bonnet LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 58 of 667

10 - MAINTENANCE

CONTENTS

Page

MAINTENANCE

UNDERBONNET VIEW - Td5 1..............................................................................

SEATS AND SEAT BELTS 2..................................................................................

LAMPS, HORNS AND WARNING INDICATORS 2................................................

WIPERS AND WASHERS 3...................................................................................

HANDBRAKE 3.......................................................................................................

BATTERY CONDITION - Td5 4..............................................................................

HANDSET BATTERY 5...........................................................................................

HEADLAMP ALIGNMENT 5....................................................................................

ROAD WHEELS 6...................................................................................................

TYRE PRESSURES, CONDITION AND TREAD DEPTH 6....................................

BRAKE PADS, CALIPERS AND DISCS 7..............................................................

ROAD WHEEL SPEED SENSOR HARNESS - Td5 7............................................

FUEL FILTER ELEMENT 8.....................................................................................

FUEL FILTER SEDIMENTER - Td5 8.....................................................................

INTERCOOLER / COOLING SYSTEM 9................................................................

AMBIENT AIR PRESSURE (AAP) SENSOR - Td5 9..............................................

DOOR LOCKS AND HINGES 10............................................................................

ENGINE COOLANT 10...........................................................................................

BRAKE FLUID 11....................................................................................................

AIR FILTER ELEMENT AND DUMP VALVE 11.....................................................

AUXILIARY DRIVE BELT 12...................................................................................

PAS FLUID, CLUTCH FLUID AND SCREEN WASHER LEVELS 12.....................

STEERING BOX 13................................................................................................

ENGINE OIL 14.......................................................................................................

CENTRIFUGE ROTOR - Td5 14.............................................................................

FULL FLOW OIL FILTER 15...................................................................................

GEARBOX OIL 15...................................................................................................

TRANSFER BOX OIL 16.........................................................................................

FRONT AND REAR AXLE OIL 17..........................................................................

PROPELLER SHAFTS 18.......................................................................................

CLUTCH PIPES AND UNIONS 18..........................................................................

PAS PIPES AND UNIONS 19.................................................................................

ENGINE, GEARBOX, TRANSFER BOX AND AXLES 19.......................................

EXHAUST SYSTEM 20...........................................................................................

STEERING BOX AND SUSPENSION 20...............................................................

STEERING BALL JOINTS 21.................................................................................

SHOCK ABSORBERS 22.......................................................................................

TOWING BRACKET 22...........................................................................................

ENGINE AND TRANSMISSION MOUNTINGS 23..................................................

ProCarManuals.com

Page 60 of 667

MAINTENANCE

1

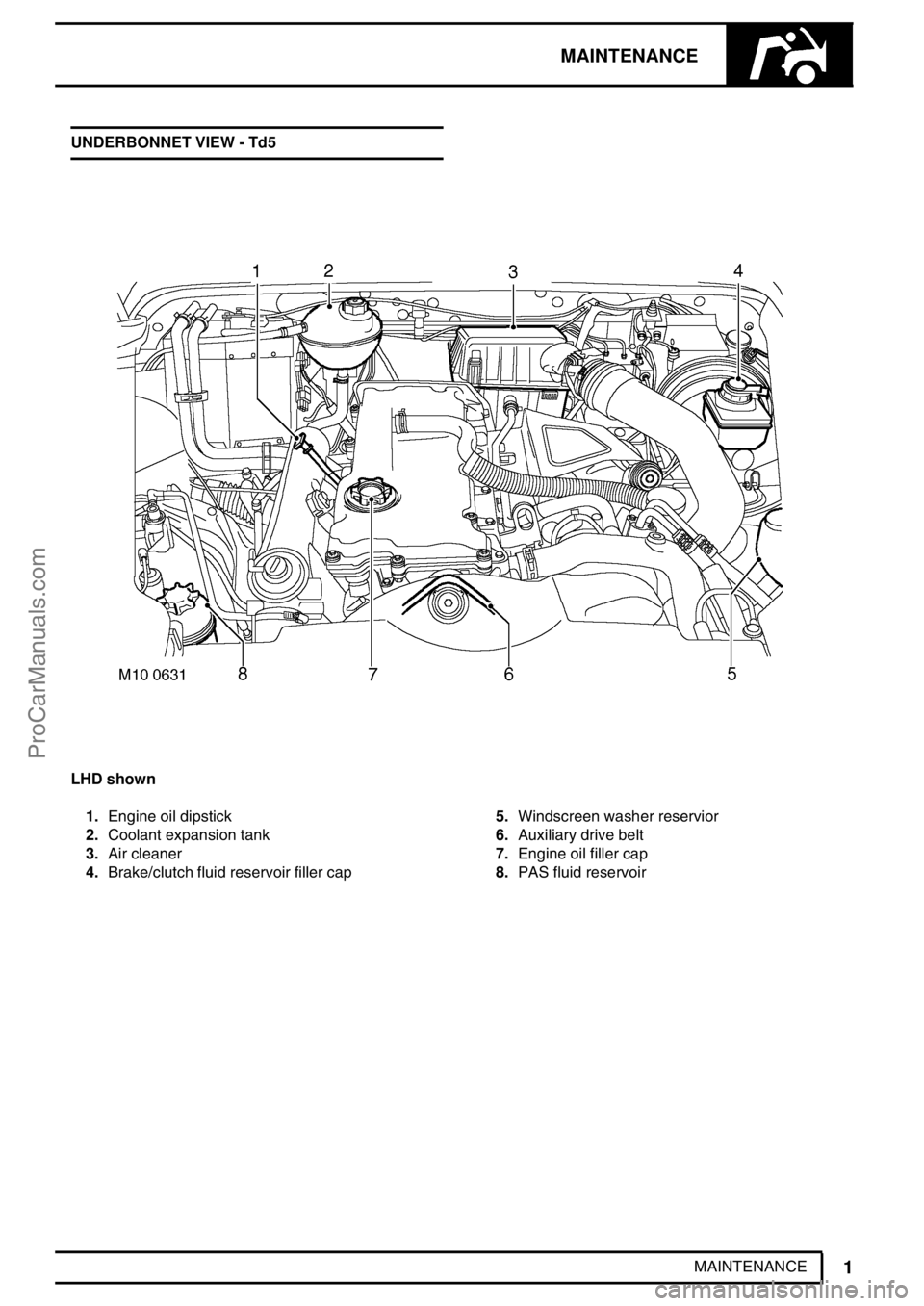

MAINTENANCE UNDERBONNET VIEW - Td5

LHD shown

1.Engine oil dipstick

2.Coolant expansion tank

3.Air cleaner

4.Brake/clutch fluid reservoir filler cap5.Windscreen washer reservior

6.Auxiliary drive belt

7.Engine oil filler cap

8.PAS fluid reservoir

ProCarManuals.com

Page 69 of 667

10MAINTENANCE

10

MAINTENANCE DOOR LOCKS AND HINGES

Front, rear and tail doors

1.Open each door in turn and lubricate door

hinges and check strap using recommended

lubricant.

2.Lubricate door lock, striker and private lock using

PTFE lubricant. Remove excessive lubricant,

particularly from door striker area, to avoid

customer complaint.

3.Check tightness of accessible door lock and

striker fixings

4.Open and close door to check for smooth,

noise-free operation. Ensure door closes

securely.

5.Check for smooth operation of private lock.

Bonnet

1.With bonnet open, lubricate hinges, striker, lock

and safety catch using a suitable lubricant.ENGINE COOLANT

1.Renew engine coolant.See COOLING

SYSTEM, Adjustment.

ProCarManuals.com

Page 82 of 667

MAINTENANCE

23

MAINTENANCE ENGINE AND TRANSMISSION MOUNTINGS

1.Check condition of front LH engine mounting.

Tighten fixings if necessary.See ENGINE ,

Repair.

2.Check condition of front RH engine mounting.

Tighten fixings if necessary.See ENGINE ,

Repair.

3.Check condition of rear LH gearbox mounting.

Tighten fixings if necessary.See ENGINE ,

Repair.

4.Check condition of rear RH gearbox mounting.

Tighten fixings if necessary.See ENGINE ,

Repair.ROAD TEST

There are two purposes for conducting a road test.

Firstly, to ensure the work completed within the

dealership meets the standards required as layed

down by dealership processes. Secondly, for a skilled

technician to assess the general condition of the

vehicle and report any conditions that the customer

should be made aware of.

CAUTION: Two wheel roller tests must not

be carried out. Four wheel roller tests

must be restricted to 3 mph (5 kph).

1.Check for correct operation of starter switch.

Ensure the engine starts in a correct manner.

Leave the engine running.

2.With vehicle stationary, turn steering from lock to

lock. Check for smooth operation and ensure

there is no undue noise from the power steering

pump or drive belt.

3.Depress clutch and select all gears in turn.

Check for smooth notch free engagement.

4.Drive vehicle on a short road test. Check all

vehicle systems for correct operation. Pay

particular attention to:

Engine noise

Gearbox noise

Suspension noise

Body noise

Braking system operation

Gear selection

Engine performance

5.Check for correct operation of all instruments

and warning devices where practical.

6.After road test, carry out a final inspection of the

vehicle on vehicle ramps.

7.Check all underbonnet fluid levels and top-up if

necessary.

ProCarManuals.com

Page 306 of 667

COOLING SYSTEM

3

REPAIR RADIATOR

Service repair no - 26.40.01

Remove

1.Remove front grille.See CHASSIS AND

BODY, Repair.

2.Drain cooling system.See Adjustment.

3.Remove cooling fan.See this Section.

4.Remove 5 bolts and move bonnet platform

aside.

5.Release clip and disconnect bleed hose from

radiator.

6.Release clip and disconnect top hose from

radiator.

7.Release clip and disconnect fuel cooler hose

from radiator.

8.Release clip and disconnect coolant rail hose

from radiator.

ProCarManuals.com

Page 308 of 667

COOLING SYSTEM

5

REPAIR Refit

17.Fit rubber mountings to bottom of radiator.

18.Fit lower cooling fan cowl to radiator and secure

with screws.

19.Fit nuts to radiator side brackets.

20.Position intercooler to radiator and tighten bolts.

21.Fit rubber mountings to intercooler.

22.Position mounting spacers and fit radiator.

23.Fit bottom hose into bracket on lower cooling fan

cowl.

24.Position air hose to turbocharger pipe and

secure with clip.

25.Position LH and RH radiator mounting brackets

to body and radiator and tighten bolts.

26.Position coolant rail hose to radiator and secure

with clip.

27.Position fuel cooler hose to radiator and secure

with clip.

28.Position top hose to radiator and secure with

clip.

29.Position bleed hose to radiator and secure with

clip.

30.Position bonnet platform and tighten bolts.

31.Fit cooling fan.See this Section.

32.Fit front grille.See CHASSIS AND BODY,

Repair.

33.Fill cooling system.See Adjustment.

ProCarManuals.com

Page 474 of 667

CHASSIS AND BODY

5

REPAIR

13.Remove 4 bolts securing radiator mounting

bracket to wing.

14.Loosen screw and release bonnet lock inner

cable from bonnet lock.

15.Release bonnet lock outer cable from from

bonnet lock.

16.Push centre pins from studs securing wheel arch

extension to wing, remove studs and remove

wheel arch extension.

17.Remove bolt securing inner and outer wing to

chassis.

18.Remove nut and bolt securing support stay to

wing.

19.Remove 4 bolts securing wing to’A’post.

20.Remove bolt securing wing to bulkhead.

ProCarManuals.com

Page 475 of 667

76CHASSIS AND BODY

6

REPAIR

21.Disconnect headlamp, side lamp, repeater and

indicator multiplugs.

22.With assistance, remove wing.

23.Remove bolt, remove grille support bracket.

24.Remove 4 screws securing side and indicator

lamps.

25.Remove 2 screws securing headlamp finisher to

wing, remove finisher.

26.Remove 4 screws and remove headlamp from

wing, collect sealing ring.

27.Release side repeater lamp from wing.

28.Remove bonnet cable grommet.

ProCarManuals.com

Page 476 of 667

CHASSIS AND BODY

7

REPAIR Refit

29.Fit bonnet cable grommet.

30.Fit side repeater lamp to wing.

31.Fit headlamp sealing ring, fit headlamp and

tighten screws.

32.Fit headlamp finisher, side and indicator lamps

and tighten screws.

33.Fit grille support bracket and tighten bolt.

34.With assistance, position and align wing to body

and locate bonnet cable to wing.

35.Connect headlamp, indicator, side lamp and side

repeater lamp multiplugs.

36.Fit bolt securing wing to bulkhead.

37.Fit bolts securing wing to’A’post.

38.Fit nut and bolt securing support stay to wing.

39.Fit bolt securing inner and outer wing to chassis.

40.Fit bolts securing radiator bracket to wing.

41.Fit bolts securing outer wing to inner wing.

42.Align wing and finally tighten all bolts.

43.Position wheel arch extension to wing, and fit

securing studs.

44.Position PAS reservoir to wing and tighten bolts.

45.Position expansion tank pipe and secure with

studs.

46.Position EGR solenoid and tighten bolts.

47.Position heater air intake seal and fit air intake.

48.Fit heater air intake bracket and tighten bolts.

49.Fit heater air intake grille and tighten screws.

50.Align air cleaner intake elbow, tighten screws

and fit grille.

51.Fit wheel arch liner.See this Section.

52.Position bonnet release cable to lock and tighten

screw.

53.Fit cooling fan cowl.

54.Fit front grille.See this Section.STEP - FOLDING - REAR DOOR

Service repair no - 76.10.41

Remove

1.Remove 2 bolts securing step to chassis

member, remove step and collect spacers.

Refit

2.Position step, fit spacer washers and tighten

bolts.

ProCarManuals.com

Page 510 of 667

PANEL REPAIRS

1

INFORMATION BODY REPAIRS

Body shells are of riveted, bolted and welded

construction and are bolted to the chassis frame.

It is essential that design dimensions and strength are

restored in accident rectification. It is important that

neither structural weakness nor excessive local

stiffness are introduced into the vehicle during body or

chassis repair.

Repairs usually involve a combination of operations

ranging from straightening procedures to renewal of

either individual panels or panel assemblies. The

repairer will determine the repair method and this

decision will take into account a balance of economics

between labour and material costs and the availability

of repair facilities in both equipment and skills. It may

also involve considerations of vehicles down-time,

replacement vehicle availability and repair turn-around

time.

It is expected that a repairer will select the best and

most economic repair method possible, making use of

the facilities available. The instructions given are

intended to assist a skilled body repairer by expanding

approved procedures for panel replacement with the

objective of restoring the vehicle to a safe running

condition and effecting a repair which is visually

acceptable and which, even to the experienced eye,

does not advertise the fact that it has been damaged.

This does not necessarily mean that the repaired

vehicle will be identical in all respects with original

factory build. Repair facilities cannot always duplicate

methods of construction used during production.

The panel repairs shown in this section are all based

on a 110 Station Wagon. Therefore all illustrations

and text relate only to this model. Although certain

areas of the vehicle, such as the front end, are

relevant to all models.

Operations covered in this Manual do not include

reference to testing the vehicle after repair. It is

essential that work is inspected and suspension

geometry checked after completion and if necessary a

road test of the vehicle is carried out, particularly

where safety related items are concerned.Where major units have been disconnected or

removed, it is necessary to ensure that fluid levels are

checked and topped up when necessary. It is also

necessary to ensure that the repaired vehicle is in a

roadworthy condition in respect of tyre pressures,

lights, washer fluid etc.

Body repairs often involve the removal of mechanical

and electrical units as well as associated wiring.

Where this is necessary use the relevant section in

this manual.

Taking into consideration the differences in body

styles, steering and suspension systems as well as

engine and suspension layouts, the location of the

following components as applicable to a particular

vehicle is critical:

Front suspension upper damper

mountings.

Front suspension or sub frame mountings.

Engine mountings on RH and LH chassis

longitudinals.

Rear suspension upper damper mountings.

Rear suspension mountings or lower

pivots.

Steering rack mountings.

Additional points which can be used to check

alignment and assembly are:

Inner holes in crossmember - side - main

floor.

Holes in valance front assembly.

Body to chassis mounting holes.

Holes in rear floor.

Holes in rear lower panels or extension

rear floor.

Fuel tank mountings.

Apertures for windscreen, backlight, bonnet and doors

can be checked by offering up an undamaged

component as a gauge and also by measuring known

dimensions.See BODY DIMENSIONS section.

ProCarManuals.com