ESP LAND ROVER DEFENDER 1999 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 211 of 667

17EMISSION CONTROL

10

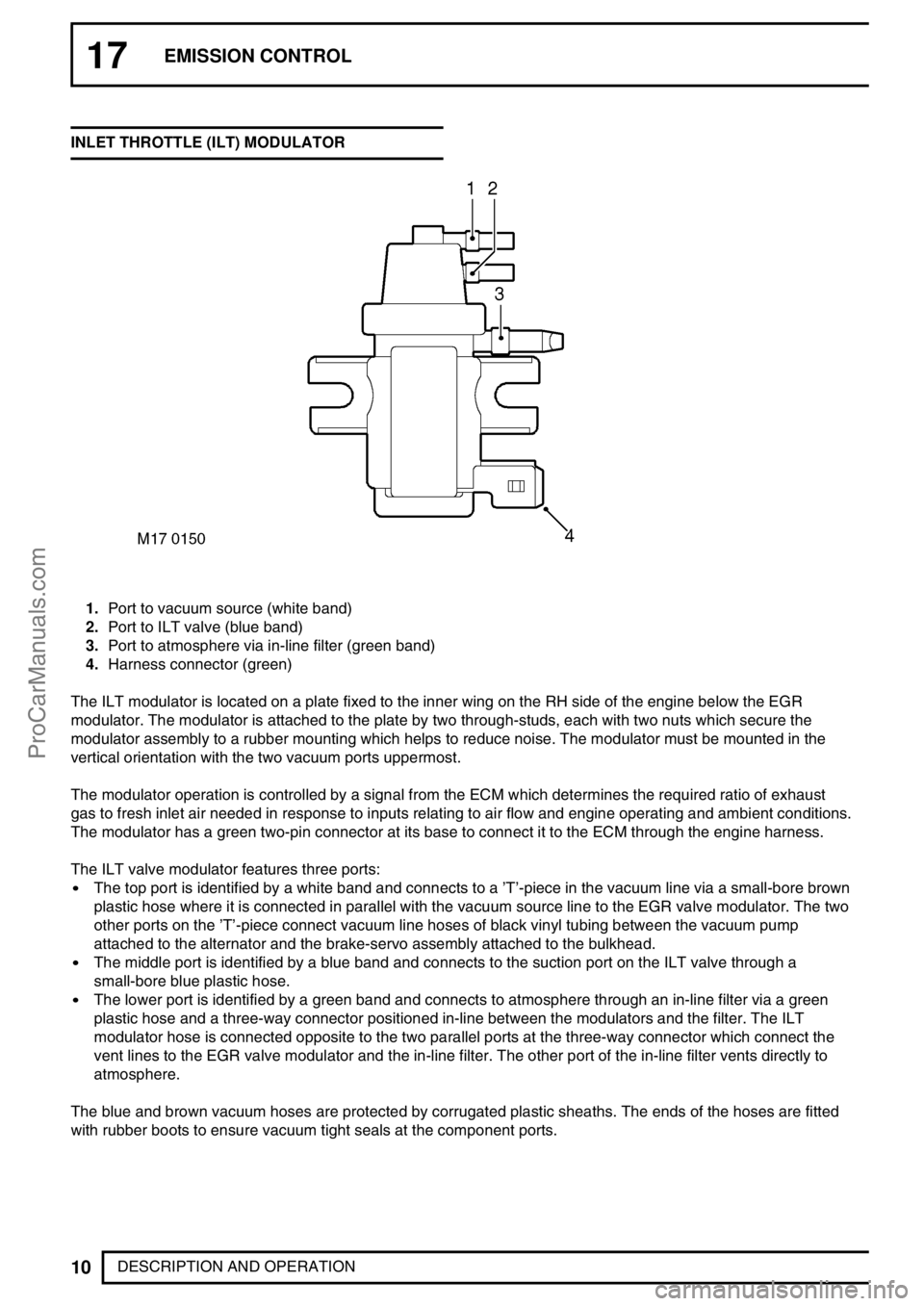

DESCRIPTION AND OPERATION INLET THROTTLE (ILT) MODULATOR

1.Port to vacuum source (white band)

2.Port to ILT valve (blue band)

3.Port to atmosphere via in-line filter (green band)

4.Harness connector (green)

The ILT modulator is located on a plate fixed to the inner wing on the RH side of the engine below the EGR

modulator. The modulator is attached to the plate by two through-studs, each with two nuts which secure the

modulator assembly to a rubber mounting which helps to reduce noise. The modulator must be mounted in the

vertical orientation with the two vacuum ports uppermost.

The modulator operation is controlled by a signal from the ECM which determines the required ratio of exhaust

gas to fresh inlet air needed in response to inputs relating to air flow and engine operating and ambient conditions.

The modulator has a green two-pin connector at its base to connect it to the ECM through the engine harness.

The ILT valve modulator features three ports:

The top port is identified by a white band and connects to a’T’-piece in the vacuum line via a small-bore brown

plastic hose where it is connected in parallel with the vacuum source line to the EGR valve modulator. The two

other ports on the’T’-piece connect vacuum line hoses of black vinyl tubing between the vacuum pump

attached to the alternator and the brake-servo assembly attached to the bulkhead.

The middle port is identified by a blue band and connects to the suction port on the ILT valve through a

small-bore blue plastic hose.

The lower port is identified by a green band and connects to atmosphere through an in-line filter via a green

plastic hose and a three-way connector positioned in-line between the modulators and the filter. The ILT

modulator hose is connected opposite to the two parallel ports at the three-way connector which connect the

vent lines to the EGR valve modulator and the in-line filter. The other port of the in-line filter vents directly to

atmosphere.

The blue and brown vacuum hoses are protected by corrugated plastic sheaths. The ends of the hoses are fitted

with rubber boots to ensure vacuum tight seals at the component ports.

ProCarManuals.com

Page 215 of 667

17EMISSION CONTROL

14

DESCRIPTION AND OPERATION EGR SYSTEMS

There are two types of exhaust gas recirculation system used with the Td5 engine dependent on legislation and

market requirements, these are type 1 and type 2.

Type 1 EGR system is fitted to all Td5’s built up to the introduction of 2002 MY, except for Japanese specification

vehicles.

Type 2 EGR system is fitted to all Japanese specification vehicles and was introduced into European markets for

2002 MY to meet EU3 emission requirements. An additional feature introduced at 2002 MY is the EGR cooler,

which is bolted to the front of the cylinder head.

EGR System - Type 1

This EGR system features a modulator which is electrically controlled to modulate a vacuum source to the EGR

valve. The controlled vacuum opens the valve by the amount required to ensure the optimal proportion of exhaust

gas is allowed through to the inlet manifold to be combined with the fresh air intake. Control feedback is achieved

by monitoring the mass of fresh air flowing through the MAF sensor.

EGR modulator operation is controlled by a signal from the ECM, which determines the required amount of EGR

needed in response to inputs relating to air flow and engine operating and ambient conditions. The ECM is

low-side driven, sinking current returned from the vacuum modulator for switching operating condition.

The exhaust gases are routed from the exhaust manifold through a shaped metal pipe which connects to the

underside of the EGR valve. The pipe is held securely in position to the front of the cylinder head using a clamp

bracket. The EGR pipe is attached to a mating port at the front end of the exhaust manifold using 2 Allen screws,

and at the EGR valve assembly by a metal band clamp. The 2 Allen screws should be replaced every time the

EGR pipe is removed.

CAUTION: Extreme caution should be exercised when removing and refitting the EGR pipe to

avoid damage.

When a vacuum is applied to the EGR suction port, it causes a spindle with sealing disc (EGR valve) to be raised,

thus opening the port at the EGR pipe to allow the recirculated exhaust gas to pass through into the inlet manifold.

The valve is spring loaded so that when the vacuum is removed from the suction port the valve returns to its rest

position to tightly close the exhaust gas port.

By controlling the quantity of recirculated exhaust gas available in the inlet manifold, the optimum mix for the

prevailing engine operating conditions can be maintained. This ensures the intake gas to the combustion

chambers will have burning rate properties which will reduce NO

Xemissions to an acceptable level. Normally, full

recirculation is only applicable when NO

Xemissions are most prevalent.

ProCarManuals.com

Page 216 of 667

EMISSION CONTROL

15

DESCRIPTION AND OPERATION EGR System - Type 2

This system features twin modulators mounted one above the other on a metal plate located on the inner wing at

the RH side of the engine. The modulators are electrically controlled by the engine management system and are

used to modulate a vacuum source to the EGR valve and a supplementary Inlet Throttle (ILT) valve; the two

valves are controlled to operate in tandem. The ILT valve vacuum pot is mounted adjacent to the EGR valve

housing and has a linkage which connects to a butterfly valve mounted in front of the EGR valve at the air intake

manifold.

The modulator operations are electrically controlled by signals from the engine management system which

determines the required volume of exhaust gas needed in response to inputs relating to air flow, engine operating

conditions and ambient parameters such as temperature and altitude. The engine management ECM switches on

the circuit by completing the path to ground, operating the vacuum modulators.

Pre EU3 models:The exhaust gases are routed from the exhaust manifold through a shaped metal pipe which

connects to the underside of the EGR valve. The pipe is held securely in position to the front of the engine cylinder

head using a metal clamp bracket. The EGR pipe is attached to a mating port at the front end of the exhaust

manifold using two Allen screws and at the EGR valve assembly by a metal band clamp. The two Allen screws

fixing the EGR pipe to the exhaust manifold should be replaced every time the EGR pipe is removed.

CAUTION: Extreme care should be exercised when removing and refitting the EGR pipe to avoid

damage.

EU3 models:The exhaust gases are routed from the exhaust manifold through the EGR cooler to the underside

of the EGR valve. The EGR cooler is bolted to the front of the engine cylinder head. An EGR pipe connects the

EGR cooler to the exhaust manifold and is secured by two Allen screws. The two Allen screws fixing the EGR pipe

to the exhaust manifold should be replaced every time the EGR pipe is removed. A second pipe connects the

EGR cooler to the EGR valve; this pipe is secured to the EGR valve by a clip, and to the cooler by two Allen

screws.

CAUTION: Extreme care should be exercised when removing and refitting the EGR pipe to avoid

damage. When refitting the EGR cooler, always tighten the pipe connections BEFORE tightening

the bolts securing the cooler to the cylinder head.

When a vacuum is applied to the EGR suction port, it causes a spindle with sealing disc (EGR valve) to be raised,

opening the port at the EGR pipe to allow the recirculated exhaust gas to pass through into the inlet manifold. The

valve is spring loaded so that when the vacuum is removed from the suction port, the valve returns to its rest

position to tightly close the exhaust gas port.

A vacuum is simultaneously applied to the inlet throttle (ILT) valve suction port which causes the butterfly valve in

the inlet manifold to close by means of a spindle and lever mechanism. Closing the butterfly valve limits the supply

of fresh intercooled air entering the inlet manifold and causes a depression within the inlet manifold to create a

greater suction at the open port to the EGR delivery pipe. In this condition a greater mass of recirculated exhaust

gas is drawn into the inlet manifold for use in the combustion process. When the vacuum is released from the ILT

valve suction port a spring returns the butterfly valve to its fully open position.

By controlling the quantities of recirculated exhaust gas and fresh intake air available in the inlet manifold, the

optimum mix for the prevailing engine operating conditions can be maintained which ensures the intake gas to the

combustion chambers will have burning rate properties which will reduce the NO

2emissions to an acceptable

level. Normally, full recirculation is only applicable when the NO

2emissions are most prevalent.

ProCarManuals.com

Page 230 of 667

ENGINE MANAGEMENT SYSTEM

7

DESCRIPTION AND OPERATION SENSOR - MASS AIR FLOW (MAF)

The MAF sensor is located in the intake system between the air filter housing and the turbocharger. The ECM

uses the information generated by the MAF sensor to control exhaust gas recirculation (EGR).

The MAF sensor works on the hot film principal. The MAF sensor has 2 sensing elements contained within a film.

One element is controlled at ambient temperature e.g. 25°C (77°F) while the other is heated to 200°C (360°F)

above this temperature e.g. 225°C (437°F). As air passes through the MAF sensor the hot film will be cooled.

The current required to keep the constant 200°C (360°F) difference provides a precise although non-linear signal

of the air drawn into the engine. The MAF sensor sends a voltage of between 0 and 5 volts to the ECM,

proportional to the mass of the incoming air. This calculation allows the ECM to set the EGR ratio for varying

operating conditions.

Inputs / Outputs

The MAF sensor receives battery voltage (C0149-3) via the ECM on a brown/orange wire. Signal output on a

slate/light green wire from the MAF sensor (C0149-2) to the ECM (C0158-11) is a variable voltage proportional to

the air drawn into the engine. The MAF sensor is provided an earth (C0149-1) via the ECM (C0158-20) on a

pink/black wire.

The MAF sensor can fail or supply an incorrect signal if one or more of the following occurs:

Sensor open circuit.

Short circuit to vehicle supply.

Short circuit to vehicle earth.

Contaminated sensor element.

Damaged sensor element.

Damaged wiring harness.

MAF sensor supplies incorrect signal (due to air leak or air inlet restriction).

In the event of a MAF sensor signal failure any of the following symptoms my be observed:

During driving, engine speed may dip before recovering.

Difficult starting.

Engine stalls after starting.

Delayed throttle response.

EGR inoperative.

Reduced engine performance.

MAF signal out of parameters.

In the event of a MAF sensor failure, the ECM will use a fixed default value from its memory.

ProCarManuals.com

Page 235 of 667

18ENGINE MANAGEMENT SYSTEM

12

DESCRIPTION AND OPERATION SENSOR - CRANKSHAFT SPEED AND

POSITION (CKP)

The CKP sensor is located in the transmission housing with its tip adjacent to the outer circumference of the

flywheel. The CKP sensor works on the variable reluctance principal, which sends a signal back to the ECM in the

form of an ac voltage.

The ECM uses the signal from the CKP sensor for the following functions.

To calculate engine speed.

To determine engine crank position.

To determine fuel injection timing.

The CKP sensor works as a Variable Reluctance Sensor (VRS). It uses an electromagnet and a target ring to

generate a signal. As the target ring passes the tip of the CKP sensor the magnetic field produced by the sensor is

cut and then re-instated. The ECM measures the signal as an ac voltage.

The outer circumference of the flywheel acts as the target ring for the sensor. The flywheel is divided into 36

segments, each of 10°. 31 segments have drilled holes and 5 segments are spaces. This equals 360°or one

engine revolution. The 5 spaces correspond to the TDC position of the 5 cylinders. This allows the ECM to control

fuel injection timing for each of the cylinders.

Inputs / Outputs

The two pins of the CKP sensor (C1068-1 & C1068-2) are both outputs. The ECM (C0158-13 & C0158-36)

processes the outputs of the sensor. To protect the integrity of the CKP sensor signal, an earth screen is used.

The ECM measures the outputs from the CKP sensor. The ECM (C0158-13) measures a positive signal on a

pink/black wire, and a negative signal (C0158-36) on a white/blue wire. The earth path for the sensor is via the

ECM (C0158-16).

ProCarManuals.com

Page 237 of 667

18ENGINE MANAGEMENT SYSTEM

14

DESCRIPTION AND OPERATION SENSOR - THROTTLE POSITION (TP)

UP TO VIN 607224

The TP sensor is located on the throttle pedal assembly. It detects throttle pedal movement and position. It uses

two position sensors to provide the ECM with the exact throttle pedal position. As the pedal operates, the voltage

of one position sensor increases as the other decreases.

Input / Output

The ECM (C0658-14) provides a 5 volt reference feed to both sensors (C0787-B & C0787-J) on white/purple wires

via header 291. The signal output from sensor 1 (C0787-F) is connected to the ECM (C0658-12) by a white/green

wire. Signal output from sensor 2 (C787-K) is connected to the ECM (C0658-36) by a white/slate wire. An earth

path is provided for both sensors (C0787-B & C0787-G) on black/yellow wires via the ECM (C0658-26)

The TP sensor can fail or supply an incorrect signal if one or more of the following occurs:

Sensor open circuit.

Short circuit to vehicle supply.

Short circuit to vehicle earth.

Water ingress.

Sensor incorrectly fitted.

In the event of a TP sensor signal failure, any of the following symptoms may be observed:

Engine performance concern.

Delayed throttle response.

Failure of emission control.

If the TP sensor fails, the engine will only run at idle speed until the fault is eliminated.

ProCarManuals.com

Page 243 of 667

18ENGINE MANAGEMENT SYSTEM

20

DESCRIPTION AND OPERATION SENSOR - FUEL TEMPERATURE (FT)

The FT sensor is located at the RH rear of the engine in the connector block, with the tip of the sensor inserted at

least 10mm into the fuel flow. This allows the sensor to respond correctly to changes in fuel density in relation to

fuel temperature.

The FT sensor works as an NTC sensor. As fuel temperature rises the resistance in the sensor decreases. As

temperature decreases the resistance in the sensor increases. The ECM is able to compare the voltage signal to

stored values and compensates fuel delivery as necessary for hot engine start.

The operating range of the sensor is -40 to 130°C (-40 to 266°F).

Input / Output

The ECM (C0158-19) provides the FT sensor (C0184-2) with a 5 volt supply signal on a yellow/white wire. The

sensor is earthed (C0184-1) via the ECM (C0158-5) on a pink/black wire.

The FT sensor can fail or supply an incorrect signal if one or more of the following occurs:

Sensor open circuit.

Short circuit to vehicle supply.

Short circuit to vehicle earth.

Sensor fitted incorrectly.

In the event of an FT sensor signal failure any of the following symptoms may be observed:

Difficult cold start.

Difficult hot start.

Driveability concern.

In the event of a component failure, the ECM reverts to a fixed value of 60°C stored in its memory.

ProCarManuals.com

Page 251 of 667

18ENGINE MANAGEMENT SYSTEM

28

DESCRIPTION AND OPERATION OPERATION

Engine Management

The ECM controls the operation of the engine using stored information within its memory. This guarantees

optimum performance from the engine in terms of torque delivery, fuel consumption and exhaust emissions in all

operating conditions, while still giving optimum driveability.

The ECM will receive information from its sensors under all operating conditions, especially during:

Cold starting.

Hot starting.

Idle.

Wide open throttle.

Acceleration.

Adaptive strategy.

Backup strategy for sensor failures.

The ECM receives information from various sensors to determine the current operating state of the engine. The

ECM then refers this information to stored values in its memory and makes any necessary changes to optimise

air/fuel mixture and fuel injection timing. The ECM controls the air/fuel mixture and fuel injection timing via the

Electronic Unit Injectors (EUI), by the length of time the EUI’s are to inject fuel into the cylinder. This is a rolling

process and is called adaptive strategy. By using this adaptive strategy the ECM is able to control the engine to

give optimum driveability under all operating conditions.

During cold start conditions the ECM uses ECT information to allow more fuel to be injected into the cylinders.

This, combined with the glow plug timing strategy supplied by the ECM, facilitates good cold starting.

During hot start conditions, the ECM uses ECT and FT information to implement the optimum fuelling strategy to

facilitate good hot starting.

During idle and wide open throttle conditions, the ECM uses mapped information within its memory to respond to

input information from the TP sensor to implement the optimum fuelling strategy to facilitate idle and wide open

throttle.

To achieve an adaptive strategy for acceleration, the ECM uses input information from the CKP sensor, the TP

sensor, the ECT sensor, the MAP/IAT sensor, and the FT sensor. This is compared to mapped information within

its memory to implement the optimum fuelling strategy to facilitate acceleration.

Fuel Delivery / Injection Control

The fuel delivery/injection control delivers a precise amount of finely atomised fuel to mix with the air in the

combustion chamber to create a controlled explosion. To precisely control fuel delivery and control fuel injection,

the following input conditions must be met:

CKP information.

Injection timing map information.

FT information.

ECT information.

The ECM monitors the conditions required for optimum combustion of fuel in the cylinder from the various sensors

around the engine and then compares it against stored information. From this calculation, the ECM can adjust the

quantity and timing of the fuel being delivered into the cylinder. The ECM uses CKP information as follows:

To calculate engine speed.

To determine engine crankshaft position.

Engine speed and crankshaft position allows the ECM to determine fuel injection timing.

The ECM also uses ECT and FT information to allow optimum fuel delivery and injection control for all engine

coolant and fuel temperatures.

ProCarManuals.com

Page 265 of 667

19FUEL SYSTEM

10

DESCRIPTION AND OPERATION WATER SENSOR

The water sensor has a three pin electrical connector. When the sensor detects water in the fuel filter it illuminates

a warning lamp in the instrument pack.

The water sensor attachment thread has a slot machined down one side. The filter can be purged of water by

partially unscrewing the sensor which aligns the slot in the threads with a corresponding hole in the sensor. When

aligned, water and fuel can flow down the slot and flows from a small cast tube on the side of the sensor.

Re-tightening the sensor mis-aligns the slot and stops the flow of fuel.

The sensor operates by measuring the resistance between its two electrodes, which are submerged in fuel, and

activated by the presence of water. When the ignition switch is moved to position’II’, the warning lamp will

illuminate for approximately 2 seconds to check warning lamp functionality.

When the filter is full with fuel and no water is present, the resistance of the Diesel fuel will show a reading of 15

mA maximum on the feed wire to the instrument pack. When sufficient water surrounds both electrodes, the

resistance of the water will show a reading of 130 mA maximum. This will supply sufficient voltage to the

instrument pack to illuminate the warning lamp, and alert the driver to the presence of water in the fuel system.

ProCarManuals.com

Page 380 of 667

PROPELLER SHAFTS

1

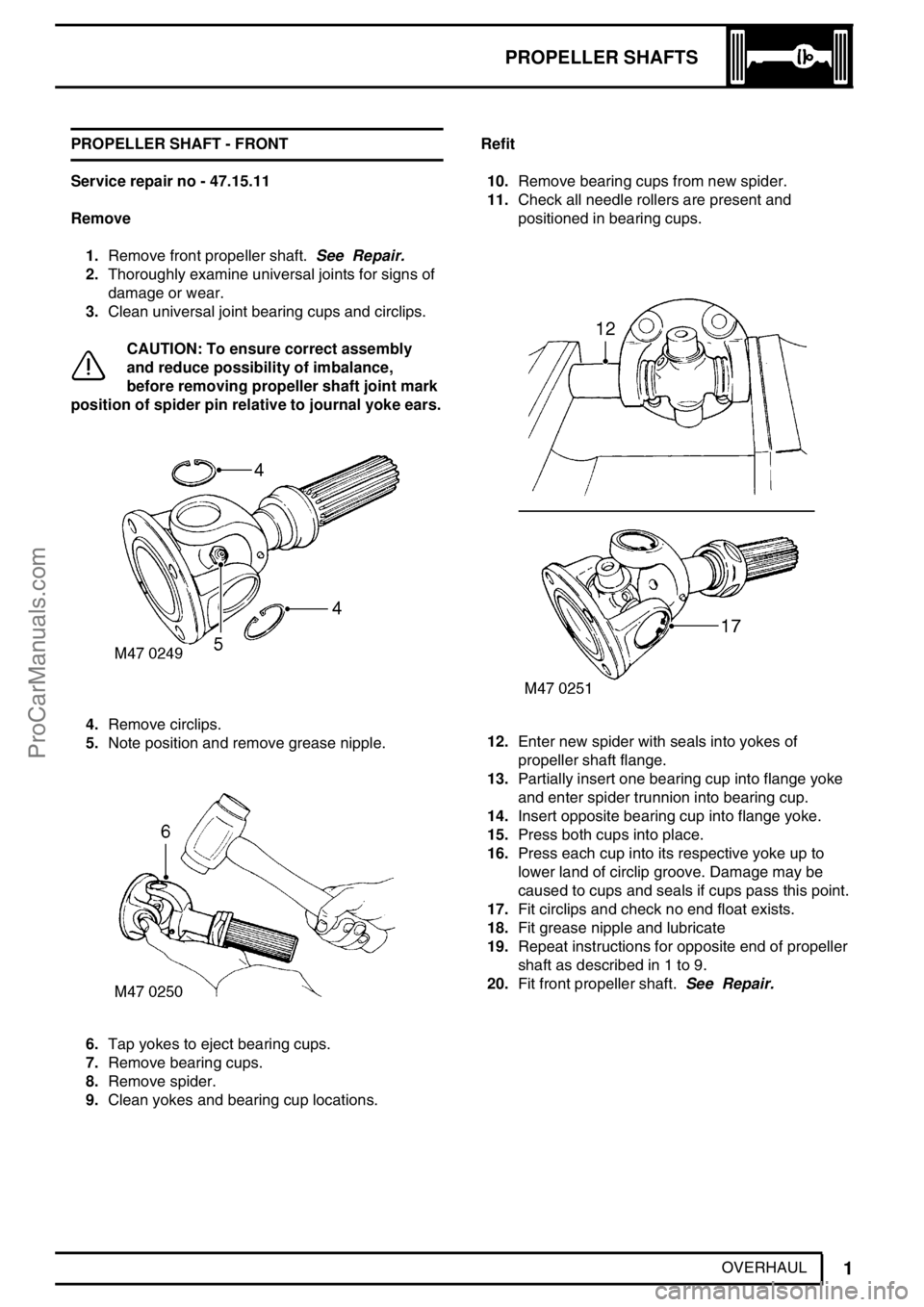

OVERHAUL PROPELLER SHAFT - FRONT

Service repair no - 47.15.11

Remove

1.Remove front propeller shaft.See Repair.

2.Thoroughly examine universal joints for signs of

damage or wear.

3.Clean universal joint bearing cups and circlips.

CAUTION: To ensure correct assembly

and reduce possibility of imbalance,

before removing propeller shaft joint mark

position of spider pin relative to journal yoke ears.

4.Remove circlips.

5.Note position and remove grease nipple.

6.Tap yokes to eject bearing cups.

7.Remove bearing cups.

8.Remove spider.

9.Clean yokes and bearing cup locations.Refit

10.Remove bearing cups from new spider.

11.Check all needle rollers are present and

positioned in bearing cups.

12.Enter new spider with seals into yokes of

propeller shaft flange.

13.Partially insert one bearing cup into flange yoke

and enter spider trunnion into bearing cup.

14.Insert opposite bearing cup into flange yoke.

15.Press both cups into place.

16.Press each cup into its respective yoke up to

lower land of circlip groove. Damage may be

caused to cups and seals if cups pass this point.

17.Fit circlips and check no end float exists.

18.Fit grease nipple and lubricate

19.Repeat instructions for opposite end of propeller

shaft as described in 1 to 9.

20.Fit front propeller shaft.See Repair.

ProCarManuals.com