oil type LAND ROVER DEFENDER 1999 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 109 of 667

12ENGINE

24

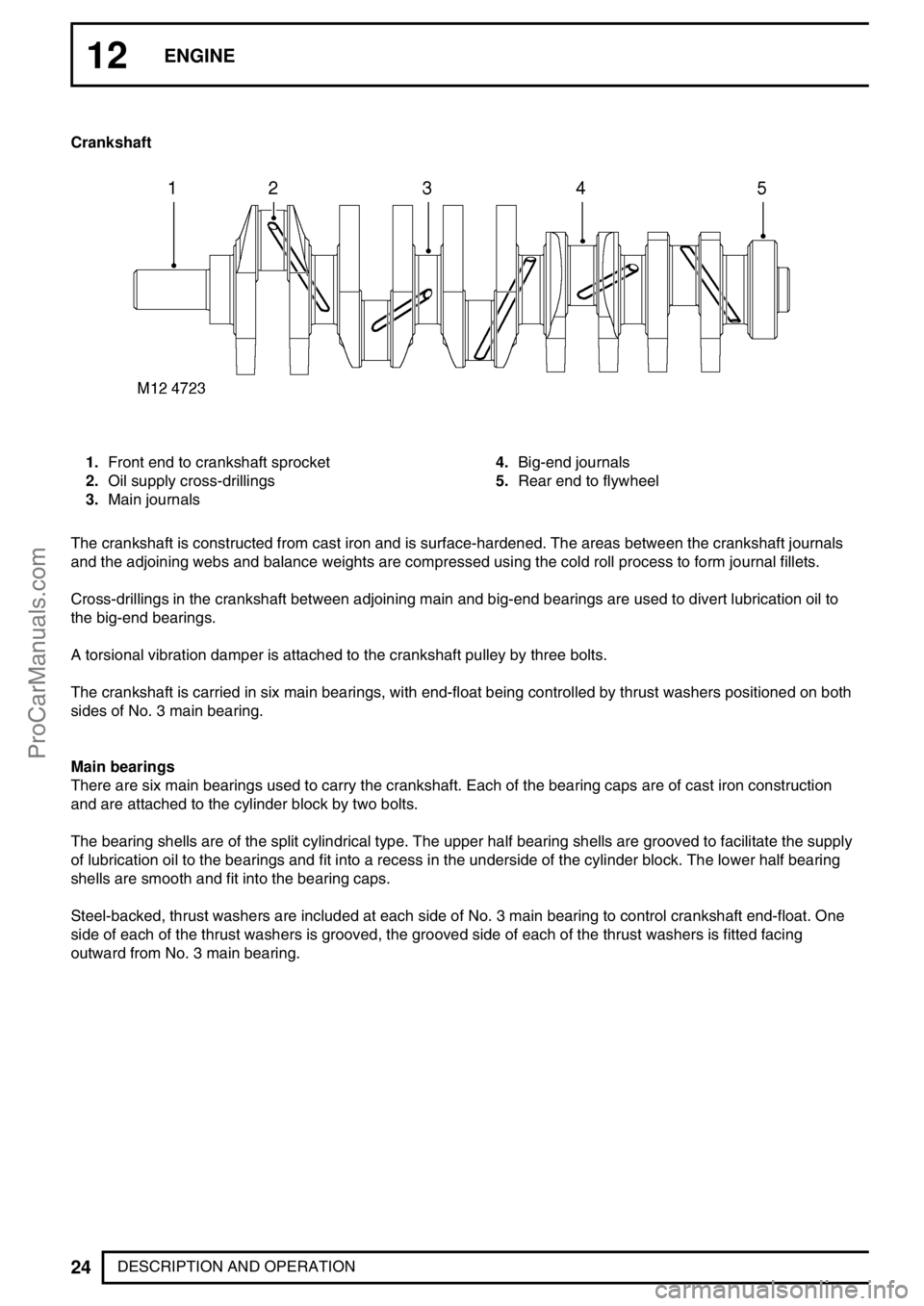

DESCRIPTION AND OPERATION Crankshaft

1.Front end to crankshaft sprocket

2.Oil supply cross-drillings

3.Main journals4.Big-end journals

5.Rear end to flywheel

The crankshaft is constructed from cast iron and is surface-hardened. The areas between the crankshaft journals

and the adjoining webs and balance weights are compressed using the cold roll process to form journal fillets.

Cross-drillings in the crankshaft between adjoining main and big-end bearings are used to divert lubrication oil to

the big-end bearings.

A torsional vibration damper is attached to the crankshaft pulley by three bolts.

The crankshaft is carried in six main bearings, with end-float being controlled by thrust washers positioned on both

sides of No. 3 main bearing.

Main bearings

There are six main bearings used to carry the crankshaft. Each of the bearing caps are of cast iron construction

and are attached to the cylinder block by two bolts.

The bearing shells are of the split cylindrical type. The upper half bearing shells are grooved to facilitate the supply

of lubrication oil to the bearings and fit into a recess in the underside of the cylinder block. The lower half bearing

shells are smooth and fit into the bearing caps.

Steel-backed, thrust washers are included at each side of No. 3 main bearing to control crankshaft end-float. One

side of each of the thrust washers is grooved, the grooved side of each of the thrust washers is fitted facing

outward from No. 3 main bearing.

ProCarManuals.com

Page 111 of 667

12ENGINE

26

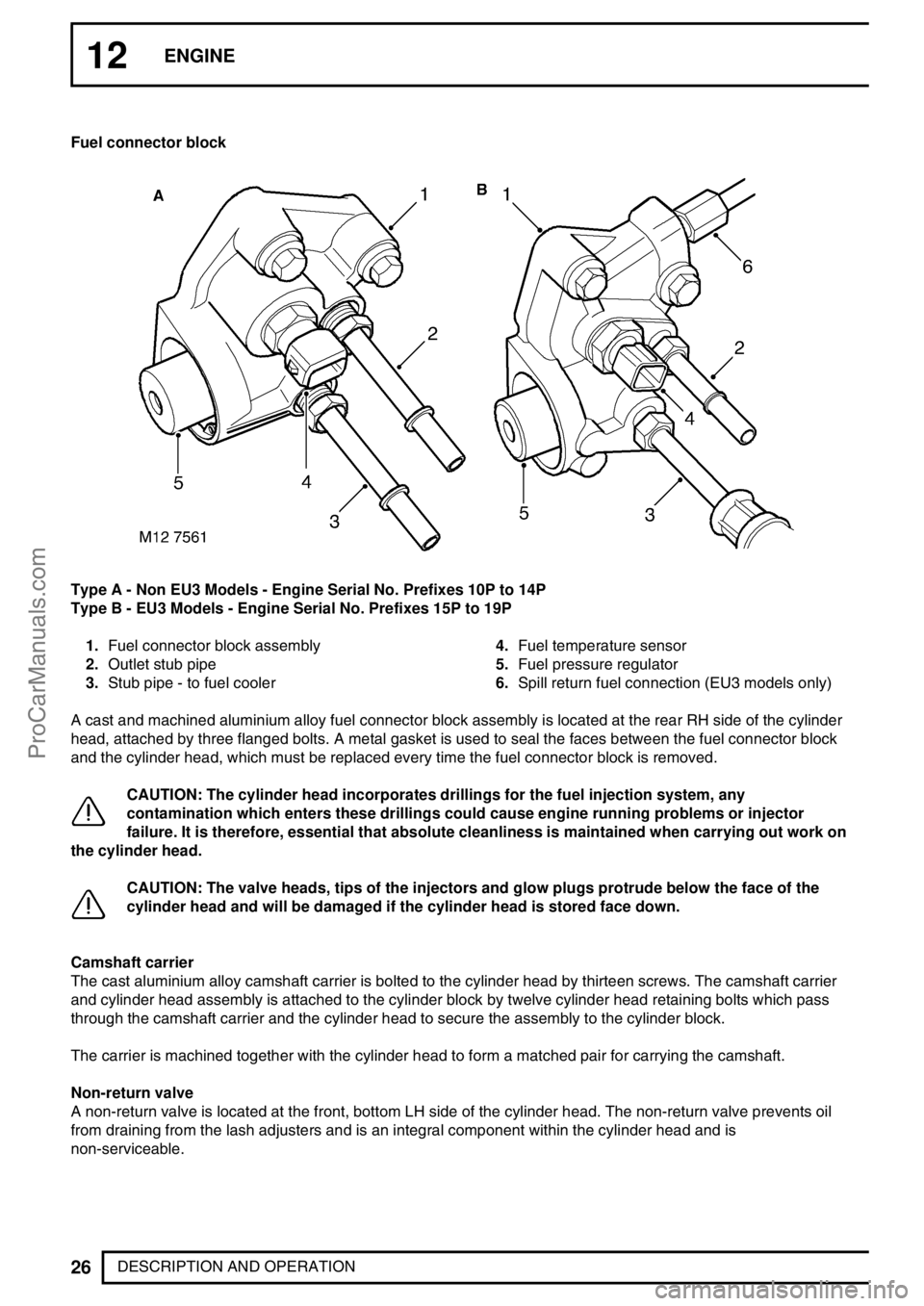

DESCRIPTION AND OPERATION Fuel connector block

Type A - Non EU3 Models - Engine Serial No. Prefixes 10P to 14P

Type B - EU3 Models - Engine Serial No. Prefixes 15P to 19P

1.Fuel connector block assembly

2.Outlet stub pipe

3.Stub pipe - to fuel cooler4.Fuel temperature sensor

5.Fuel pressure regulator

6.Spill return fuel connection (EU3 models only)

A cast and machined aluminium alloy fuel connector block assembly is located at the rear RH side of the cylinder

head, attached by three flanged bolts. A metal gasket is used to seal the faces between the fuel connector block

and the cylinder head, which must be replaced every time the fuel connector block is removed.

CAUTION: The cylinder head incorporates drillings for the fuel injection system, any

contamination which enters these drillings could cause engine running problems or injector

failure. It is therefore, essential that absolute cleanliness is maintained when carrying out work on

the cylinder head.

CAUTION: The valve heads, tips of the injectors and glow plugs protrude below the face of the

cylinder head and will be damaged if the cylinder head is stored face down.

Camshaft carrier

The cast aluminium alloy camshaft carrier is bolted to the cylinder head by thirteen screws. The camshaft carrier

and cylinder head assembly is attached to the cylinder block by twelve cylinder head retaining bolts which pass

through the camshaft carrier and the cylinder head to secure the assembly to the cylinder block.

The carrier is machined together with the cylinder head to form a matched pair for carrying the camshaft.

Non-return valve

A non-return valve is located at the front, bottom LH side of the cylinder head. The non-return valve prevents oil

from draining from the lash adjusters and is an integral component within the cylinder head and is

non-serviceable.

ProCarManuals.com

Page 112 of 667

ENGINE

27

DESCRIPTION AND OPERATION Camshaft

The camshaft is machined from cast steel and is located between the cylinder head and the camshaft carrier and

the six bearing journals are line bored between the two components to form a matched pair. The machined

camshaft has 15 lobes. Ten lobes operate the inlet and exhaust valves through hydraulic lash adjusters and finger

followers which are located below the camshaft. Five larger lobes activate the injector rockers which are located

above the camshaft on the rocker shaft and are used to generate fuel pressure in the EUI injectors.

The camshaft sprocket is driven via a Duplex chain connected to the crankshaft sprocket at a speed ratio of 2:1.

The camshaft sprocket is fixed to the front end of the camshaft by three bolts.

Camshaft lubrication is by splash and channel fed via pressurised oil flowing through galleries in the cylinder head.

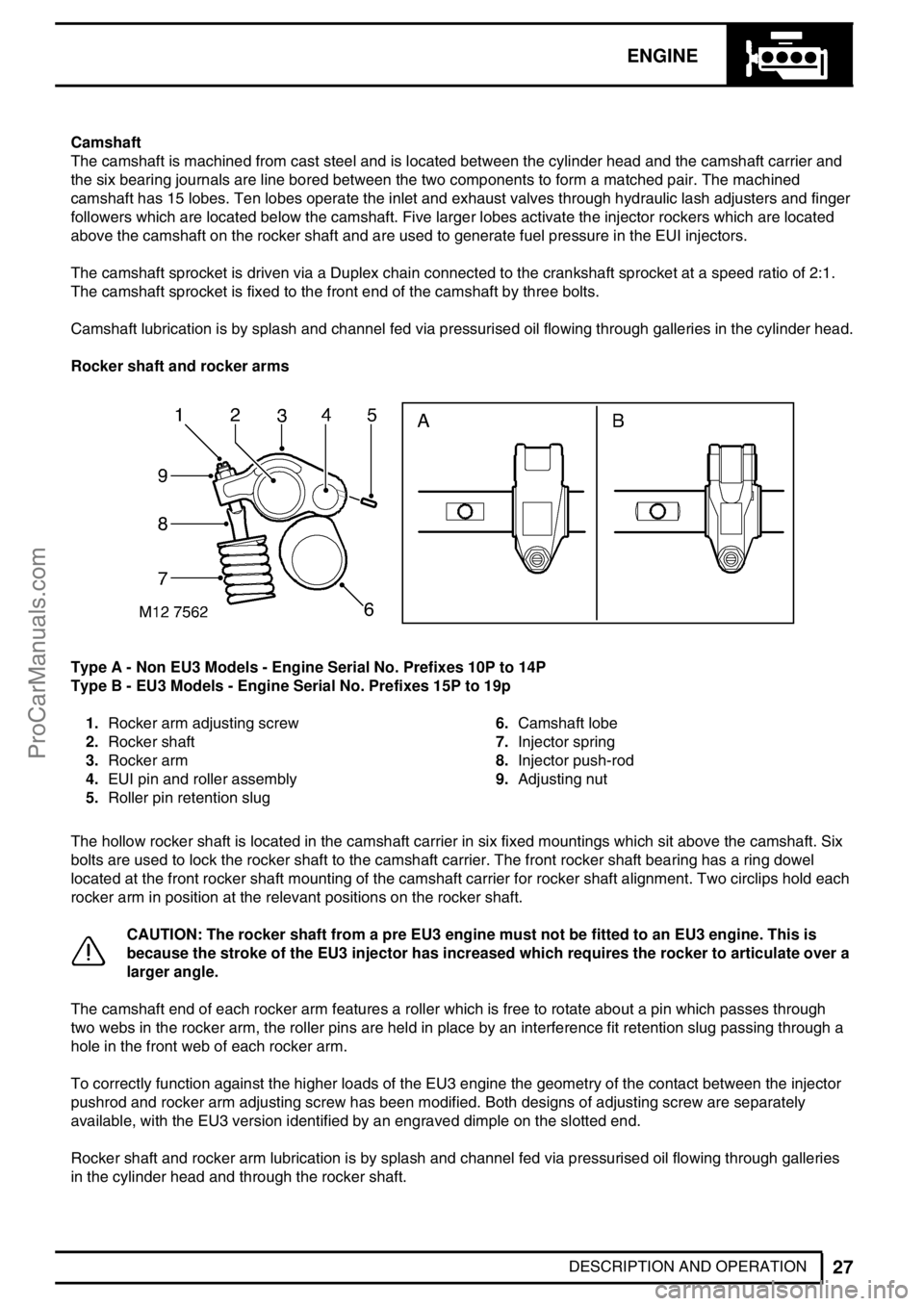

Rocker shaft and rocker arms

Type A - Non EU3 Models - Engine Serial No. Prefixes 10P to 14P

Type B - EU3 Models - Engine Serial No. Prefixes 15P to 19p

1.Rocker arm adjusting screw

2.Rocker shaft

3.Rocker arm

4.EUI pin and roller assembly

5.Roller pin retention slug6.Camshaft lobe

7.Injector spring

8.Injector push-rod

9.Adjusting nut

The hollow rocker shaft is located in the camshaft carrier in six fixed mountings which sit above the camshaft. Six

bolts are used to lock the rocker shaft to the camshaft carrier. The front rocker shaft bearing has a ring dowel

located at the front rocker shaft mounting of the camshaft carrier for rocker shaft alignment. Two circlips hold each

rocker arm in position at the relevant positions on the rocker shaft.

CAUTION: The rocker shaft from a pre EU3 engine must not be fitted to an EU3 engine. This is

because the stroke of the EU3 injector has increased which requires the rocker to articulate over a

larger angle.

The camshaft end of each rocker arm features a roller which is free to rotate about a pin which passes through

two webs in the rocker arm, the roller pins are held in place by an interference fit retention slug passing through a

hole in the front web of each rocker arm.

To correctly function against the higher loads of the EU3 engine the geometry of the contact between the injector

pushrod and rocker arm adjusting screw has been modified. Both designs of adjusting screw are separately

available, with the EU3 version identified by an engraved dimple on the slotted end.

Rocker shaft and rocker arm lubrication is by splash and channel fed via pressurised oil flowing through galleries

in the cylinder head and through the rocker shaft.

ProCarManuals.com

Page 113 of 667

12ENGINE

28

DESCRIPTION AND OPERATION Inlet and exhaust valves

The inlet and exhaust valves are mounted directly above the engine block cylinders.

Each valve is a forged and ground solid one-piece head and stem which is hardened by heat treatment. The

stems are chrome-plated then ground for improved heat transfer, wear resistance and smooth operation. It is not

possible to recut the valve’s face angle, but the valves can be lapped to their seats using grinding paste.

The valve springs are made from spring steel and are of the parallel single-coil type. The bottom end of the spring

rests on the flange of a spring seal which has a centre bore that locates on a recess ground into the lower valve

stem. The top end of the spring is held in place by a spring cap which is held in position at the top end of the valve

stem by split taper collets. The taper collets have grooves on the internal bore that locate in grooves ground into

the upper stems of the valves.

The valve seats and valve guides are sintered and are an interference fit into the cylinder head. The valve seats

and guides are non-serviceable.

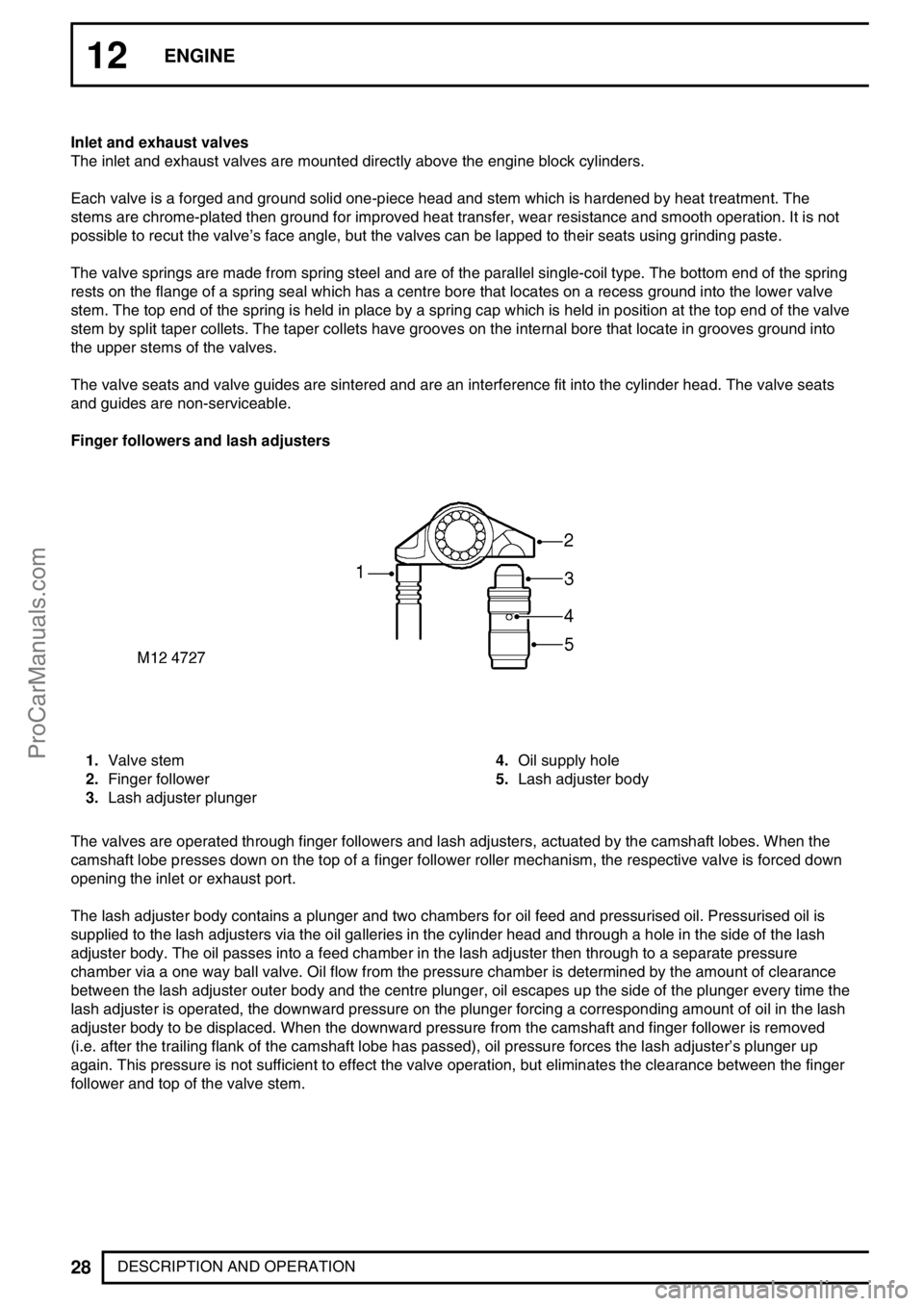

Finger followers and lash adjusters

1.Valve stem

2.Finger follower

3.Lash adjuster plunger4.Oil supply hole

5.Lash adjuster body

The valves are operated through finger followers and lash adjusters, actuated by the camshaft lobes. When the

camshaft lobe presses down on the top of a finger follower roller mechanism, the respective valve is forced down

opening the inlet or exhaust port.

The lash adjuster body contains a plunger and two chambers for oil feed and pressurised oil. Pressurised oil is

supplied to the lash adjusters via the oil galleries in the cylinder head and through a hole in the side of the lash

adjuster body. The oil passes into a feed chamber in the lash adjuster then through to a separate pressure

chamber via a one way ball valve. Oil flow from the pressure chamber is determined by the amount of clearance

between the lash adjuster outer body and the centre plunger, oil escapes up the side of the plunger every time the

lash adjuster is operated, the downward pressure on the plunger forcing a corresponding amount of oil in the lash

adjuster body to be displaced. When the downward pressure from the camshaft and finger follower is removed

(i.e. after the trailing flank of the camshaft lobe has passed), oil pressure forces the lash adjuster’s plunger up

again. This pressure is not sufficient to effect the valve operation, but eliminates the clearance between the finger

follower and top of the valve stem.

ProCarManuals.com

Page 115 of 667

12ENGINE

30

DESCRIPTION AND OPERATION CAMSHAFT COVER COMPONENTS

The camshaft cover cover components are described below:

Camshaft cover

The camshaft cover is cast from aluminium alloy and is fixed to the camshaft carrier / cylinder head assembly by

thirteen bolts. The cover has spacers and sealing washers inserted into each of the thirteen bolt holes.

A breather hose is connected to a port at the top of the camshaft cover by means of a hose clip which vents

crankcase gases back to the air intake via a breather valve in the air intake tract, located forward of the

turbocharger in the flexible air intake duct.

A rubber seal is fitted between the camshaft cover and camshaft carrier.

An oil filler aperture is included in the top of the camshaft cover, which is sealed with a plastic cap with integral

rubber seal.

CAMSHAFT TIMING CHAIN COMPONENTS

The timing chain cover and timing chain components are described below:

Timing chain cover

The timing chain cover is cast and machined aluminium alloy and is attached to the cylinder head by a bolt at the

RH top of the cover and by a stud and nut at the LH top of the cover. Eight screws are used to attach the timing

chain cover to the front of the engine block. The timing cover is located to the cylinder block front face by two

dowels.

A viscous fan is attached to an idler pulley at the front of the engine block. The fan bearing is located on a shaft

and held in place by a circlip and a bearing flange, the inner race of the fan bearing is an interference fit on the

shaft. The fan idler pulley is attached to the bearing hub by three bolts and the fan itself is secured to the pulley

and bearing shaft by a left-hand threaded nut.

The front of the crankshaft passes through a hole in the lower part of the timing cover. An oil seal is pressed into a

recess in the front of the timing cover to seal the interface between the front of the crankshaft and the timing

cover.

A stub pipe is fitted to the front RH side of the timing cover which is used to attach the oil drain pipe from the

vacuum pump by means of a hose and spring clip.

Timing chains

The timing chain between the camshaft and crankshaft sprockets is a duplex type, each chain having 56 links.

The timing chain is contained between a fixed plastic guide and an hydraulically adjustable plastic tensioner arm

which are attached to the front of the engine block.

To cope with the higher injection loads of the EU3 engine, the timing drive between the camshaft and crankshaft

has been upgraded. This requires thicker chain links to be used, therefore the individual pre EU3 and EU3

components are not interchangeable.

To distinguish between the two timing chains the links are different colours. A pre EU3 chain has blue links. An

EU3 chain has bronze links.

The oil pump timing chain is a single type and traverses the oil pump sprocket and the rear crankshaft sprocket.

The timing chains are oil lubricated, with oil being provided by a chain lubrication jet and from oil flow returning

back to the sump from the cylinder head. An oil hole is included at the front left hand side of the cylinder head

which supplies oil from the cylinder head oil galleries.

ProCarManuals.com

Page 127 of 667

12ENGINE

2

REPAIR

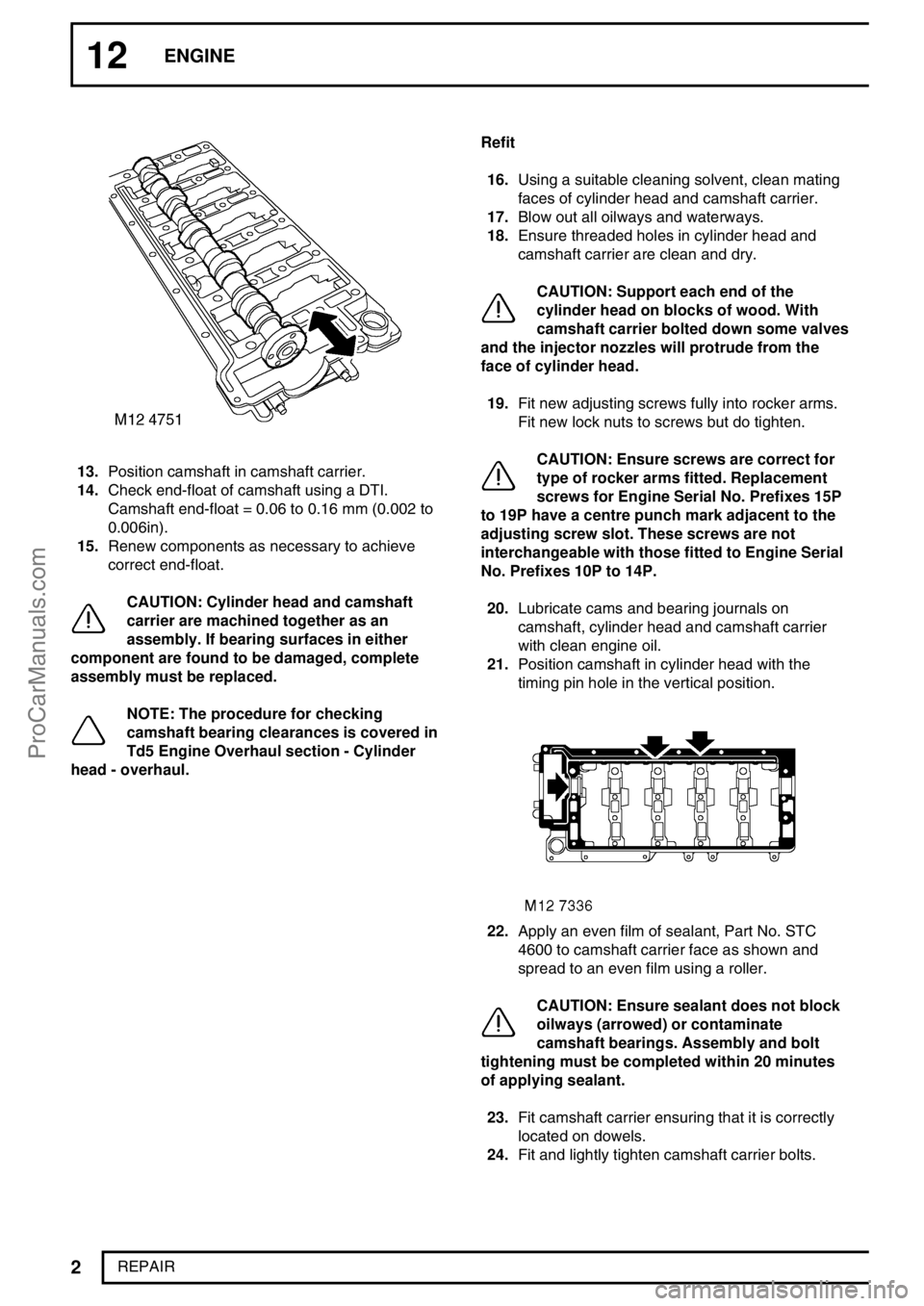

13.Position camshaft in camshaft carrier.

14.Check end-float of camshaft using a DTI.

Camshaft end-float = 0.06 to 0.16 mm (0.002 to

0.006in).

15.Renew components as necessary to achieve

correct end-float.

CAUTION: Cylinder head and camshaft

carrier are machined together as an

assembly. If bearing surfaces in either

component are found to be damaged, complete

assembly must be replaced.

NOTE: The procedure for checking

camshaft bearing clearances is covered in

Td5 Engine Overhaul section - Cylinder

head - overhaul.Refit

16.Using a suitable cleaning solvent, clean mating

faces of cylinder head and camshaft carrier.

17.Blow out all oilways and waterways.

18.Ensure threaded holes in cylinder head and

camshaft carrier are clean and dry.

CAUTION: Support each end of the

cylinder head on blocks of wood. With

camshaft carrier bolted down some valves

and the injector nozzles will protrude from the

face of cylinder head.

19.Fit new adjusting screws fully into rocker arms.

Fit new lock nuts to screws but do tighten.

CAUTION: Ensure screws are correct for

type of rocker arms fitted. Replacement

screws for Engine Serial No. Prefixes 15P

to 19P have a centre punch mark adjacent to the

adjusting screw slot. These screws are not

interchangeable with those fitted to Engine Serial

No. Prefixes 10P to 14P.

20.Lubricate cams and bearing journals on

camshaft, cylinder head and camshaft carrier

with clean engine oil.

21.Position camshaft in cylinder head with the

timing pin hole in the vertical position.

22.Apply an even film of sealant, Part No. STC

4600 to camshaft carrier face as shown and

spread to an even film using a roller.

CAUTION: Ensure sealant does not block

oilways (arrowed) or contaminate

camshaft bearings. Assembly and bolt

tightening must be completed within 20 minutes

of applying sealant.

23.Fit camshaft carrier ensuring that it is correctly

located on dowels.

24.Fit and lightly tighten camshaft carrier bolts.

ProCarManuals.com

Page 175 of 667

12ENGINE

16

OVERHAUL 5.Repeat above procedures for remaining rocker

arms.

CAUTION: Keep rocker arms in their fitted

order.Rocker arms and shaft - Inspection

1.Clean rocker arms and shaft, ensure oilways are

clear.

CAUTION: Identify type of rocker shaft

fitted. Engine Serial No. Prefixes 10P to

14P - Type A rocker shaft. Engine Serial

No. Prefixes 15P to 19P - Type B rocker shaft.

Type B rocker arms and shaft may be fitted to

Engine Serial No. Prefixes 10P to 14P as an

assembly.

2.Check diameter of each rocker arm journal on

shaft, take 2 measurements at 180°in centre of

journal.

Journal diameter =26.971 to 26.998 mm

(1.062 to 1.063 in)

CAUTION: Any ovality must be within

limits given.

ProCarManuals.com

Page 176 of 667

ENGINE

17

OVERHAUL

3.Using a vernier, check internal diameter of each

rocker arm, take 2 measurements at 180°.

Rocker arm internal diameter =27.0 to 27.013

mm (1.102 to 1.103 in)

CAUTION: Any ovality must be within

limits given.Rocker shaft - Assembling

1.Fit new spring ring to groove in rocker shaft.

2.Lubricate rocker shaft journals and rocker arms

with engine oil.

3.Fit rocker arm to shaft ensuring that it is in its

original fitted order.

4.Fit new spring ring to retain rocker arm.

5.Repeat above procedures for remaining rocker

arms ensuring they are in their original fitted

order.

6.Fit new rocker adjusting screws and locknuts to

rocker arms; do not tighten screws fully into

arms at this stage.

CAUTION: Ensure screws are correct for

type of rocker arms fitted. Replacement

screws for Engine Serial No. Prefixes 15P

to 19P have a centre punch mark adjacent to the

adjusting slot. These screws are not

interchangeable with those fitted to Engine Serial

No. Prefixes 10P to 14P.

Cylinder head - Assembling

1.Lubricate new valve stem oil seals with engine

oil.

2.Using toolLRT-12-071, fit valve stem oil seals.

3.Lubricate valve guides, valve stems, valve

spring caps and springs with engine oil.

ProCarManuals.com

Page 190 of 667

ENGINE

31

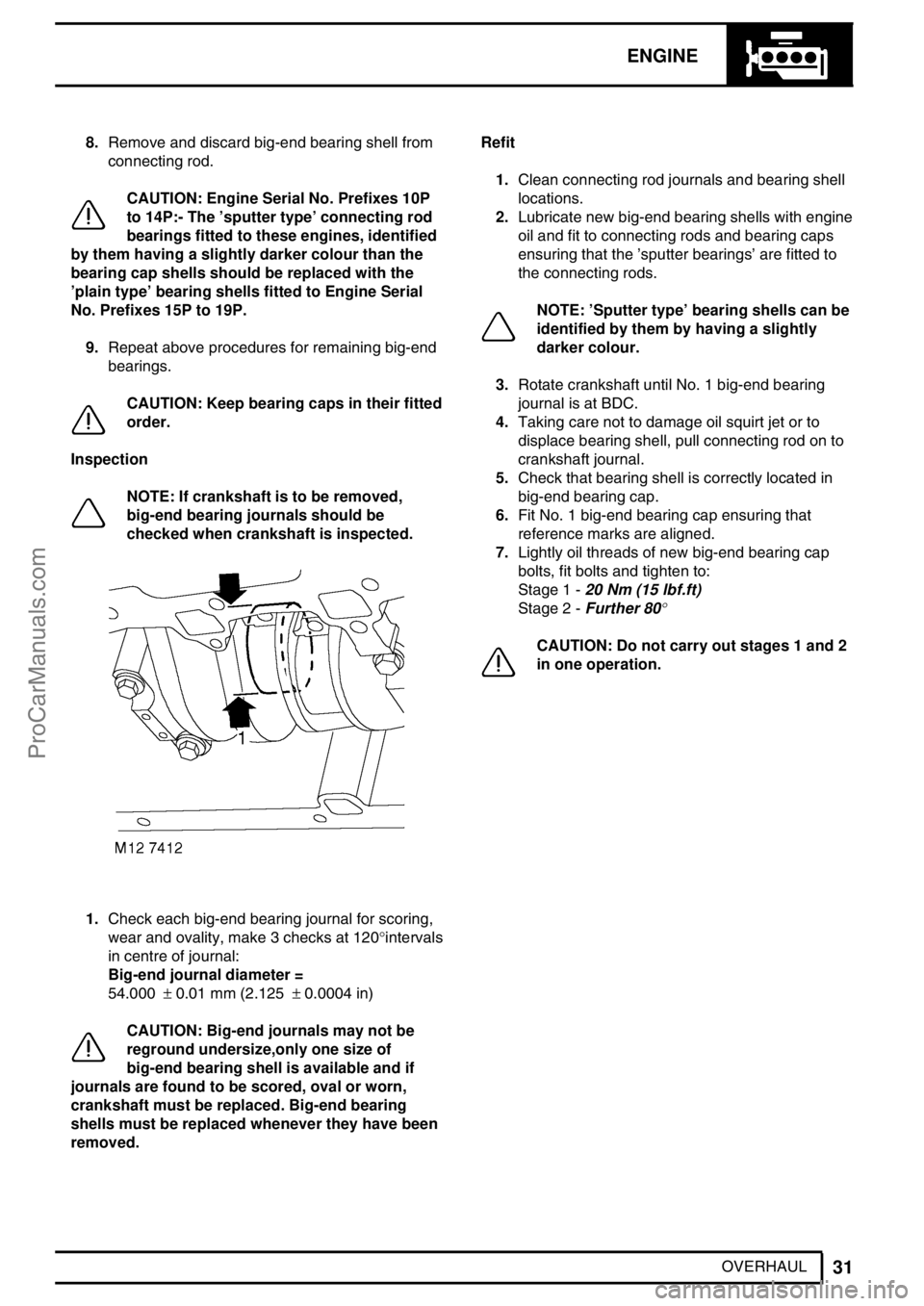

OVERHAUL 8.Remove and discard big-end bearing shell from

connecting rod.

CAUTION: Engine Serial No. Prefixes 10P

to 14P:- The’sputter type’connecting rod

bearings fitted to these engines, identified

by them having a slightly darker colour than the

bearing cap shells should be replaced with the

’plain type’bearing shells fitted to Engine Serial

No. Prefixes 15P to 19P.

9.Repeat above procedures for remaining big-end

bearings.

CAUTION: Keep bearing caps in their fitted

order.

Inspection

NOTE: If crankshaft is to be removed,

big-end bearing journals should be

checked when crankshaft is inspected.

1.Check each big-end bearing journal for scoring,

wear and ovality, make 3 checks at 120°intervals

in centre of journal:

Big-end journal diameter =

54.000±0.01 mm (2.125±0.0004 in)

CAUTION: Big-end journals may not be

reground undersize,only one size of

big-end bearing shell is available and if

journals are found to be scored, oval or worn,

crankshaft must be replaced. Big-end bearing

shells must be replaced whenever they have been

removed.Refit

1.Clean connecting rod journals and bearing shell

locations.

2.Lubricate new big-end bearing shells with engine

oil and fit to connecting rods and bearing caps

ensuring that the’sputter bearings’are fitted to

the connecting rods.

NOTE:’Sputter type’bearing shells can be

identified by them by having a slightly

darker colour.

3.Rotate crankshaft until No. 1 big-end bearing

journal is at BDC.

4.Taking care not to damage oil squirt jet or to

displace bearing shell, pull connecting rod on to

crankshaft journal.

5.Check that bearing shell is correctly located in

big-end bearing cap.

6.Fit No. 1 big-end bearing cap ensuring that

reference marks are aligned.

7.Lightly oil threads of new big-end bearing cap

bolts, fit bolts and tighten to:

Stage 1 -20 Nm (15 lbf.ft)

Stage 2 -Further 80

°

CAUTION: Do not carry out stages 1 and 2

in one operation.

ProCarManuals.com

Page 292 of 667

COOLING SYSTEM

5

DESCRIPTION AND OPERATION A - EU 3 Models

B- Pre EU3 Models

GENERAL

The cooling system used on the Diesel engine is a pressure relief by-pass type system which allows coolant to

circulate around the engine block and heater circuit when the thermostat is closed. With coolant not passing

through the by-pass or the radiator promotes faster heater warm-up which in turn improves passenger comfort.

A coolant pump is mounted on a casting behind the PAS pump and is driven from the PAS pump at crankshaft

speed by the auxiliary drive belt. The pump mounting casting connects with passages in the cylinder block and

pumps coolant from the radiator through the cylinder block.

A viscous fan is attached to an idler pulley at the front of the engine. The fan is attached to a threaded spigot on

the pulley with a right hand threaded nut. The fan draws air through the radiator to assist in cooling when the

vehicle is stationary. The fan rotational speed is controlled relative to the running temperature of the engine by a

thermostatic valve regulated by a bi-metallic coil.

The cooling system uses a 50/50 mix of anti-freeze and water.

Thermostat Housing

A plastic thermostat housing is located behind the radiator. The housing has three connections which locate the

radiator bottom hose, top hose and coolant pump feed pipe. The housing contains a wax element thermostat and

a spring loaded by-pass flow valve.

Thermostat - Main valve

The thermostat is used to maintain the coolant at the optimum temperature for efficient combustion and to aid

engine warm-up. The thermostat is closed at temperatures below approximately 82°C (179°F). When the coolant

temperature reaches approximately 82°C the thermostat starts to open and is fully open at approximately 96°C

(204°F). In this condition the full flow of coolant is directed through the radiator.

The thermostat is exposed to 90% hot coolant from the engine on one side and 10% cold coolant returning from

the radiator bottom hose on the other side.

Hot coolant from the engine passes from the by-pass pipe through four sensing holes in the flow valve into a tube

surrounding 90% of the thermostat sensitive area. Cold coolant returning from the radiator, cooled by the ambient

air, conducts through 10% of the thermostat sensitive area.

In cold ambient temperatures, the engine temperature is raised approximately 10°C (50°F) to compensate for the

heat loss of 10% exposure to the cold coolant returning from the radiator bottom hose.

ProCarManuals.com