engine coolant LAND ROVER DEFENDER 1999 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 142 of 667

ENGINE

17

REPAIR

23.Disconnect oil pressure switch multiplug.

24.Release engine harness from underside of inlet

manifold and tie aside.

25.Release clips and remove coolant top hose from

cylinder head and coolant rail.

26.Remove 4 bolts and move A/C compressor

aside.

27.Remove 3 bolts and remove PAS pump pulley.

28.Remove 4 bolts and move PAS pump aside.

29.Raise vehicle on ramp.

30.Remove 6 bolts securing gearbox housing to

engine.

31.Lower vehicle ramp.

32.Remove 2 upper bolts securing gearbox housing

to engine.

33.Remove bolt securing engine closing panel to

gearbox.

34.Release clip and coolant hose from engine oil

cooler.

ProCarManuals.com

Page 143 of 667

12ENGINE

18

REPAIR

35.Remove 2 bolts and remove acoustic cover from

rear of cylinder head.

36.FitLRT-12-138to suitable lifting chains and

connect to lifting eyes on engine.

37.Remove 2 nuts from RH and LH front engine

mountings.

38.Fit trolley jack to support gearbox.

39.With assistance raise chains and remove engine

from vehicle.Refit

40.With assistance, raise engine from bench and

position in vehicle.

41.With assistance, align engine to gearbox input

shaft.

42.Position 2 upper bolts securing gearbox housing

to engine and tighten to50 Nm (37 lbf.ft).

43.Lower engine onto mountings and tighten nuts to

85 Nm (63 lbf.ft).

44.RemoveLRT-12-138from engine.

45.Fit and tighten bolt securing engine closing panel

to gearbox.

46.Raise vehicle on ramp.

47.Fit bolts securing gearbox housing to engine and

tighten to50 Nm (37 lbf.ft).

48.Lower ramp.

49.Fit acoustic cover to rear of cylinder head and

tighten bolts.

50.Position coolant hose to engine oil cooler and

secure clip.

51.Position PAS pump and tighten bolts to25 Nm

(18 lbf.ft).

52.Position PAS pulley and tighten bolts to25 Nm

(18 lbf.ft).

53.Position A/C compressor and tighten bolts to25

Nm (18 lbf.ft).

54.Route engine harness beneath inlet manifold

and connect multiplugs to oil pressure switch,

A/C compressor, and ECT sensor.

55.Fit and tighten bolts securing engine harness to

camshaft carrier.

56.Connect multiplug to alternator.

57.Connect battery lead to alternator and tighten

nut.

58.Clean CKP sensor and mating face.

CAUTION: If originally fitted:- Fit spacer to

CKP sensor.

59.Using a new’O’ring, fit CKP sensor, tighten bolt

to10 Nm (7 lbf.ft).

60.Connect CKP sensor multiplug.

61.Connect multiplugs to EGR solenoid, inlet

manifold sensor, injector harness, fuel

temperature sensor and CKP sensor.

62.Connect glow plug leads.

63.Connect multiplug to condensor cooling fan.

64.Connect vacuum hose to EGR valve.

65.Connect EGR vacuum hose to vacuum pipe.

66.Position pipe to vacuum pump and secure pipe

to acoustic cover clips.

67.Position fuel cooler. Apply Loctite 242 to bolts

and tighten to18 Nm (13 lbf.ft).

68.Disconnect fuel hose from connector block and

connect to fuel cooler.

69.Connect fuel hoses to fuel cooler and connector

block on cylinder head.

ProCarManuals.com

Page 144 of 667

ENGINE

19

REPAIR 70.Connect coolant hoses to fuel cooler and coolant

rail and secure clips.

71.Fit air intake hose to intake elbow and tighten

clip screw.

72.Fit starter motor.See ELECTRICAL, Repair.

73.Fit turbocharger.See FUEL SYSTEM, Repair.

74.Fit radiator.See COOLING SYSTEM, Repair.

75.Fit air filter.See FUEL SYSTEM, Repair.

76.Fill engine with oil.

77.Fit underbelly panel.See CHASSIS AND

BODY, Repair.MOUNTING - FRONT - LH

Service repair no - 12.45.01

Remove

1.Remove centrifuge assembly.See this

Section.

2.Remove 3 bolts, remove oil filter adaptor

housing and discard gasket.

3.Fit suitable lifting chains to support engine.

4.Remove 2 nuts securing engine mounting to

chassis.

5.Remove 4 bolts securing engine mounting

bracket to cylinder block.

6.Remove nut securing mounting to mounting

bracket.

7.Remove mounting and mounting bracket.

8.Remove mounting shield.

ProCarManuals.com

Page 154 of 667

ENGINE

29

REPAIR VALVE - RELIEF - OIL PRESSURE

Service repair no - 12.60.56

Remove

1.Remove sump gasket.See this Section.

2.Remove and discard oil pressure relief valve

plug from oil pump housing.

3.Remove spring and valve.

Refit

4.Clean valve and spring.

5.Clean valve seating inside oil pump housing.

6.Lubricate valve and seating.

7.Fit valve and spring to pump.

8.Apply Loctite 243 sealant to threads of a new

plug.

9.Fit plug and tighten to23 Nm ( 17 lbf.ft).

10.Fit sump gasket.See this Section.

11.Check engine oil level, top-up if necessary.COOLER - ENGINE OIL

Service repair no - 12.60.68

Remove

1.Drain cooling system.See COOLING

SYSTEM, Adjustment.

2.Remove centrifuge assembly.See this

Section.

3.Remove clutch housing bolt and release coolant

pipe from rear of engine.

4.Release clip and coolant hose from oil cooler.

5.Disconnect oil pressure switch multiplug.

6.Remove oil filter element using a suitable strap

wrench.

7.Remove 3 bolts, remove oil filter adaptor and

discard gasket.

8.Remove 7 bolts, remove oil cooler and discard

gasket.

9.Remove oil pressure switch.

ProCarManuals.com

Page 155 of 667

12ENGINE

30

REPAIR Refit

10.Clean oil cooler and mating faces.

11.Fit oil pressure switch and tighten to9Nm(7

lbf.ft).

12.Position oil cooler using a new gasket and

tighten bolts to25 Nm (18 lbf.ft).

13.Position oil filter adaptor, fit new gasket and

tighten bolts to25 Nm (18 lbf.ft).

14.Position oil filter element hand tight then a

further half turn.

15.Position coolant hose to oil cooler and secure

clip.

16.Position coolant pipe and tighten clutch housing

bolt to50 Nm (37 lbf.ft).

17.Connect oil pressure switch multiplug.

18.Fit centrifuge assembly.See this Section.

19.Refill cooling system.See COOLING SYSTEM,

Adjustment.

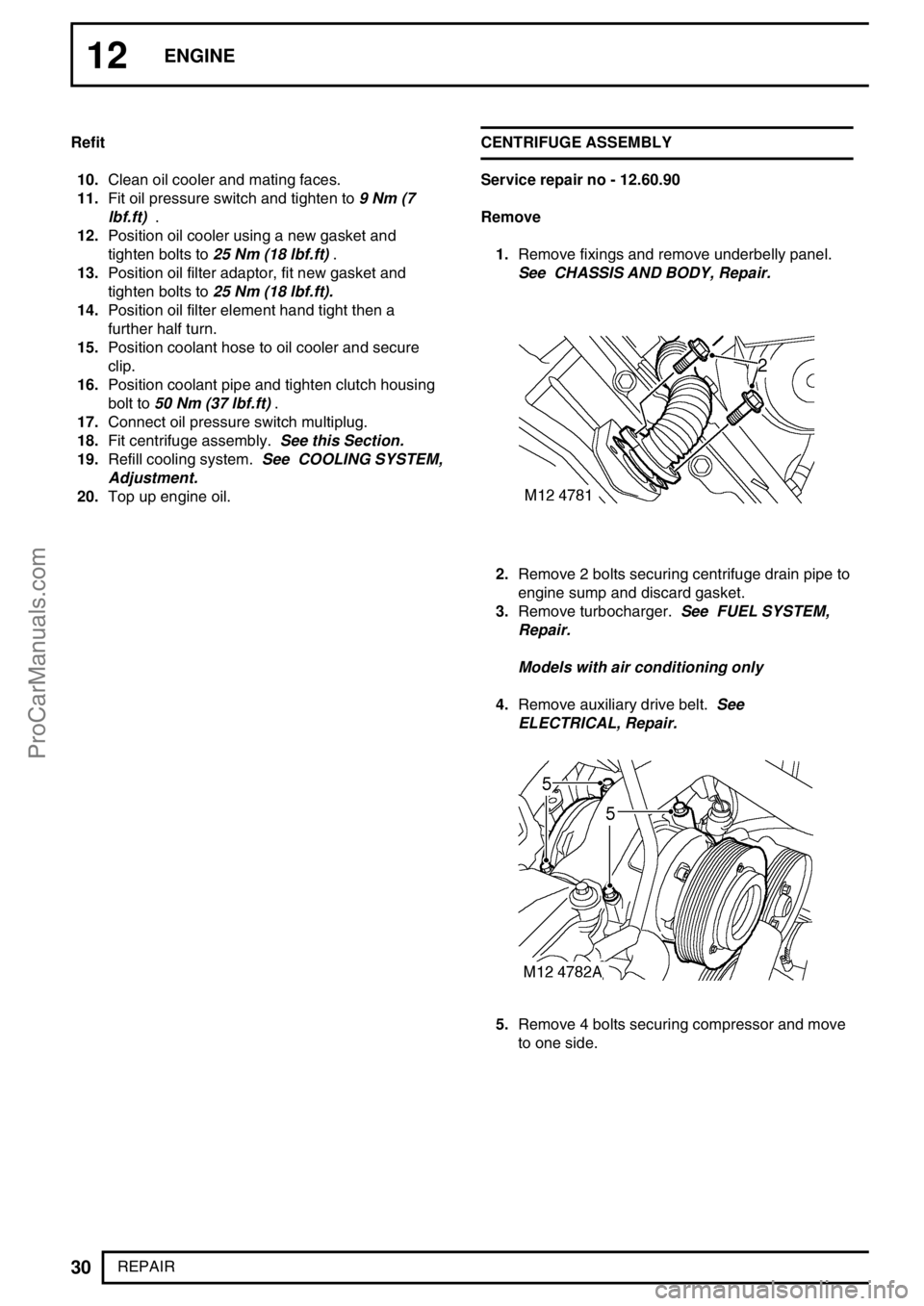

20.Top up engine oil.CENTRIFUGE ASSEMBLY

Service repair no - 12.60.90

Remove

1.Remove fixings and remove underbelly panel.

See CHASSIS AND BODY, Repair.

2.Remove 2 bolts securing centrifuge drain pipe to

engine sump and discard gasket.

3.Remove turbocharger.See FUEL SYSTEM,

Repair.

Models with air conditioning only

4.Remove auxiliary drive belt.See

ELECTRICAL, Repair.

5.Remove 4 bolts securing compressor and move

to one side.

ProCarManuals.com

Page 164 of 667

ENGINE

5

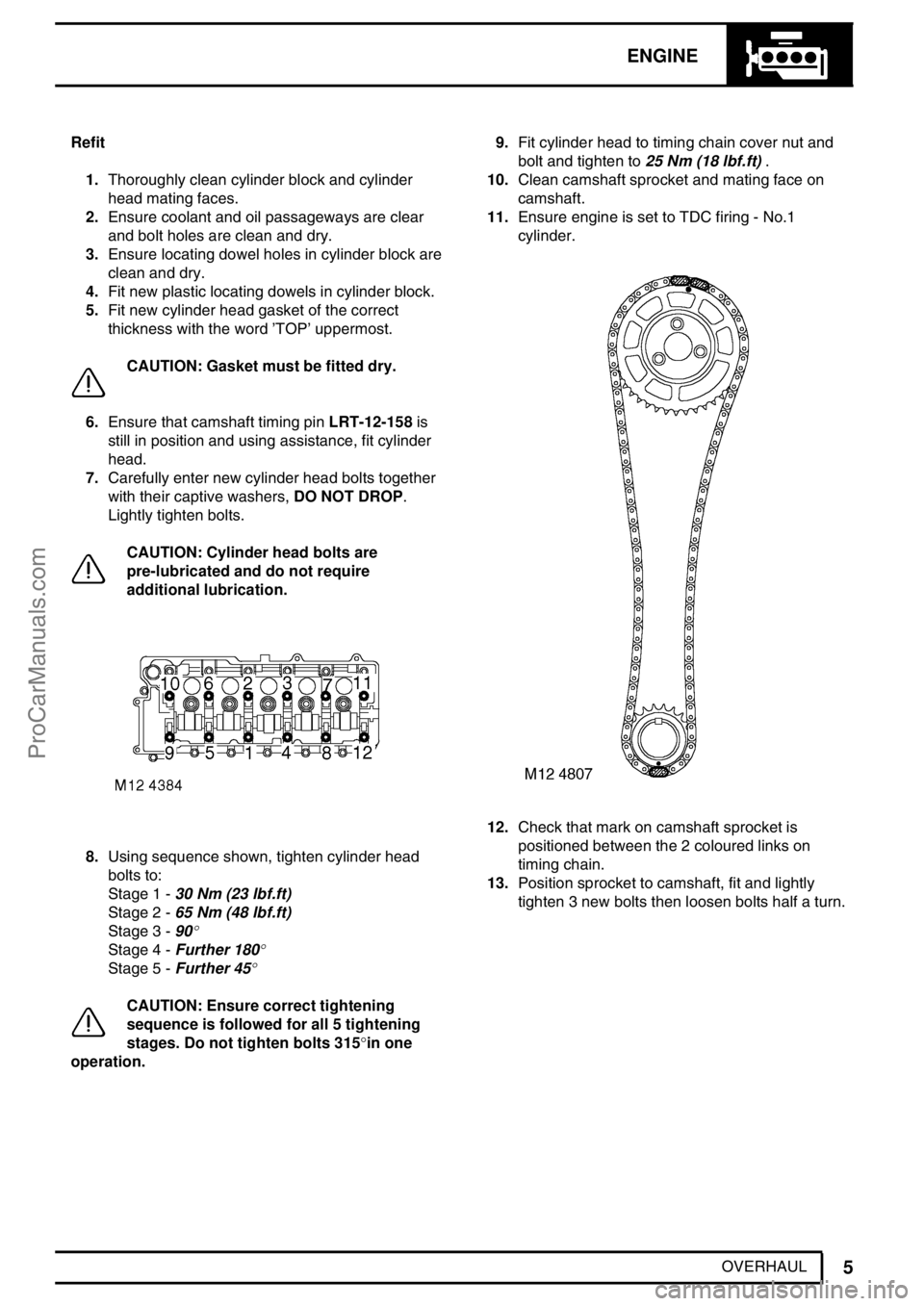

OVERHAUL Refit

1.Thoroughly clean cylinder block and cylinder

head mating faces.

2.Ensure coolant and oil passageways are clear

and bolt holes are clean and dry.

3.Ensure locating dowel holes in cylinder block are

clean and dry.

4.Fit new plastic locating dowels in cylinder block.

5.Fit new cylinder head gasket of the correct

thickness with the word’TOP’uppermost.

CAUTION: Gasket must be fitted dry.

6.Ensure that camshaft timing pinLRT-12-158is

still in position and using assistance, fit cylinder

head.

7.Carefully enter new cylinder head bolts together

with their captive washers,DO NOT DROP.

Lightly tighten bolts.

CAUTION: Cylinder head bolts are

pre-lubricated and do not require

additional lubrication.

8.Using sequence shown, tighten cylinder head

bolts to:

Stage 1 -30 Nm (23 lbf.ft)

Stage 2 -65 Nm (48 lbf.ft)

Stage 3 -90

°

Stage 4 -Further 180°

Stage 5 -Further 45°

CAUTION: Ensure correct tightening

sequence is followed for all 5 tightening

stages. Do not tighten bolts 315°in one

operation.9.Fit cylinder head to timing chain cover nut and

bolt and tighten to25 Nm (18 lbf.ft).

10.Clean camshaft sprocket and mating face on

camshaft.

11.Ensure engine is set to TDC firing - No.1

cylinder.

12.Check that mark on camshaft sprocket is

positioned between the 2 coloured links on

timing chain.

13.Position sprocket to camshaft, fit and lightly

tighten 3 new bolts then loosen bolts half a turn.

ProCarManuals.com

Page 170 of 667

ENGINE

11

OVERHAUL

23.Remove 3 bolts and remove fuel connector

block from cylinder head.

24.Remove and discard gasket,’O’ring and fuel

filter.

25.Remove spacer block and gasket (if fitted).Cylinder head and camshaft carrier - cleaning

1.Thoroughly clean cylinder head mating faces,

ensure oil and coolant passages are clear and

bolt holes are clean and dry.

CAUTION: Take care to ensure that EUI

drillings are clear.

2.Using suitable solvent, remove all traces of

sealant and gasket material.

CAUTION: Do not use metal scrapers.

3.Remove all traces of oil from camshaft bearings

and journals.

4.Clean glow plug threads.

Cylinder head - Inspection

1.Check core plugs for signs of leakage and

corrosion, seal replacement plugs with Loctite

243.

2.Check cylinder head for warping across centre

and from corner to corner.

Maximum cylinder head warp =0.1 mm (0.004

in).

CAUTION: Cylinder heads may not be

refaced, replace the head assembly if

warping exceeds the limit given.

ProCarManuals.com

Page 209 of 667

17EMISSION CONTROL

8

DESCRIPTION AND OPERATION EXHAUST GAS RECIRCULATION

The exhaust gas recirculation (EGR) valve permits a controlled amount of exhaust gas to combine with the fresh

air entering the engine. The exhaust gas reduces the combustion temperature by delaying the fuel burning rate,

which assists in reducing the quantity of oxides of nitrogen.

On EU3 models, an EGR cooler is employed to further reduce the combustion temperature. By passing the

exhaust gas through a bundle of pipes flooded by coolant, the density of the exhaust gas going into the engine is

increased. This process further reduces the amount of NO

2in the exhaust.

Recirculation of too much exhaust gas can result in higher emissions of soot, HC and CO due to insufficient air.

The recirculated exhaust gas must be limited so that there is sufficient oxygen available for combustion of the

injected fuel in the combustion chamber. To do this the ECM is used to control the precise quantity of exhaust gas

to be recirculated in accordance with the prevailing operating conditions. Influencing factors include:

The mass of air flow detected by the MAF sensor.

The ambient air temperature detected by the AAP sensor. This is used to initiate adjustments to reduce the

amount of smoke produced at high altitudes.

The mass of air flow detected by the MAF sensor.

The ambient air temperature detected by the AAP sensor. This is used to initiate adjustments to reduce the

amount of smoke produced at high altitudes.

Other factors which are taken into consideration by the engine management system for determining the optimum

operating condition include:

Manifold inlet air temperature

Coolant temperature

Engine speed

Fuel delivered

The main components of the EGR system are as follows.

ProCarManuals.com

Page 222 of 667

18 - ENGINE MANAGEMENT SYSTEM

CONTENTS

Page

DESCRIPTION AND OPERATION

COMPONENT LOCATION 2...................................................................................

DESCRIPTION 5.....................................................................................................

ENGINE CONTROL MODULE (ECM) 6.................................................................

SENSOR - MASS AIR FLOW (MAF) 7....................................................................

SENSOR - AMBIENT AIR PRESSURE AND 8.......................................................

SENSOR - MANIFOLD ABSOLUTE PRESSURE 9................................................

SENSOR - ENGINE COOLANT TEMPERATURE 11.............................................

SENSOR - CRANKSHAFT SPEED AND 12...........................................................

SENSOR - THROTTLE POSITION (TP) 14............................................................

SENSOR - THROTTLE POSITION (TP) 15............................................................

ELECTRONIC UNIT INJECTOR (EUI) 18...............................................................

SENSOR - FUEL TEMPERATURE (FT) 20............................................................

RELAY - FUEL PUMP 21........................................................................................

RELAY - MAIN 21...................................................................................................

SWITCH - BRAKE PEDAL 22.................................................................................

SWITCH - CLUTCH PEDAL 22...............................................................................

MODULATOR - EXHAUST GAS REGULATOR (EGR) 23.....................................

WARNING LAMP - GLOW PLUG 23......................................................................

GLOW PLUGS 24...................................................................................................

TURBOCHARGER 26.............................................................................................

INTERCOOLER 27.................................................................................................

OPERATION 28......................................................................................................

REPAIR

ENGINE CONTROL MODULE (ECM) 1.................................................................

SENSOR - ENGINE COOLANT TEMPERATURE (ECT) 1....................................

SENSOR - CRANKSHAFT SPEED AND POSITION (CKP) 2................................

ProCarManuals.com

Page 226 of 667

ENGINE MANAGEMENT SYSTEM

3

DESCRIPTION AND OPERATION 1.Mass Air Flow (MAF) sensor.

2.Engine Coolant Temperature (ECT) sensor.

3.Glow plugs.

4.Manifold Absolute Pressure (MAP) / Inlet Air Temperature (IAT) sensor.

5.Fuel pump relay.

6.Engine Control Module (ECM).

7.Air Conditioning (A/C) and cooling fan relay.

8.Fuel Temperature (FT) sensor.

9.Crankshaft Speed and Position (CKP) sensor.

10.Electronic Unit Injectors (EUI).

11.Ambient Air Pressure (AAP) sensor.

ProCarManuals.com