gearbox LAND ROVER DEFENDER 1999 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 326 of 667

CLUTCH

3

DESCRIPTION AND OPERATION 1.Brake/clutch reservoir

2.Connecting hose

3.Bolt - 2 off

4.Master cylinder

5.Clutch pedal

6.Gearbox housing

7.Primary driveshaft

8.Bolt - 2 off

9.Slave cylinder

10.Bleed nipple

11.Pressure plate

12.Drive plate

13.Dual mass flywheel

14.Metal hydraulic pipe

15.Ball spigot

16.Clutch release bearing sleeve

17.Bolt - 2 off

18.Pivot washer

19.Release lever

20.Release bearing

21.Retaining clip

22.Bolt

23.Plastic hydraulic pipe

ProCarManuals.com

Page 329 of 667

33CLUTCH

6

DESCRIPTION AND OPERATION DESCRIPTION

General

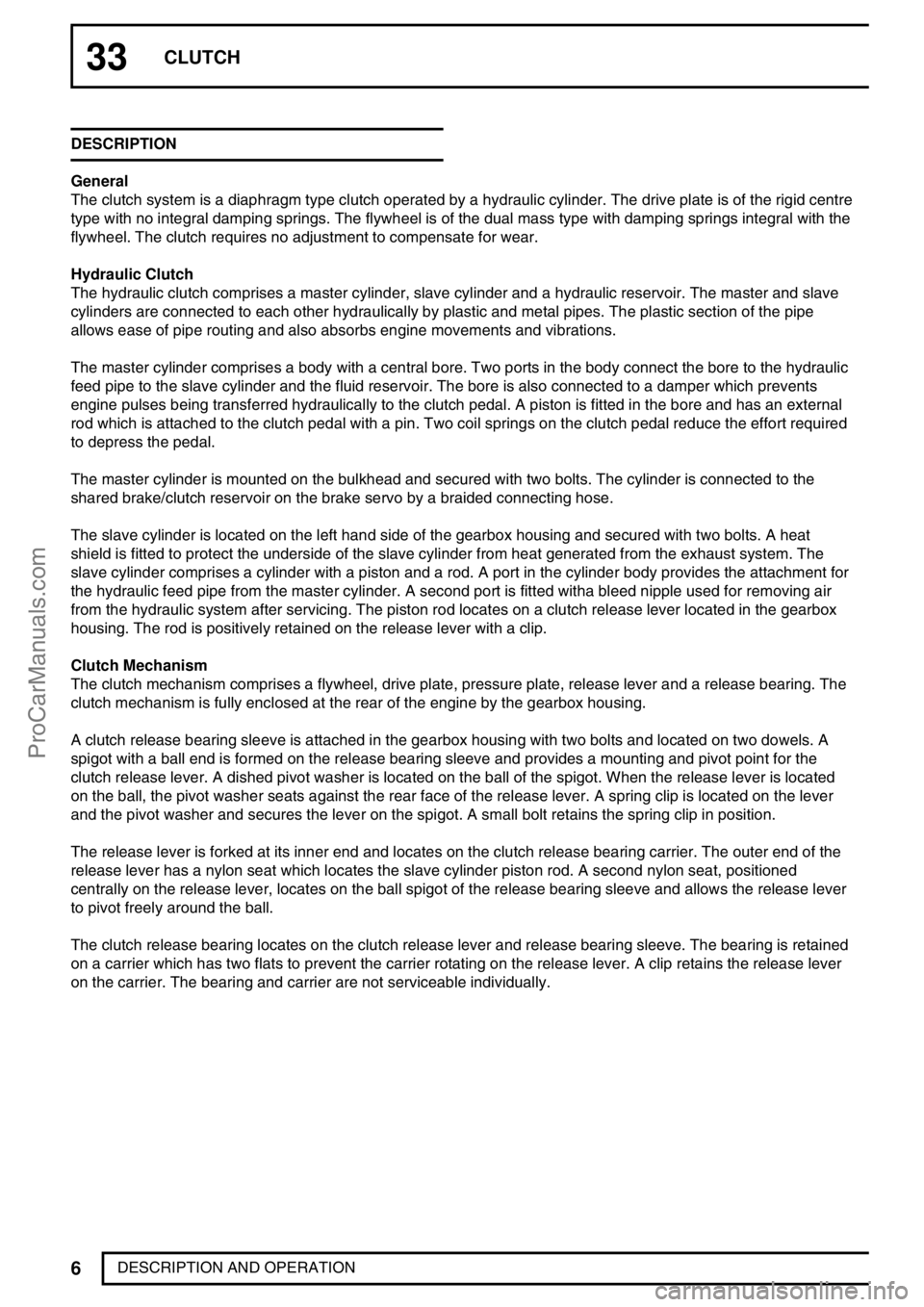

The clutch system is a diaphragm type clutch operated by a hydraulic cylinder. The drive plate is of the rigid centre

type with no integral damping springs. The flywheel is of the dual mass type with damping springs integral with the

flywheel. The clutch requires no adjustment to compensate for wear.

Hydraulic Clutch

The hydraulic clutch comprises a master cylinder, slave cylinder and a hydraulic reservoir. The master and slave

cylinders are connected to each other hydraulically by plastic and metal pipes. The plastic section of the pipe

allows ease of pipe routing and also absorbs engine movements and vibrations.

The master cylinder comprises a body with a central bore. Two ports in the body connect the bore to the hydraulic

feed pipe to the slave cylinder and the fluid reservoir. The bore is also connected to a damper which prevents

engine pulses being transferred hydraulically to the clutch pedal. A piston is fitted in the bore and has an external

rod which is attached to the clutch pedal with a pin. Two coil springs on the clutch pedal reduce the effort required

to depress the pedal.

The master cylinder is mounted on the bulkhead and secured with two bolts. The cylinder is connected to the

shared brake/clutch reservoir on the brake servo by a braided connecting hose.

The slave cylinder is located on the left hand side of the gearbox housing and secured with two bolts. A heat

shield is fitted to protect the underside of the slave cylinder from heat generated from the exhaust system. The

slave cylinder comprises a cylinder with a piston and a rod. A port in the cylinder body provides the attachment for

the hydraulic feed pipe from the master cylinder. A second port is fitted witha bleed nipple used for removing air

from the hydraulic system after servicing. The piston rod locates on a clutch release lever located in the gearbox

housing. The rod is positively retained on the release lever with a clip.

Clutch Mechanism

The clutch mechanism comprises a flywheel, drive plate, pressure plate, release lever and a release bearing. The

clutch mechanism is fully enclosed at the rear of the engine by the gearbox housing.

A clutch release bearing sleeve is attached in the gearbox housing with two bolts and located on two dowels. A

spigot with a ball end is formed on the release bearing sleeve and provides a mounting and pivot point for the

clutch release lever. A dished pivot washer is located on the ball of the spigot. When the release lever is located

on the ball, the pivot washer seats against the rear face of the release lever. A spring clip is located on the lever

and the pivot washer and secures the lever on the spigot. A small bolt retains the spring clip in position.

The release lever is forked at its inner end and locates on the clutch release bearing carrier. The outer end of the

release lever has a nylon seat which locates the slave cylinder piston rod. A second nylon seat, positioned

centrally on the release lever, locates on the ball spigot of the release bearing sleeve and allows the release lever

to pivot freely around the ball.

The clutch release bearing locates on the clutch release lever and release bearing sleeve. The bearing is retained

on a carrier which has two flats to prevent the carrier rotating on the release lever. A clip retains the release lever

on the carrier. The bearing and carrier are not serviceable individually.

ProCarManuals.com

Page 331 of 667

33CLUTCH

8

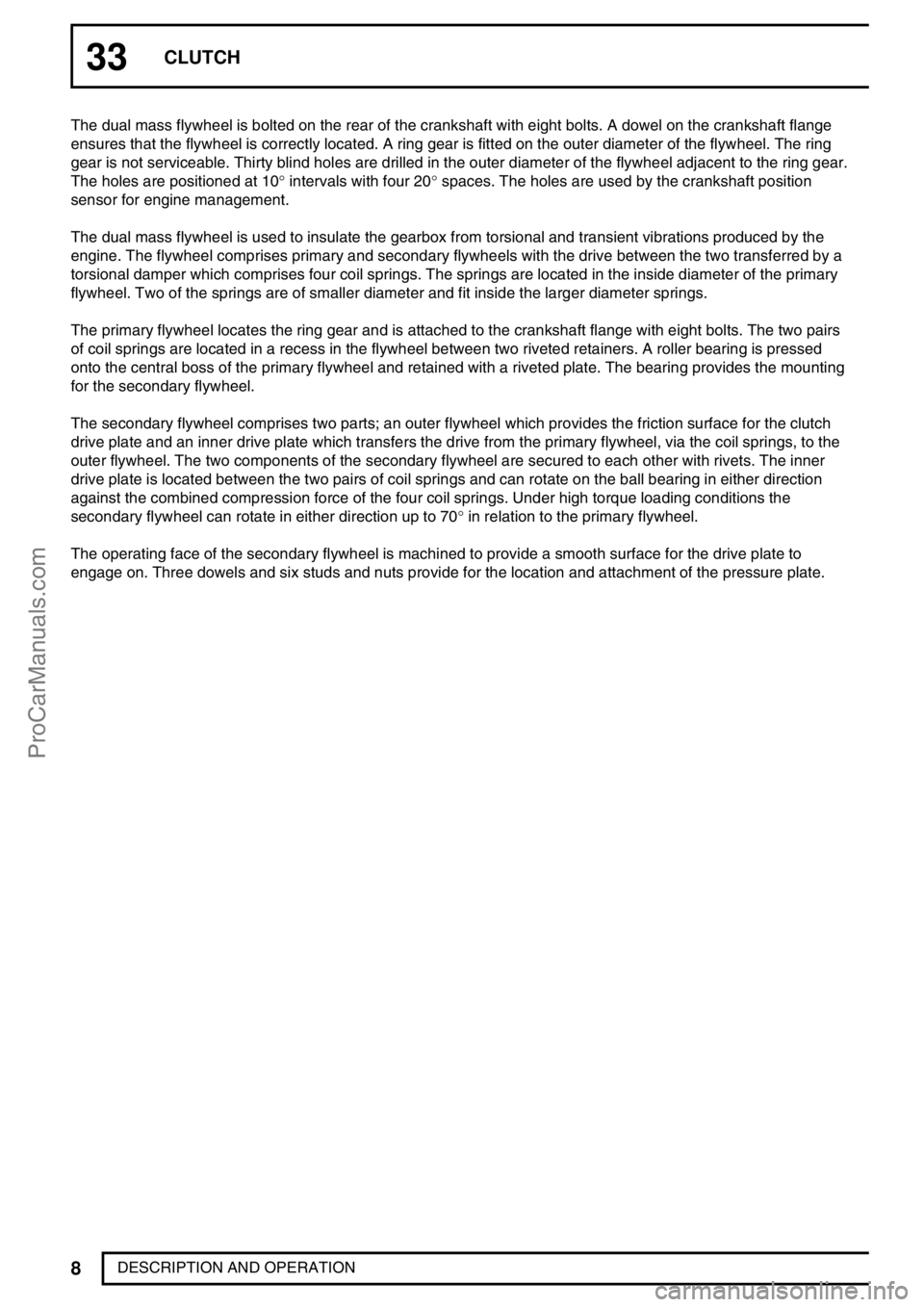

DESCRIPTION AND OPERATION The dual mass flywheel is bolted on the rear of the crankshaft with eight bolts. A dowel on the crankshaft flange

ensures that the flywheel is correctly located. A ring gear is fitted on the outer diameter of the flywheel. The ring

gear is not serviceable. Thirty blind holes are drilled in the outer diameter of the flywheel adjacent to the ring gear.

The holes are positioned at 10°intervals with four 20°spaces. The holes are used by the crankshaft position

sensor for engine management.

The dual mass flywheel is used to insulate the gearbox from torsional and transient vibrations produced by the

engine. The flywheel comprises primary and secondary flywheels with the drive between the two transferred by a

torsional damper which comprises four coil springs. The springs are located in the inside diameter of the primary

flywheel. Two of the springs are of smaller diameter and fit inside the larger diameter springs.

The primary flywheel locates the ring gear and is attached to the crankshaft flange with eight bolts. The two pairs

of coil springs are located in a recess in the flywheel between two riveted retainers. A roller bearing is pressed

onto the central boss of the primary flywheel and retained with a riveted plate. The bearing provides the mounting

for the secondary flywheel.

The secondary flywheel comprises two parts; an outer flywheel which provides the friction surface for the clutch

drive plate and an inner drive plate which transfers the drive from the primary flywheel, via the coil springs, to the

outer flywheel. The two components of the secondary flywheel are secured to each other with rivets. The inner

drive plate is located between the two pairs of coil springs and can rotate on the ball bearing in either direction

against the combined compression force of the four coil springs. Under high torque loading conditions the

secondary flywheel can rotate in either direction up to 70°in relation to the primary flywheel.

The operating face of the secondary flywheel is machined to provide a smooth surface for the drive plate to

engage on. Three dowels and six studs and nuts provide for the location and attachment of the pressure plate.

ProCarManuals.com

Page 334 of 667

CLUTCH

11

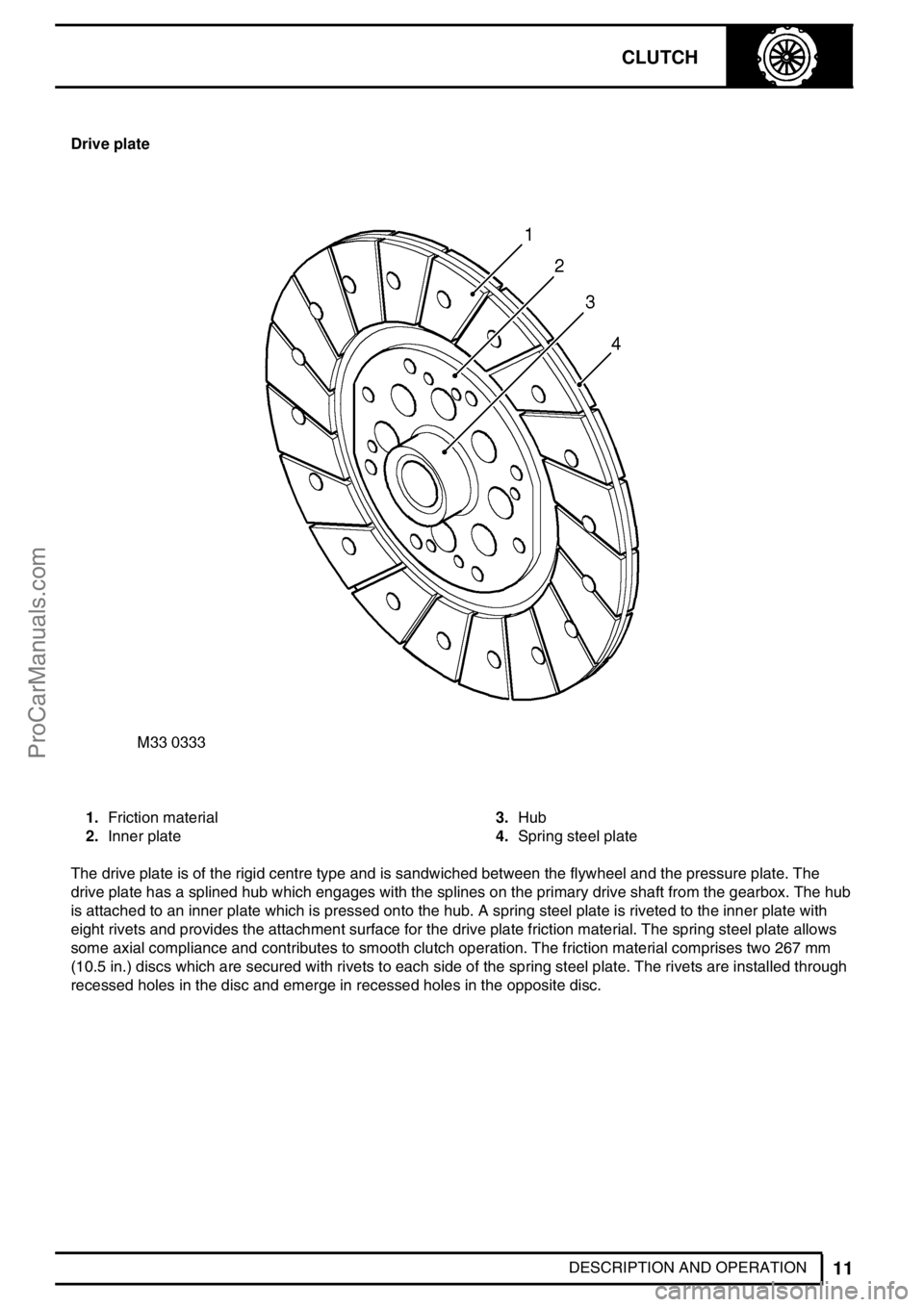

DESCRIPTION AND OPERATION Drive plate

1.Friction material

2.Inner plate3.Hub

4.Spring steel plate

The drive plate is of the rigid centre type and is sandwiched between the flywheel and the pressure plate. The

drive plate has a splined hub which engages with the splines on the primary drive shaft from the gearbox. The hub

is attached to an inner plate which is pressed onto the hub. A spring steel plate is riveted to the inner plate with

eight rivets and provides the attachment surface for the drive plate friction material. The spring steel plate allows

some axial compliance and contributes to smooth clutch operation. The friction material comprises two 267 mm

(10.5 in.) discs which are secured with rivets to each side of the spring steel plate. The rivets are installed through

recessed holes in the disc and emerge in recessed holes in the opposite disc.

ProCarManuals.com

Page 338 of 667

CLUTCH

1

REPAIR CLUTCH ASSEMBLY

Service repair no - 33.10.01.01

Remove

1.Remove gearbox assembly.See MANUAL

GEARBOX, Repair.

2.Restrain flywheel.

3.Working in sequence, loosen 6 nuts securing

clutch cover to flywheel.

4.Remove clutch cover and clutch plate.

Refit

5.Clean clutch cover and flywheel mating faces

and spigot bush in end of crankshaft.

6.Position clutch drive plate to flywheel with

’gearbox side’ facing towards gearbox.

7.PositionLRT-12-152alignment tool through

drive plate into spigot bearing in crankshaft.8.Fit clutch cover and locate on dowels.

9.Position clutch cover nuts and tighten in diagonal

sequence to25 Nm (18 lbf.ft).

10.Fit gearbox assembly.See MANUAL

GEARBOX, Repair.

ProCarManuals.com

Page 339 of 667

33CLUTCH

2

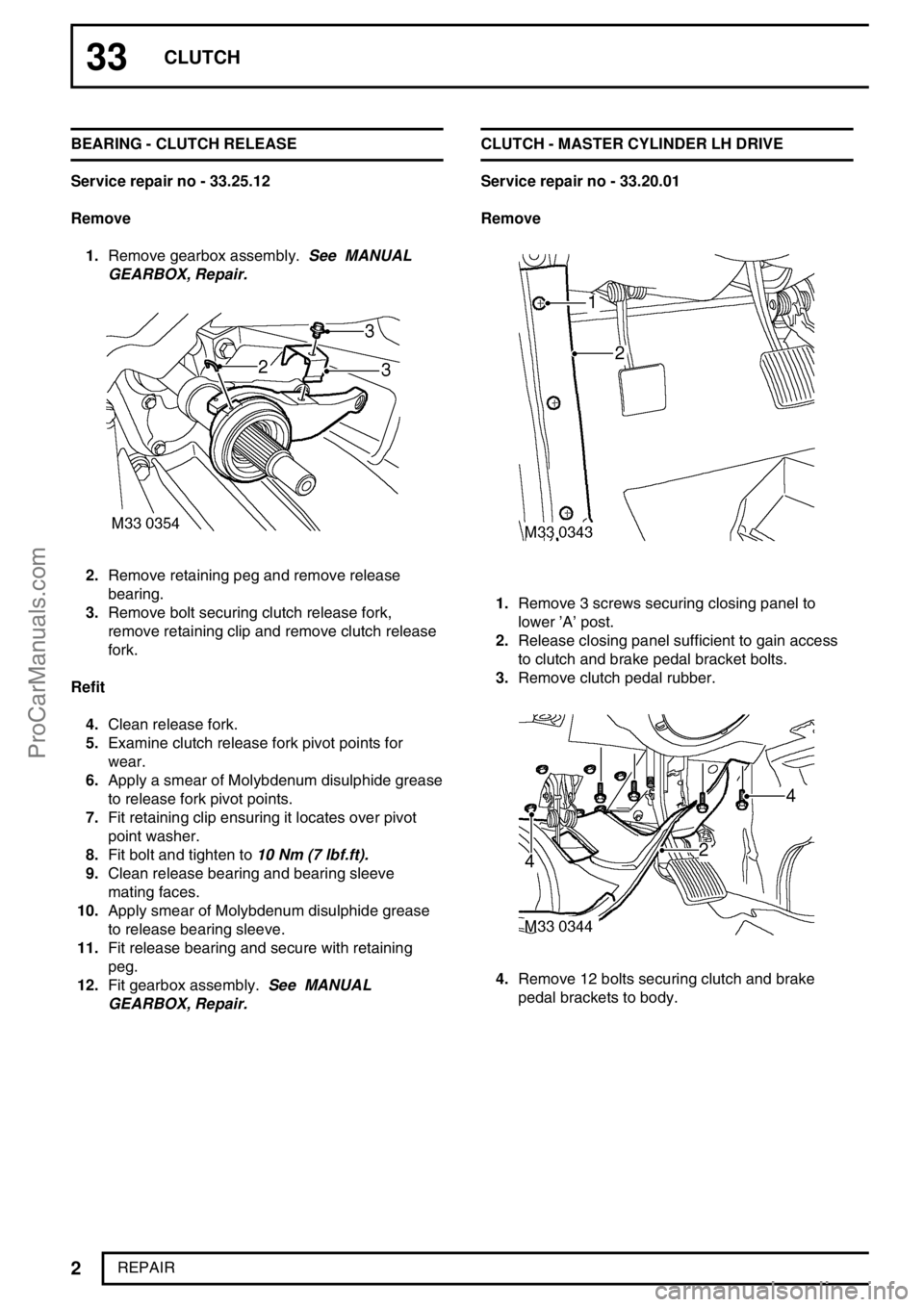

REPAIR BEARING - CLUTCH RELEASE

Service repair no - 33.25.12

Remove

1.Remove gearbox assembly.See MANUAL

GEARBOX, Repair.

2.Remove retaining peg and remove release

bearing.

3.Remove bolt securing clutch release fork,

remove retaining clip and remove clutch release

fork.

Refit

4.Clean release fork.

5.Examine clutch release fork pivot points for

wear.

6.Apply a smear of Molybdenum disulphide grease

to release fork pivot points.

7.Fit retaining clip ensuring it locates over pivot

point washer.

8.Fit bolt and tighten to10 Nm (7 lbf.ft).

9.Clean release bearing and bearing sleeve

mating faces.

10.Apply smear of Molybdenum disulphide grease

to release bearing sleeve.

11.Fit release bearing and secure with retaining

peg.

12.Fit gearbox assembly.See MANUAL

GEARBOX, Repair.CLUTCH - MASTER CYLINDER LH DRIVE

Service repair no - 33.20.01

Remove

1.Remove 3 screws securing closing panel to

lower’A’post.

2.Release closing panel sufficient to gain access

to clutch and brake pedal bracket bolts.

3.Remove clutch pedal rubber.

4.Remove 12 bolts securing clutch and brake

pedal brackets to body.

ProCarManuals.com

Page 342 of 667

37 - MANUAL GEARBOX

CONTENTS

Page

ADJUSTMENT

SPRINGS - GEAR LEVER BIAS 1..........................................................................

GEARBOX OIL - DRAIN AND REFILL 2.................................................................

REPAIR

COVER - FRONT - RESEAL AND FIT NEW INPUT SHAFT OIL SEAL 1..............

LEVER - GEAR CHANGE 3....................................................................................

MECHANISM AND HOUSING - GEAR SELECTOR 4...........................................

MECHANISM AND HOUSING - GEAR SELECTOR - RESEAL 6..........................

GEARBOX 7...........................................................................................................

SWITCH - REVERSE LIGHT 12.............................................................................

ProCarManuals.com

Page 344 of 667

MANUAL GEARBOX

1

ADJUSTMENT SPRINGS - GEAR LEVER BIAS

Service repair no - 37.16.26

Check

NOTE: The purpose of this adjustment is

to set both bolts so that the bias spring

legs apply equal pressure on both ends of

the gear lever cross pin when 3rd or 4th gear is

engaged. This will ensure that when the gear lever

is in neutral, the gear change mechanism is

automatically aligned for 3rd or 4th gears.

1.Remove gear lever knobs.

2.Release and remove gear lever gaiter.

3.Select 3rd or 4th gear.

4.Adjust the two adjusting screws until both legs of

the spring are approximately 0.5 mm (0.02 in)

clear of cross pin in the gear lever.

5.Apply a light load to the gear lever in a RH

direction and adjust the LH adjusting screw

downwards until the LH spring leg just makes

contact with the cross pin.

6.Repeat the same procedure for the RH adjusting

screw.

7.Lower both adjusting screws equal amounts until

the radial play is just eliminated. Tighten lock

nuts.

8.Return gear lever to neutral position and move

gear lever across the gate several times. The

gear lever should return to the 3rd and 4th gate.

9.Fit gear lever gaiter.

10.Fit gear lever knobs.

ProCarManuals.com

Page 345 of 667

37MANUAL GEARBOX

2

ADJUSTMENT GEARBOX OIL - DRAIN AND REFILL

Service repair no - 37.24.01

Drain

1.The oil should be drained when the gearbox is

warm and the vehicle is standing on a level

surface.

WARNING: Observe due care when

draining gearbox as oil can be very hot.

2.Raise vehicle on ramp.

3.Position container to collect oil.

4.Clean area around filler/level plug.

5.Remove filler/level plug.

NOTE: Later gearboxes: Use No. 55 Torx

bit to remove filler/level plug.

6.Remove gearbox drain plug and discard sealing

washer.Refill

1.Clean gearbox drain plug and fit new sealing

washer.

2.Fit gearbox drain plug and tighten to50 Nm (36

lbf.ft).

3.Fill gearbox with correct grade of oil.See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information.

4.Apply Loctite 290 to the filler/level plug and

tighten to30 Nm (22 lbf.ft).

5.Remove fluid container.

6.Lower vehicle on ramp.

ProCarManuals.com

Page 346 of 667

MANUAL GEARBOX

1

REPAIR COVER - FRONT - RESEAL AND FIT NEW INPUT

SHAFT OIL SEAL

Service repair no - 37.12.33.01

Remove

1.Remove gearbox.See this Section.

2.Remove retaining peg and remove release

bearing.

3.Remove bolt securing clutch release fork,

remove retaining clip and remove clutch release

fork.

4.Remove 2 bolts securing release bearing sleeve,

remove bearing sleeve.

5.Remove 6 bolts securing clutch housing, remove

housing.

6.Remove and discard 6 bolts securing front

cover, remove cover.

ProCarManuals.com