brake LAND ROVER DEFENDER 1999 Owners Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 458 of 667

BRAKES

9

REPAIR Refit

12.Clean caliper to axle bracket mating faces.

13.Position caliper to axle bracket, fit bolts and

tighten to82 Nm (60 lbf.ft).

14.Remove plugs from pipe and caliper.

15.Clean brake pipe union and caliper.

16.Connect pipe to caliper, tighten union to15 Nm

(11 lbf.ft).

17.Apply a light film of grease to rear of brake pads.

18.Fit brake pads.

From 02MY, ensure shims are correctly fitted,

see illustration.

NOTE: Vehicles from 02MY have leading

and trailing edge chamfers on rear pads.

19.Fit pad retainer springs.

20.Fit brake pad retaining pins and secure with new

split pins.

21.Bleed brakes.See Adjustment.

22.Depress brake pedal to seat pads onto discs.

23.Fit road wheels, remove axle stands and tighten

nuts to130 Nm (96 lbf.ft).SWITCH - STOP LIGHT

Service repair no - 70.35.42

Remove

1.Disconnect 2 Lucars from stop light switch.

2.Remove mastic from around switch.

3.Remove switch from pedal box.

Refit

4.Fit and tighten switch to pedal box.

5.Apply mastic to switch.

6.Connect 2 Lucars to switch.

ProCarManuals.com

Page 459 of 667

70BRAKES

10

REPAIR FRONT BRAKE PADS - FROM 02MY

Service repair no - 70.40.02

Remove

1.Remove front road wheels.

2.Clean exterior of calipers.

3.Remove split pin from retaining pins.

4.Remove pad retaining pins and anti-rattle

springs.

5.Remove brake pads.

6.Clean exposed parts of pistons, using new brake

fluid. Wipe away excess with a lint free cloth.

7.Using piston clampLRT-70-500press each

piston back into its bore. Ensure that displaced

brake fluid does not overflow from reservoir.

Refit

8.Fit brake pads.

NOTE: Ensure pads are correctly fitted,

with leading edge chamfer fitted as shown.

9.Fit pad retaining pins and anti-rattle springs.

Secure with new split pins.

ProCarManuals.com

Page 460 of 667

BRAKES

11

REPAIR 10.Apply service brake pedal several times to locate

pads.

11.Fit road wheels, remove chassis stands and

jack. Tighten wheel nuts to130 Nm (96 lbf/ft).

12.Check fluid reservoir. Top up if necessary, using

correct grade of fluid.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information.REAR BRAKE PADS - FROM 02MY

Service repair no - 70.40.03

Remove

1.Remove rear road wheels.

2.Clean exterior of calipers.

90 Models

110/130 Models

3.Remove pad retaining pins and anti-rattle

springs. Note differences between 90 and

110/130 models.

4.Remove brake pads and shims.

ProCarManuals.com

Page 461 of 667

70BRAKES

12

REPAIR 5.Clean exposed parts of pistons, using new brake

fluid.

6.Wipe away excess fluid with lint free cloth.

7.Using piston clampLRT-70-500press each

piston back into its bore. Ensure that displaced

brake fluid does not overflow from reservoir.

Refit

8.Fit brake pads and shims.

Ensure shims are correctly fitted, see illustration.

NOTE: Vehicles from 02MY have leading

and trailing edge chamfers on rear pads.

Shims are also fitted.

9.Fit anti-rattle springs and secure with retaining

pins.10.Apply service brake pedal several times to locate

pads.

11.Fit road wheels, remove chassis stands and

jack. Tighten wheel nuts to130 Nm (96 lbf/ft).

12.Check fluid reservoir, top up if necessary, using

correct grade of fluid.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information.

ProCarManuals.com

Page 533 of 667

77PANEL REPAIRS

8

SEALING AND CORROSION PROTECTION CORROSION PROTECTION

The following information details the materials that are

applied during manufacture for corrosion protection.

Factory Treatments

The Defender is treated with the following

anti-corrosion materials in production:

A PVC-based underbody sealer material

which is sprayed onto the underfloor, wheel

arches and undersill areas.

An application of cavity wax which is

sprayed into enclosed cavities and box

sections.

A final coating of underbody wax to cover

the complete underfloor including

components but excluding brake discs,

exhaust system and propeller shafts.

A coat of protective lacquer applied to the

whole body.

A coat of protective wax applied to the

engine bay and wheel arch areas.

NOTE: Do not apply wax to engine bay of

Td5 models.

In addition to the above measures, all steel parts are

zinc-coated both sides.

Underbody Sealer

Underfloor areas and outer sill panels are treated with

a Plastisol PVC underbody sealer. This material is not

suitable for re-treatment.

When repairing areas of underbody sealer, strip the

factory-applied material back to a suitable break point,

ensuring that a clean metal surface is exposed and

that the edge of the existing material adheres soundly

to the panel.

Blanking plugs and grommets in the floor pan (except

those used for wax injection) MUST be fitted before

underbody sealer application. Heat-fusible plugs

which have been disturbed should either be refitted

with the aid of a hot air blower or replaced with rubber

grommets.

NOTE: Application of new underbody

sealer must be carried out between primer

and surfacer paint operations. Areas

where seam sealer is used should be re-treated as

necessary before application of underbody sealer.

CAUTION: Ensure that suspension units,

wheels, tyres, power unit, driveshafts,

exhaust and brakes (including all

mounting points) are shielded prior to application

of fresh underbody sealer.

Cavity Wax

Cavity wax is applied to certain box sctions The

information given on the following pages is intended

as a guide and shows the areas to be treated with

cavity wax, as well as the access holes used during

manufacture.See GENERAL INFORMATION DATA,

Sealing and corrosion protection section.

Underbody Wax

A coat of underbody wax is applied to the entire

underbody inboard of the sill vertical flanges, and

covers all moving and flexible components EXCEPT

for wheels and tyres, brakes and exhaust. The wax is

applied over paints and underbody sealers.

The underbody wax must be reinstated following all

repairs affecting floor panels.

CAUTION: Old underbody wax must be

completely removed from a zone

extending at least 200 mm (7.9 in) beyond

the area where new underbody sealer is to be

applied.

Engine Bay Wax

Reinstate protective engine bay wax disturbed during

repairs using the approved material.

Wheel Arch Wax

Reinstate protective wheel arch wax disturbed during

repairs using the approved material.

ProCarManuals.com

Page 535 of 667

77PANEL REPAIRS

10

SEALING AND CORROSION PROTECTION Underbody Protection Repairs

When body repairs are carried out, always ensure that

full sealing and corrosion protection treatments are

restored. This applies both to the damaged area, and

also to areas where protection has been indirectly

impaired as a result of accident damage or repair

operations.

Prior to straightening out or panel beating, remove all

corrosion protection material in the damaged area.

This applies in particular to panels coated with wax,

PVC underbody sealer, sound deadening pads etc.

WARNING: DO NOT use oxy-acetylene gas

equipment to remove corrosion prevention

materials. Large amounts of fumes and

gases are liberated by these materials when they

burn.

Equipment for the removal of tough anti-corrosion

sealers offers varying degrees of speed and

effectiveness. The compressed air-operated scraper

(NOT an air chisel) offers a relatively quiet mechanical

method of removal using an extremely rapid

reciprocating action. During use, direct the operating

end of the tool along the work surface.

The most common method is by the use of a hot air

blower with integral scraper.

CAUTION: High temperatures can be

generated with this equipment which may

cause fumes. Always exercise care in its

use.

Another tool, and one of the most efficient methods, is

the rapid-cutting’hot knife’. This tool uses a wide

blade and is quick and versatile, able to be used

easily in profiled sections where access is otherwise

awkward.

Use the following procedure when repairing

underbody coatings:

1.Remove existing underbody coatings.2.After panel repair, clean the affected area with a

solvent wipe, and treat bare metal with an etch

phosphate material.

3.Re-prime the affected area.DO NOT under any

circumstances apply underbody sealer

directly to bare metal surfaces.

4.Replace all heat-fusible plugs which have been

disturbed. Use rubber grommets of equivalent

size if plugs are not available, but ensure that

they are embedded in sealer.

5.Mask off all mounting faces from which

mechanical components, hoses and pipe clips,

have been removed. Underbody sealer must be

appliedbeforesuch components are refitted.

6.Brush sealer into all exposed seams.

7.Spray the affected area with an approved

service underbody sealer.

8.Remove masking from component mating faces,

and touch-in where necessary. Allow adequate

drying time before applying underbody wax.

Underbody Wax

After refitting mechanical components, including

hoses, pipes and small fixtures, mask off the brake

discs and apply a coat of approved underbody wax.

NOTE: Where repairs include the

application of finish paint coats in the

areas requiring underbody wax, paint

operations must be carried out BEFORE wax

application.

Underbonnet Wax

Where repairs have involved replacement of engine

bay panels, treat the entire engine compartment

including all components, clips and small fixtures with

an approved underbonnet lacquer or wax.

Proprietary Anti-Corrosion Treatments

The application of proprietary anti-corrosion

treatments in addition to the factory-applied treatment

could invalidate the Corrosion Warranty and should be

discouraged. This does not apply to approved,

compatible, preservative waxes which may be applied

on top of existing coatings.

ProCarManuals.com

Page 568 of 667

PANEL REPAIRS

3

REPAIR WHEEL ARCH - FRONT

Remove

The procedure to change the Inner Front Wheelarch is

the same as for the Wing Upper, except for removal of

the ABS sensors and shield, if fitted.

BULKHEAD ASSEMBLY

Remove

1.Disconnect both battery leads, negative lead

first.

2.Remove front lower wing.See this Section.

3.Remove RH and LH front upper wing.See this

Section.

4.Remove headlamp mounting panels.See this

Section.

5.Remove screen aperture.See this Section.

6.Remove both front doors.

7.Remove lower fascia panel.See CHASSIS

AND BODY, Repair.

8. Models with A/C:Remove relevant A/C pipes.

9.Remove front grille.

10.Drain cooling system.See COOLING

SYSTEM, Adjustment.

11.Remove radiator and intercooler.

12. Models with A/C:Remove condensor.

13.Remove air cleaner assembly.

14.Remove heater unit.See HEATING AND

VENTILATION, Repair.

15.Remove brake servo assembly.

16.Remove heater ducts.

17.Remove both front seats.

18.Remove front carpets.

19.Release all relevant harnesses and position

aside.

20.Remove facia support bracket.

Refit

21.Prepare and clean panel joint faces. Ensure all

necessary grommets and sealant is applied to

new bulkhead.

22.Reverse removal procedure.

23.Bleed brake system.See BRAKES,

Adjustment.

24.Align headlamps.See ELECTRICAL,

Adjustment.

25.Water test after refitting.

ProCarManuals.com

Page 608 of 667

86 - ELECTRICAL

CONTENTS

Page

DESCRIPTION AND OPERATION

SECURITY AND CENTRAL DOOR LOCKING 1....................................................

SECURITY AND CENTRAL DOOR LOCKING 2....................................................

ANTI-THEFT ALARM - FROM 02MY 3...................................................................

IMMOBILISATION SYSTEM - FROM 02MY 12......................................................

CENTRAL DOOR LOCKING (CDL) - FROM 02MY 15...........................................

ANTI-THEFT ALARM SYSTEM SELF TEST 17.....................................................

FASCIA CONSOLE 18............................................................................................

HEATED FRONT SCREEN - FROM 02MY 20.......................................................

HEATED FRONT SEATS - FROM 02MY 22..........................................................

ELECTRIC FRONT WINDOWS - FROM 02MY 24.................................................

PASSENGER COMPARTMENT FUSE BOX 26.....................................................

UNDER SEAT FUSE BOX 27.................................................................................

ADJUSTMENT

HEADLAMPS - ALIGN BEAM 1..............................................................................

SOLENOID/MOTOR - FRONT DOOR - ADJUST 1................................................

REPAIR

BELT - AUXILLARY DRIVE 1.................................................................................

HARNESS - INJECTORS 1....................................................................................

STARTER MOTOR 2..............................................................................................

CENTRE HIGH MOUNTED STOP LIGHT (CHMSL) - UP TO 02MY 2...................

ALTERNATOR 3.....................................................................................................

HORN - LH 4...........................................................................................................

HEADLAMP 5.........................................................................................................

LAMP - TAIL 6.........................................................................................................

RADIO6 ..................................................................................................................

SPEAKER - FRONT 7.............................................................................................

SWITCH - TRANSMISSION BRAKE 7...................................................................

LAMP - FRONT FLASHER 8..................................................................................

BATTERY - DISCONNECT - FROM 02MY 8..........................................................

MOTOR & REGULATOR - FRONT DOOR - FROM 02MY 9..................................

SWITCH - FASCIA - FROM 02MY 10.....................................................................

HARNESS - FRONT DOOR - FROM 02MY 10.......................................................

SOLENOID/MOTOR - TAIL DOOR - FROM 02MY 11............................................

SOLENOID/MOTOR - FRONT DOOR - FROM 02MY 12.......................................

SOLENOID/MOTOR - REAR DOOR - FROM 02MY 13.........................................

HARNESS - REAR DOOR - FROM 02MY 14.........................................................

REVERSE AND FOG GUARD LAMP - BULB 15....................................................

ProCarManuals.com

Page 635 of 667

86ELECTRICAL

26

DESCRIPTION AND OPERATION PASSENGER COMPARTMENT FUSE BOX

FROM 02MY

The increase in electrical systems on Defender 02MY vehicles has necessitated an increase in the number of

fuses required.

The passenger compartment fuse box now contains three rows of fuses instead of the previous two rows and

relays to control the CDL system, heated front screen, headlamps, anti-theft alarm ECU and seat heaters and

window lift system.

1.Fuse 8 - Anti-theft alarm ECU/BBUS (10A)

2.Fuse 9 - Front wiper motor and washer pump

(15A)

3.Fuse 10 - Rear wiper relay (10A)

4.Fuse 11 - ABS ECU (10A)

5.Fuse 12 - Engine Control Module (10A)

6.Fuse 13 - Brake pedal switch (10A)

7.Fuse 14 - Reverse lamp switch/Glowplugs (10A)

8.Fuse 15 - Miscellaneous relay control. See

Electrical Library (5A)

9.Fuse 16 - Cigar lighter/Heater blower (20A)

10.Fuse 17 - Radio (5A)

11.Fuse 18 - LH side lamps/trailer pick up (10A)

12.Fuse 19 - RH side lamps/trailer pick up (10A)

13.Fuse 20 - Headlamp levelling/Illumination (10A)

14.Fuse 21 - Direction indicators (10A)

15.Fuse 22 - RH headlamp dip beam (10A)

16.Fuse 23 - LH headlamp dip beam (10A)

17.Fuse 24 - RH headlamp main beam (10A)

18.Fuse 25 - LH headlamp main beam (10A)19.Fuse 26 - Rear fog lamp ECU (10A)

20.Fuse 27 - Alarm relay (10A)

21.Fuse 28 - Air conditioning blower relay (30A)

22.Fuse 29 - Air conditioning compressor

relay/cooling fan relay (20A)

23.Fuse 30 - Interior lamps/radio/alarm

LED/clock/diagnostic socket/tachometer (South

African vehicles only) (5A)

24.Fuse 31 - Hazard warning lamps (15A)

25.Fuse 32 - Heated rear window (20A)

26.Fuse 33 - Seat heat relay (20A)

27.Fuse 34 - RH window lift switch (20A)

28.Fuse 35 - LH window lift switch (20A)

29.Fuse 36 - Heated front screen (30A)

30.Relay - Heated Front Screen

31.Relay - Starter motor

32.Relay - Heated Rear Window

33.Relay - Headlamps

34.Relay - Anti-theft alarm

35.Relay - Seat heat/window lift

ProCarManuals.com

Page 646 of 667

ELECTRICAL

7

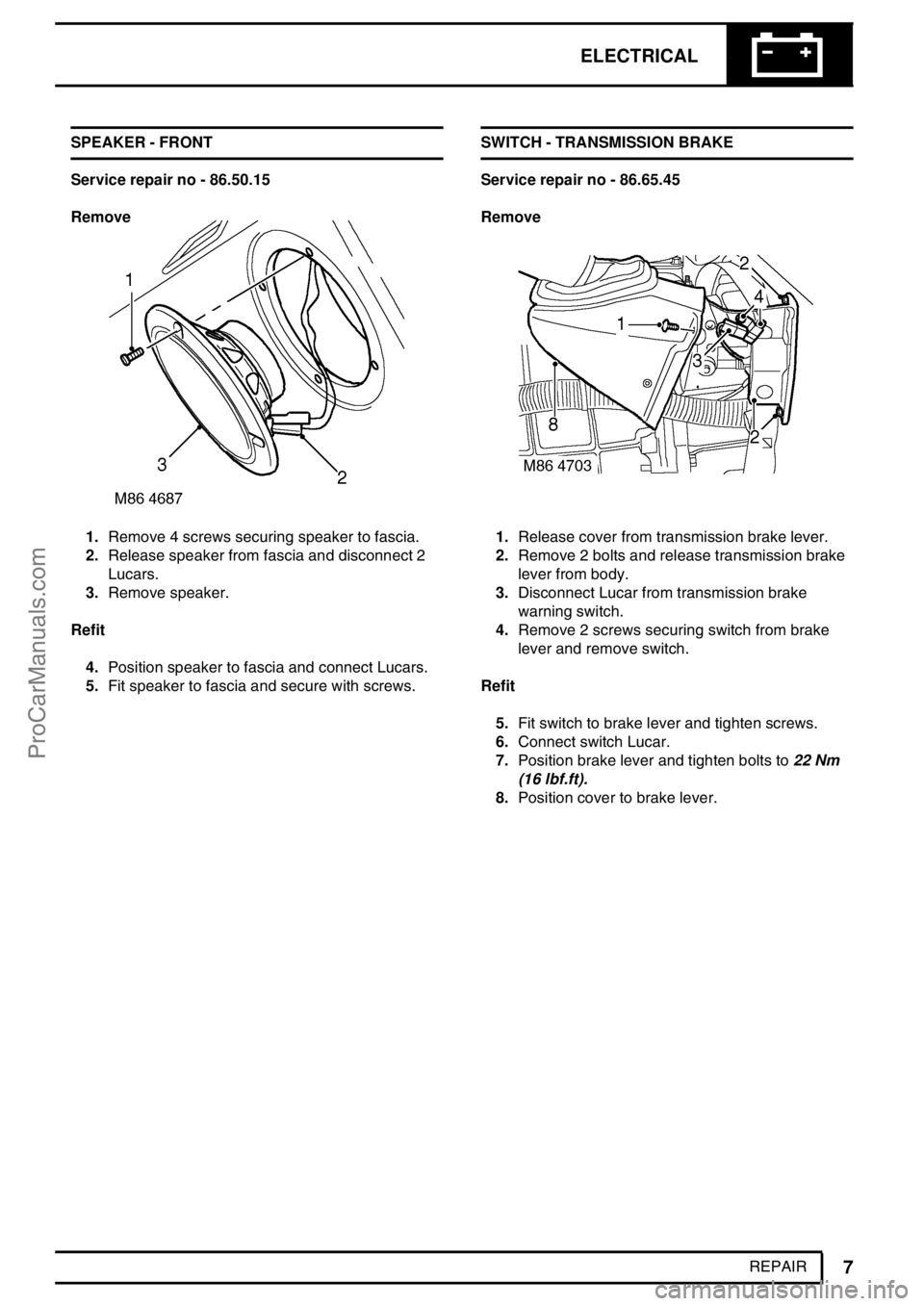

REPAIR SPEAKER - FRONT

Service repair no - 86.50.15

Remove

1.Remove 4 screws securing speaker to fascia.

2.Release speaker from fascia and disconnect 2

Lucars.

3.Remove speaker.

Refit

4.Position speaker to fascia and connect Lucars.

5.Fit speaker to fascia and secure with screws.SWITCH - TRANSMISSION BRAKE

Service repair no - 86.65.45

Remove1.Release cover from transmission brake lever.

2.Remove 2 bolts and release transmission brake

lever from body.

3.Disconnect Lucar from transmission brake

warning switch.

4.Remove 2 screws securing switch from brake

lever and remove switch.

Refit

5.Fit switch to brake lever and tighten screws.

6.Connect switch Lucar.

7.Position brake lever and tighten bolts to22 Nm

(16 lbf.ft).

8.Position cover to brake lever.

ProCarManuals.com