differential LAND ROVER DEFENDER 1999 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 365 of 667

41TRANSFER GEARBOX

4

REPAIR

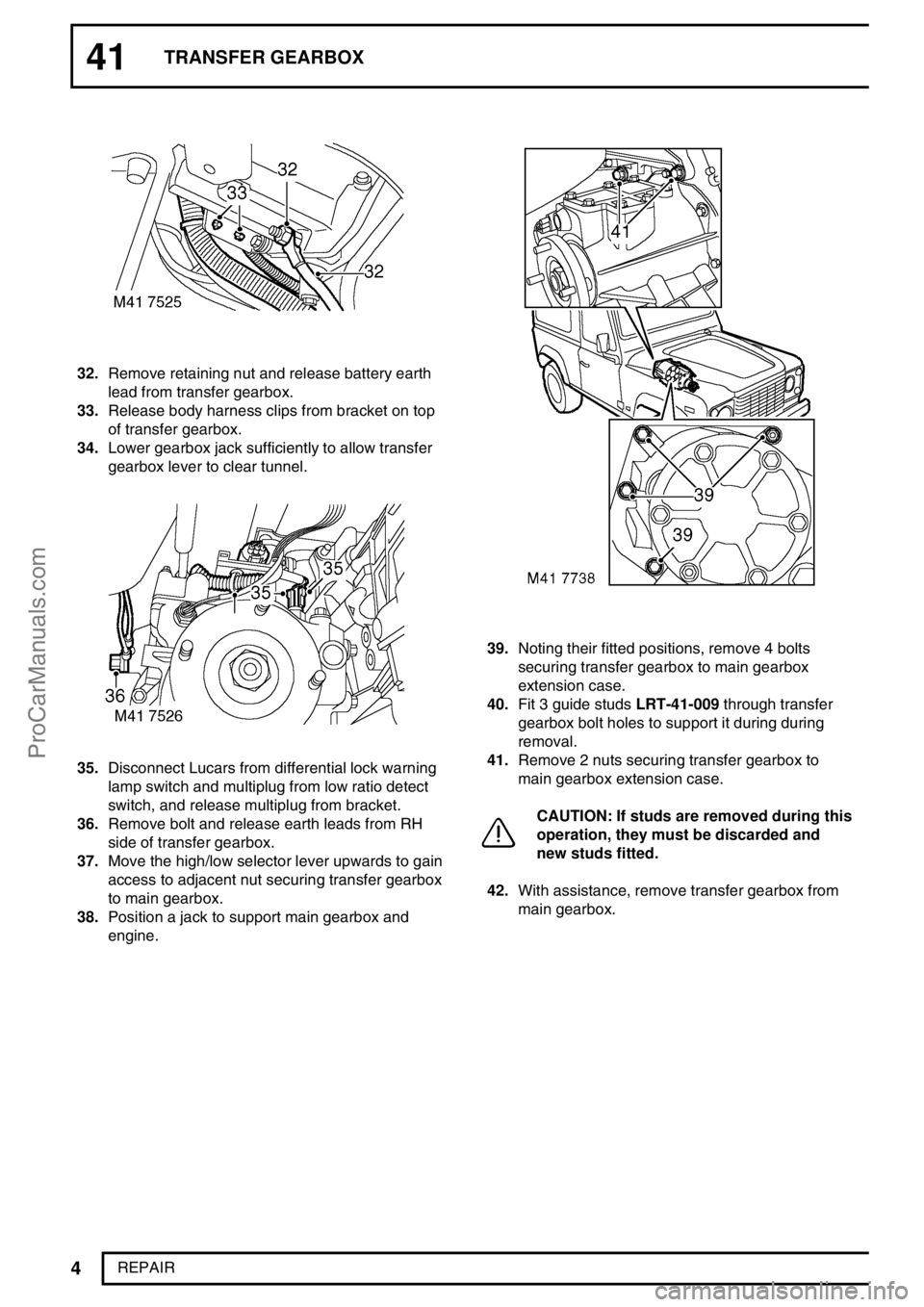

32.Remove retaining nut and release battery earth

lead from transfer gearbox.

33.Release body harness clips from bracket on top

of transfer gearbox.

34.Lower gearbox jack sufficiently to allow transfer

gearbox lever to clear tunnel.

35.Disconnect Lucars from differential lock warning

lamp switch and multiplug from low ratio detect

switch, and release multiplug from bracket.

36.Remove bolt and release earth leads from RH

side of transfer gearbox.

37.Move the high/low selector lever upwards to gain

access to adjacent nut securing transfer gearbox

to main gearbox.

38.Position a jack to support main gearbox and

engine.

39.Noting their fitted positions, remove 4 bolts

securing transfer gearbox to main gearbox

extension case.

40.Fit 3 guide studsLRT-41-009through transfer

gearbox bolt holes to support it during during

removal.

41.Remove 2 nuts securing transfer gearbox to

main gearbox extension case.

CAUTION: If studs are removed during this

operation, they must be discarded and

new studs fitted.

42.With assistance, remove transfer gearbox from

main gearbox.

ProCarManuals.com

Page 366 of 667

TRANSFER GEARBOX

5

REPAIR

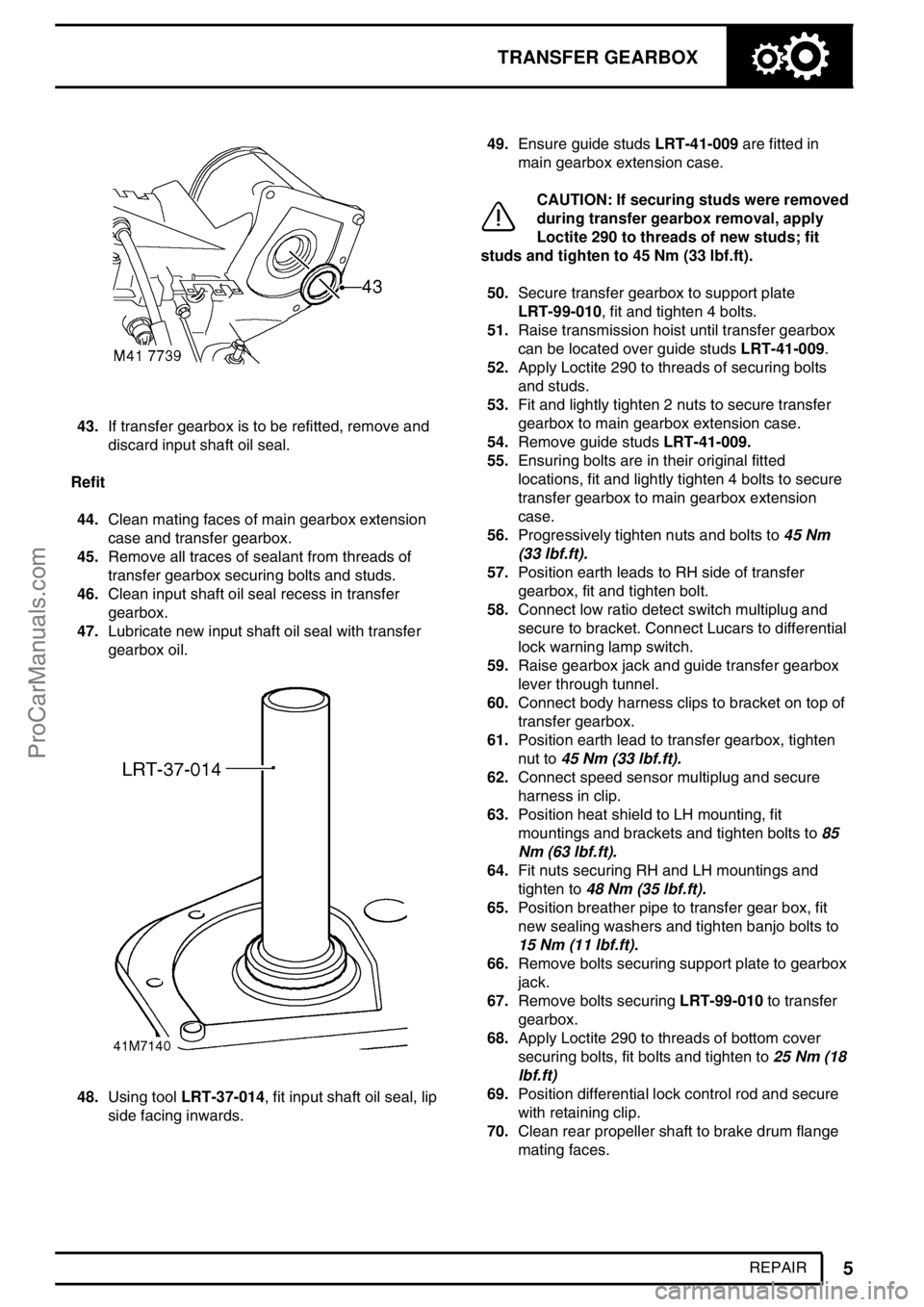

43.If transfer gearbox is to be refitted, remove and

discard input shaft oil seal.

Refit

44.Clean mating faces of main gearbox extension

case and transfer gearbox.

45.Remove all traces of sealant from threads of

transfer gearbox securing bolts and studs.

46.Clean input shaft oil seal recess in transfer

gearbox.

47.Lubricate new input shaft oil seal with transfer

gearbox oil.

48.Using toolLRT-37-014, fit input shaft oil seal, lip

side facing inwards.49.Ensure guide studsLRT-41-009are fitted in

main gearbox extension case.

CAUTION: If securing studs were removed

during transfer gearbox removal, apply

Loctite 290 to threads of new studs; fit

studs and tighten to 45 Nm (33 lbf.ft).

50.Secure transfer gearbox to support plate

LRT-99-010, fit and tighten 4 bolts.

51.Raise transmission hoist until transfer gearbox

can be located over guide studsLRT-41-009.

52.Apply Loctite 290 to threads of securing bolts

and studs.

53.Fit and lightly tighten 2 nuts to secure transfer

gearbox to main gearbox extension case.

54.Remove guide studsLRT-41-009.

55.Ensuring bolts are in their original fitted

locations, fit and lightly tighten 4 bolts to secure

transfer gearbox to main gearbox extension

case.

56.Progressively tighten nuts and bolts to45 Nm

(33 lbf.ft).

57.Position earth leads to RH side of transfer

gearbox, fit and tighten bolt.

58.Connect low ratio detect switch multiplug and

secure to bracket. Connect Lucars to differential

lock warning lamp switch.

59.Raise gearbox jack and guide transfer gearbox

lever through tunnel.

60.Connect body harness clips to bracket on top of

transfer gearbox.

61.Position earth lead to transfer gearbox, tighten

nut to45 Nm (33 lbf.ft).

62.Connect speed sensor multiplug and secure

harness in clip.

63.Position heat shield to LH mounting, fit

mountings and brackets and tighten bolts to85

Nm (63 lbf.ft).

64.Fit nuts securing RH and LH mountings and

tighten to48 Nm (35 lbf.ft).

65.Position breather pipe to transfer gear box, fit

new sealing washers and tighten banjo bolts to

15 Nm (11 lbf.ft).

66.Remove bolts securing support plate to gearbox

jack.

67.Remove bolts securingLRT-99-010to transfer

gearbox.

68.Apply Loctite 290 to threads of bottom cover

securing bolts, fit bolts and tighten to25 Nm (18

lbf.ft)

69.Position differential lock control rod and secure

with retaining clip.

70.Clean rear propeller shaft to brake drum flange

mating faces.

ProCarManuals.com

Page 368 of 667

TRANSFER GEARBOX

7

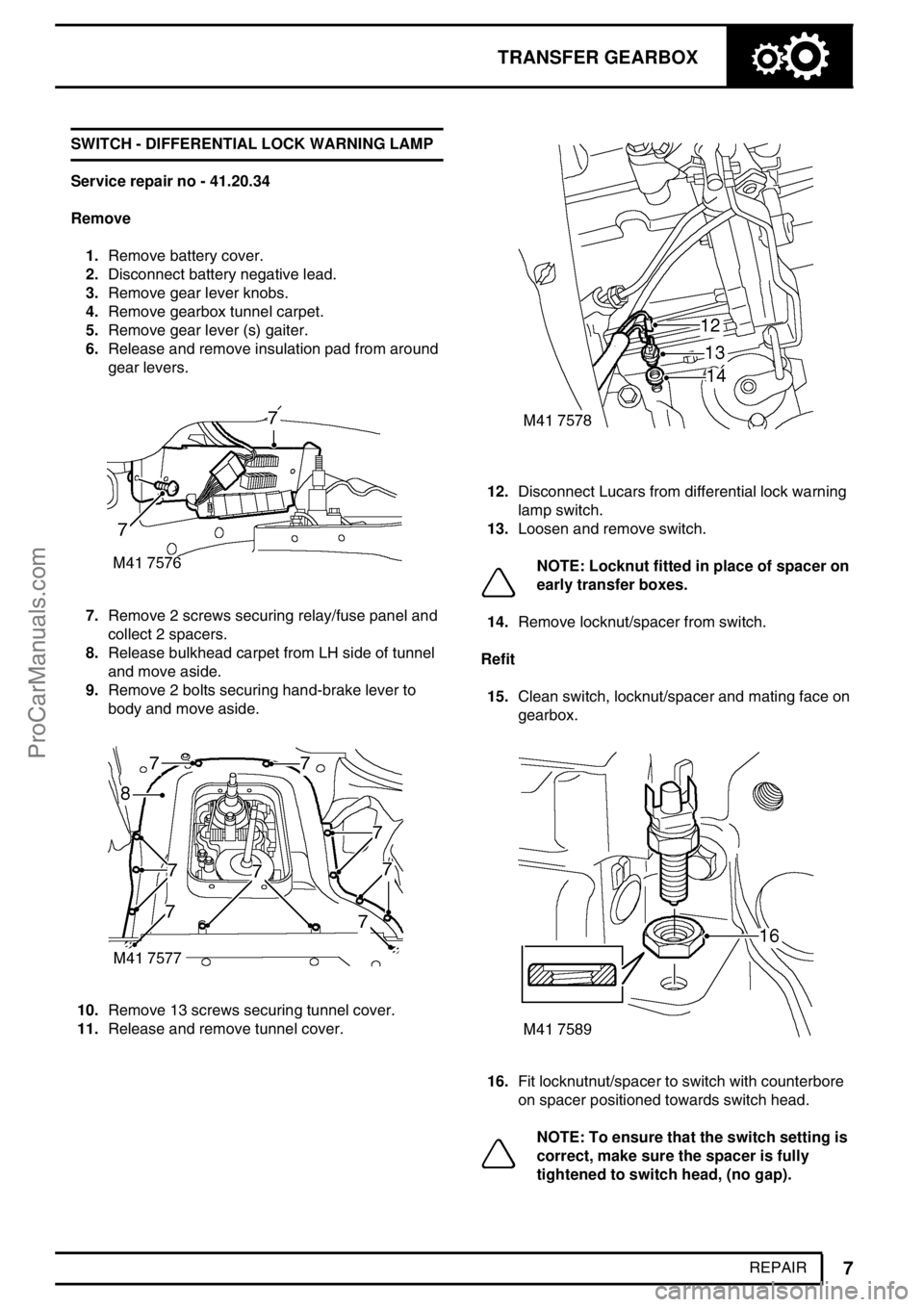

REPAIR SWITCH - DIFFERENTIAL LOCK WARNING LAMP

Service repair no - 41.20.34

Remove

1.Remove battery cover.

2.Disconnect battery negative lead.

3.Remove gear lever knobs.

4.Remove gearbox tunnel carpet.

5.Remove gear lever (s) gaiter.

6.Release and remove insulation pad from around

gear levers.

7.Remove 2 screws securing relay/fuse panel and

collect 2 spacers.

8.Release bulkhead carpet from LH side of tunnel

and move aside.

9.Remove 2 bolts securing hand-brake lever to

body and move aside.

10.Remove 13 screws securing tunnel cover.

11.Release and remove tunnel cover.

12.Disconnect Lucars from differential lock warning

lamp switch.

13.Loosen and remove switch.

NOTE: Locknut fitted in place of spacer on

early transfer boxes.

14.Remove locknut/spacer from switch.

Refit

15.Clean switch, locknut/spacer and mating face on

gearbox.

16.Fit locknutnut/spacer to switch with counterbore

on spacer positioned towards switch head.

NOTE: To ensure that the switch setting is

correct, make sure the spacer is fully

tightened to switch head, (no gap).

ProCarManuals.com

Page 369 of 667

41TRANSFER GEARBOX

8

REPAIR 17.Apply Hylomar PL32 sealant to switch threads.

18.Position switch into gearbox housing until

locknut/spacer bottoms out on housing.

19. Switches fitted with spacer:Tighten spacer

securing differential lock switch to11 Nm (8

lbf.ft).

20.Connect Lucars to switch.

21. Switches fitted with locknut:Adjust switch.

See Adjustment.

22.Fit and align tunnel cover, fit and tighten screws.

23.Fit hand-brake lever and tighten bolts to25 Nm

(18 lbf.ft).

24.Secure bulkhead carpet to LH side of tunnel.

25.Position relay/fuse panel, fit spacers and tighten

screws.

26.Fit insulation pad around gear levers.

27.Fit gear lever (s) gaiter.

28.Fit gearbox tunnel carpet.

29.Fit gear lever knobs.

30.Reconnect battery negative lead.

31.Fit battery cover.SEAL - INPUT SHAFT

Service repair no - 41.20.50

Remove

1.Remove transfer gearbox.See this Section.

2.Remove and discard input shaft oil seal from

transfer gearbox.

Refit

3.Clean oil seal recess in transfer gearbox.

4.Lubricate new oil seal with transfer gearbox oil.

5.UsingLRT-37-014, fit input shaft seal to transfer

gearbox.

6.Fit transfer gearbox.See this Section.

ProCarManuals.com

Page 373 of 667

41TRANSFER GEARBOX

12

REPAIR

10.Fit new seal usingLRT-41-012.

NOTE: Use end of tool marked’REAR’to

fit seal.

11.Position drive flange, fit new felt and steel

washers.

12.PositionLRT-51-003fit and tighten new drive

flange nut to148 Nm (109 lbf.ft).

13.Position brake drum and tighten screw.

14.Tighten adjuster bolt to25 Nm (18 lbf.ft)then

back off 1 1/2 turns.

15.Check that brake drum is free to rotate.

16.Fit propeller shaft.See PROPELLER SHAFTS,

Repair.

17.Top-up transfer gearbox oil.GASKET - REAR OUTPUT SHAFT HOUSING

Service repair no - 41.20.55

Remove

1.Drain transfer gearbox oil.See

MAINTENANCE ,

2.Remove rear output shaft seal.See this

Section.

3.Mark output shaft housing to main casing for

assembly purposes.

4.Note position of shoulder bolt, remove 6 bolts

securing housing to main casing.

Refit

5.Clean output shaft housing, mating face on main

casing and sealant from bolt threads.

6.Apply Hylosil RTV 102 to mating flange on

output shaft housing.

7.Fit output shaft housing to main casing ensuring

that splines of output shaft are engaged in

differential.

8.Apply Loctite 290 to bolt threads.

9.Fit bolts and tighten by diagonal selection to45

Nm (33 lbf.ft).

10.Fit rear output shaft seal.See this Section.

11.Fill transfer gearbox with oil.See

MAINTENANCE ,

ProCarManuals.com

Page 378 of 667

PROPELLER SHAFTS

1

REPAIR PROPELLER SHAFT - FRONT

Service repair no - 47.15.02

Remove

1.Remove underbelly panel.See CHASSIS AND

BODY, Repair.

NOTE: To remove the underbelly panel,

the propeller shaft has to be released from

the front differential flange.

2.Mark propeller shaft to transfer gearbox.

3.Remove 4 nuts securing propeller shaft to

transfer gearbox flange.

4.Remove propeller shaft.

Refit

5.Clean propeller shaft flanges and mating faces.

6.Position propeller shaft to transfer gearbox

flange and tighten nuts to48 Nm (35 lbf.ft).

7.Fit underbelly panel.See CHASSIS AND

BODY, Repair.PROPELLER SHAFT - REAR

Service repair no - 47.15.03

Remove

1.Raise rear of vehicle.

WARNING: Support on safety stands.

2.Using a centre punch, mark relationship of

propeller shaft flanges.

3.Remove 4 nuts securing propeller shaft to park

brake flange.

NOTE: Rotation of propeller shaft may be

required during the above procedure.

4.Remove 4 nuts and bolts securing propeller

shaft to rear axle flange.

NOTE: Rotation of propeller shaft may be

required during the above procedure.

5.Release propeller shaft from park brake.

6.Remove propeller shaft.

ProCarManuals.com

Page 382 of 667

51 - REAR AXLE AND FINAL DRIVE

CONTENTS

Page

DESCRIPTION AND OPERATION

DESCRIPTION 1.....................................................................................................

FAULT DIAGNOSIS

FAULT DIAGNOSIS 1.............................................................................................

REPAIR

REAR AXLE 1.........................................................................................................

REAR HUB ASSEMBLY - 90 3...............................................................................

DIFFERENTIAL ASSEMBLY - 90 5........................................................................

OVERHAUL

DIFFERENTIAL ASSEMBLY - 110/130 1...............................................................

REAR HUB ASSEMBLY - 90 10.............................................................................

REAR STUB AXLE - 90 12.....................................................................................

REAR STUB AXLE - 110/130 13............................................................................

ProCarManuals.com

Page 384 of 667

REAR AXLE AND FINAL DRIVE

1

DESCRIPTION AND OPERATION DESCRIPTION

The welded steel rear axle casing houses a separate

spiral bevel type differential unit, which is off set to the

right of the vehicle centre line. The differential unit

drives the rear wheels via the axle shafts and fully

floating hubs which are mounted on tapered roller

bearings.

Lubrication

The differential is lubricated with oil and the hub

bearings with grease.The hub bearings are fitted with inner and outer seals.

The outer seals prevent the differential oil mixing with

the hub grease and the inner seals prevent dirt

ingress into the hub.

Ventilation

Ventilation of the hub bearings is through the outer oil

seals and the differential ventilation pipe, which

terminates at a high level.

Rear axle hub - 90

1.Axle casing

2.Ventilation pipe

3.Axle shaft

4.Wheel studs and hub

5.Wheel bearing stub axle6.Wheel bearings

7.Inner hub seal

8.Outer hub/axle shaft seal

9.Hub lock plate, thrust washer and nuts

10.Brake disc

ProCarManuals.com

Page 386 of 667

REAR AXLE AND FINAL DRIVE

1

FAULT DIAGNOSIS FAULT DIAGNOSIS

Complaint - Oil leaks

An external leak of lubrication from the hub seals can

be caused by a faulty internal seal. For example, if the

seals which separate the differential from the hubs are

faulty and the vehicle is operating or parked on an

embankment, oil from the differential may flood one

hub resulting in a lack of lubrication in the differential.

When a seal is found to be leaking check the axle

ventilation system, as a blockage can cause internal

pressure to force oil past the seals.

See’Description and Operation’for illustrations of oil

seal locations.

When investigating hub seal leaks check the grease

for dilution with oil. Also check the differential oil level,

for signs of metal particles in the oil and the condition

of internal seals.

If the vehicle is driven in deep water with defective oil

seals, water may contaminate the lubricants and raise

the differential oil level, giving a false impression that

the housing has been over filled.

Do not assume that a high oil level in the

differential is due to over filling or, that a low level

is because of an external leak.

ProCarManuals.com

Page 388 of 667

REAR AXLE AND FINAL DRIVE

1

REPAIR REAR AXLE

Service repair no - 51.25.01

Remove

WARNING: Remove and refit of axle

requires a further two persons to steady

the axle when lowering or repositioning

axle.

1.Drain brake system.

2.Support chassis rear.

3.Remove road wheels.

4.Support axle weight with hydraulic jack.

5.Disconnect shock absorbers.

6.Disconnect flexible brake hose at RH chassis

side member and breather hose at banjo

connection on axle casing.

7.Disconnect lower links at axle.8.Mark differential and propeller shaft flanges with

identification marks for assembly.

9.Remove 4 nuts and bolts, lower propeller shaft

and tie to one side.

10.Disconnect pivot bracket ball joint at axle

bracket.

11.Release bolts and remove coil spring retaining

plates.

12.Lower axle and remove road springs.

13.If applicable, remove anti-roll bar links at axle

See REAR SUSPENSION, Repair. anti-roll

bar.

14.Remove axle assembly.

ProCarManuals.com