service LAND ROVER DEFENDER 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 195 of 667

12ENGINE

36

OVERHAUL 9.Check that the cut-out in piston skirt is

positioned above the oil squirt jet.

10.Repeat for other pistons in turn ensuring that

pistons and connecting rods are fitted in cylinder

bores from which they were removed.

11.Fit connecting rod bearings.See this Section.

CAUTION: If new pistons, connecting rods

or crankshaft have been fitted, it will be

necessary to select correct thickness of

cylinder head gasket.See this Section.CRANKSHAFT

Service repair no - 12.21.33.01

Remove

1.Remove timing chain and sprockets.See this

Section.

2.Remove crankshaft rear oil seal.See this

Section.

3.Remove connecting rod bearings.See this

Section.

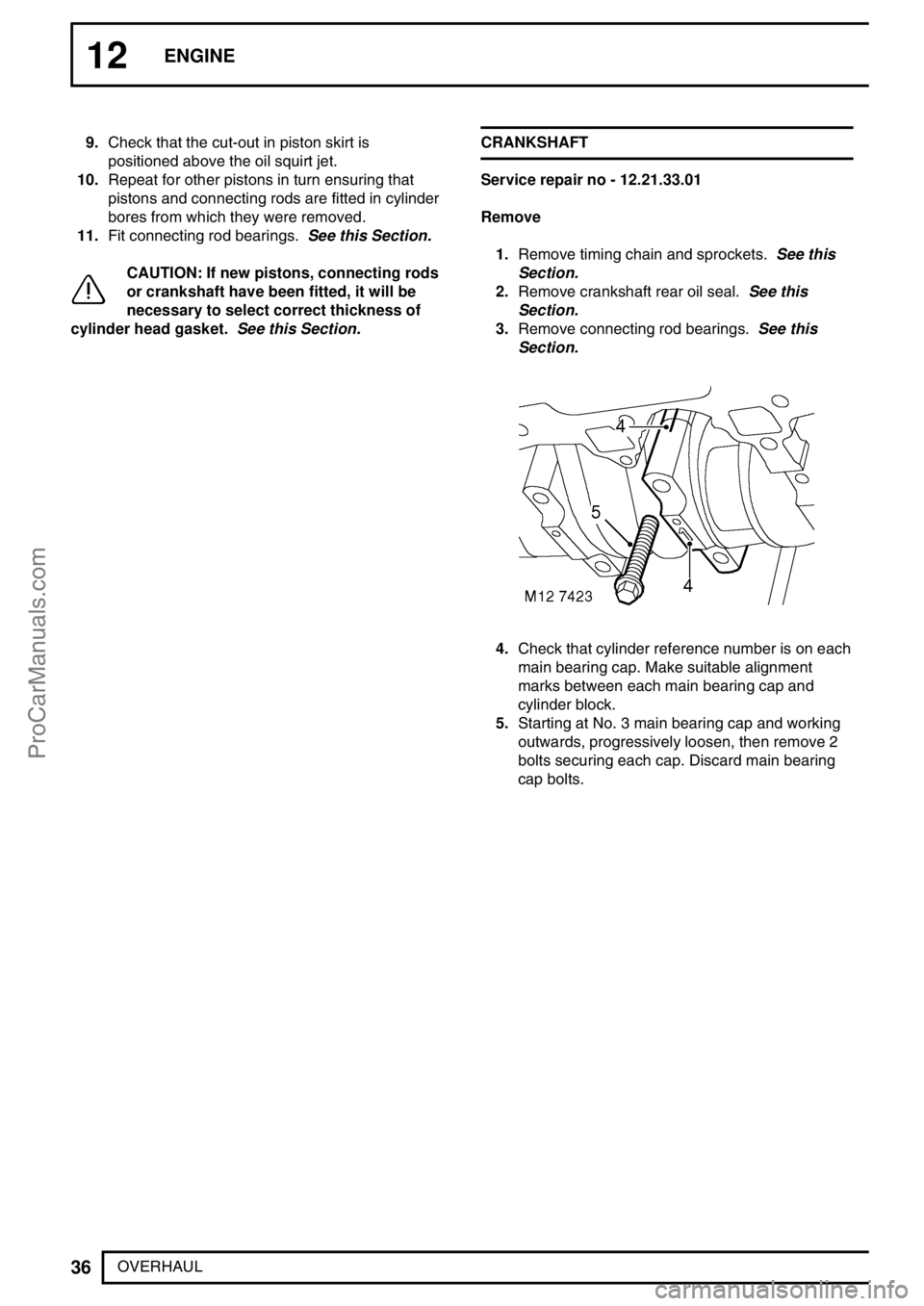

4.Check that cylinder reference number is on each

main bearing cap. Make suitable alignment

marks between each main bearing cap and

cylinder block.

5.Starting at No. 3 main bearing cap and working

outwards, progressively loosen, then remove 2

bolts securing each cap. Discard main bearing

cap bolts.

ProCarManuals.com

Page 214 of 667

EMISSION CONTROL

13

DESCRIPTION AND OPERATION IN-LINE AIR FILTER - PRE EU´ u MODELS

1.To modulator vent port

2.Filter element3.To atmosphere

The in-line air filter is placed in the ventilation line from the EGR modulator. The modulator needs to be able to

vent to atmosphere in order to release the vacuum supplied to the EGR valve. The filter prevents contamination

entering the modulator via the vent port which could cause failure. The filter should be periodically changed in

accordance with the recommended service intervals. The filter is attached to the RH inner front wing, and is held

in position by a clamping bracket. The filter must be mounted vertically.

NOTE: EU3 models are not fitted with an in-line air filter. The ventilation line connects directly to

the air cleaner housing, where it vents to atmosphere.

ProCarManuals.com

Page 218 of 667

EMISSION CONTROL

1

REPAIR VALVE - EGR - NON EU3 MODELS

Service repair no - 17.45.01

Remove

1.Disconnect battery negative lead.

2.Remove 3 bolts and remove engine acoustic

cover.

3.Remove cooling fan.See COOLING SYSTEM,

Repair.

4.Remove battery cover.

5.Disconnect battery negative lead.

6.Disconnect vacuum hose from EGR valve

7.Loosen clip screw and release air intake from

EGR valve.

8.Remove 4 bolts, release EGR valve from inlet

manifold and discard gasket.

9.Remove 2 bolts and release EGR valve clip from

cylinder head.

10.Remove and discard 2 Allen screws securing

EGR valve pipe to exhaust manifold.

11.Remove EGR valve assembly.

12.Remove clip and remove pipe from EGR valve.Refit

13.Clean EGR valve and mating face on pipe.

14.Position pipe to EGR valve, fit retaining clip and

finger tighten bolt.

15.Clean inlet manifold face.

16.Position EGR valve to inlet manifold using new

gasket and tighten bolts to10 Nm (7lbf.ft).

17.Position air intake hose and tighten clip screw.

18.Position EGR pipe bracket, fit bolts and finger

tighten.

19.Position EGR valve pipe to exhaust manifold and

finger tighten allen screws

20.Tighten EGR valve clip to5 Nm (3 lbf.ft).

21.Tighten EGR pipe bracket bolts to10 Nm (7

lbf.ft).

22.Tighten 2 Allen screws to10 Nm (7 lbf.ft).

23.Connect vacuum hose to EGR valve.

24.Fit cooling fan.See COOLING SYSTEM,

Repair.

25.Fit engine acoustic cover.

26.Reconnect battery negative lead.

27.Fit battery cover.

ProCarManuals.com

Page 219 of 667

17EMISSION CONTROL

2

REPAIR VALVE - EGR - EU3 MODELS

Service repair no - 17.45.01

Remove

1.Release turnbuckles and remove battery cover.

2.Disconnect battery earth lead.

3.Remove 3 bolts and remove engine acoustic

cover.

4.Remove cooling fan coupling.See COOLING

SYSTEM, Repair.

5.Disconnect vacuum hose(s) from EGR valve.

6.Loosen screw and disconnect air intake hose

from EGR valve.

7.Remove screw and remove clamp securing EGR

pipe to EGR valve.

8.Remove 4 bolts securing EGR valve, remove

valve and discard gasket.

9.Discard EGR pipe gasket.Refit

10.Clean EGR valve and mating faces.

11.Fit new gasket to EGR pipe.

12.Using new gasket, position EGR valve to inlet

manifold fit bolts and tighten to10 Nm (7 lbf.ft).

13.Fit EGR pipe clamp and tighten screw to6Nm

(4.4 lbf.ft).

14.Connect air intake hose to EGR valve and

tighten clip.

15.Connect vacuum hoses to EGR valve.

16.Fit cooling fan coupling.See COOLING

SYSTEM, Repair.

17.Fit engine acoustic cover and tighten bolts to10

Nm (7 lbf.ft).

18.Connect battery earth lead.

19.Fit battery cover and secure the fixings.

ProCarManuals.com

Page 220 of 667

EMISSION CONTROL

3

REPAIR INLET THROTTLE (ILT) MODULATOR

Service repair no - 17.45.03

Remove

1.Identify the fitted positions of the 3 vacuum

pipes, then disconnect from the ILT modulator

valve.

2.Disconnect multiplug from ILT modulator.

3.Remove 2 nuts securing modulator and remove

ILT modulator from its moutings.

Refit

4.Fit ILT modulator to its mountings, fit the nuts

and tighten to10 Nm (7 lbf.ft).

5.Connect vacuum pipes to the positions identified

during removal.

6.Connect multiplug to ILT modulator.SOLENOID - VALVE - EGR

Service repair no - 17.45.04

Remove

1.Disconnect vacuum pipes and multiplug from

EGR solenoid.

2.Remove 2 nuts and remove EGR solenoid.

Refit

3.Position EGR solenoid and tighten securing

nuts.

4.Connect vacuum hoses and multiplug.

ProCarManuals.com

Page 252 of 667

ENGINE MANAGEMENT SYSTEM

1

REPAIR ENGINE CONTROL MODULE (ECM)

Service repair no - 18.30.03

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery negative lead.

3.Remove RH seat cushion, release clip and

remove ECM access panel.

4.Remove 3 bolts, release ECM and disconnect 2

multiplugs. Remove ECM.

Refit

5.Position new ECM and connect multiplugs.

6.Fit ECM and tighten bolts.

7.Fit access panel and RH seat cushion.

8.Reconnect battery negative lead.

9.Fit battery cover and secure with fixings.SENSOR - ENGINE COOLANT TEMPERATURE

(ECT)

Service repair no - 18.30.10

Remove

1.Disconnect battery negative lead.

2.Remove spring clip and disconnect ECT sensor

multiplug.

3.Position cloth around ECT sensor to absorb

coolant spillage.

4.Remove ECT sensor.

5.Remove sealing washer and discard.

Refit

6.Clean sealing washer, sensor threads and

sensor location.

7.Coat sensor threads with Loctite 577 and fit new

sealing washer.

8.Fit ECT sensor and tighten to20 Nm (14 lbf.ft).

9.Fit spring clip to multiplug and connect multiplug

to ECT sensor.

10.Top up cooling system.

11.Run engine to normal operating temperature.

Check for leaks around ECT sensor.

12.Reconnect battery negative lead.

ProCarManuals.com

Page 253 of 667

18ENGINE MANAGEMENT SYSTEM

2

REPAIR SENSOR - CRANKSHAFT SPEED AND POSITION

(CKP)

Service repair no - 18.30.12

Remove

1.Disconnect CKP sensor multiplug.

2.Remove bolt, remove CKP sensor from gearbox

housing and discard’O’ring.

3.If fitted, collect spacer.

Refit

4.Clean gearbox housing and CKP sensor.

5.If fitted, refit spacer.

6.Fit new’O’ring, position CKP sensor to gearbox

housing and tighten bolt to10 Nm (7 lbf.ft).

7.Connect sensor multiplug.

ProCarManuals.com

Page 268 of 667

FUEL SYSTEM

1

ADJUSTMENT HEATER PLUG TEST

Service repair no - 19.90.20.01

Check

1. Test out of engine

2.Remove heater plug.See Repair.

3.UsingLRT-12-511,connect RED lead to battery

’+’positive and the BLACK lead to battery’-’

negative.

4.Position heater plug into tester and retain with

spring loaded bar.

5.Connect YELLOW lead to heater plug terminal.

6.Press red button on tester and note ammeter

reading. Keep button depressed, heater plug tip

should start to glow after 5 seconds

CAUTION: The heater plug tip must glow

first, if it fails to do so, replace heater plug.

7.The ammeter reading should show an initial

current draw of 25 amps, which should fall to 12

amps after 20 seconds.

8.Refit heater plug.See Repair.FUEL SYSTEM - BLEED

Service repair no - 19.50.07

Fuel Purging Procedure

1.If the vehicle runs out of fuel, or the fuel level is

so low that the fuel system draws air into the fuel

rail, the fuel rail will need to be purged before the

engine will start. This can be achieved by

following a set procedure. The process does not

require the use of any specialist equipment and

can be performed by the driver of the vehicle.

The process is as follows:

2.Switch off ignition and wait 15 seconds.

3.Turn ignition key to position 2 and wait 3

minutes, (this ensures that the fuel system

purges all the air from the fuel rail within the

cylinder head).

4.Depress the throttle pedal to more than 90% of

its total travel, (to the throttle stop).

5.Crank the engine keeping the throttle pedal

depressed.

NOTE: This operation is controlled by the

ECM and it is important that the purging

operation is not carried out on a vehicle

that has not run out of fuel. If it is carried out

unnecessarily it can lead to the engine flooding

and failing to start.

This operation will be cancelled:

6.As soon as engine speed exceeds 600 rev/min.

7.The driver allows the throttle pedal to close to a

position less than 90% of its travel.

8.The ignition key is released from the start

position.

NOTE: The engine must not be cranked for

more than 30 seconds in any one period.

9.Repeat the above procedure if the engine fails to

start.

ProCarManuals.com

Page 269 of 667

19FUEL SYSTEM

2

ADJUSTMENT FUEL TANK - DRAIN

Service repair no - 19.55.02

1.Remove battery cover.

2.Disconnect both leads from battery, earth lead

first.

WARNING: Fuel vapour is highly

flammable and in contained spaces is also

explosive and toxic. Always have a fire

extinguisher containing FOAM, CO2, GAS OR

POWDER close at hand when handling or draining

fuel.

3.Using a fuel recovery appliance, drain the fuel

from the tank into a sealed container. Follow the

manufacturers instructions for the connection

and safe use of the appliance.

4.Remove filler cap and insert hose into filler neck.

5.Connect bowser earth line. Drain fuel.

6.Connect battery leads.

7.Fit battery cover.

ProCarManuals.com

Page 270 of 667

FUEL SYSTEM

1

REPAIR ELEMENT - AIR FILTER

Service repair no - 19.10.10

Remove

1.Release 2 clips and disconnect air flow meter

from air filter cover.

2.Disconnect multiplug from AAP sensor.

3.Release 2 clips and remove cover from air filter.

4.Remove air filter element.

Refit

5.Clean air filter body and cover.

6.Fit new air filter element.

7.Position air cleaner cover and secure clips.

8.Position air flow meter and secure clips.

9.Connect AAP sensor multiplug.SENSOR - FUEL TEMPERATURE

Service repair no - 19.22.08

Remove

1.Remove 3 bolts and remove engine acoustic

cover.

2.Release fixings and remove battery cover.

3.Disconnect battery negative lead.

4.Disconnect multiplug from fuel temperature

sensor.

5.Thoroughly clean area around fuel temperature

sensor before removal.

6.Remove fuel temperature sensor and discard

sealing washer.

Refit

7.Clean fuel temperature sensor mating faces.

8.Fit new sealing washer and tighten fuel

temperature sensor to13 Nm (9 lbf. ft).

9.Connect multiplug to fuel temperature sensor.

10.Reconnect battery negative lead.

11.Fit battery cover and secure fixings.

12.Fit engine acoustic cover and secure with bolts.

ProCarManuals.com