ECU LAND ROVER DISCOVERY 1995 Service Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 976, PDF Size: 14.57 MB

Page 938 of 976

ENGINE

OVERHAUL43

Refit

1.Clean all traces of carbon from injector ports.

2.Fit a new sealing washer to injector, insert

injector into port ensuring that spill return banjo

bolt hole faces away from cylinder head.

3.Position injector clamp to injector and cylinder

head stud ensuring that raised 'pip' on concave

face of clamp faces upwards.

4.Fit and tighten injector clamp nut to 25 Nm.

5.Position spill return pipes to injector, fit banjo

bolt and 2 new sealing washers.

6.Tighten banjo bolt to 10 Nm.

7.Repeat above procedures for remaining

injectors.

8.Position fuel pipes to injector and fuel injection

pump, tighten connections.GLOW PLUGS

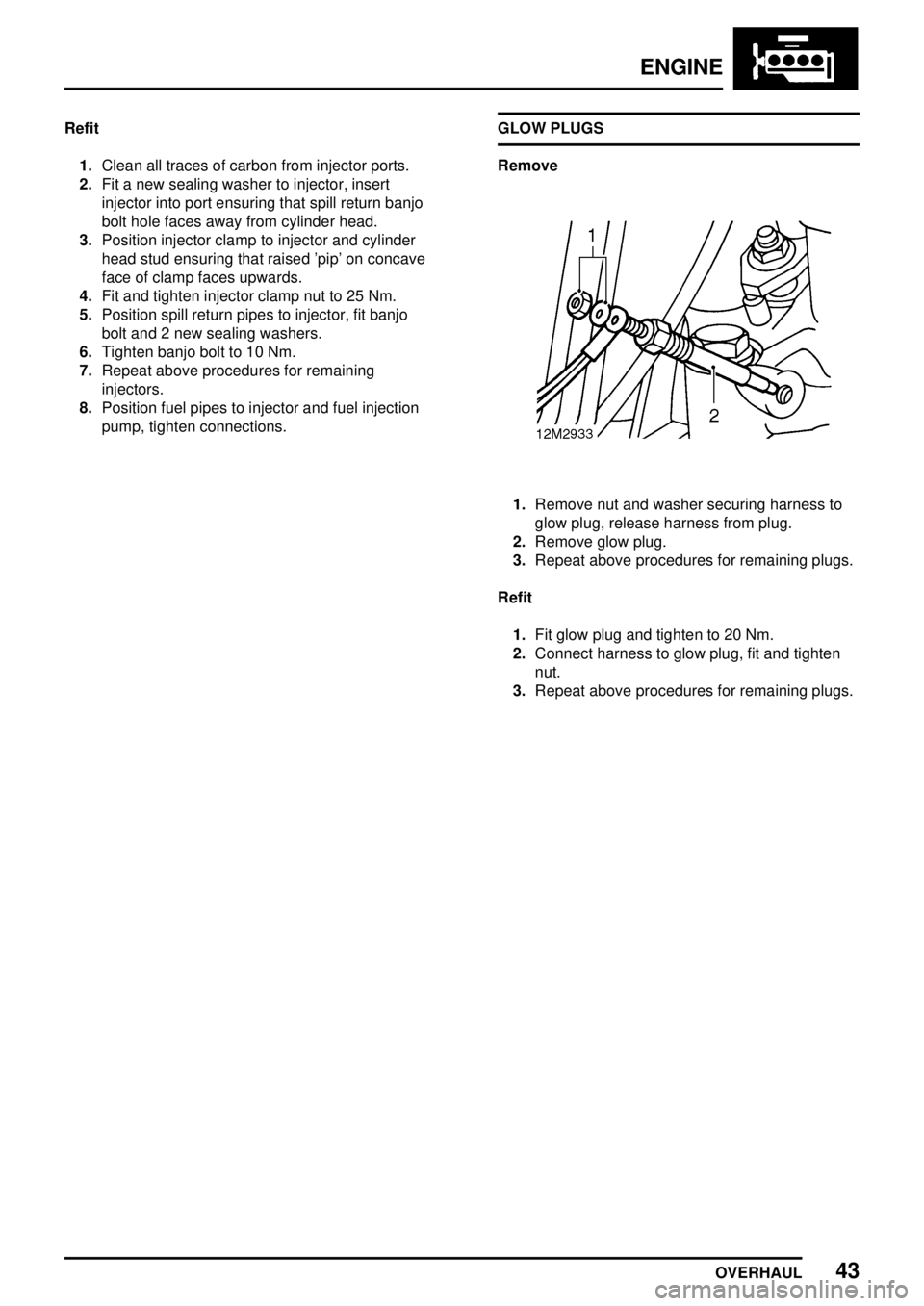

Remove

1.Remove nut and washer securing harness to

glow plug, release harness from plug.

2.Remove glow plug.

3.Repeat above procedures for remaining plugs.

Refit

1.Fit glow plug and tighten to 20 Nm.

2.Connect harness to glow plug, fit and tighten

nut.

3.Repeat above procedures for remaining plugs.

Page 940 of 976

ENGINE

OVERHAUL45

SUMP, OIL PICK-UP AND DRAIN PIPES

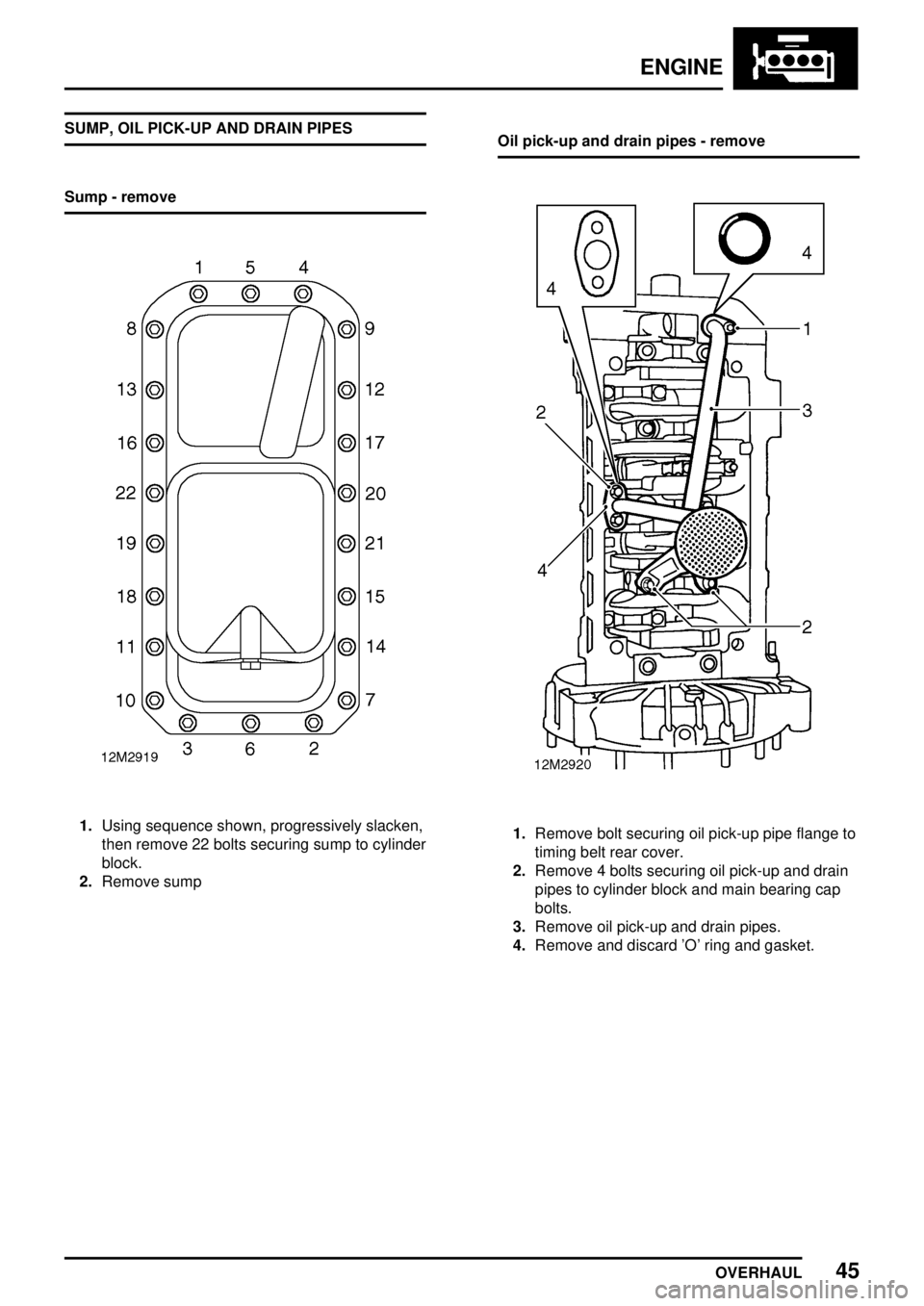

Sump - remove

1.Using sequence shown, progressively slacken,

then remove 22 bolts securing sump to cylinder

block.

2.Remove sumpOil pick-up and drain pipes - remove1.Remove bolt securing oil pick-up pipe flange to

timing belt rear cover.

2.Remove 4 bolts securing oil pick-up and drain

pipes to cylinder block and main bearing cap

bolts.

3.Remove oil pick-up and drain pipes.

4.Remove and discard 'O' ring and gasket.

Page 941 of 976

ENGINE

46

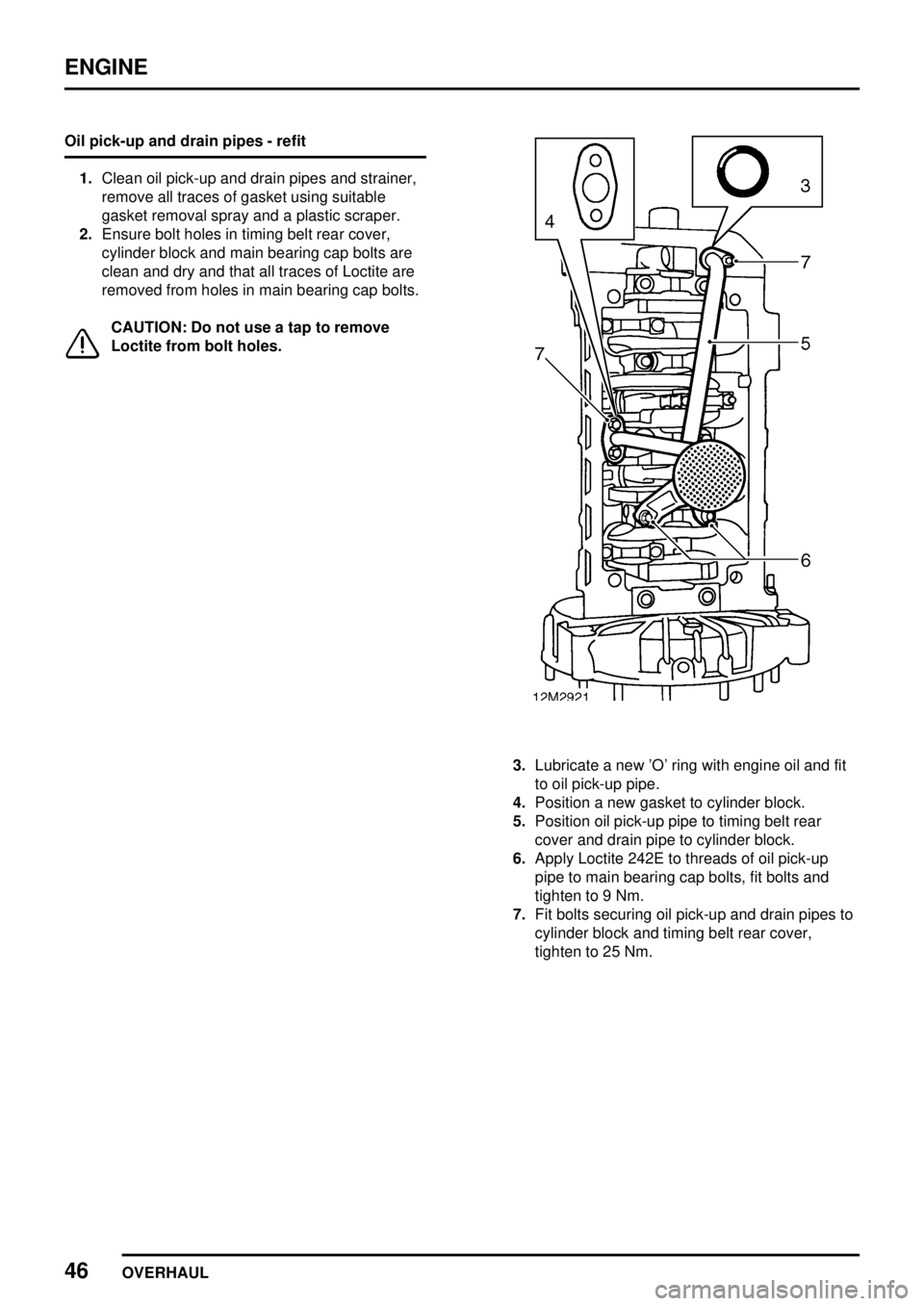

OVERHAUL Oil pick-up and drain pipes - refit

1.Clean oil pick-up and drain pipes and strainer,

remove all traces of gasket using suitable

gasket removal spray and a plastic scraper.

2.Ensure bolt holes in timing belt rear cover,

cylinder block and main bearing cap bolts are

clean and dry and that all traces of Loctite are

removed from holes in main bearing cap bolts.

CAUTION: Do not use a tap to remove

Loctite from bolt holes.

3.Lubricate a new 'O' ring with engine oil and fit

to oil pick-up pipe.

4.Position a new gasket to cylinder block.

5.Position oil pick-up pipe to timing belt rear

cover and drain pipe to cylinder block.

6.Apply Loctite 242E to threads of oil pick-up

pipe to main bearing cap bolts, fit bolts and

tighten to 9 Nm.

7.Fit bolts securing oil pick-up and drain pipes to

cylinder block and timing belt rear cover,

tighten to 25 Nm.

Page 943 of 976

ENGINE

48

OVERHAUL

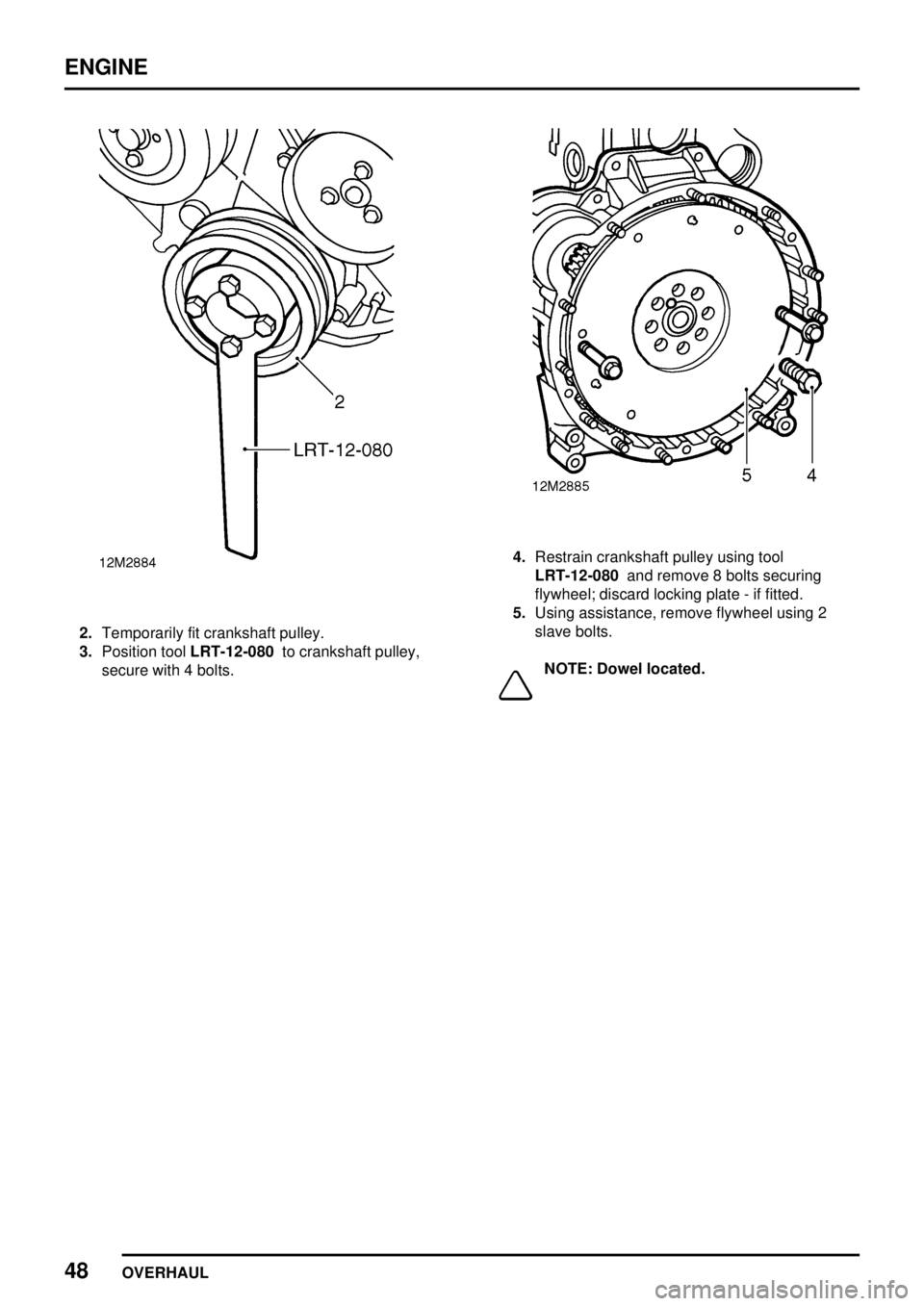

2.Temporarily fit crankshaft pulley.

3.Position toolLRT-12-080to crankshaft pulley,

secure with 4 bolts.

4.Restrain crankshaft pulley using tool

LRT-12-080and remove 8 bolts securing

flywheel; discard locking plate - if fitted.

5.Using assistance, remove flywheel using 2

slave bolts.

NOTE: Dowel located.

Page 946 of 976

ENGINE

OVERHAUL51

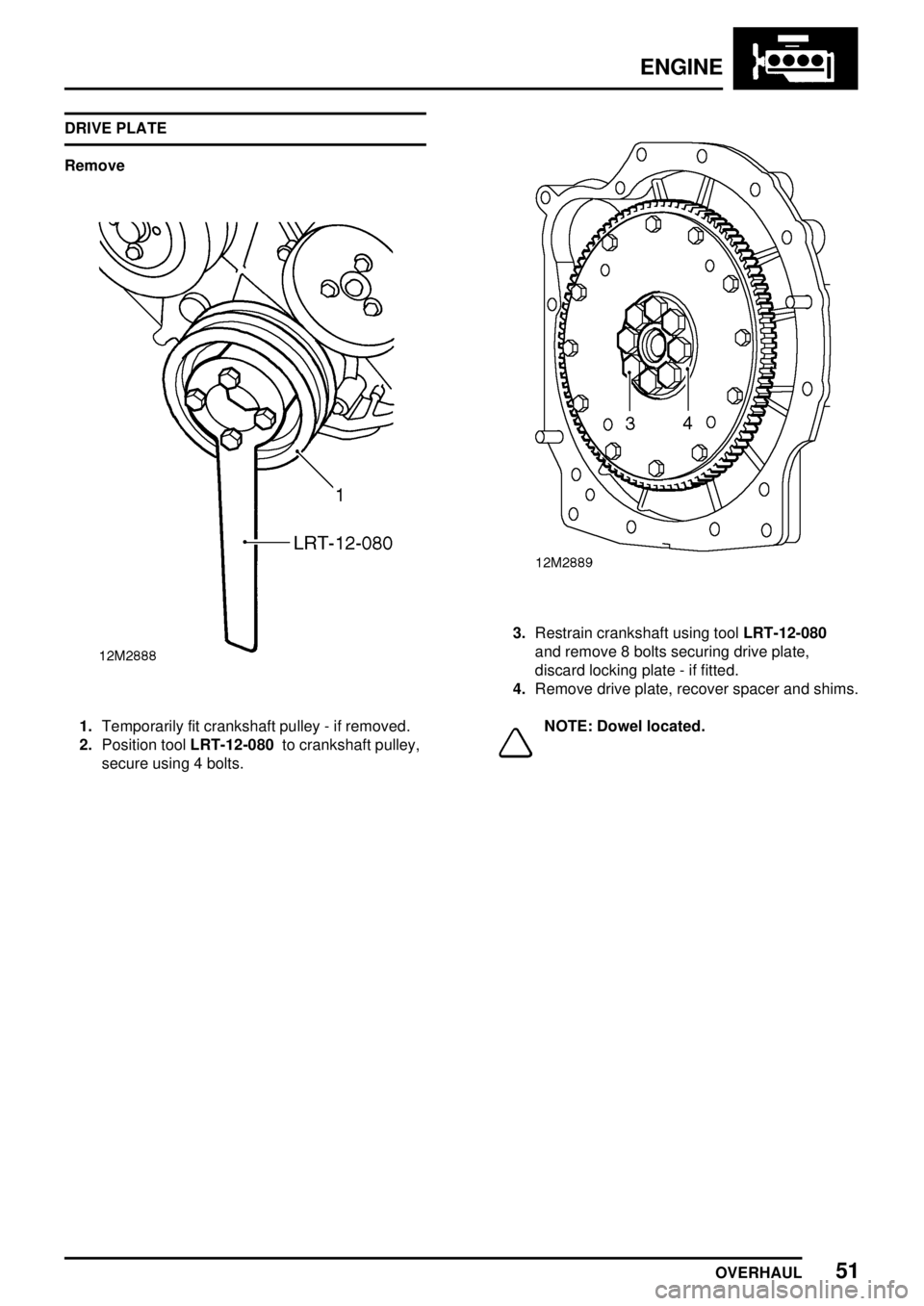

DRIVE PLATE

Remove

1.Temporarily fit crankshaft pulley - if removed.

2.Position toolLRT-12-080to crankshaft pulley,

secure using 4 bolts.

3.Restrain crankshaft using toolLRT-12-080

and remove 8 bolts securing drive plate,

discard locking plate - if fitted.

4.Remove drive plate, recover spacer and shims.

NOTE: Dowel located.

Page 948 of 976

ENGINE

OVERHAUL53

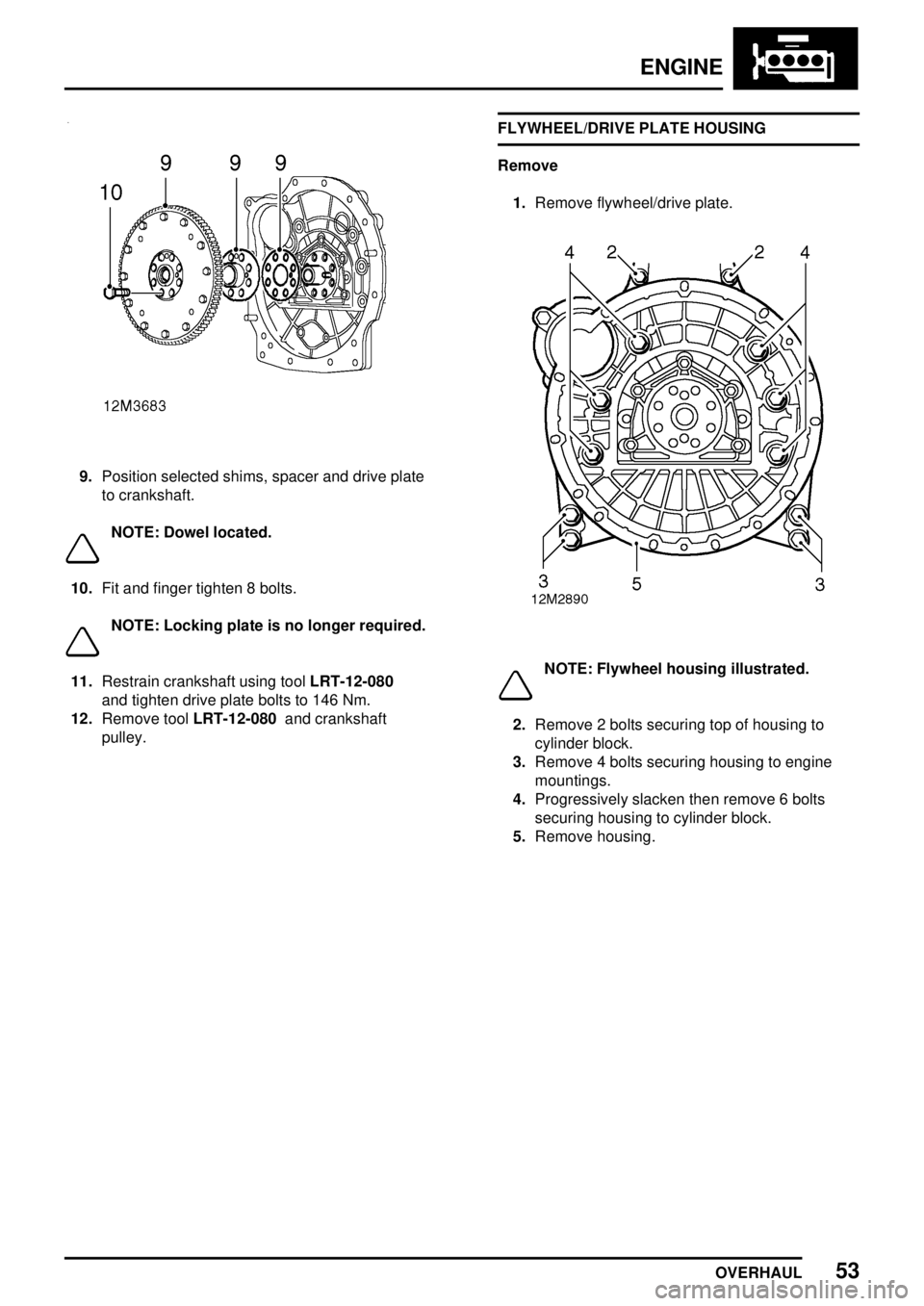

9.Position selected shims, spacer and drive plate

to crankshaft.

NOTE: Dowel located.

10.Fit and finger tighten 8 bolts.

NOTE: Locking plate is no longer required.

11.Restrain crankshaft using toolLRT-12-080

and tighten drive plate bolts to 146 Nm.

12.Remove toolLRT-12-080and crankshaft

pulley.FLYWHEEL/DRIVE PLATE HOUSING

Remove

1.Remove flywheel/drive plate.

NOTE: Flywheel housing illustrated.

2.Remove 2 bolts securing top of housing to

cylinder block.

3.Remove 4 bolts securing housing to engine

mountings.

4.Progressively slacken then remove 6 bolts

securing housing to cylinder block.

5.Remove housing.

Page 950 of 976

ENGINE

OVERHAUL55

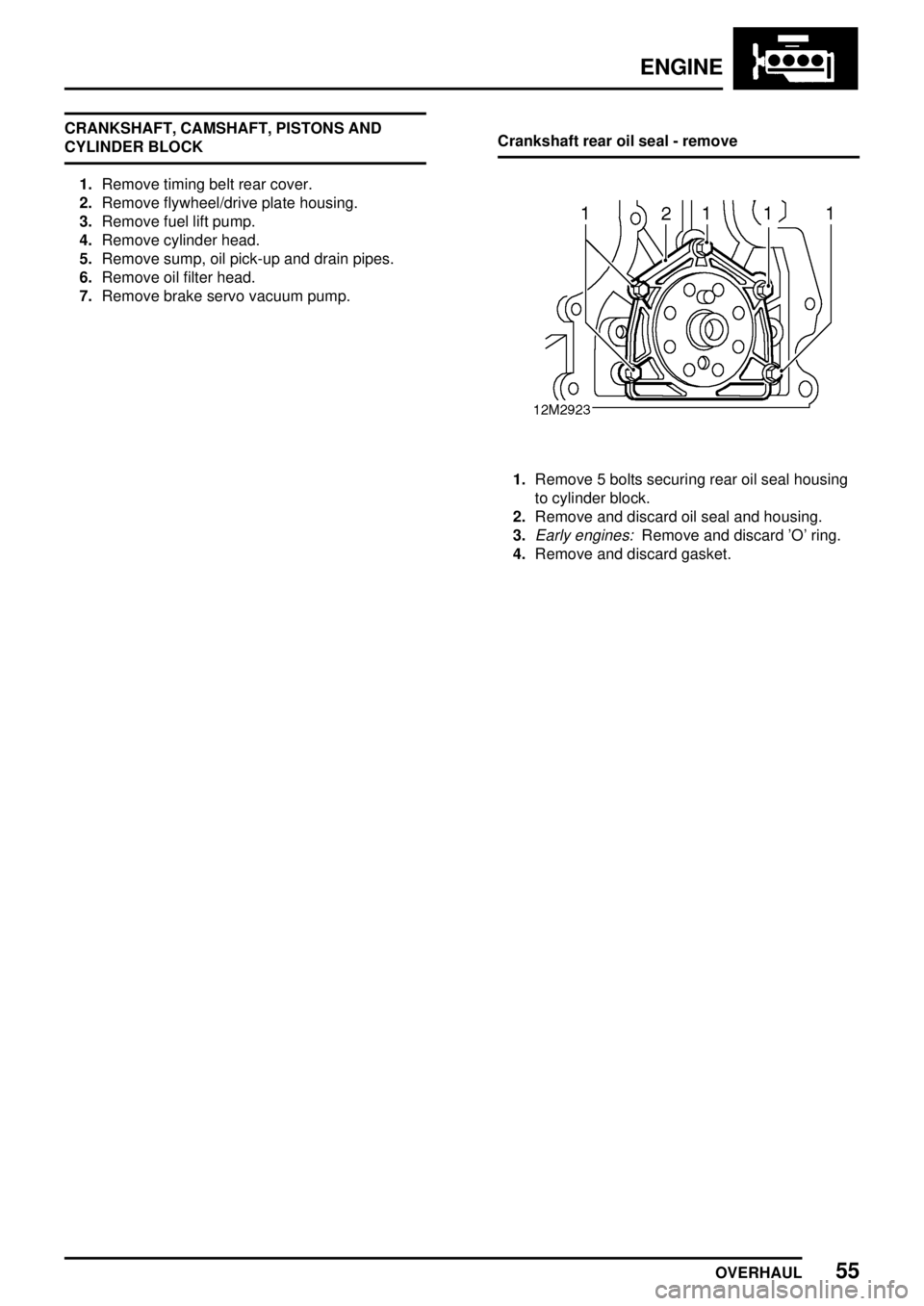

CRANKSHAFT, CAMSHAFT, PISTONS AND

CYLINDER BLOCK

1.Remove timing belt rear cover.

2.Remove flywheel/drive plate housing.

3.Remove fuel lift pump.

4.Remove cylinder head.

5.Remove sump, oil pick-up and drain pipes.

6.Remove oil filter head.

7.Remove brake servo vacuum pump.Crankshaft rear oil seal - remove

1.Remove 5 bolts securing rear oil seal housing

to cylinder block.

2.Remove and discard oil seal and housing.

3.

Early engines:Remove and discard 'O' ring.

4.Remove and discard gasket.

Page 951 of 976

ENGINE

56

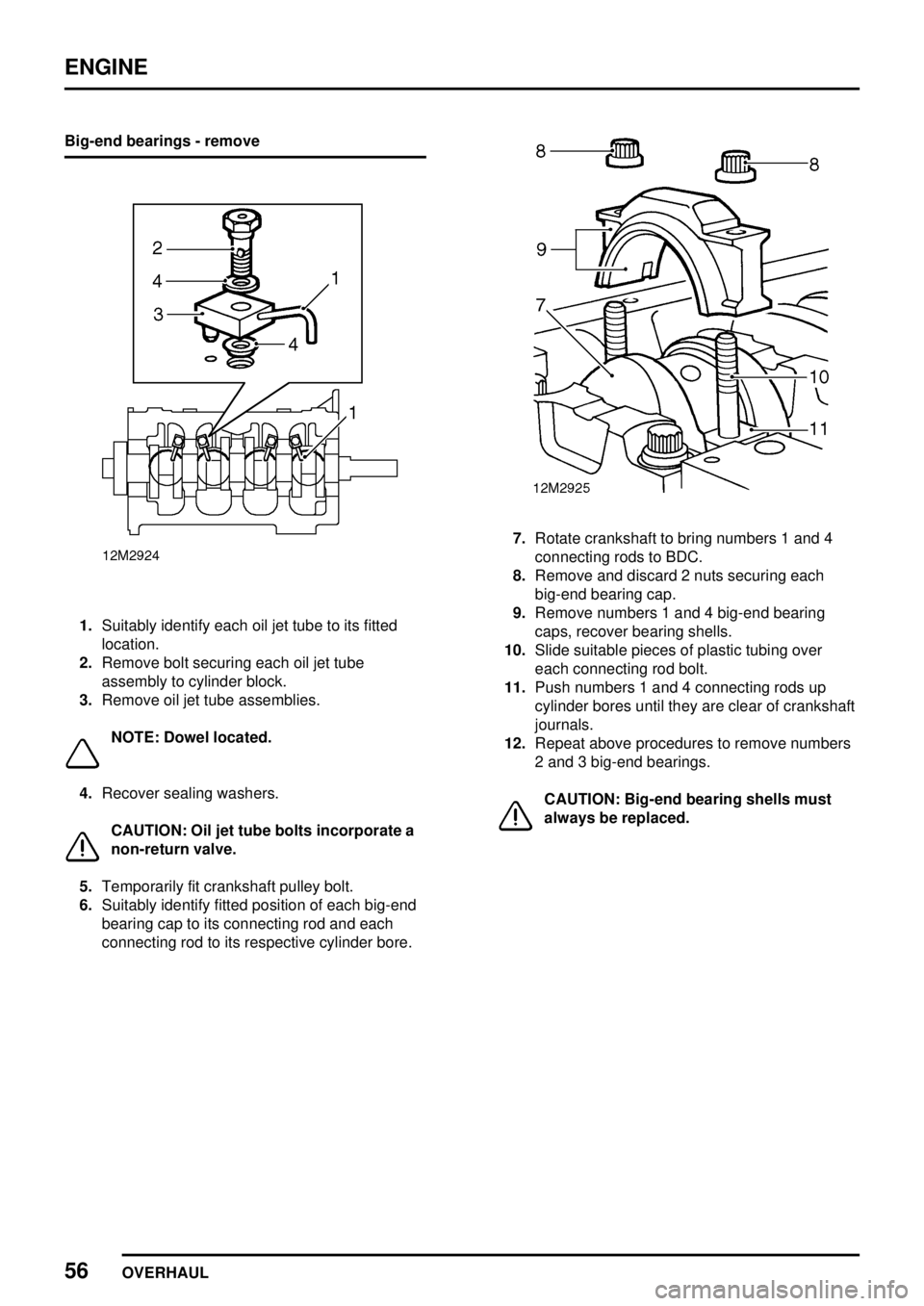

OVERHAUL Big-end bearings - remove

1.Suitably identify each oil jet tube to its fitted

location.

2.Remove bolt securing each oil jet tube

assembly to cylinder block.

3.Remove oil jet tube assemblies.

NOTE: Dowel located.

4.Recover sealing washers.

CAUTION: Oil jet tube bolts incorporate a

non-return valve.

5.Temporarily fit crankshaft pulley bolt.

6.Suitably identify fitted position of each big-end

bearing cap to its connecting rod and each

connecting rod to its respective cylinder bore.

7.Rotate crankshaft to bring numbers 1 and 4

connecting rods to BDC.

8.Remove and discard 2 nuts securing each

big-end bearing cap.

9.Remove numbers 1 and 4 big-end bearing

caps, recover bearing shells.

10.Slide suitable pieces of plastic tubing over

each connecting rod bolt.

11.Push numbers 1 and 4 connecting rods up

cylinder bores until they are clear of crankshaft

journals.

12.Repeat above procedures to remove numbers

2 and 3 big-end bearings.

CAUTION: Big-end bearing shells must

always be replaced.

Page 968 of 976

ENGINE

OVERHAUL73

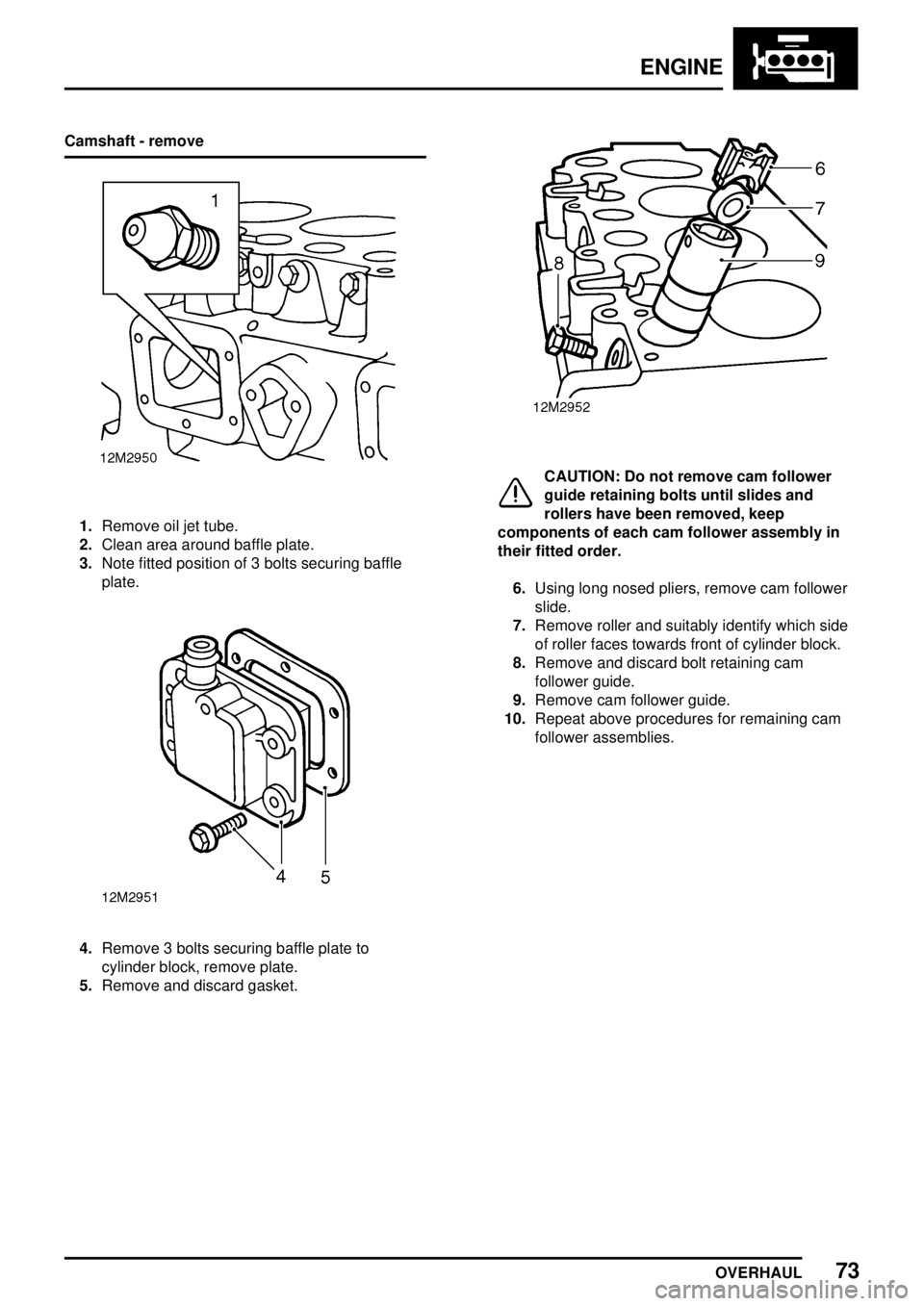

Camshaft - remove

1.Remove oil jet tube.

2.Clean area around baffle plate.

3.Note fitted position of 3 bolts securing baffle

plate.

4.Remove 3 bolts securing baffle plate to

cylinder block, remove plate.

5.Remove and discard gasket.

CAUTION: Do not remove cam follower

guide retaining bolts until slides and

rollers have been removed, keep

components of each cam follower assembly in

their fitted order.

6.Using long nosed pliers, remove cam follower

slide.

7.Remove roller and suitably identify which side

of roller faces towards front of cylinder block.

8.Remove and discard bolt retaining cam

follower guide.

9.Remove cam follower guide.

10.Repeat above procedures for remaining cam

follower assemblies.

Page 969 of 976

ENGINE

74

OVERHAUL

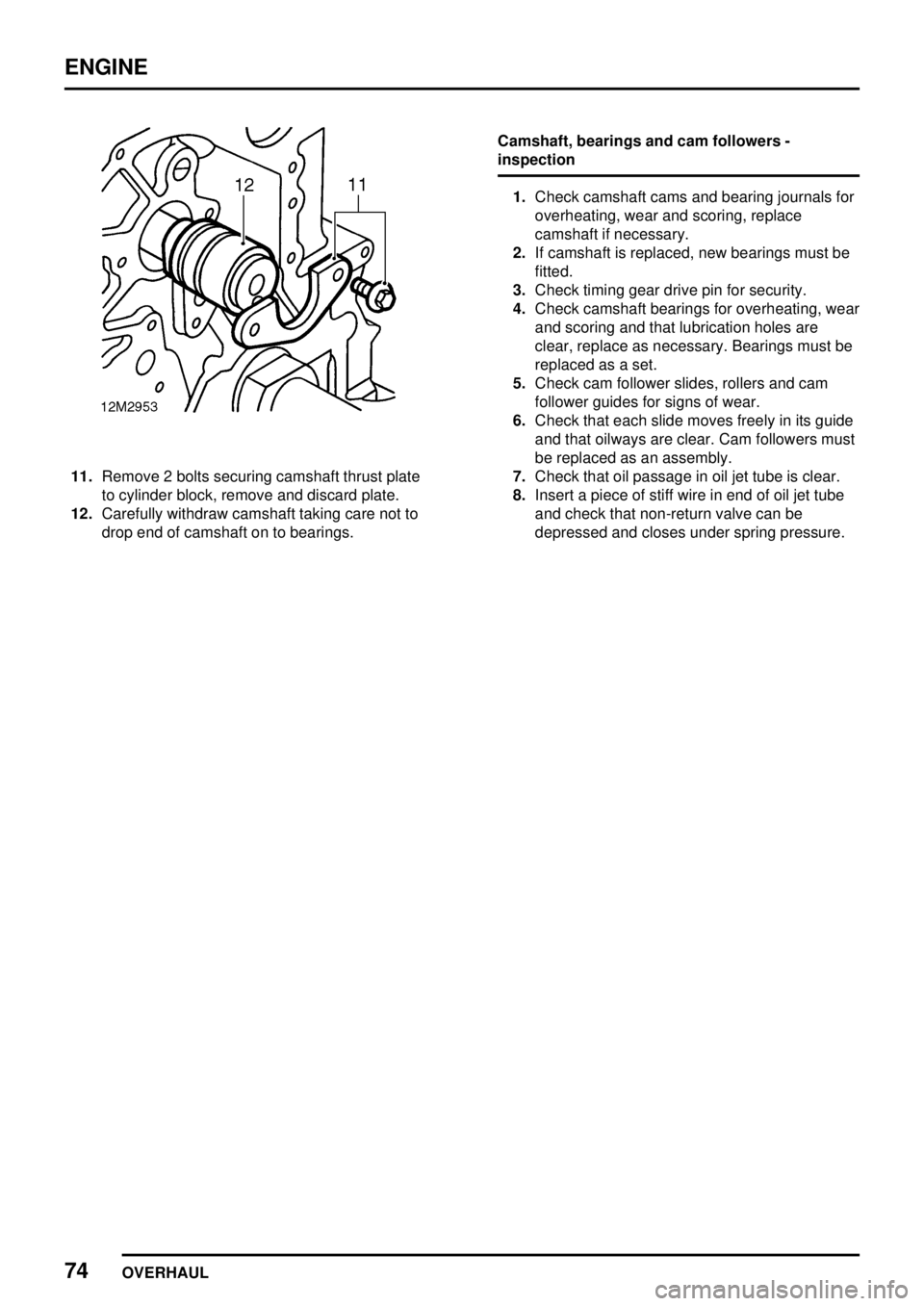

11.Remove 2 bolts securing camshaft thrust plate

to cylinder block, remove and discard plate.

12.Carefully withdraw camshaft taking care not to

drop end of camshaft on to bearings.Camshaft, bearings and cam followers -

inspection

1.Check camshaft cams and bearing journals for

overheating, wear and scoring, replace

camshaft if necessary.

2.If camshaft is replaced, new bearings must be

fitted.

3.Check timing gear drive pin for security.

4.Check camshaft bearings for overheating, wear

and scoring and that lubrication holes are

clear, replace as necessary. Bearings must be

replaced as a set.

5.Check cam follower slides, rollers and cam

follower guides for signs of wear.

6.Check that each slide moves freely in its guide

and that oilways are clear. Cam followers must

be replaced as an assembly.

7.Check that oil passage in oil jet tube is clear.

8.Insert a piece of stiff wire in end of oil jet tube

and check that non-return valve can be

depressed and closes under spring pressure.