

bracket located under heads of bolts noted

during Remove.

9.Evenly tighten bolts, to depress pump plunger,

finally tightening to

25 Nm (18 lbf/ft).

10.Secure strut to air cleaner bracket.

11.Connect vacuum hose and secure with clip.

12.Refit air cleaner

See FUEL SYSTEM, Repair,

Air cleaner

.

Page 301 of 455

70BRAKES

2

OVERHAUL MASTER CYLINDER

Service repair no - 70.30.09

Before starting overhaul procedure refer to general

brake service practice

See Repair, General brake

service practice

.

Dismantling master cylinder

1.Disconnect battery and remove master cylinder

from servo

See Repair, Master cylinder.

2.Before commencing overhaul procedure

thoroughly clean master cylinder and inspect

outer surfaces for damage and condition, renew

complete assembly if necessary.

3.The reservoir is a push fit in master cylinder and

secured by seals. Carefully ease reservoir from

master cylinder by rolling it from seals as

illustrated.

4.Using soft jaws, one either side of master

cylinder flange and clamp flange in a suitable

vice. Remove water ingress 'O' ring seal from

master cylinder to servo flange and discard.

5.Hold outside of transfer housing with a suitable

pair of grips, carefully pull, while working pliers in

a backwards and forwards rocking motion to

ease housing off master cylinder, discard

housing and vacuum seal.

6.Withdraw 2 reservoir seals from master cylinder

and note their positions in inlet ports for

reassembly. Discard both seals.

7.Remove retaining ring and 'O' ring seal from

machined outer surface of master cylinder,

discard both seal and retaining ring.

Page 303 of 455

70BRAKES

4

OVERHAUL Assembling master cylinder

CAUTION: It is important that the following

instructions are carried out precisely,

otherwise damage could be caused to new

seals when inserting plungers into cylinder bore.

Generous amounts of new brake fluid should be

used to lubricate parts during assembly.

NOTE: Thoroughly check that no debris is

lodged in fluid passageways and drillings.

If debris is found, carefully remove,

re-clean cylinder and re-check.

16.Fit new swirl tube to bottom of cylinder bore.

17.Lubricate secondary plunger and cylinder bore.

Offer plunger assembly to cylinder until

recuperation seal is resting centrally in mouth of

bore. Gently introduce plunger with a circular

rocking motion, as illustrated. Ensuring that seal

does not become trapped, ease seal into bore

and slowly push plunger down bore in one

continuous movement.

18.Fit primary plunger assembly using same

method as for secondary plunger, push plunger

down bore.

19.Fit original guide ring to support primary plunger.

20.Coat a new 'O' ring with brake fluid and fit to its

respective groove on outer location surface of

master cylinder.

CAUTION: 'O' ring should not be rolled

down outer location surface of master

cylinder but should be slightly stretched

and eased down cylinder and into its groove. Do

not over stretch seal.21.Fit a new retaining ring on outer surface of

master cylinder ensuring that serrations of ring

are facing mounting flange.

22.Fit two new reservoir seals in their respective

ports.

23.Fit a new vacuum seal to either primary plunger

or to bottom of transfer housing bore, open face

of seal towards primary plunger guide ring.

24.Lubricate vacuum seal with brake fluid, fit

transfer housing to master cylinder, push

housing fully up to cylinder mounting flange. Do

not adjust transfer housing after fitting.

25.Lubricate a new water ingress seal with brake

fluid, slightly stretch seal and ease it down

housing until seal is in correct position between

housing and flange.

26.Roll reservoir into top of master cylinder,

reversing procedure described in instruction 3.

27.Fit master cylinder to servo

See Repair,

Master cylinder

.

28.Reconnect battery, and road test vehicle.