door lock LAND ROVER DEFENDER 1996 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 41 of 455

09LUBRICANTS, FLUIDS AND CAPACITIES

2

INFORMATIONREV: 05/99 Propeller shaft Front

and RearNLGI - 2 Multi-purpose Lithium based GREASE

Lubrication nipples

(hubs, ball joints

etc.)

Seat slides

Door lock striker

Brake and clutch

reservoirsBrake fluids having a minimum boiling point of 260°C (500°F) and complying with

FMVSS 116 DOT4

Engine coolant

(Pre-99MY)Use an ethylene glycol based anti-freeze (containing no methanol) with non-phosphate

corrosion inhibitors suitable for use in aluminium engines to ensure the protection of the

cooling system against frost and corrosion in all seasons. Use one part anti-freeze to

one part water for protection down to -36°C (-33°F).

IMPORTANT: Coolant solution must not fall below proportions one part

anti-freeze to three parts water, i.e. minimum 25% anti-freeze in coolant otherwise

damage to engine is liable to occur. Maximum concentration is 60%.

Engine coolant

(99MY on)Use Texaco XLC long life coolant. Use one part anti-freeze to one part water for

protection down to -36°C (-33°F).

IMPORTANT: Coolant solution must not fall below 50% anti-freeze otherwise

damage to the engine is liable to occur. Maximum concentration is 60%.

Battery lugs, Petroleum jelly.

earthing surfaces

where paint has

been removed.NOTE: Do not use Silicone Grease

Air Conditioning

System Refrigerant Use only refrigerant R134a

Compressor Oil Sanden oil

LUBRICATION PRACTICE

Use a high quality oil of the correct viscosity range and service classification in the engine during maintenance and

when topping up. The use of oil not to the correct specification can lead to high oil and fuel consumption and

ultimately to damaged components.

Oil to the correct specification contains additives which disperse the corrosive acids formed by combustion and

prevent the formation of sludge which can block the oilways. Additional oil additives should not be used. Always

adhere to the recommended servicing intervals.

WARNING: Many liquids and other substances used in motor vehicles are poisonous. They must

not be consumed and must be kept away from open wounds. These substances, among others,

include anti-freeze, windscreen washer additives, lubricants and various adhesives.

Page 45 of 455

10MAINTENANCE

2

MAINTENANCE BATTERY CONNECTIONS

NOTE: The vehicle may be fitted with an

alarm and immobilisation system using a

battery backed-up alarm sounder.

See

ELECTRICAL, Repair, Battery

Disconnect battery leads, clean and grease with

petroleum jelly, including battery terminals.

CHECK OPERATION OF DOOR SWITCHES

When a Vehicle Immobilisation and Alarm System is

fitted it is important that all door and bonnet switches

operate correctly, otherwise perimeter and interior

protection may not function if a door or the bonnet is

opened.VEHICLE EXTERIOR

CHECK/ADJUST HEADLAMP ALIGNMENT

Check/adjust headlamp alignment.

CHECK ROAD WHEELS AND TYRES

Check road wheels for damage.

Check tyres, including spare, for compliance with

manufacture's specificaton.

Check visually for cuts, lumps, bulges, uneven tread

wear and tread depth.

See INTRODUCTION,

Information, wheels and tyres

Check/adjust tyre pressures.See WHEELS AND

TYRES, Repair, Tyres pressures

INSPECT BRAKE PADS FOR WEAR, CALIPERS

FOR LEAKS AND CONDITION OF DISCS

Check thickness of brake pads, and renew if thickness

is less than 3,00 mm (0.12 in). Check brake pads for

oil contamination and fit a new set, if necessary,

See

BRAKES, Repair, front brake pads

orSee

BRAKES, Repair, rear brake pads

WARNING: When renewing brake pads, it

is essential that only genuine components

with correct grade of lining are used.

Always fit new pads as complete axle sets, NEVER

individually or as a single wheel set. Serious

consequences could result from out of balance

braking due to mixing of linings.

CHECK FRONT WHEEL ALIGNMENT

Use recognised wheel alignment equipment to carry

out this operation.

See STEERING, Adjustment,

front wheel alignment

CHECK OPERATION OF ALL DOORS/TAILGATE,

BONNET AND LOCKS

LUBRICATE ALL DOOR/TAILGATE HINGES, AND

DOOR CHECK/LOCK MECHANISMS

Page 109 of 455

FUEL SYSTEM

7

REPAIR REV: 05/99

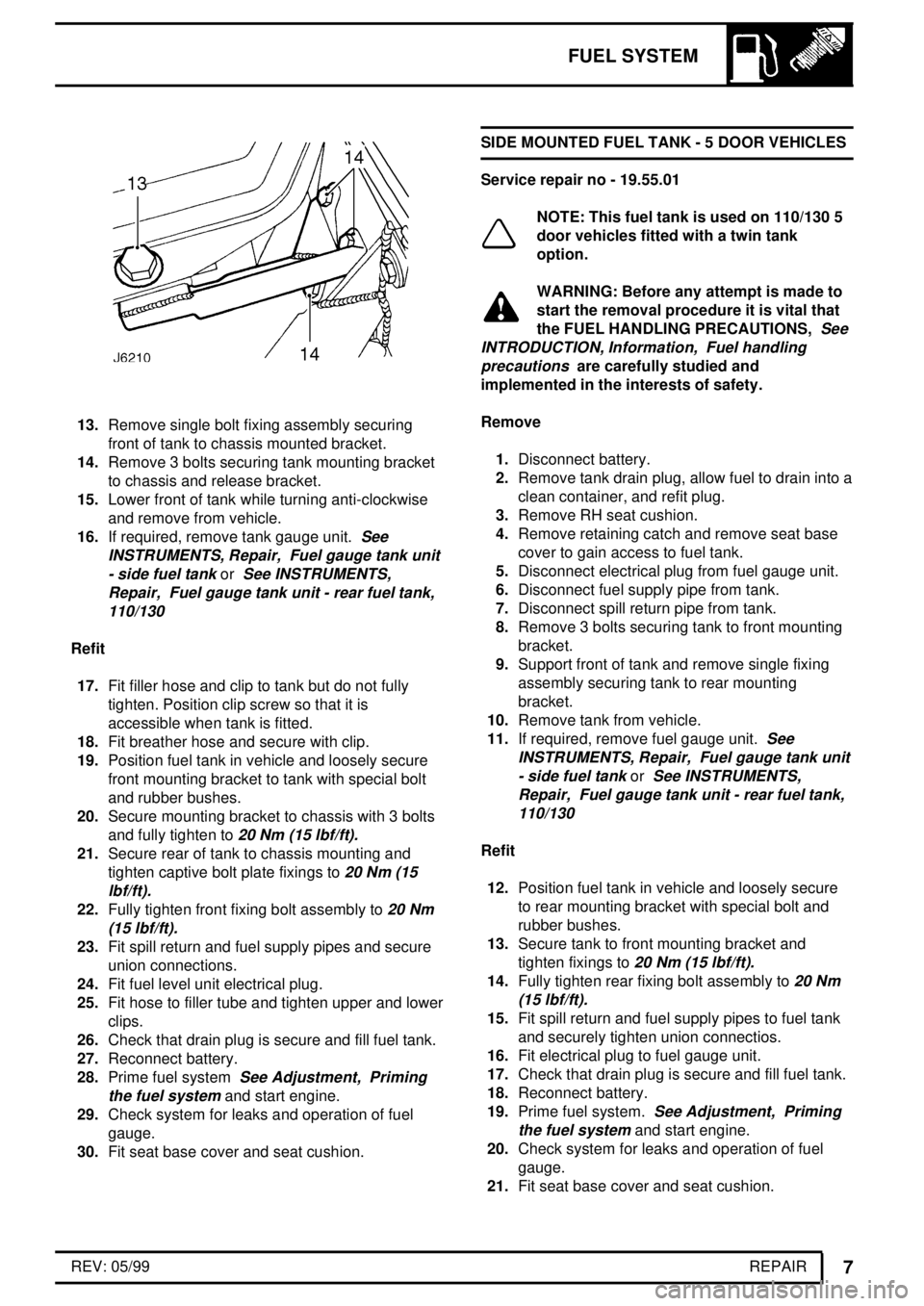

13.Remove single bolt fixing assembly securing

front of tank to chassis mounted bracket.

14.Remove 3 bolts securing tank mounting bracket

to chassis and release bracket.

15.Lower front of tank while turning anti-clockwise

and remove from vehicle.

16.If required, remove tank gauge unit.

See

INSTRUMENTS, Repair, Fuel gauge tank unit

- side fuel tank

orSee INSTRUMENTS,

Repair, Fuel gauge tank unit - rear fuel tank,

110/130

Refit

17.Fit filler hose and clip to tank but do not fully

tighten. Position clip screw so that it is

accessible when tank is fitted.

18.Fit breather hose and secure with clip.

19.Position fuel tank in vehicle and loosely secure

front mounting bracket to tank with special bolt

and rubber bushes.

20.Secure mounting bracket to chassis with 3 bolts

and fully tighten to

20 Nm (15 lbf/ft).

21.Secure rear of tank to chassis mounting and

tighten captive bolt plate fixings to

20 Nm (15

lbf/ft).

22.Fully tighten front fixing bolt assembly to20 Nm

(15 lbf/ft).

23.Fit spill return and fuel supply pipes and secure

union connections.

24.Fit fuel level unit electrical plug.

25.Fit hose to filler tube and tighten upper and lower

clips.

26.Check that drain plug is secure and fill fuel tank.

27.Reconnect battery.

28.Prime fuel system

See Adjustment, Priming

the fuel system

and start engine.

29.Check system for leaks and operation of fuel

gauge.

30.Fit seat base cover and seat cushion.SIDE MOUNTED FUEL TANK - 5 DOOR VEHICLES

Service repair no - 19.55.01

NOTE: This fuel tank is used on 110/130 5

door vehicles fitted with a twin tank

option.

WARNING: Before any attempt is made to

start the removal procedure it is vital that

the FUEL HANDLING PRECAUTIONS,

See

INTRODUCTION, Information, Fuel handling

precautions

are carefully studied and

implemented in the interests of safety.

Remove

1.Disconnect battery.

2.Remove tank drain plug, allow fuel to drain into a

clean container, and refit plug.

3.Remove RH seat cushion.

4.Remove retaining catch and remove seat base

cover to gain access to fuel tank.

5.Disconnect electrical plug from fuel gauge unit.

6.Disconnect fuel supply pipe from tank.

7.Disconnect spill return pipe from tank.

8.Remove 3 bolts securing tank to front mounting

bracket.

9.Support front of tank and remove single fixing

assembly securing tank to rear mounting

bracket.

10.Remove tank from vehicle.

11.If required, remove fuel gauge unit.

See

INSTRUMENTS, Repair, Fuel gauge tank unit

- side fuel tank

orSee INSTRUMENTS,

Repair, Fuel gauge tank unit - rear fuel tank,

110/130

Refit

12.Position fuel tank in vehicle and loosely secure

to rear mounting bracket with special bolt and

rubber bushes.

13.Secure tank to front mounting bracket and

tighten fixings to

20 Nm (15 lbf/ft).

14.Fully tighten rear fixing bolt assembly to20 Nm

(15 lbf/ft).

15.Fit spill return and fuel supply pipes to fuel tank

and securely tighten union connectios.

16.Fit electrical plug to fuel gauge unit.

17.Check that drain plug is secure and fill fuel tank.

18.Reconnect battery.

19.Prime fuel system.

See Adjustment, Priming

the fuel system

and start engine.

20.Check system for leaks and operation of fuel

gauge.

21.Fit seat base cover and seat cushion.

Page 322 of 455

CHASSIS AND BODY

1

REPAIR DOORS

RH rear door lock mechanism

RH front door lock mechanism

Page 323 of 455

76CHASSIS AND BODY

2

REPAIR DOOR TRIM CASING

Service repair no - 76.34.01 - Front doors

Service repair no - 76.34.04 - Rear doors

Remove

1.Prise open finisher caps, remove 2 screws, and

detach door pull.

2.Remove single screw behind remote control

lever.

3.Prise off remote control lever bezel.

4.Prise off door locking button bezel.

5.Prise out window regulator handle centre

finisher, remove retaining screw, and withdraw

handle and bezel.

6.Using a screwdriver to release trim fasteners,

carefully ease trim casing from door.

Page 324 of 455

CHASSIS AND BODY

3

REPAIR

Refit

7.Remove any trim fasteners held in door panel.

Refit or insert new clips to trim panel.

8.Ensure that anti-vibration pads are in position

and offer-up trim casing to door. Align fasteners

with holes in door and firmly push trim into

position.

9.Fit bezels to locking button and remote control

lever.

10.Fit single screw behind remote control lever.

11.Fit door pull and secure with 2 screws and

finisher caps.

12.Fit window regulator handle and retain with

single screw and finisher.WINDOW REGULATOR - REAR SIDE DOOR

Service repair no - 76.31.45

Remove

1.Remove door trim casing

See Door trim casing

.

2.Remove plastic sheet.

3.Temporarily fit handle, wind window up to its

fullest extent and support glass with a length of

timber, to prevent it falling when removing

regulator.

4.Remove 4 screws retaining regulator to

mounting panel and withdraw regulator whilst

sliding lifting arm button from lifting channel. To

assist this operation, remove timber and lower

glass.

Page 326 of 455

CHASSIS AND BODY

5

REPAIR SILL LOCKING BUTTON - REAR SIDE DOOR

Service repair no - 76.37.30

Remove

1.Remove door trim casing

See Door trim casing

.

2.Peel back sufficient of plastic sheet to reveal

mechanism.

3.Release spring clip securing button to operating

rod and withdraw rod from button.

4.Remove 2 screws securing button to door panel

and remove button.

Refit

5.Secure locking button assembly to door panel

with 2 screws.

6.Fit operating rod to button assembly and secure

with spring clip.

7.Re-seal plastic sheet and fit door trim casing

See Door trim casing.REMOTE CONTROL LEVER - REAR SIDE DOOR

Service repair no - 76.37.32

Remove

1.Remove door trim casing

See Door trim casing

.

2.Peel-back sufficient of plastic sheet to gain

access to remote lever.

3.Remove spring clip and disconnect control rod

from locking button.

4.Release spring clip and disconnect short locking

button control rod from latch mechanism.

5.Disconnect long remote control rod from latch

assembly.

Page 327 of 455

76CHASSIS AND BODY

6

REPAIR 6.Remove 2 screws securing remote control lever

to mounting panel.

7.Release control rods from plastic retaining clips

located in mounting panel.

8.Withdraw remote control lever and rods from

door.

Refit

9.Fit plastic retaining clips to rod assembly into

position and secure with 2 screws.

10.Connect control rods to latch assembly and

secure with clips.

11.Fit plastic retaining rod clips to mounting panel.

12.Connect control rod to locking button and secure

with clip.

13.Re-seal plastic sheet and fit door trim casing

See Door trim casing.DOOR LATCH - REAR SIDE DOOR

Service repair no - 76.37.13.

Remove

1.Remove door trim casing

See Door trim

casing

.

2.Peel-back sufficient of plastic sheet to reveal

latch.

3.Release remote control lever rod from latch

assembly.

4.Disconnect door outer handle control rod from

latch assembly.

5.Disconnect door locking button remote control

rod from latch mechanism.

6.Remove 3 retaining screws and withdraw latch

assembly from door.

Refit

7.Fit latch assembly to door and secure with 3

screws, noting that uppermost screw is longer.

8.Connect remote control levers to latch

mechanism reversing instructions 3, 4 and 5.

9.Re-seal plastic sheet and fit door trim casing

See Door trim casing.

Page 328 of 455

CHASSIS AND BODY

7

REPAIR DOOR GLASS - REAR SIDE DOOR

Service repair no - 76.31.02

Remove

1.Disconnect door check rod from door post.

2.Remove door trim casing

See Door trim casing

.

3.Remove plastic sheet.

4.Remove window regulator assembly

See

Window regulator - rear side door

.

5.Disconnect and remove door sill locking button

See Sill locking button.

6.Disconnect control rods from latch and door

outer handle mechanism.

7.Remove 4 screws retaining mounting panel to

door and remove panel, complete with rods and

control lever.

8.Remove single self tapping screw to remove

water channel.

9.Remove 2 screws and remove door check

torsion bar.

10.Remove door check rod by bending back end

stop to enable rod to be withdrawn.

Page 329 of 455

76CHASSIS AND BODY

8

REPAIR

11.Remove 2 self-tapping screws from each side

and remove glass lower channels.

12.Remove inner and outer weather strips from

door sill.

13.Lower glass down to bottom of door, lift glass

over lower edge and withdraw from door.

14.Remove lift channel from glass, if necessary.Refit

15.Fit lift channel to new glass, if necessary.

16.Insert glass into lower channels and carefully

push glass up to top of frame.

17.Secure lower channels with 4 self-tapping

screws. Ensure that screw heads are screwed

down firmly below bottom of channels to prevent

damage to glass.

18.Fit door check rod and bend end stop back to

closed position.

19.Fit check stop torsion bar and secure with 2 nuts

and bolts.

20.Fit water channel and secure with single

self-tapping screw.

21.Fit mounting panel complete with rods and

remote control lever.

22.Connect control rods to latch and door outer

handle mechanism.

23.Fit door sill locking button and connect control

rod

See Sill locking button.

24.Fit window regulator

See Window regulator.

25.Fit door inner and outer sill wear strips.

26.Fit and re-seal plastic sheet.

27.Fit door trim casing

See Door trim casing.

28.Connect door check rod to door post.