gearbox LAND ROVER DEFENDER 1999 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 135 of 667

12ENGINE

10

REPAIR Refit

39.Clean mating faces of cylinder head and cylinder

block.

40.Check cylinder head for warping, across centre

and from corner to corner:

Maximum warp = 0.10 mm (0.004 in)

CAUTION: Cylinder heads may not be

refaced, replace cylinder head assembly if

warping exceeds figure given.

41.Ensure coolant and oil passages are clean.

42.Clean dowel holes and fit new dowels.

43.Fit new cylinder head gasket of the correct

thickness with the word’TOP’uppermost.

44.Using assistance, fit cylinder head and locate on

to dowels.

45.Carefully enter new cylinder head bolts together

with their captive washers,DO NOT DROP.

Lightly tighten bolts.

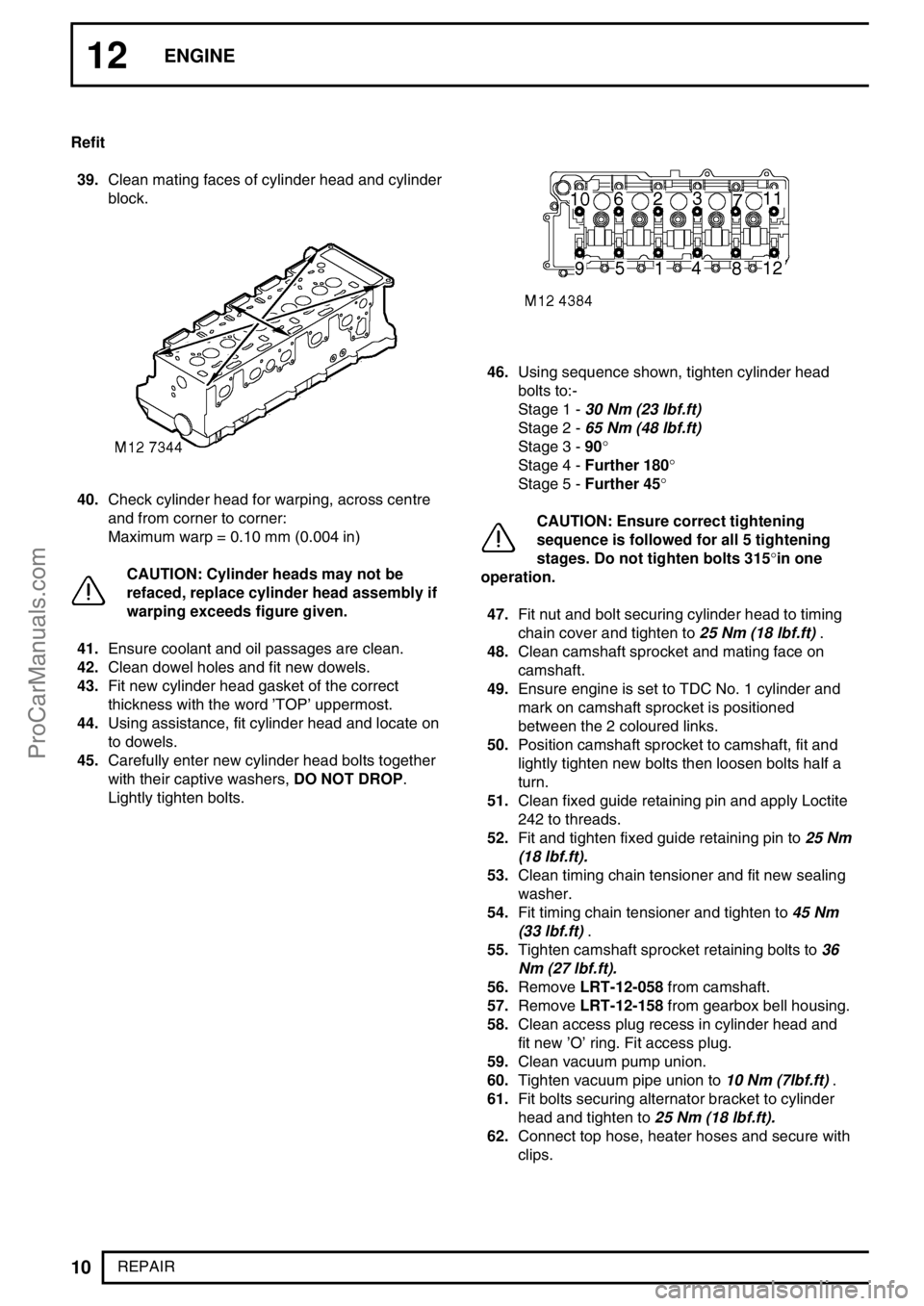

46.Using sequence shown, tighten cylinder head

bolts to:-

Stage 1 -30 Nm (23 lbf.ft)

Stage 2 -65 Nm (48 lbf.ft)

Stage 3 -90°

Stage 4 -Further 180°

Stage 5 -Further 45°

CAUTION: Ensure correct tightening

sequence is followed for all 5 tightening

stages. Do not tighten bolts 315°in one

operation.

47.Fit nut and bolt securing cylinder head to timing

chain cover and tighten to25 Nm (18 lbf.ft).

48.Clean camshaft sprocket and mating face on

camshaft.

49.Ensure engine is set to TDC No. 1 cylinder and

mark on camshaft sprocket is positioned

between the 2 coloured links.

50.Position camshaft sprocket to camshaft, fit and

lightly tighten new bolts then loosen bolts half a

turn.

51.Clean fixed guide retaining pin and apply Loctite

242 to threads.

52.Fit and tighten fixed guide retaining pin to25 Nm

(18 lbf.ft).

53.Clean timing chain tensioner and fit new sealing

washer.

54.Fit timing chain tensioner and tighten to45 Nm

(33 lbf.ft).

55.Tighten camshaft sprocket retaining bolts to36

Nm (27 lbf.ft).

56.RemoveLRT-12-058from camshaft.

57.RemoveLRT-12-158from gearbox bell housing.

58.Clean access plug recess in cylinder head and

fit new’O’ring. Fit access plug.

59.Clean vacuum pump union.

60.Tighten vacuum pipe union to10 Nm (7lbf.ft).

61.Fit bolts securing alternator bracket to cylinder

head and tighten to25 Nm (18 lbf.ft).

62.Connect top hose, heater hoses and secure with

clips.

ProCarManuals.com

Page 142 of 667

ENGINE

17

REPAIR

23.Disconnect oil pressure switch multiplug.

24.Release engine harness from underside of inlet

manifold and tie aside.

25.Release clips and remove coolant top hose from

cylinder head and coolant rail.

26.Remove 4 bolts and move A/C compressor

aside.

27.Remove 3 bolts and remove PAS pump pulley.

28.Remove 4 bolts and move PAS pump aside.

29.Raise vehicle on ramp.

30.Remove 6 bolts securing gearbox housing to

engine.

31.Lower vehicle ramp.

32.Remove 2 upper bolts securing gearbox housing

to engine.

33.Remove bolt securing engine closing panel to

gearbox.

34.Release clip and coolant hose from engine oil

cooler.

ProCarManuals.com

Page 143 of 667

12ENGINE

18

REPAIR

35.Remove 2 bolts and remove acoustic cover from

rear of cylinder head.

36.FitLRT-12-138to suitable lifting chains and

connect to lifting eyes on engine.

37.Remove 2 nuts from RH and LH front engine

mountings.

38.Fit trolley jack to support gearbox.

39.With assistance raise chains and remove engine

from vehicle.Refit

40.With assistance, raise engine from bench and

position in vehicle.

41.With assistance, align engine to gearbox input

shaft.

42.Position 2 upper bolts securing gearbox housing

to engine and tighten to50 Nm (37 lbf.ft).

43.Lower engine onto mountings and tighten nuts to

85 Nm (63 lbf.ft).

44.RemoveLRT-12-138from engine.

45.Fit and tighten bolt securing engine closing panel

to gearbox.

46.Raise vehicle on ramp.

47.Fit bolts securing gearbox housing to engine and

tighten to50 Nm (37 lbf.ft).

48.Lower ramp.

49.Fit acoustic cover to rear of cylinder head and

tighten bolts.

50.Position coolant hose to engine oil cooler and

secure clip.

51.Position PAS pump and tighten bolts to25 Nm

(18 lbf.ft).

52.Position PAS pulley and tighten bolts to25 Nm

(18 lbf.ft).

53.Position A/C compressor and tighten bolts to25

Nm (18 lbf.ft).

54.Route engine harness beneath inlet manifold

and connect multiplugs to oil pressure switch,

A/C compressor, and ECT sensor.

55.Fit and tighten bolts securing engine harness to

camshaft carrier.

56.Connect multiplug to alternator.

57.Connect battery lead to alternator and tighten

nut.

58.Clean CKP sensor and mating face.

CAUTION: If originally fitted:- Fit spacer to

CKP sensor.

59.Using a new’O’ring, fit CKP sensor, tighten bolt

to10 Nm (7 lbf.ft).

60.Connect CKP sensor multiplug.

61.Connect multiplugs to EGR solenoid, inlet

manifold sensor, injector harness, fuel

temperature sensor and CKP sensor.

62.Connect glow plug leads.

63.Connect multiplug to condensor cooling fan.

64.Connect vacuum hose to EGR valve.

65.Connect EGR vacuum hose to vacuum pipe.

66.Position pipe to vacuum pump and secure pipe

to acoustic cover clips.

67.Position fuel cooler. Apply Loctite 242 to bolts

and tighten to18 Nm (13 lbf.ft).

68.Disconnect fuel hose from connector block and

connect to fuel cooler.

69.Connect fuel hoses to fuel cooler and connector

block on cylinder head.

ProCarManuals.com

Page 146 of 667

ENGINE

21

REPAIR Refit

11.Fit mounting and mounting bracket.

12.Fit mounting bracket to cylinder block bolts and

tighten to48 Nm (35 lbf.ft).

13.Fit nuts securing mounting to chassis and tighten

to85 Nm (63 lbf. ft).

14.Fit mounting to mounting bracket nut and tighten

to85 Nm (63 lbf.ft).

15.Remove engine support chains.

16.Position fuel cooler. Apply Loctite 242 to bolts

and tighten to18 Nm (13 lbf.ft).

17.Remove stand(s) and lower vehicle.

18.Reconnect battery negative lead.

19.Fit engine acoustic cover.See this Section.MOUNTING - GEARBOX - REAR - LH

Service repair no - 12.45.07

Remove

1.Raise vehicle on ramp.

2.Position jack to support gearbox.

3.Remove 4 bolts securing mounting bracket to

transfer gearbox.

4.Remove 2 nuts, remove mounting and mounting

bracket.

5.Remove heat shield from mounting.

Refit

6.Clean mounting and mating faces.

7.Position heat shield to mounting.

8.Position mounting and mounting bracket and

tighten nuts to48 Nm (35 lbf.ft)and bolts to85

Nm (63 lbf. ft).

9.Lower support jack.

10.Lower vehicle.

ProCarManuals.com

Page 147 of 667

12ENGINE

22

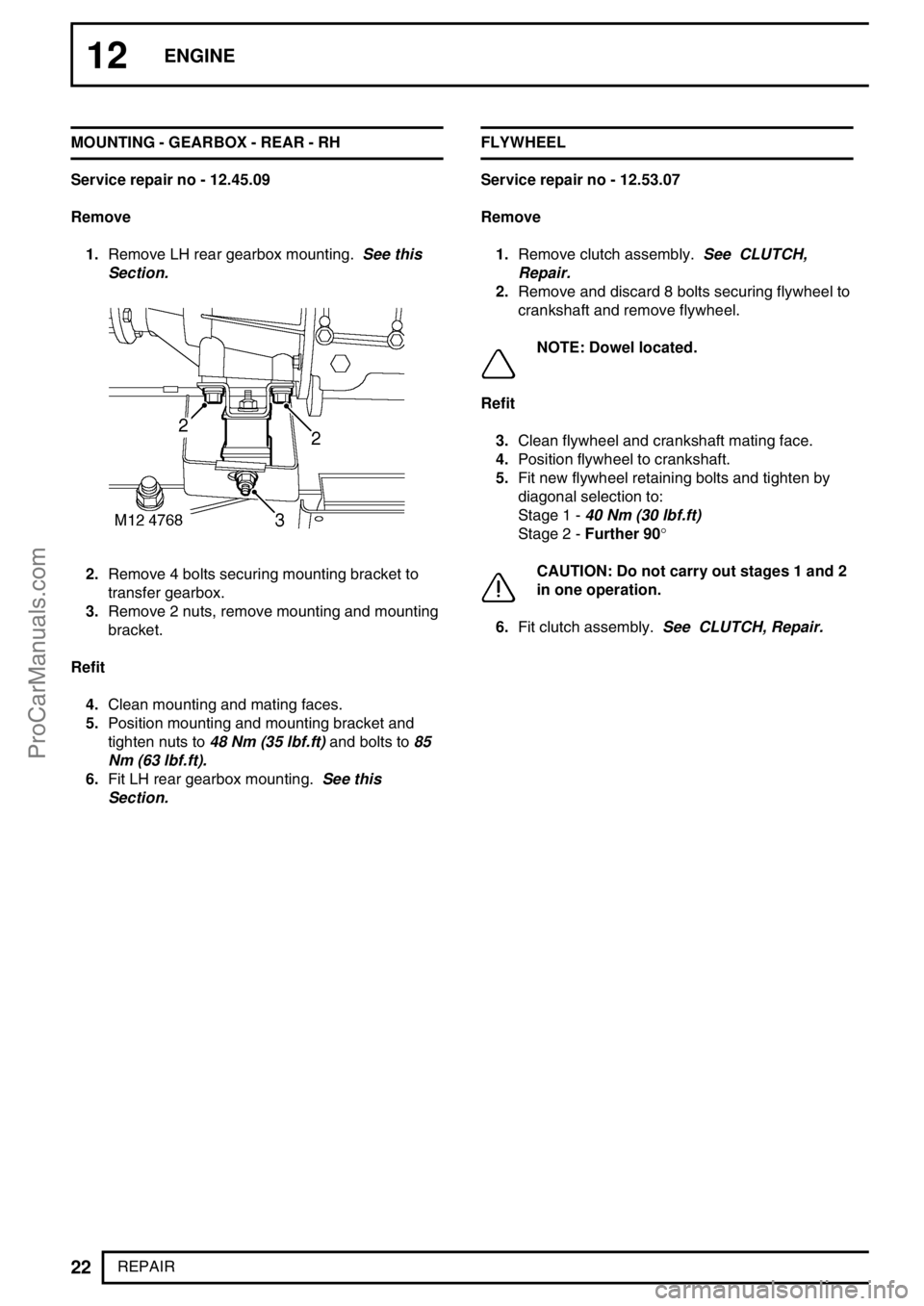

REPAIR MOUNTING - GEARBOX - REAR - RH

Service repair no - 12.45.09

Remove

1.Remove LH rear gearbox mounting.See this

Section.

2.Remove 4 bolts securing mounting bracket to

transfer gearbox.

3.Remove 2 nuts, remove mounting and mounting

bracket.

Refit

4.Clean mounting and mating faces.

5.Position mounting and mounting bracket and

tighten nuts to48 Nm (35 lbf.ft)and bolts to85

Nm (63 lbf.ft).

6.Fit LH rear gearbox mounting.See this

Section.FLYWHEEL

Service repair no - 12.53.07

Remove

1.Remove clutch assembly.See CLUTCH,

Repair.

2.Remove and discard 8 bolts securing flywheel to

crankshaft and remove flywheel.

NOTE: Dowel located.

Refit

3.Clean flywheel and crankshaft mating face.

4.Position flywheel to crankshaft.

5.Fit new flywheel retaining bolts and tighten by

diagonal selection to:

Stage 1 -40 Nm (30 lbf.ft)

Stage 2 -Further 90°

CAUTION: Do not carry out stages 1 and 2

in one operation.

6.Fit clutch assembly.See CLUTCH, Repair.

ProCarManuals.com

Page 151 of 667

12ENGINE

26

REPAIR

15.Position oil pump drive sprocket and chain on to

oil pump ensuring that the’D’shape on the drive

sprocket is located on flat on the oil pump drive

shaft.

16.Clean oil pump drive sprocket retaining bolt and

apply Loctite 242 to bolt threads.

17.Fit oil pump drive sprocket retaining bolt and

tighten to25 Nm (18 lbf.ft).

18.Fit new sump gasket.See this Section.GASKET - ENGINE TO SUMP

Service repair no - 12.60.38

Remove

1.Remove battery cover.

2.Disconnect battery negative lead.

3.Remove exhaust front pipe.See MANIFOLD

AND EXHAUST SYSTEM, Repair.

4.Drain engine oil.

5.Loosen 4 bolts securing sump to gearbox bell

housing.

6.Remove 2 bolts securing centrifuge drain pipe to

sump and discard gasket.

7.Using sequence shown and noting their fitted

position, remove 20 bolts securing sump.

8.Remove sump, remove and discard gasket.

CAUTION: Do not lever between sump and

cylinder block.

ProCarManuals.com

Page 152 of 667

ENGINE

27

REPAIR Refit

9.Clean sump and mating faces.

10.Apply a bead of sealant, Part No. STC 3254 to

joint faces of timing chain cover and crankshaft

rear oil seal.

11.Position new sump gasket.

CAUTION: Gasket must be fitted dry.

12.Position sump, fit bolts ensuring they are in their

correct fitted position, lightly tighten bolts.

13.Fit bolts securing sump to gearbox bell housing

and tighten to15 Nm (11 lbf.ft).

14.Using sequence shown, tighten sump bolts to25

Nm (18 lbf.ft).

15.Tighten sump to gearbox bell housing bolts to50

Nm (37 lbf ft).

16.Fit new gasket to centrifuge drain pipe and

tighten bolts to10 Nm (7 lbf.ft).

17.Fit exhaust front pipe.See MANIFOLD AND

EXHAUST SYSTEM, Repair.

18.Refill engine with oil.

19.Reconnect battery negative lead.

20.Refit battery cover.

ProCarManuals.com

Page 253 of 667

18ENGINE MANAGEMENT SYSTEM

2

REPAIR SENSOR - CRANKSHAFT SPEED AND POSITION

(CKP)

Service repair no - 18.30.12

Remove

1.Disconnect CKP sensor multiplug.

2.Remove bolt, remove CKP sensor from gearbox

housing and discard’O’ring.

3.If fitted, collect spacer.

Refit

4.Clean gearbox housing and CKP sensor.

5.If fitted, refit spacer.

6.Fit new’O’ring, position CKP sensor to gearbox

housing and tighten bolt to10 Nm (7 lbf.ft).

7.Connect sensor multiplug.

ProCarManuals.com

Page 290 of 667

COOLING SYSTEM

3

DESCRIPTION AND OPERATION

NOTE: Inset A shows differences for Pre

EU3 models

1.Pressure cap

2.Overflow pipe

3.Heater return hose

4.Heater matrix

5.Heater inlet hose

6.Oil cooler return pipe - EU3 models

7.Connecting hose

8.Oil cooler housing assembly

9.Heater inlet pipe

10.Connecting hose

11.Outlet housing

12.Engine Coolant Temperature (ECT) sensor

13.Bleed screw

14.Radiator top hose

15.Radiator - upper

16.Intercooler

17.Gearbox oil cooler

18.Radiator - lower

19.Viscous fan

20.Drain plug

21.Connecting hose

22.Fuel cooler feed hose

23.Radiator bottom hose

24.Thermostat housing

25.Connecting hose

26.Coolant pump feed pipe

27.Coolant by-pass pipe

28.Radiator bleed pipe

29.Connecting hose

30.Coolant pump

31.Fuel cooler

32.Heater/expansion tank return hose

33.Expansion tank

34.EGR Cooler - EU3 models

35.Connecting hose - EU3 models

36.Connecting hose - EU3 models

37.Hose - EGR Cooler to oil cooler return pipe -

EU3 models

38.Radiator lower feed hose - Pre EU3 models

39.Oil cooler return pipe - Pre EU3 models

ProCarManuals.com

Page 294 of 667

COOLING SYSTEM

7

DESCRIPTION AND OPERATION Radiator

The 44 row radiator is located at the front of the vehicle in the engine compartment. The cross flow type radiator is

manufactured from aluminium with moulded plastic end tanks interconnected with tubes. The bottom four rows are

separate from the upper radiator and form the lower radiator for the fuel cooler. Aluminium fins are located

between the tubes and conduct heat from the hot coolant flowing through the tubes, reducing the coolant

temperature as it flows through the radiator. Air intake from the front of the vehicle when moving carries the heat

away from the fins. When the vehicle is stationary, the viscous fan draws air through the radiator fins to prevent

the engine from overheating.

Two connections at the top of the radiator provide for the attachment of the top hose from the outlet housing and

bleed pipe to the expansion tank. Three connections at the bottom of the radiator allow for the attachment of the

bottom hose to the thermostat housing and the return hose from the oil cooler and the feed hose to the fuel cooler.

The bottom four rows of the lower radiator are dedicated to the fuel cooler. The upper of the two connections at

the bottom of the radiator receives coolant from the oil cooler. This is fed through the four rows of the lower

radiator in a dual pass and emerges at the lower connection. The dual pass lowers the coolant temperature by up

to 24°C before being passed to the fuel cooler. Two smaller radiators are located in front of the cooling radiator.

The upper radiator is the intercooler for the air intake system and the lower radiator provides cooling of the

gearbox oil.

Pipes and Hoses

The coolant circuit comprises flexible hoses and metal formed pipes which direct the coolant into and out of the

engine, radiator and heater matrix. Plastic pipes are used for the bleed and overflow pipes to the expansion tank.

A bleed screw is installed in the radiator top hose and is used to bleed air during system filling. A drain plug to

drain the heater and cylinder block circuit of coolant is located on the underside of the coolant pump feed pipe.

Oil Cooler

The oil cooler is located on the left hand side of the engine block behind the oil centrifuge and oil filter. Oil from the

oil pump is passed through a heat exchanger which is surrounded by coolant in a housing on the side of the

engine.

Full water pump flow is directed along the cooler housing which also distributes the flow evenly along the block

into three core holes for cylinder cooling. This cools the engine oil before it is passed into the engine. A small

percentage of the coolant from the oil cooler passes into a metal pipe behind the engine. It then flows into the

lower radiator via a hose.

Fuel Cooler

The fuel cooler is located on the right hand side of the engine and is attached to the inlet manifold. The cooler is

cylindrical in design and has a coolant feed connection at its forward end. A’T’connection at the rear of the cooler

provides a connection for the coolant return from the heater matrix and coolant return from the fuel cooler.

The’T’connection houses a thermostat which opens at approximately 82°C. This prevents the cooler operating in

cold climates. Two quick release couplings on the cooler allow for the connection of the fuel feed from the

pressure regulator and return to the fuel tank. A counter flow system is used within the cooler.

Fuel flows around a coolant jacket within the cooler and flows from the back to the front of the cooler. As the hot

fuel cools travelling slowly forwards it meets progressively colder coolant travelling in the opposite direction

maintaining a differential cooling effect.

ProCarManuals.com