boot LAND ROVER DEFENDER 1996 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 9 of 455

01INTRODUCTION

4

INFORMATIONREV: 05/99 ACCESSORIES AND CONVERSIONS

DO NOT FITunapproved accessories or conversions,

as they could affect the safety of the vehicle.

Land Rover will not accept liability for death, personal

injury, or damage to property which may occur as a

direct result of the fitting of non-approved conversions

to the vehicle.

WHEELS AND TYRES

WARNING: DO NOT replace the road

wheels with any type other than genuine

Land Rover wheels which are designed for

multi-purpose on and off road use and have very

important relationships with the proper operation

of the suspension system and vehicle handling.

Replacement tyres must be of the make and sizes

recommended for the vehicle, and all tyres must

be the same make, ply rating and tread pattern.

STEAM CLEANING

To prevent consequential rusting, any steam cleaning

within the engine bayMUSTbe followed by careful

re-waxing of the metallic components affected.

Particular attention must be given to the steering

column, engine coolant pipes and hose clips.

SPECIFICATION

The specification details and instructions set out in

this Manual apply only to a range of vehicles and not

to any one. For the specification of a particular vehicle

purchasers should consult their Dealer.

The Manufacturer reserves the right to vary

specifications with or without notice, and at such times

and in such manner as it thinks fit. Major as well as

minor changes may be involved in accordance with

the Manufacturer's policy of constant product

improvement.

Whilst every effort is made to ensure the accuracy of

the particulars contained in this Manual, neither the

Manufacturer or Dealer, by whom this Manual is

supplied, shall in any circumstances be held liable for

any inaccuracy or the consequences thereof.SPECIAL SERVICE TOOLS

The use of approved special service tools is

important. They are essential if service operations are

to be carried out efficiently, and safely. Where special

tools are specified,only these tools should be used

to avoid the possibility of personal injury or

damage to the components.Also, the amount of

time which they save can be considerable.

Special tools bulletins will be issued periodically giving

details of new tools as they are introduced.

All orders and enquiries from the United Kingdom

should be sent direct to Cartool (UK) Ltd. Overseas

orders should be placed with the local Cartool

distributor, where one exists. Countries where there is

no distributor may order direct from:

Cartool (UK) Ltd.

Unit 3,

Sterling Business Park,

Brackmills,

Northampton,

England, NN4 7EX.

The tools recommended in this Workshop Manual are

listed in an illustrated catalogue, obtainable from:

Land Rover Publications,

Character Mailing,

Heysham Road,

Bootle,

Merseyside, L70 1JL

COPYRIGHT

Ó1999 Rover Group Limited

All rights reserved. No part of this publication may be

produced, stored in a retrieval system or transmitted

in any form, electronic, mechanical, recording or other

means without prior written permission of Rover

Group.

Page 44 of 455

MAINTENANCE

1

MAINTENANCE SERVICE SCHEDULE

The following section describes the items detailed in

the vehicle Service Schedule. Where required

instructions are given for carrying out the service

procedure, or a cross reference is given to the section

in the manual where the procedure may be found.

Service Maintenance Schedules are published

separately to reflect the needs and intervals for each

vehicle variant. Procedures in the Workshop Manual

must be used in conjunction with the Service

Schedule sheets.

Service Maintenance Schedules are available from:

Land Rover Publications,

Character Mailing,

Heysham Road,

Bootle,

Merseyside, L70 1JL

VEHICLE INTERIOR

CHECK SEATS & BELTS

Check condition and security of seat belts, seat belt

mountings, seat belt buckles and operation of inertia

seat belts.

CHECK OPERATION OF LAMPS

Check operation of all lamps, horns and warning

indicators.

CHECK OPERATION OF WIPERS

Check operation of front/rear wipers and washers and

condition of wiper blades.CHECK OPERATION OF HANDBRAKE

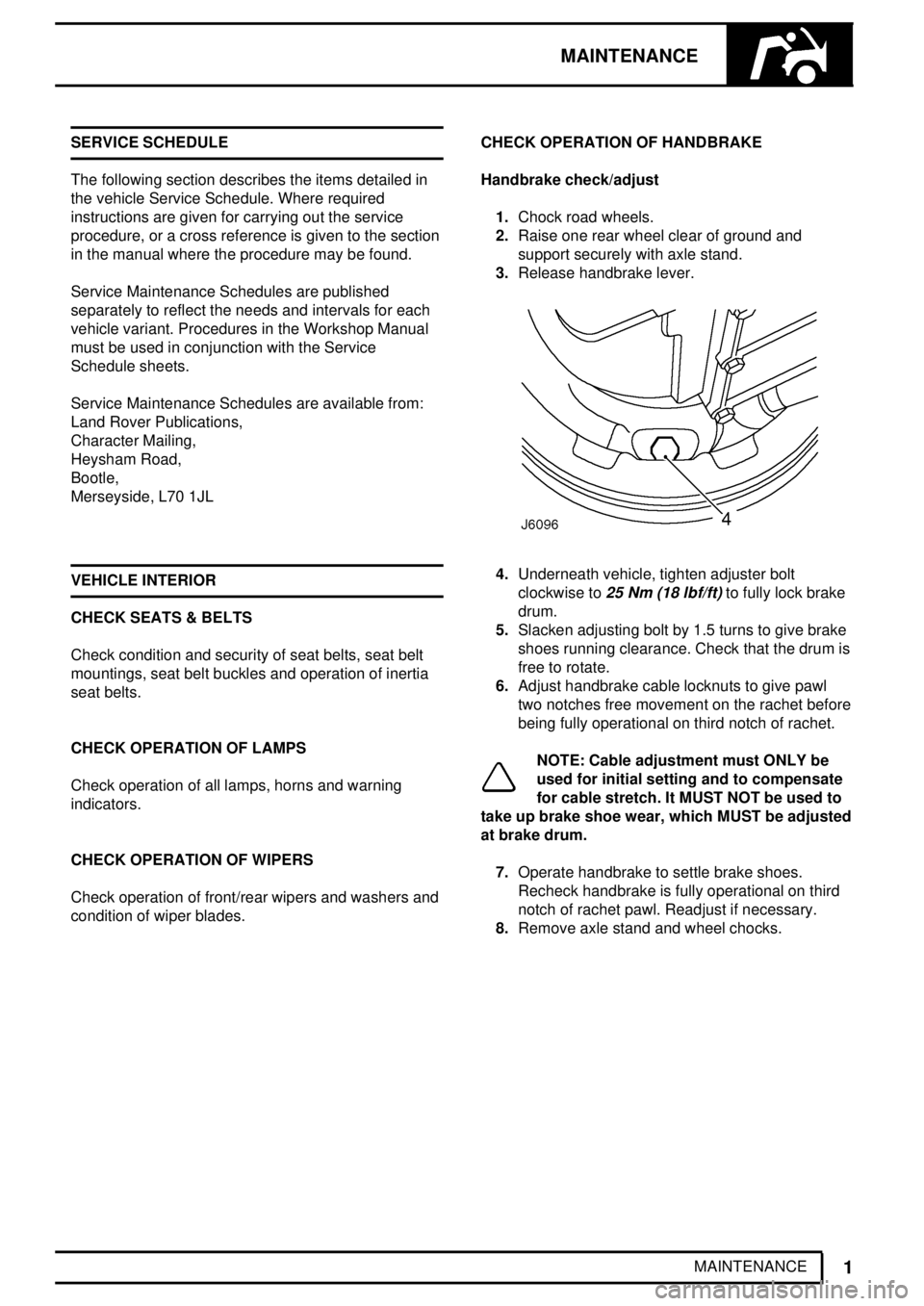

Handbrake check/adjust

1.Chock road wheels.

2.Raise one rear wheel clear of ground and

support securely with axle stand.

3.Release handbrake lever.

4.Underneath vehicle, tighten adjuster bolt

clockwise to

25 Nm (18 lbf/ft)to fully lock brake

drum.

5.Slacken adjusting bolt by 1.5 turns to give brake

shoes running clearance. Check that the drum is

free to rotate.

6.Adjust handbrake cable locknuts to give pawl

two notches free movement on the rachet before

being fully operational on third notch of rachet.

NOTE: Cable adjustment must ONLY be

used for initial setting and to compensate

for cable stretch. It MUST NOT be used to

take up brake shoe wear, which MUST be adjusted

at brake drum.

7.Operate handbrake to settle brake shoes.

Recheck handbrake is fully operational on third

notch of rachet pawl. Readjust if necessary.

8.Remove axle stand and wheel chocks.

Page 55 of 455

10MAINTENANCE

12

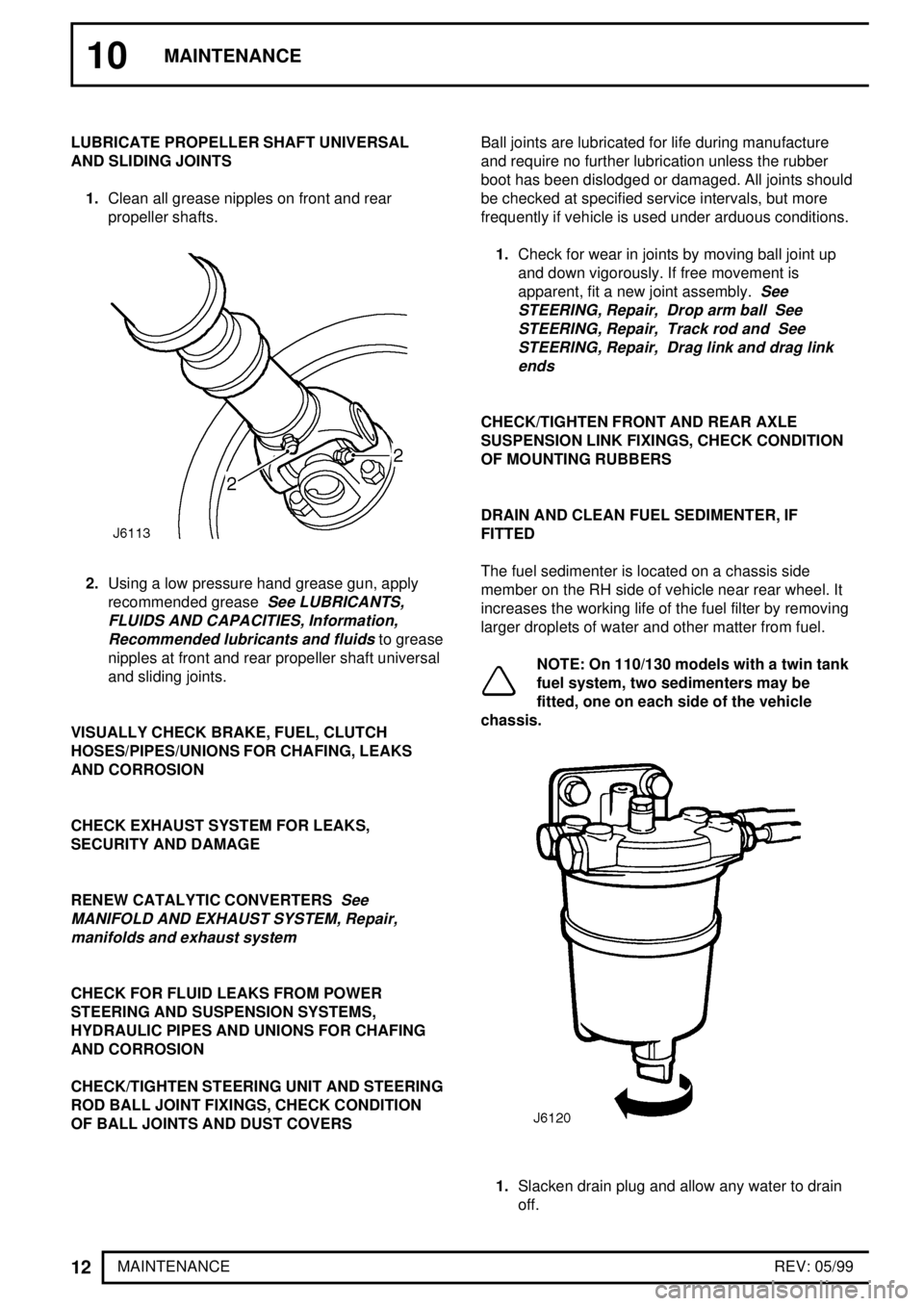

MAINTENANCEREV: 05/99 LUBRICATE PROPELLER SHAFT UNIVERSAL

AND SLIDING JOINTS

1.Clean all grease nipples on front and rear

propeller shafts.

2.Using a low pressure hand grease gun, apply

recommended grease

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended lubricants and fluids

to grease

nipples at front and rear propeller shaft universal

and sliding joints.

VISUALLY CHECK BRAKE, FUEL, CLUTCH

HOSES/PIPES/UNIONS FOR CHAFING, LEAKS

AND CORROSION

CHECK EXHAUST SYSTEM FOR LEAKS,

SECURITY AND DAMAGE

RENEW CATALYTIC CONVERTERS

See

MANIFOLD AND EXHAUST SYSTEM, Repair,

manifolds and exhaust system

CHECK FOR FLUID LEAKS FROM POWER

STEERING AND SUSPENSION SYSTEMS,

HYDRAULIC PIPES AND UNIONS FOR CHAFING

AND CORROSION

CHECK/TIGHTEN STEERING UNIT AND STEERING

ROD BALL JOINT FIXINGS, CHECK CONDITION

OF BALL JOINTS AND DUST COVERSBall joints are lubricated for life during manufacture

and require no further lubrication unless the rubber

boot has been dislodged or damaged. All joints should

be checked at specified service intervals, but more

frequently if vehicle is used under arduous conditions.

1.Check for wear in joints by moving ball joint up

and down vigorously. If free movement is

apparent, fit a new joint assembly.

See

STEERING, Repair, Drop arm ball See

STEERING, Repair, Track rod and See

STEERING, Repair, Drag link and drag link

ends

CHECK/TIGHTEN FRONT AND REAR AXLE

SUSPENSION LINK FIXINGS, CHECK CONDITION

OF MOUNTING RUBBERS

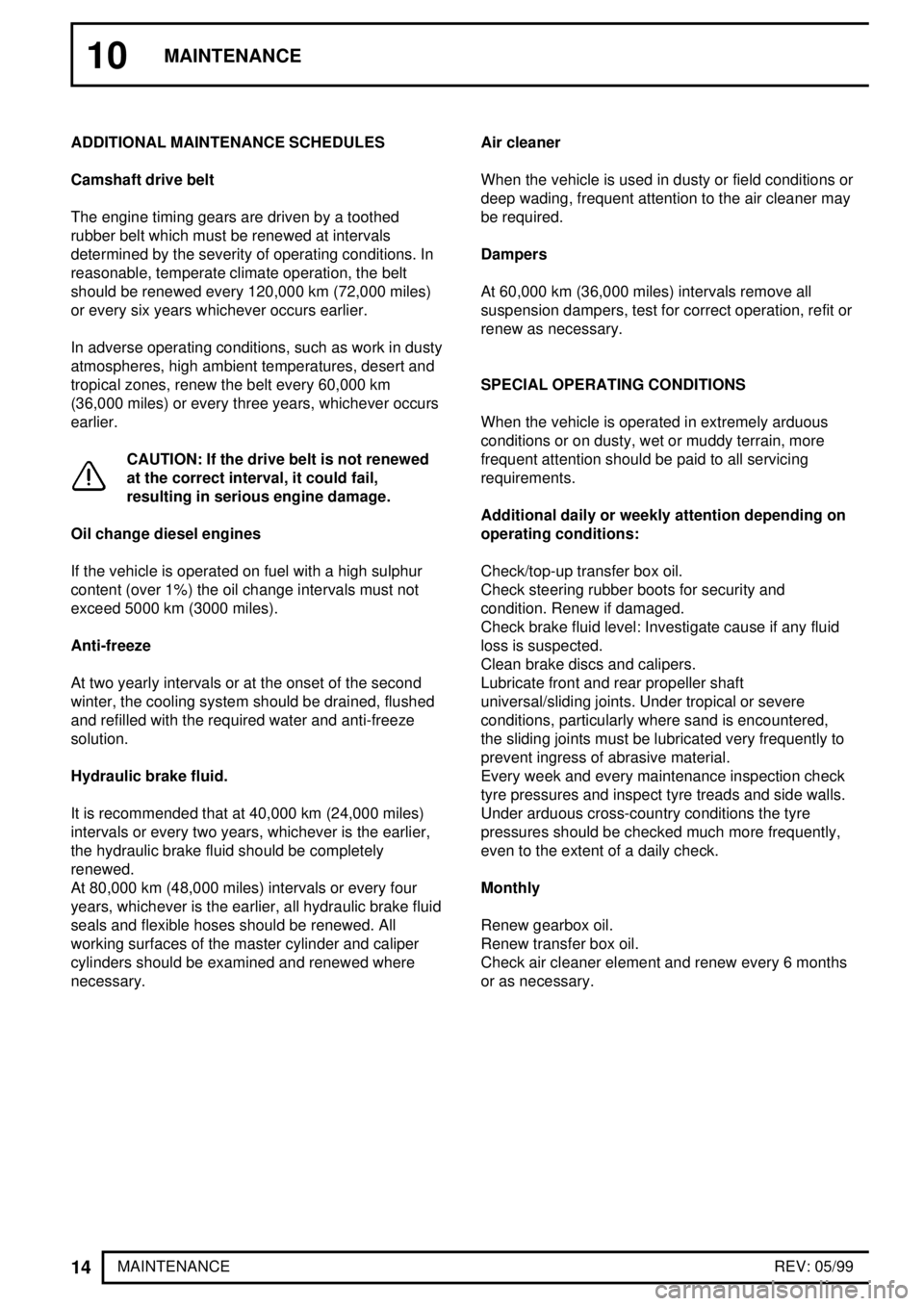

DRAIN AND CLEAN FUEL SEDIMENTER, IF

FITTED

The fuel sedimenter is located on a chassis side

member on the RH side of vehicle near rear wheel. It

increases the working life of the fuel filter by removing

larger droplets of water and other matter from fuel.

NOTE: On 110/130 models with a twin tank

fuel system, two sedimenters may be

fitted, one on each side of the vehicle

chassis.

1.Slacken drain plug and allow any water to drain

off.

Page 57 of 455

10MAINTENANCE

14

MAINTENANCEREV: 05/99 ADDITIONAL MAINTENANCE SCHEDULES

Camshaft drive belt

The engine timing gears are driven by a toothed

rubber belt which must be renewed at intervals

determined by the severity of operating conditions. In

reasonable, temperate climate operation, the belt

should be renewed every 120,000 km (72,000 miles)

or every six years whichever occurs earlier.

In adverse operating conditions, such as work in dusty

atmospheres, high ambient temperatures, desert and

tropical zones, renew the belt every 60,000 km

(36,000 miles) or every three years, whichever occurs

earlier.

CAUTION: If the drive belt is not renewed

at the correct interval, it could fail,

resulting in serious engine damage.

Oil change diesel engines

If the vehicle is operated on fuel with a high sulphur

content (over 1%) the oil change intervals must not

exceed 5000 km (3000 miles).

Anti-freeze

At two yearly intervals or at the onset of the second

winter, the cooling system should be drained, flushed

and refilled with the required water and anti-freeze

solution.

Hydraulic brake fluid.

It is recommended that at 40,000 km (24,000 miles)

intervals or every two years, whichever is the earlier,

the hydraulic brake fluid should be completely

renewed.

At 80,000 km (48,000 miles) intervals or every four

years, whichever is the earlier, all hydraulic brake fluid

seals and flexible hoses should be renewed. All

working surfaces of the master cylinder and caliper

cylinders should be examined and renewed where

necessary.Air cleaner

When the vehicle is used in dusty or field conditions or

deep wading, frequent attention to the air cleaner may

be required.

Dampers

At 60,000 km (36,000 miles) intervals remove all

suspension dampers, test for correct operation, refit or

renew as necessary.

SPECIAL OPERATING CONDITIONS

When the vehicle is operated in extremely arduous

conditions or on dusty, wet or muddy terrain, more

frequent attention should be paid to all servicing

requirements.

Additional daily or weekly attention depending on

operating conditions:

Check/top-up transfer box oil.

Check steering rubber boots for security and

condition. Renew if damaged.

Check brake fluid level: Investigate cause if any fluid

loss is suspected.

Clean brake discs and calipers.

Lubricate front and rear propeller shaft

universal/sliding joints. Under tropical or severe

conditions, particularly where sand is encountered,

the sliding joints must be lubricated very frequently to

prevent ingress of abrasive material.

Every week and every maintenance inspection check

tyre pressures and inspect tyre treads and side walls.

Under arduous cross-country conditions the tyre

pressures should be checked much more frequently,

even to the extent of a daily check.

Monthly

Renew gearbox oil.

Renew transfer box oil.

Check air cleaner element and renew every 6 months

or as necessary.

Page 58 of 455

MAINTENANCE

15

MAINTENANCE ADDITIONAL MAINTENANCE SCHEDULES

Camshaft drive belt

The engine timing gears are driven by a toothed

rubber belt which must be renewed at intervals

determined by the severity of operating conditions. In

reasonable, temperate climate operation, the belt

should be renewed every 120,000 km (72,000 miles)

or every six years whichever occurs earlier.

In adverse operating conditions, such as work in dusty

atmospheres, high ambient temperatures, desert and

tropical zones, renew the belt every 60,000 km

(36,000 miles) or every three years, whichever occurs

earlier.

CAUTION: If the drive belt is not renewed

at the correct interval, it could fail,

resulting in serious engine damage.

Oil change diesel engines

If the vehicle is operated on fuel with a high sulpher

content (over 1%) the oil change intervals must not

exceed 5000 km (3000 miles).

Anti-freeze

At two yearly intervals or at the onset of the second

winter, the cooling system should be drained, flushed

and refilled with the required water and anti-freeze

solution.

Hydraulic brake fluid.

It is recommended that at 40,000 km (24,000 miles)

intervals or every two years, whichever is the earlier,

the hydraulic brake fluid should be completely

renewed.

At 80,000 km (48,000 miles) intervals or every four

years, whichever is the earlier, all hydraulic brake fluid

seals and flexible hoses should be renewed. All

working surfaces of the master cylinder and caliper

cylinders should be examined and renewed where

necessary.Air cleaner

When the vehicle is used in dusty or field conditions or

deep wading, frequent attention to the air cleaner may

be required.

Dampers

At 60,000 km (36,000 miles) intervals remove all

suspension dampers, test for correct operation, refit or

renew as necessary.

SPECIAL OPERATING CONDITIONS

When the vehicle is operated in extremely arduous

conditions or on dusty, wet or muddy terrain, more

frequent attention should be paid to all servicing

requirements.

Additional daily or weekly attention depending on

operating conditions:

Check/top-up transfer box oil.

Check steering rubber boots for security and

condition. Renew if damaged.

Check brake fluid level: Investigate cause if any fluid

loss is suspected.

Clean brake discs and calipers.

Lubricate front and rear propeller shaft

universal/sliding joints. Under tropical or severe

conditions, particularly where sand is encountered,

the sliding joints must be lubricated very frequently to

prevent ingress of abrasive material.

Every week and every maintenance inspection check

tyre pressures and inspect tyre treads and side walls.

Under arduous cross-country conditions the tyre

pressures should be checked much more frequently,

even to the extent of a daily check.

Monthly

Renew gearbox oil.

Renew transfer box oil.

Check air cleaner element and renew every 6 months

or as necessary.

Page 234 of 455

57STEERING

12

FAULT DIAGNOSISREV: 05/99 VISUAL CHECK AND BASIC ADJUSTMENTS

NOTE: It is important that the following

instructions are carried out in the

sequence shown and the results recorded.

1.Road springs - check that road springs are

correctly seated and are to correct specification

for vehicle. For spring specification

See

GENERAL SPECIFICATION DATA,

Information, Road Spring Data

.

2.Ride height - measure trim height from wheel

centre to wheelarch eyebrow. Record results on

data sheet.

3.Check/top up power steering fluid

See Repair,

Power Steering Fluid Reservoir

.

4.Check tension and condition of drive belt

See

ELECTRICAL, Repair, Auxiliary drive belt

.

5.Track rod/drag link - check condition of track rod,

drag link and ball joints

See Repair, Drag Link

and Drag Link Ends

.

If either component is damaged, check operation

of steering damper and steering box for

smoothness. Replace all damaged or worn

components that impair the operation of the

steering system.

6.Suspension bushes - examine all steering and

suspension bushes for signs of wear and

deterioration. Also check all fixings for torque

relaxation. Tighten to correct torque value

See

FRONT SUSPENSION, Specifications, torque,

Torque Values

.

7.Oil leaks - check front and rear axle hubs for

leak and repair as necessary.

8.Brake system - check brake system for leaks,

pipe condition, pad wear/contamination, disc

wear/condition.

9.Hub end float - check movement in the hubs by

rocking the wheels.

10.Check front wheel alignment. Vehicles displaying

a tendency to veer more than considered

allowable, it is permissible to set the front track

to parallel.11.Having completed all the above checks and

adjustments, road test vehicle

See Road Test

Procedure

.

Attempt to reproduce the symptoms established

earlier. If symptoms still exist refer to relevant

Diagnostic Chart.

STEERING LINKAGE INSPECT

NOTE: When inspecting steering linkages

and ball joints for wear the following items

must be checked.

Steering ball joints

1.Check ball joint rubber boots for security, signs

of cracking or deterioration.

2.Check ball joint assemblies for seizure i.e. no

movement on ball joint and associated

assemblies.

3.Check for excessive wear. This will be evident

as extreme movement on track rod and steering

linkages. Renew parts as necessary

See

Repair, Track Rod and Linkage

,See Repair,

Drag Link and Drag Link Ends

.

Steering linkages

1.Check all linkages for wear, deterioration and

damage. Renew parts as necessary

See

Repair, Track Rod and Linkage

,See Repair,

Drag Link and Drag Link Ends

.

Page 376 of 455

AIR CONDITIONING

1

ADJUSTMENT GENERAL PRECAUTIONS

The refrigerant used in the air conditioning system is

HFC (Hydrofluorocarbon) R134a.

WARNING: R134a is a hazardous liquid

and when handled incorrectly can cause

serious injury. Suitable protective clothing

must be worn when carrying out servicing

operations on the air conditioning system.

WARNING: R134a is odourless and

colourless. Do not handle or discharge in

an enclosed area, or in any area where the

vapour or liquid can come in contact with naked

flame or hot metal. R134a is not flammable, but

can form a highly toxic gas.

WARNING: Do not smoke or weld in areas

where R134a is in use. Inhalation of

concentrations of the vapour can cause

dizziness, disorientation. uncoordination,

narcosis, nausea or vomiting.

WARNING: Do not allow fluids other than

R134a or compressor lubricant to enter the

air conditioning system. Spontaneous

combustion may occur.

WARNING: R134a splashed on any part of

the body will cause immediate freezing of

that area. Also refrigerant cylinders and

replenishment trolleys when discharging will

freeze skin to them if contact is made.

WARNING: The refrigerant used in an air

conditioning system must be reclaimed in

accordance with the recommendations

given with a Refrigerant Recovery Recycling

Recharging Station.

NOTE: Suitable protective clothing

comprises: Wrap around safety glasses or

helmet, heatproof gloves, rubber apron or

waterproof overalls and rubber boots.REMEDIAL ACTIONS

1.If liquid R134a strikes the eye, do not rub it.

Gently run large quantities of eyewash over the

eye to raise the temperature. If eyewash is not

available cool, clean water may be used. Cover

eye with clean pad and seek immediate medical

attention.

2.If liquid R134a is splashed on the skin run large

quantities of water over the area as soon as

possible to raise the temperature. Carry out the

same actions if skin comes into contact with

discharging cylinders. Wrap affected parts in

blankets or similar material and seek immediate

medical attention.

3.If suspected of being overcome by inhalation of

R134a vapour seek fresh air. If unconscious

remove to fresh air. Apply artificial respiration

and/or oxygen and seek immediate medical

attention.

NOTE: Due to its low evaporating

temperature of -30°C, R134a should be

handled with care.

WARNING: Do not allow a refrigerant

container to be heated by a direct flame or

to be placed near any heating appliance. A

refrigerant container must not be heated above

50°C.

WARNING: Do not leave a container of

refrigerant without its cap fitted. Do not

transport a container of refrigerant that is

unrestrained, especially in the boot of a car.