ECU LAND ROVER DISCOVERY 1995 Service Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 976, PDF Size: 14.57 MB

Page 869 of 976

ELECTRICAL

49

REPAIR Refit

8.Fit bulb to lens.

9.Secure bulb retaining clip.

10.Connect 2 Lucars to bulb.

11.Position lamp lens to shroud.

12.Position lamp to bracket and secure fog lamp

adjustment ball joint to bracket.

13.Position spacers, align lamp to bracket and

secure with Torx screws.

14.Fit front fog lamp.

See fog lamp - front; Refit

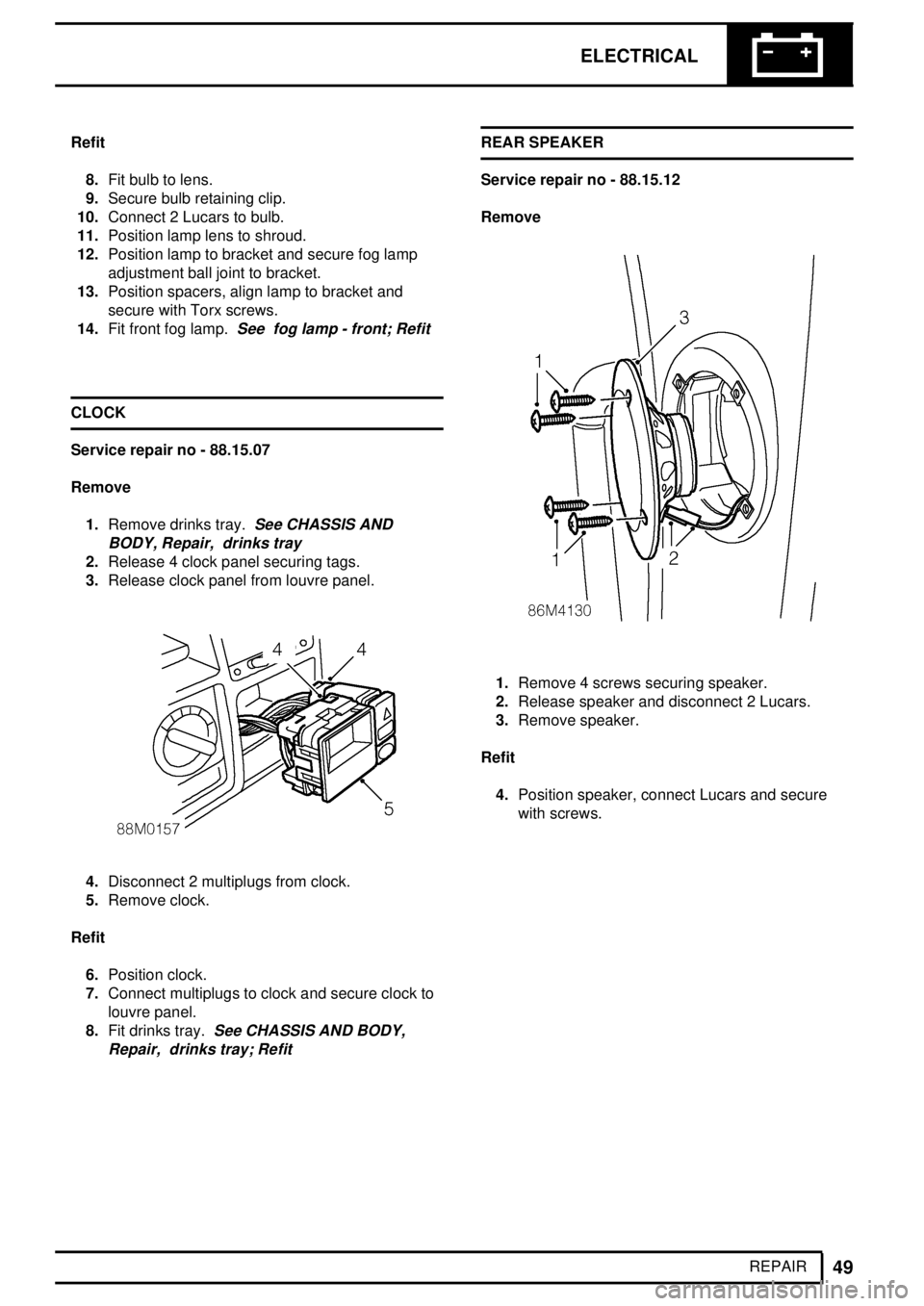

CLOCK

Service repair no - 88.15.07

Remove

1.Remove drinks tray.

See CHASSIS AND

BODY, Repair, drinks tray

2.Release 4 clock panel securing tags.

3.Release clock panel from louvre panel.

4.Disconnect 2 multiplugs from clock.

5.Remove clock.

Refit

6.Position clock.

7.Connect multiplugs to clock and secure clock to

louvre panel.

8.Fit drinks tray.

See CHASSIS AND BODY,

Repair, drinks tray; Refit

REAR SPEAKER

Service repair no - 88.15.12

Remove

1.Remove 4 screws securing speaker.

2.Release speaker and disconnect 2 Lucars.

3.Remove speaker.

Refit

4.Position speaker, connect Lucars and secure

with screws.

Page 870 of 976

86ELECTRICAL

50

REPAIR DIGITAL DIESEL SHUT-OFF VALVE (DDS) - 97 MY

Service repair no - 86.77.00

Remove

1.Remove fuel injection pump.

See FUEL

SYSTEM, Repair, fuel injection pump and

timing

2.Drill into 2 break-off screws to a depth of

approximately 5 mm using a 3.2 mm drill.

CAUTION: Use a drill bushing to guide the

drill during the above.

3.Using an 'Easy-out' remove 2 valve retaining

screws and discard.

4.Release DDS valve from fuel shut-off solenoid.

5.Remove protective cap from fuel shut-off

solenoid electrical connection.

6.Remove fuel shut-off solenoid terminal nut and

remove DDS valve.

Refit

7.Position DDS terminal lead to fuel shut-off

solenoid and secure with nut tightened to

2Nm.

8.Position DDS valve to fuel shut-off solenoid .

9.Position clamping plate to DDS valve and tighten

shear bolts simultaneously until heads shear.

10.Fit fuel injection pump.

See FUEL SYSTEM,

Repair, fuel injection pump and timing; Refit

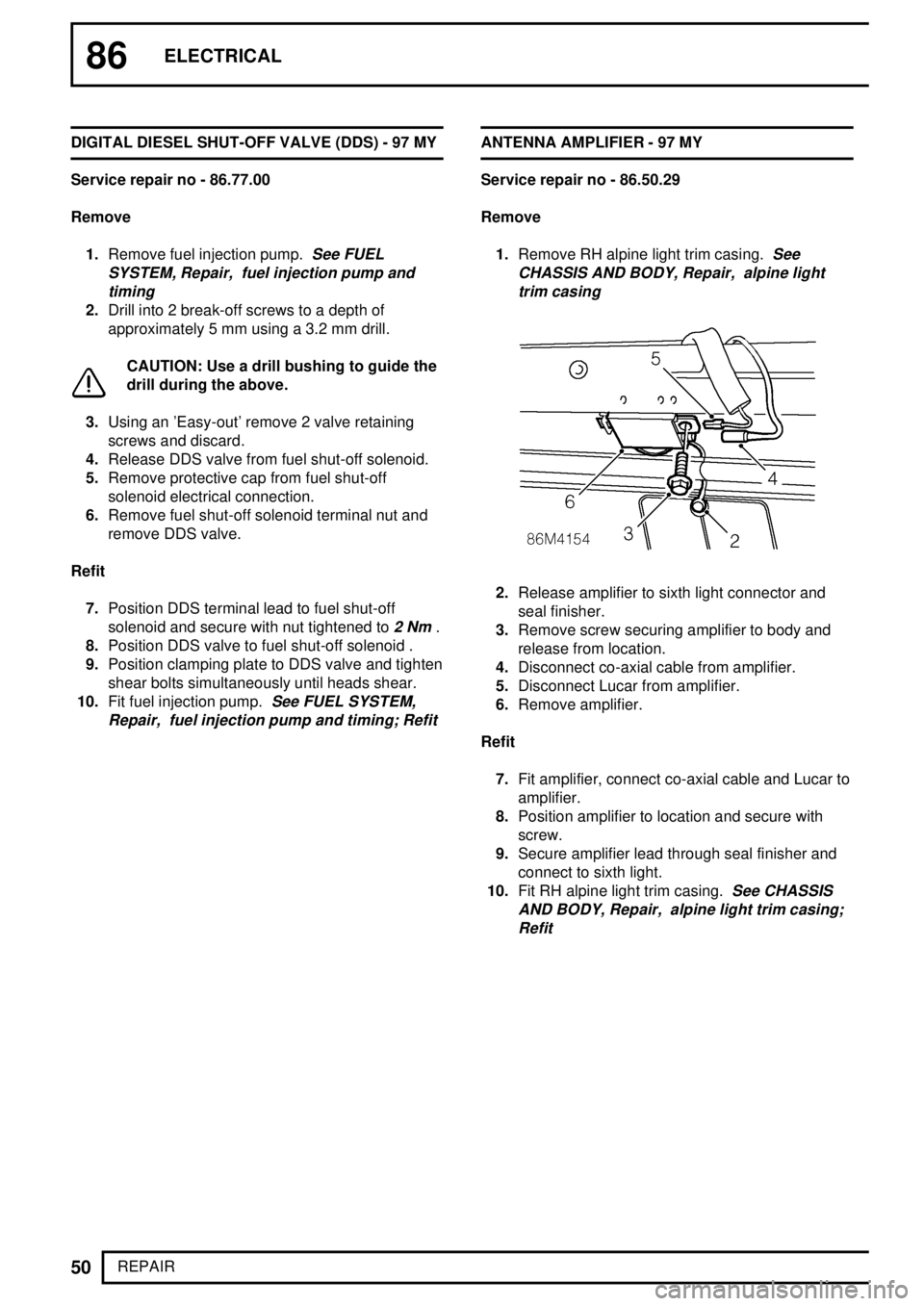

ANTENNA AMPLIFIER - 97 MY

Service repair no - 86.50.29

Remove

1.Remove RH alpine light trim casing.

See

CHASSIS AND BODY, Repair, alpine light

trim casing

2.Release amplifier to sixth light connector and

seal finisher.

3.Remove screw securing amplifier to body and

release from location.

4.Disconnect co-axial cable from amplifier.

5.Disconnect Lucar from amplifier.

6.Remove amplifier.

Refit

7.Fit amplifier, connect co-axial cable and Lucar to

amplifier.

8.Position amplifier to location and secure with

screw.

9.Secure amplifier lead through seal finisher and

connect to sixth light.

10.Fit RH alpine light trim casing.

See CHASSIS

AND BODY, Repair, alpine light trim casing;

Refit

Page 871 of 976

ELECTRICAL

1

OVERHAUL DISTRIBUTOR-LUCAS 35DLM8

Overhaul

DISTRIBUTOR CAP

Service repair no - 86.35.10

1.Unclip and remove cap

2.Fit a new cap if faulty.

3.Clean cap and HT brush with a lint free cloth.

ROTOR ARM

Service repair no - 86.35.16

1.Pull rotor arm from shaft.

2.Fit a new rotor arm if faulty.

INSULATION COVER (FLASH SHIELD)

Service repair no - 86.35.40

1.Remove cover secured by three screws.

2.Fit a new cover if faulty.

VACUUM UNIT

Service repair no - 86.35.21

1.Remove two screws from vacuum unit securing

bracket. Disengage vacuum unit connecting rod

from pick-up base plate connecting peg.

Withdraw vacuum unit from distributor body.AMPLIFIER MODULE

Service repair no - 86.35.30

1.Remove two screws and withdraw module.

2.Remove gasket.

3.Remove two screws and cast heatsink.

WARNING: Amplifier module is a sealed

unit containing Beryllia. This substance is

extremely dangerous if handled. DO NOT

attempt to open or crush module.

PICK-UP AND BASE PLATE ASSEMBLY

Service repair no - 86.35.42

1.Use circlip pliers to remove circlip retaining

reluctor on rotor shaft.

2.Remove flat washer, and 'O' ring recessed in top

of reluctor.

3.Gently withdraw reluctor from shaft, taking care

not to damage teeth.

NOTE: Coupling ring fitted beneath

reluctor.

4.Remove three support pillars and cable

grommet. Lift out pick-up and base plate

assembly.

NOTE: Do not disturb two barrel nuts

securing pick-up module, otherwise air

gap will need re-adjustment.

5.Fit a new pick-up and base plate assembly if

module is known to be faulty, otherwise check

pick-up winding resistance (2k-5k ohm).

Reassemble

6.This is mainly a reversal of dismantling

procedure, noting following points:

Page 892 of 976

ENGINE

DESCRIPTION AND OPERATION15

OPERATION

The 300 TDi is a 4 cylinder, water cooled,

turbocharged diesel engine with a capacity of 2.5

litres.

The cast iron cylinder block is integral with the

crankcase and incorporates direct bored cylinders.

The crankshaft is carried in 5 main bearings,

end-float being controlled by thrust washers which

are positioned on both sides of the centre main

bearing.

The flywheel/drive plate housing is an aluminium

alloy casting secured to the rear of the cylinder

block, it also forms the mounting for the starter

motor. A plugged aperture in the housing allows

access for the insertion of the timing pin.

The aluminium alloy cylinder head carries a

conventional rocker shaft and rockers, operating 2

valves per cylinder via camshaft followers and push

rods from a single camshaft, supported in the

cylinder block by 4 bearings and driven by a gear

and toothed belt from the crankshaft. A lobe formed

between the 2 inner bearing journals provides drive

for the fuel lift pump and another lobe, between the 2

drive end journals provides drive for the brake servo

pump. Camshaft end-float is controlled by a thrust

plate bolted to the cylinder block.

Graphite coated, aluminium alloy pistons are fitted

with 2 compression and an oil control ring and are

secured to the connecting rods by semi-floating

gudgeon pins which are an interference fit in the

small end bush. A swirl chamber is incorporated in

the piston crown to facilitate combustion.

The timing case consists of cast aluminium alloy

front and rear covers which house the oil pump,

crankshaft and camshaft front oil seals and which

also carry the fuel injection pump and drive belt idler

pulley. Housed within the timing case housing is the

crankshaft gear which provides drive for the

camshaft and fuel injection pump gears via a rubber

toothed belt.

Page 896 of 976

ENGINE

OVERHAUL1

TIMING BELT, TENSIONER AND GEARS

Timing belt - remove

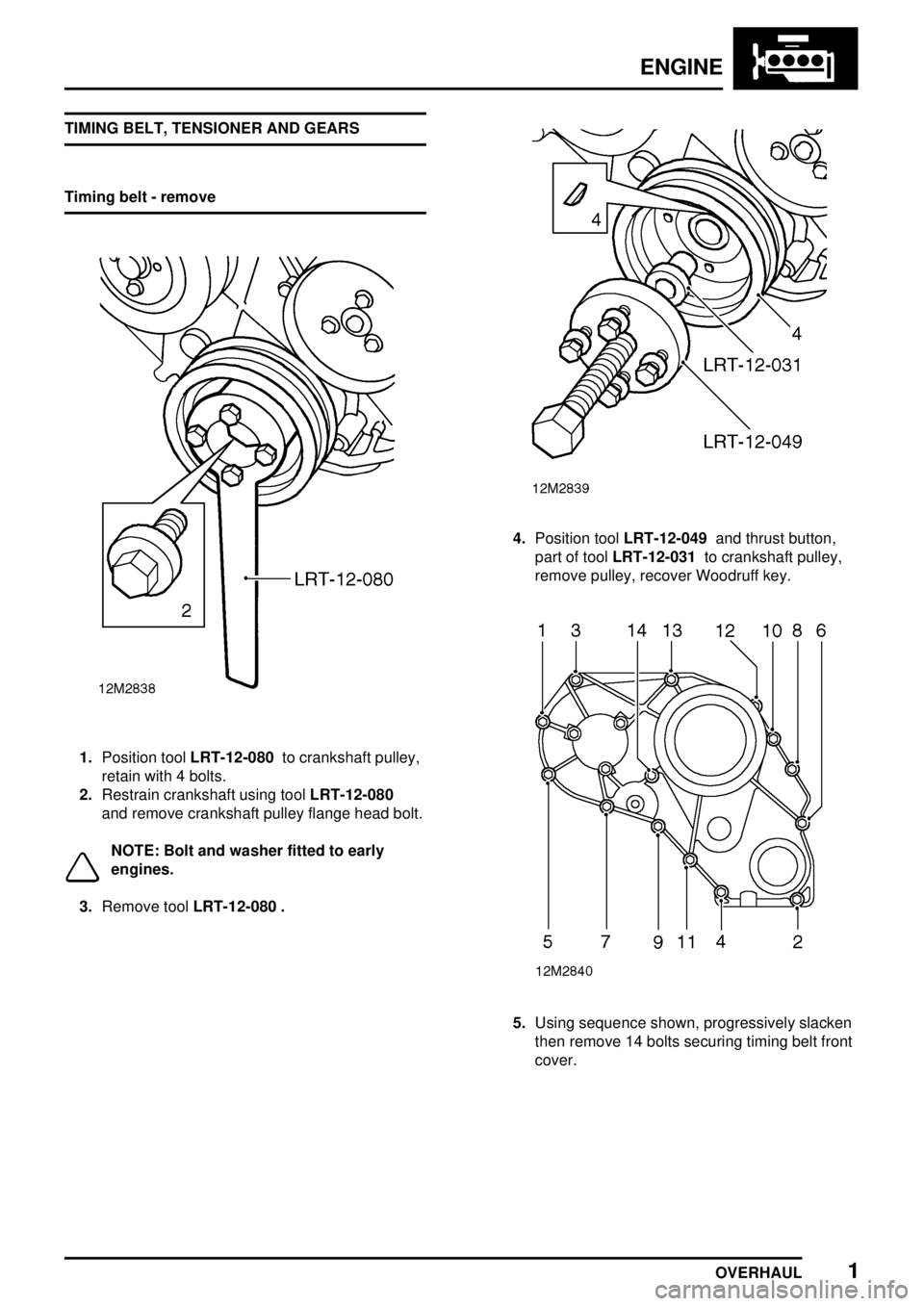

1.Position toolLRT-12-080to crankshaft pulley,

retain with 4 bolts.

2.Restrain crankshaft using toolLRT-12-080

and remove crankshaft pulley flange head bolt.

NOTE: Bolt and washer fitted to early

engines.

3.Remove toolLRT-12-080 .

4.Position toolLRT-12-049and thrust button,

part of toolLRT-12-031to crankshaft pulley,

remove pulley, recover Woodruff key.

5.Using sequence shown, progressively slacken

then remove 14 bolts securing timing belt front

cover.

Page 898 of 976

ENGINE

OVERHAUL3

All engines

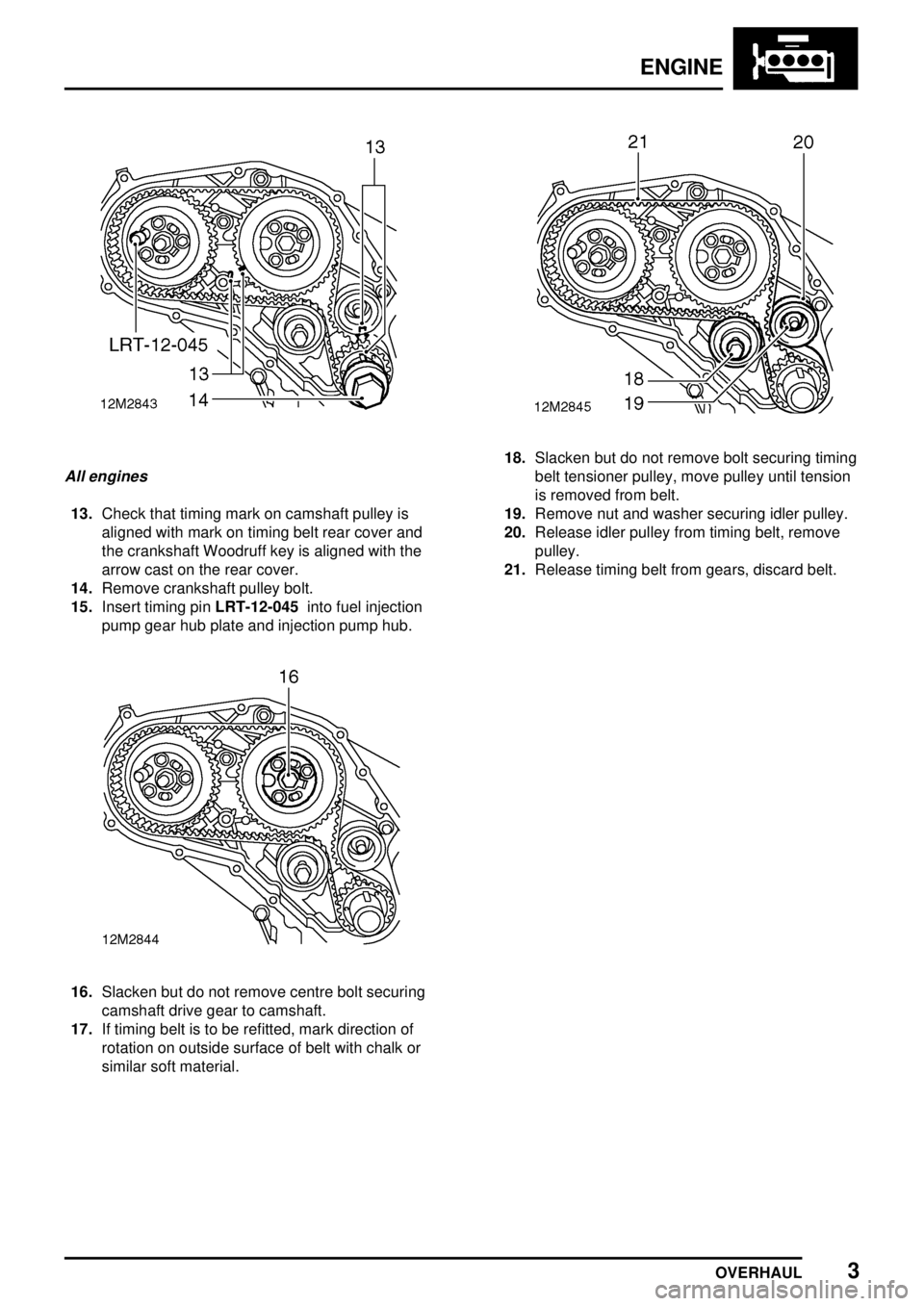

13.Check that timing mark on camshaft pulley is

aligned with mark on timing belt rear cover and

the crankshaft Woodruff key is aligned with the

arrow cast on the rear cover.

14.Remove crankshaft pulley bolt.

15.Insert timing pinLRT-12-045into fuel injection

pump gear hub plate and injection pump hub.

16.Slacken but do not remove centre bolt securing

camshaft drive gear to camshaft.

17.If timing belt is to be refitted, mark direction of

rotation on outside surface of belt with chalk or

similar soft material.

18.Slacken but do not remove bolt securing timing

belt tensioner pulley, move pulley until tension

is removed from belt.

19.Remove nut and washer securing idler pulley.

20.Release idler pulley from timing belt, remove

pulley.

21.Release timing belt from gears, discard belt.

Page 899 of 976

ENGINE

4

OVERHAUL Timing belt tensioner and timing gears - remove

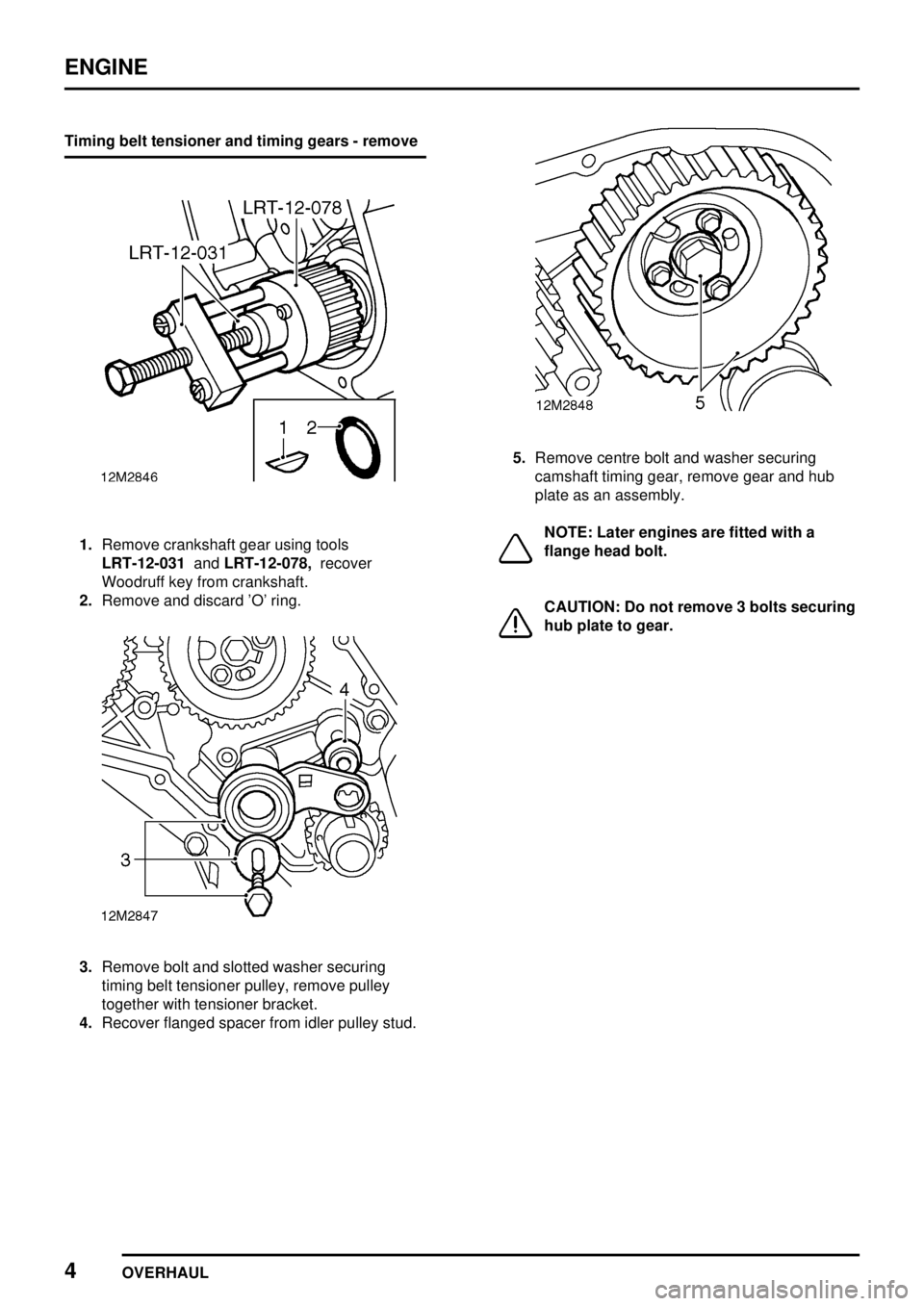

1.Remove crankshaft gear using tools

LRT-12-031andLRT-12-078,recover

Woodruff key from crankshaft.

2.Remove and discard 'O' ring.

3.Remove bolt and slotted washer securing

timing belt tensioner pulley, remove pulley

together with tensioner bracket.

4.Recover flanged spacer from idler pulley stud.

5.Remove centre bolt and washer securing

camshaft timing gear, remove gear and hub

plate as an assembly.

NOTE: Later engines are fitted with a

flange head bolt.

CAUTION: Do not remove 3 bolts securing

hub plate to gear.

Page 900 of 976

ENGINE

OVERHAUL5

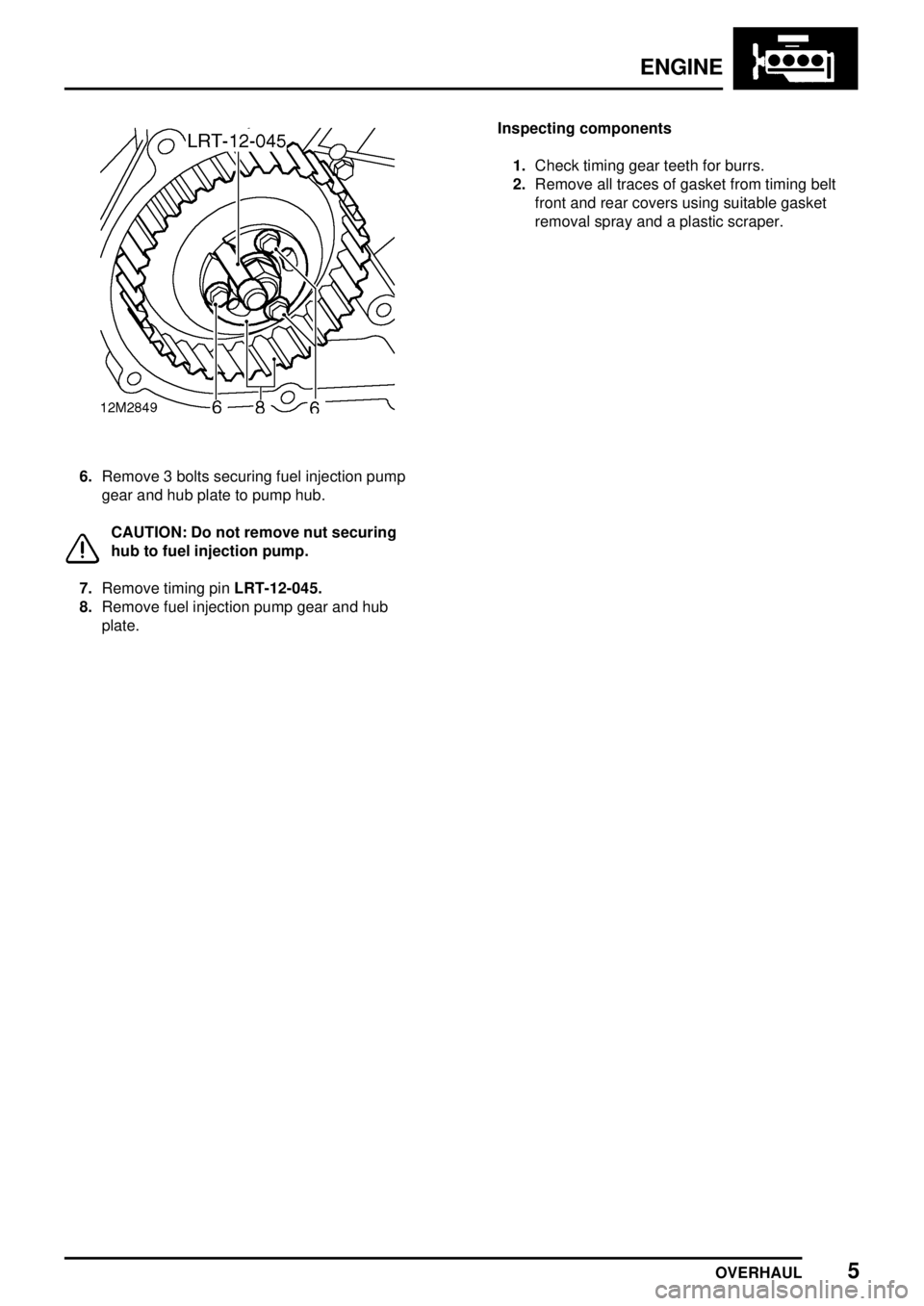

6.Remove 3 bolts securing fuel injection pump

gear and hub plate to pump hub.

CAUTION: Do not remove nut securing

hub to fuel injection pump.

7.Remove timing pinLRT-12-045.

8.Remove fuel injection pump gear and hub

plate.Inspecting components

1.Check timing gear teeth for burrs.

2.Remove all traces of gasket from timing belt

front and rear covers using suitable gasket

removal spray and a plastic scraper.

Page 904 of 976

ENGINE

OVERHAUL9

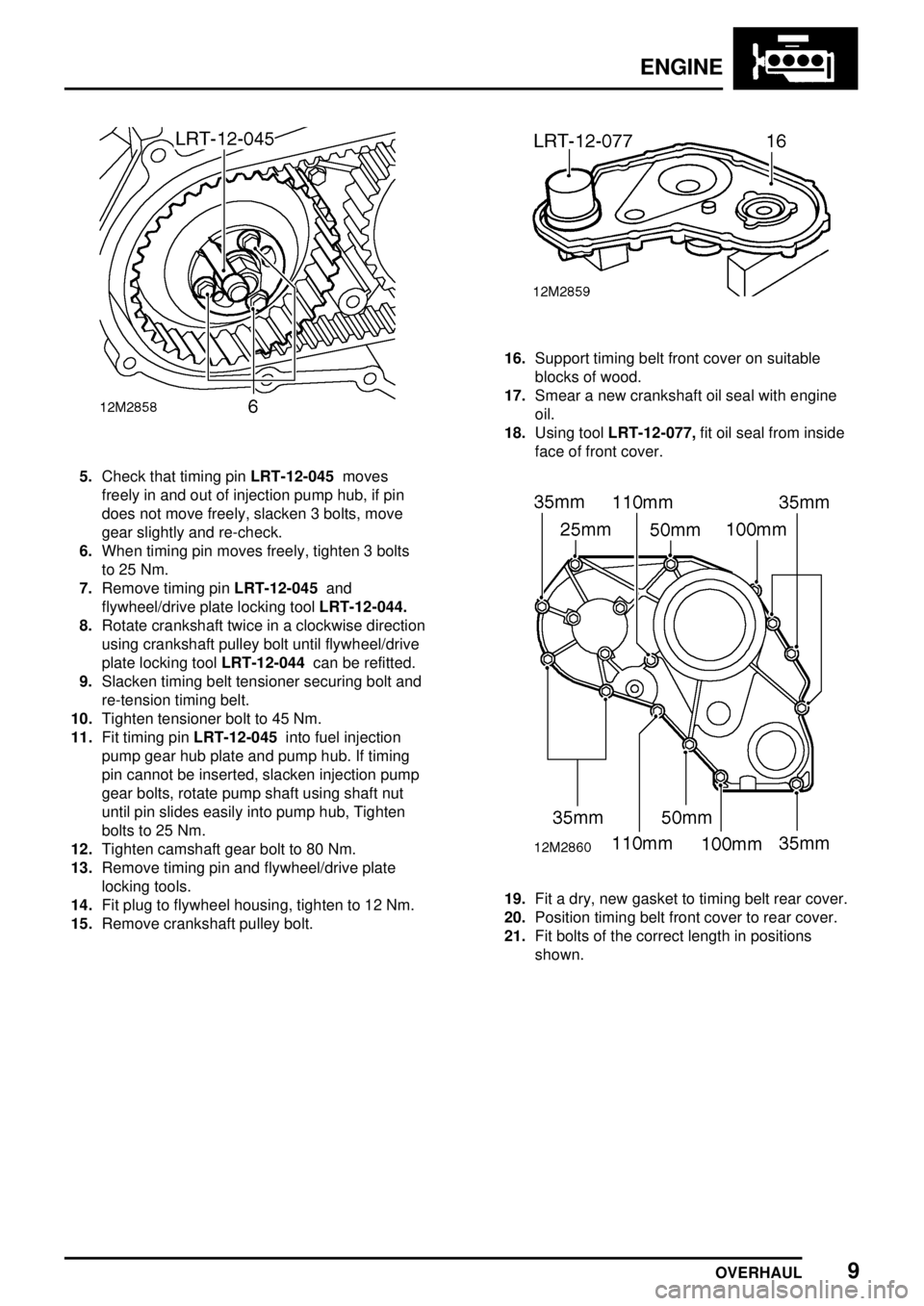

5.Check that timing pinLRT-12-045moves

freely in and out of injection pump hub, if pin

does not move freely, slacken 3 bolts, move

gear slightly and re-check.

6.When timing pin moves freely, tighten 3 bolts

to 25 Nm.

7.Remove timing pinLRT-12-045and

flywheel/drive plate locking toolLRT-12-044.

8.Rotate crankshaft twice in a clockwise direction

using crankshaft pulley bolt until flywheel/drive

plate locking toolLRT-12-044can be refitted.

9.Slacken timing belt tensioner securing bolt and

re-tension timing belt.

10.Tighten tensioner bolt to 45 Nm.

11.Fit timing pinLRT-12-045into fuel injection

pump gear hub plate and pump hub. If timing

pin cannot be inserted, slacken injection pump

gear bolts, rotate pump shaft using shaft nut

until pin slides easily into pump hub, Tighten

bolts to 25 Nm.

12.Tighten camshaft gear bolt to 80 Nm.

13.Remove timing pin and flywheel/drive plate

locking tools.

14.Fit plug to flywheel housing, tighten to 12 Nm.

15.Remove crankshaft pulley bolt.

16.Support timing belt front cover on suitable

blocks of wood.

17.Smear a new crankshaft oil seal with engine

oil.

18.Using toolLRT-12-077,fit oil seal from inside

face of front cover.

19.Fit a dry, new gasket to timing belt rear cover.

20.Position timing belt front cover to rear cover.

21.Fit bolts of the correct length in positions

shown.

Page 906 of 976

ENGINE

OVERHAUL11

ROCKER SHAFT

Remove

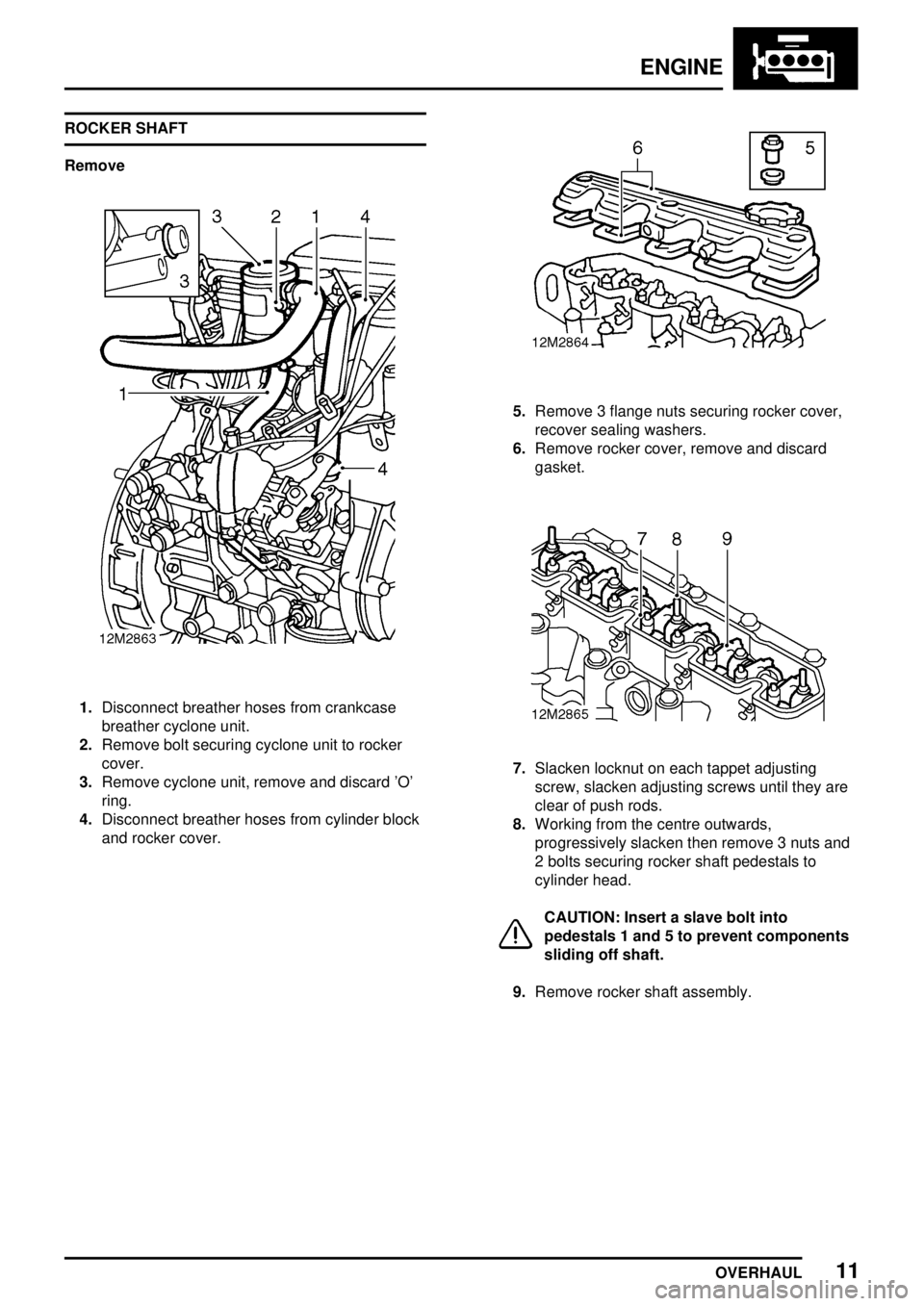

1.Disconnect breather hoses from crankcase

breather cyclone unit.

2.Remove bolt securing cyclone unit to rocker

cover.

3.Remove cyclone unit, remove and discard 'O'

ring.

4.Disconnect breather hoses from cylinder block

and rocker cover.

5.Remove 3 flange nuts securing rocker cover,

recover sealing washers.

6.Remove rocker cover, remove and discard

gasket.

7.Slacken locknut on each tappet adjusting

screw, slacken adjusting screws until they are

clear of push rods.

8.Working from the centre outwards,

progressively slacken then remove 3 nuts and

2 bolts securing rocker shaft pedestals to

cylinder head.

CAUTION: Insert a slave bolt into

pedestals 1 and 5 to prevent components

sliding off shaft.

9.Remove rocker shaft assembly.