lock LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 8 of 667

INTRODUCTION

1

INFORMATION INTRODUCTION

This Workshop Manual Supplement covers vehicles

from 1999 and 2002 model year onwards. The Body

Repair Manual has also been incorporated into this

supplement. Amendments and additional pages will

be issued, when necessary, to ensure that the

supplement covers latest models.

This Supplement is designed to assist skilled

technicians in the efficient repair and maintenance of

Land Rover Defender vehicles.

Individuals who undertake their own repairs should

have some skill and training, and limit repairs to

components which could not affect the safety of the

vehicle or its passengers. Any repairs required to

safety critical items such as steering, brakes,

suspension or supplementary restraint system should

be carried out by a Land Rover Dealer. Repairs to

such items should NEVER be attempted by untrained

individuals.

WARNINGS, CAUTIONSandNOTESare given

throughout this Manual in the following form:

WARNING: Procedures which must be

followed precisely to avoid the possibility

of personal injury.

CAUTION: This calls attention to

procedures which must be followed to

avoid damage to components.

NOTE: This calls attention to methods

which make a job easier or gives helpful

information.

DIMENSIONS

The dimensions quoted are to design engineering

specification. Alternative unit equivalents, shown in

brackets following the dimensions, have been

converted from the original specification.REFERENCES

References to the left or right hand side in the manual

are made when viewing the vehicle from the rear.

With the engine and gearbox assembly removed, the

crankshaft end of the engine is referred to as the front.

To reduce repetition, some operations covered in this

Supplement do not include reference to testing the

vehicle after repair.

It is essential that work is inspected and tested after

completion and if necessary a road test of the vehicle

is carried out, particularly where safety related items

are concerned.

REPAIRS AND REPLACEMENTS

When replacement parts are required it is essential

that Land Rover parts are used.

Attention is particularly drawn to the following points

concerning repairs and the fitting of replacement parts

and accessories: Safety features embodied in the

vehicle may be impaired if other than Land Rover

parts are fitted. In certain territories, legislation

prohibits the fitting of parts not to the vehicle

manufacturer’s specification. Torque spanner values

given in the Supplement must be strictly adhered to.

Locking devices, where specified, must be fitted. If the

efficiency of a locking device is impaired during

removal it must be replaced with a new one. Certain

fasteners must not be re-used. These fasteners are

specified in the Supplement.

POISONOUS SUBSTANCES

Many liquids and other substances used are

poisonous and therefore must not be consumed. It is

also advisable to keep all substances away from open

wounds. These substances among others include

anti-freeze, brake fluid, fuel, windscreen washer

additives, air conditioning refrigerant, lubricants and

various adhesives.

ProCarManuals.com

Page 14 of 667

INTRODUCTION

7

INFORMATION TOWING

CAUTION: The vehicle has permanent

four-wheel drive. The following towing

instructions must be adhered to:

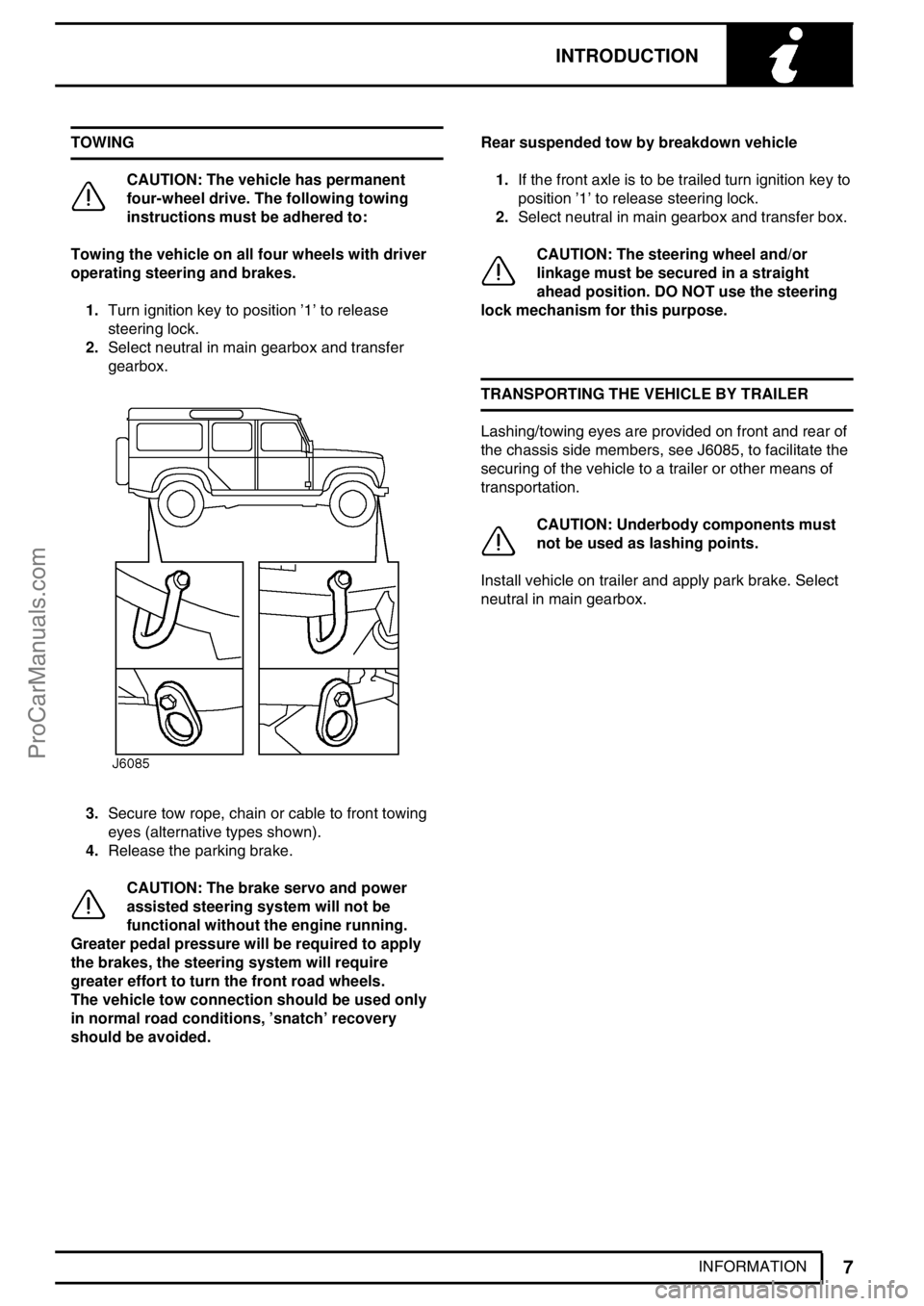

Towing the vehicle on all four wheels with driver

operating steering and brakes.

1.Turn ignition key to position’1’to release

steering lock.

2.Select neutral in main gearbox and transfer

gearbox.

3.Secure tow rope, chain or cable to front towing

eyes (alternative types shown).

4.Release the parking brake.

CAUTION: The brake servo and power

assisted steering system will not be

functional without the engine running.

Greater pedal pressure will be required to apply

the brakes, the steering system will require

greater effort to turn the front road wheels.

The vehicle tow connection should be used only

in normal road conditions,’snatch’recovery

should be avoided.Rear suspended tow by breakdown vehicle

1.If the front axle is to be trailed turn ignition key to

position’1’to release steering lock.

2.Select neutral in main gearbox and transfer box.

CAUTION: The steering wheel and/or

linkage must be secured in a straight

ahead position. DO NOT use the steering

lock mechanism for this purpose.

TRANSPORTING THE VEHICLE BY TRAILER

Lashing/towing eyes are provided on front and rear of

the chassis side members, see J6085, to facilitate the

securing of the vehicle to a trailer or other means of

transportation.

CAUTION: Underbody components must

not be used as lashing points.

Install vehicle on trailer and apply park brake. Select

neutral in main gearbox.

ProCarManuals.com

Page 19 of 667

01INTRODUCTION

12

INFORMATION LOCATION OF IDENTIFICATION NUMBERS

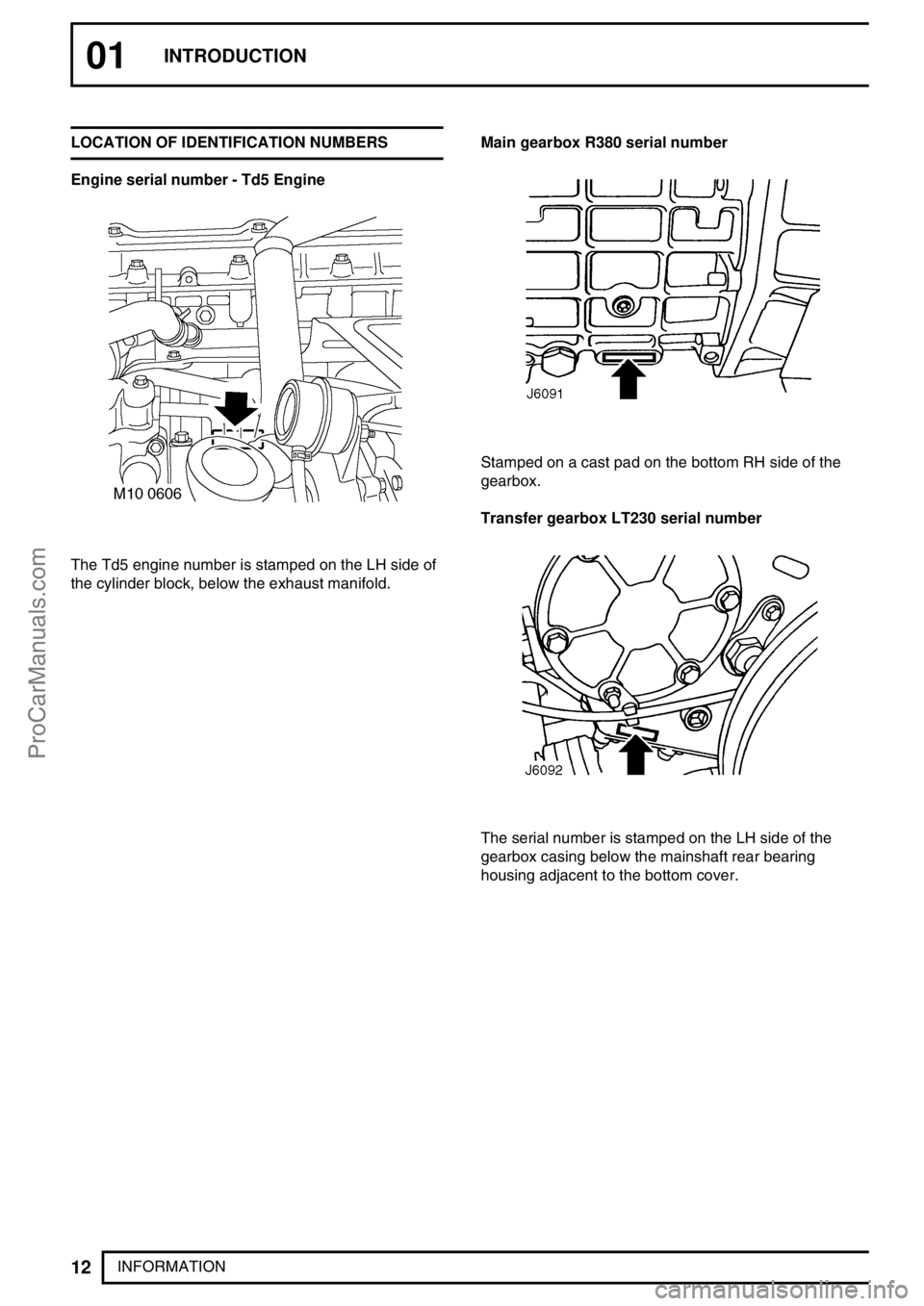

Engine serial number - Td5 Engine

The Td5 engine number is stamped on the LH side of

the cylinder block, below the exhaust manifold.Main gearbox R380 serial number

Stamped on a cast pad on the bottom RH side of the

gearbox.

Transfer gearbox LT230 serial number

The serial number is stamped on the LH side of the

gearbox casing below the mainshaft rear bearing

housing adjacent to the bottom cover.

ProCarManuals.com

Page 24 of 667

GENERAL SPECIFICATION DATA

1

INFORMATION ENGINE - Td5

Type 2.5 litre in-line direct injection Diesel, turbocharged.................................................................................

and intercooled

Number of cylinders 5 in-line, No. 1 cylinder at front of engine.........................................................

Bore 84.450 mm (3.3248 in).................................................................................

Stroke 88.950 mm (3.5020 in)...............................................................................

Capacity 2498 cm

3(152.5 in3) ...........................................................................

Firing order 1 - 2 - 4 - 5 - 3.......................................................................

Compression ratio 19.5:1............................................................

Direction of rotation Clockwise viewed from the front of the engine...........................................................

Dimensions

Length 766 mm (30.1 in).....................................................................

Width 708 mm (27.8 in).......................................................................

Height 788 mm (31.0 in)......................................................................

Emissions standard :-

Engine Serial No. Prefixes 10P to 14P - EU2 Model ECD 2........

Engine Serial No. Prefixes 15P to 19P - EU3 Model ECD 3........

Lubrication

Type Wet sump, pressure fed.................................................................................

Pump type Eccentric rotor, crankshaft driven integral with stiffener........................................................................

plate.

Filter type:

Primary Centrifuge filter....................................................................

Secondary Disposable canister with full flow by-pass...............................................................

Pressure at idle (cold) 3.0 bar (43.5 lbf.in

2) ......................................................

Pressure at 3500 rev/min (hot) 1.5 - 3.0 bar (21.75 - 43.5 lbf.in2) .........................................

Relief valve opening pressure 4.0 bar (58 lbf.in2) ..........................................

Low oil pressure switch opening pressure 0.2 - 0.6 bar (3.0 - 8.8 lbf.in2) .......................

Crankshaft

Main bearing journal diameter 61.9875 - 62.0125 mm..........................................

Crankpin journal diameter 53.99 - 54.01 mm................................................

Crankshaft end float 0.020 - 0.250 mm.........................................................

Main bearings

Number and type 6 half shells (5 main, 1 thrust)..............................................................

Pistons

Type Graphite compound skirt with combustion chamber in.................................................................................

crown.

Clearance in cylinder bore 0.172 - 0.206 mm (measured at bottom of skirt, 90°to ...............................................

gudgeon pin)

Diameter 84.270 - 85.254 mm (measured 90°to gudgeon pin, ..........................................................................

and 40.00 mm from bottom of skirt.)

ProCarManuals.com

Page 27 of 667

04GENERAL SPECIFICATION DATA

4

INFORMATION TRANSMISSION - Td5

Main gearbox

Type R380 Single helical constant mesh.......................................................................

Speeds 5 forward, 1 reverse, all synchromesh.............................................................................

Transfer box

Type LT230TE Two speed reduction on main gearbox output. Front.................................................................

and rear drive permanently engaged via a lockable

differential

Rear axle

Type Spiral bevel, fully floating shafts.................................................................................

Ratio 3.54:1.................................................................................

Front axle

Type Spiral bevel, enclosed constant velocity joints, fully.................................................................................

floating shafts, 32°angularity of universal joint on full

lock

Ratio 3.54:1.................................................................................

Propeller shafts

Type, front and rear Tubular 51 mm dia...........................................................

Universal joints Open type Hookes O3EHD.................................................................

ProCarManuals.com

Page 28 of 667

GENERAL SPECIFICATION DATA

5

INFORMATION STEERING

Power steering box

Make/type Adwest Varamatic - worm and roller box........................................................................

Ratio Variable: straight ahead 19.3:1 on lock 14.3:1.................................................................................

Steering wheel turns, lock-to-lock 3.375....................................

Steering pump

Make/type Hobourn-Eaton series 500........................................................................

Steering geometry

Steering wheel diameter 412 mm (16.22 in)..................................................

Toe-out measurement 0 to 2 mm toe out......................................................

Toe-out included angle 0°to 0°20’ .....................................................

Camber angle 0°* ..................................................................

Castor angle 3°* .....................................................................

Swivel pin inclination static 7°* ...............................................

* Check with vehicle on level ground, in unladen

condition and five gallons of fuel. Rock the front of the

vehicle up and down to allow it to take up a normal

static position.

Turning circle between kerbs

90 models:

265/75 x 16 tyres 12,65 m (41.5 ft)..............................................................

All other tyres 11,70 m (38.4 ft)...................................................................

110 models:

750 x 16 tyres 13,41 m (44 ft)..................................................................

130 models:

750 x 16 tyres 15,24 m (50 ft)..................................................................

ProCarManuals.com

Page 30 of 667

GENERAL SPECIFICATION DATA

7

INFORMATION SHOCK ABSORBERS

Type Telescopic, double-acting non-adjustable.................................................................................

Bore diameter 35.47mm...................................................................

BRAKES

Front brake

Caliper AP Lockheed, four opposed pistons..............................................................................

Operation Hydraulic, self adjusting.........................................................................

Disc 90 - Solid, outboard, 110/130 - Ventilated, outboard..................................................................................

Disc diameter 298 mm (11.73 in)...................................................................

Disc thickness 90 - 14,1 mm (0.56in), 110/130 - 24mm (0.95 in)..................................................................

Wear limit 1 mm (0.04in) per side of disc.........................................................................

Disc run-out maximum 0,15mm (0.006 in).....................................................

Pad area 58 cm

2(9.0 in2) ..........................................................................

Total swept area 801,3 cm2(124.2 in2) ...............................................................

Pad material Ferodo 3440 non asbestos.....................................................................

Pad minimum thickness 3 mm (0.12in)...................................................

Rear brake

Caliper AP Lockheed opposed piston..............................................................................

Operation Hydraulic, self adjusting.........................................................................

Disc Solid, outboard..................................................................................

Disc diameter 90 - 290 mm (11.42 in), 110/130 - 298 mm (11.73)...................................................................

Disc thickness 90 - 12,5 mm (0.49 in), 110/130 - 14,1 mm (0.56 in)..................................................................

Wear limit 90 - 0,38 mm (0.015 in), 110/130 - 1,0 mm (0.04 in).........................................................................

per side of disc

Disc run-out maximum 0,15 mm (0.006 in).....................................................

Pad area 90 - 30,5 cm

2(4.37 in2), 110/130 - 36,2 cm2(5.61 in2) ..........................................................................

Total swept area 90 - 694 cm2(106.98 in2) ...............................................................

Pad material Ferodo 3440 non asbestos.....................................................................

Pad minimum thickness UP TO 02MY - 3 mm (0.12 in)...................................................

Pad minimum thickness From 02MY - 2 mm (0.08 in)...................................................

Parking brake

Type Mechanical, cable operated drum brake on the rear of.................................................................................

the transfer gearbox output shaft

Drum internal diameter 254 mm (10.0 in).....................................................

Width 70 mm (2.75 in)................................................................................

Pad material Ferodo 3611 non asbestos.....................................................................

Servo/master cylinder

Manufacturer Lucas....................................................................

Servo type LSC 80........................................................................

Master cylinder type 25,4 mm (1.0 in) diameter, tandem.........................................................

Pressure reducing valve, failure conscious Cut-in pressure, 90 - 24 bar (360 Ibf/in

2) ratio 4.0:1, ......................

110 - 43 bar (645 Ibf/in2) ratio 2.9:1*

NOTE: * Pressure reducing valves are not fitted to all 110 specifications.

ProCarManuals.com

Page 42 of 667

07 - GENERAL FITTING REMINDERS

CONTENTS

Page

INFORMATION

GENERAL FITTING REMINDERS 1.......................................................................

PRECAUTIONS AGAINST DAMAGE 1..................................................................

SAFETY PRECAUTIONS 1....................................................................................

PREPARATION 2....................................................................................................

DISMANTLING 2.....................................................................................................

INSPECTION-GENERAL 2.....................................................................................

BALL AND ROLLER BEARINGS 3.........................................................................

OIL SEALS 4...........................................................................................................

JOINTS AND JOINT FACES 5................................................................................

FLEXIBLE HYDRAULIC PIPES, HOSES 5.............................................................

FUEL SYSTEM HOSES 6.......................................................................................

METRIC BOLT IDENTIFICATION 6........................................................................

METRIC NUT IDENTIFICATION 6..........................................................................

KEYS AND KEYWAYS 6........................................................................................

TAB WASHERS 6...................................................................................................

COTTER PINS 7.....................................................................................................

NUTS7 ...................................................................................................................

LOCKING WIRE 7...................................................................................................

SCREW THREADS 7..............................................................................................

UNIFIED THREAD IDENTIFICATION 7..................................................................

ProCarManuals.com

Page 45 of 667

07GENERAL FITTING REMINDERS

2

INFORMATION PREPARATION

1.Clean components and surrounding area prior to

removal.

2.Blank off any openings exposed by component

removal using greaseproof paper and masking

tape.

3.Immediately seal fuel, oil or hydraulic lines when

separated, using plastic caps or plugs, to

prevent loss of fluid and entry of dirt.

4.Close open ends of oilways, exposed by

component removal, with tapered hardwood

plugs or readily visible plastic plugs.

5.Immediately a component is removed, place it in

a suitable container; use a separate container for

each component and its associated parts.

6.Before dismantling a component, clean it

thoroughly with a recommended cleaning agent;

check that agent is suitable for all materials of

component.

7.Clean bench and provide marking materials,

labels, containers and locking wire before

dismantling a component.

DISMANTLING

1.Observe scrupulous cleanliness when

dismantling components, particularly when

brake, fuel or hydraulic system parts are being

worked on. A particle of dirt or a cloth fragment

could cause a dangerous malfunction if trapped

in these systems.

2.Blow out all tapped holes, crevices, oilways and

fluid passages with an air line. Ensure that any

O-rings used for sealing are correctly replaced or

renewed, if disturbed.

3.Use marking ink to identify mating parts, to

ensure correct reassembly. If a centre punch or

scriber is used they may initiate cracks or

distortion of components.

4.Wire together mating parts where necessary to

prevent accidental interchange (e.g. roller

bearing components).

5.Wire labels on to all parts which are to be

renewed, and to parts requiring further

inspection before being passed for reassembly;

place these parts in separate containers from

those containing parts for rebuild.

6.Do not discard a part due for renewal until it has

been compared with the new part, to ensure that

its correct replacement has been obtained.INSPECTION-GENERAL

1.Never inspect a component for wear or

dimensional check unless it is absolutely clean;

a slight smear of grease can conceal an incipient

failure.

2.When a component is to be checked

dimensionally against figures quoted for it, use

correct equipment (surface plates, micrometers,

dial gauges, etc.) in serviceable condition.

Makeshift checking equipment can be

dangerous.

3.Reject a component if its dimensions are outside

limits quoted, or if damage is apparent. A part

may, however, be refitted if its critical dimension

is exactly limit size, and is otherwise satisfactory.

4.Use’Plastigauge’12 Type PG-1 for checking

bearing surface clearances. Directions for its

use, and a scale giving bearing clearances in

0,0025 mm steps are provided with it.

ProCarManuals.com

Page 49 of 667

07GENERAL FITTING REMINDERS

6

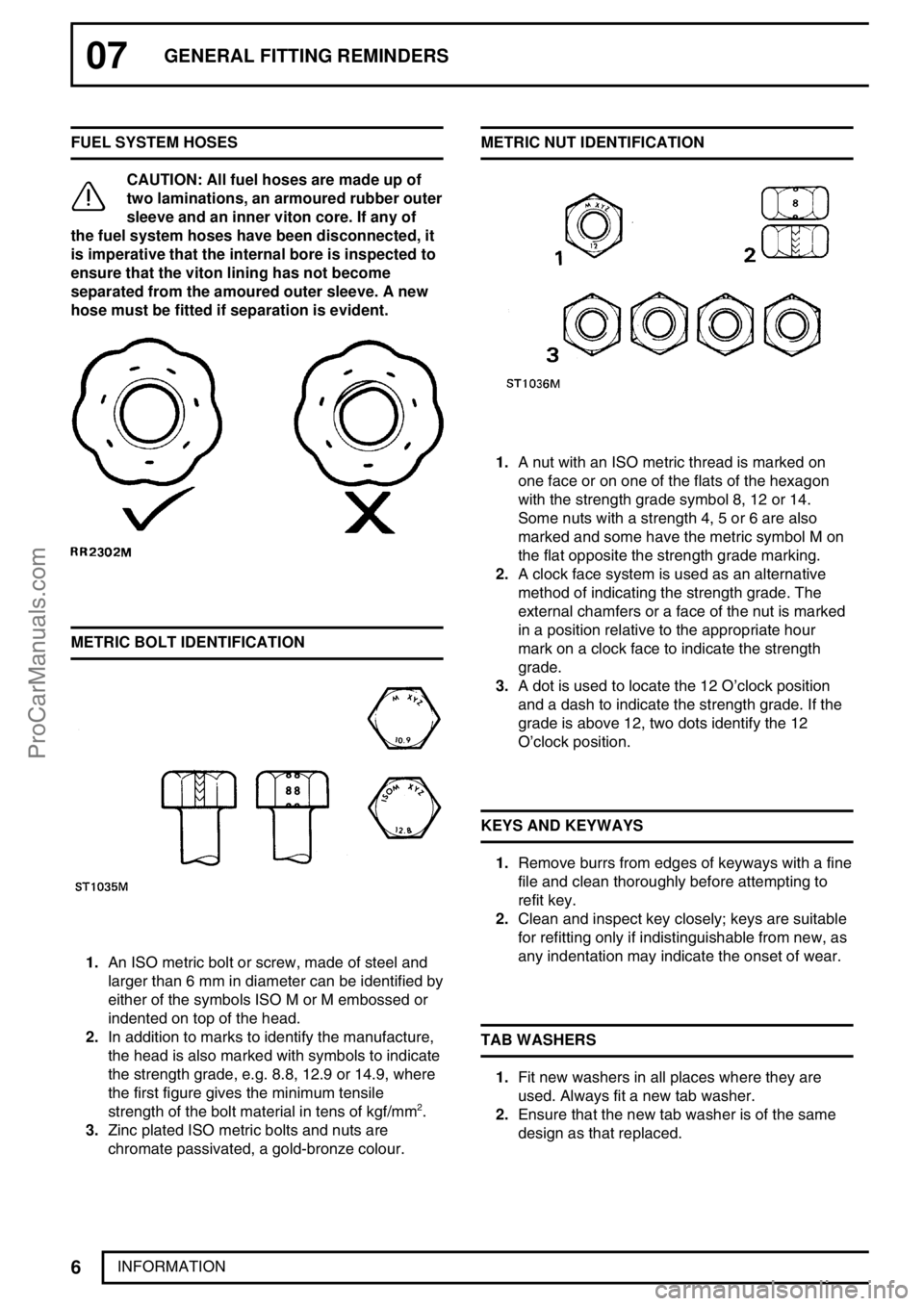

INFORMATION FUEL SYSTEM HOSES

CAUTION: All fuel hoses are made up of

two laminations, an armoured rubber outer

sleeve and an inner viton core. If any of

the fuel system hoses have been disconnected, it

is imperative that the internal bore is inspected to

ensure that the viton lining has not become

separated from the amoured outer sleeve. A new

hose must be fitted if separation is evident.

METRIC BOLT IDENTIFICATION

1.An ISO metric bolt or screw, made of steel and

larger than 6 mm in diameter can be identified by

either of the symbols ISO M or M embossed or

indented on top of the head.

2.In addition to marks to identify the manufacture,

the head is also marked with symbols to indicate

the strength grade, e.g. 8.8, 12.9 or 14.9, where

the first figure gives the minimum tensile

strength of the bolt material in tens of kgf/mm

2.

3.Zinc plated ISO metric bolts and nuts are

chromate passivated, a gold-bronze colour.METRIC NUT IDENTIFICATION

1.A nut with an ISO metric thread is marked on

one face or on one of the flats of the hexagon

with the strength grade symbol 8, 12 or 14.

Some nuts with a strength 4, 5 or 6 are also

marked and some have the metric symbol M on

the flat opposite the strength grade marking.

2.A clock face system is used as an alternative

method of indicating the strength grade. The

external chamfers or a face of the nut is marked

in a position relative to the appropriate hour

mark on a clock face to indicate the strength

grade.

3.A dot is used to locate the 12 O’clock position

and a dash to indicate the strength grade. If the

grade is above 12, two dots identify the 12

O’clock position.

KEYS AND KEYWAYS

1.Remove burrs from edges of keyways with a fine

file and clean thoroughly before attempting to

refit key.

2.Clean and inspect key closely; keys are suitable

for refitting only if indistinguishable from new, as

any indentation may indicate the onset of wear.

TAB WASHERS

1.Fit new washers in all places where they are

used. Always fit a new tab washer.

2.Ensure that the new tab washer is of the same

design as that replaced.

ProCarManuals.com