steering LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 660 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

15

REPAIR AIRBAG MANUAL DEPLOYMENT

CAUTION: Deployment in the vehicle will

damage the steering wheel; if the vehicle

is not being scrapped deploy the module

away from the vehicle in accordance with the

separate procedure.

If a vehicle is to be scrapped and contains an

undeployed airbag module, the module must be

manually deployed. This operation should only be

carried out using the following recommended manual

deployment procedure.

Before deployment is started the deployment tool self

test procedure should be carried out.

Deployment tool SMD 4082/1 self test procedure

1.Insert BLUE and YELLOW connectors of tool

lead into corresponding sockets on face of tool.

2.Connect crocodile clips of second tool lead to

battery, RED to positive and BLACK to negative.

3.RED "READY" light should illuminate.

4.Press and hold both operating buttons.5.GREEN "DEFECTIVE" light should illuminate.

6.Release both operating buttons.

7.RED "READY" light should illuminate.

8.Disconnect tool from battery.

9.Disconnect blue and yellow connectors from tool

face sockets.

10.Self test now complete.

Deployment with module fitted to vehicle

These guidelines are written to aid authorised

personnel to carry out the safe disposal of the airbag

module when fitted to the vehicle.

WARNING: Only use the LAND ROVER

approved deployment equipment. Deploy

airbag module in a well ventilated

designated area. Ensure airbag module is not

damaged or ruptured before deploying.

1.Carry out deployment tool self test.

2.Release 2 turnbuckles securing lower panel to

dash, remove lower panel.

Page 661 of 873

75SUPPLEMENTARY RESTRAINT SYSTEM

16

REPAIR

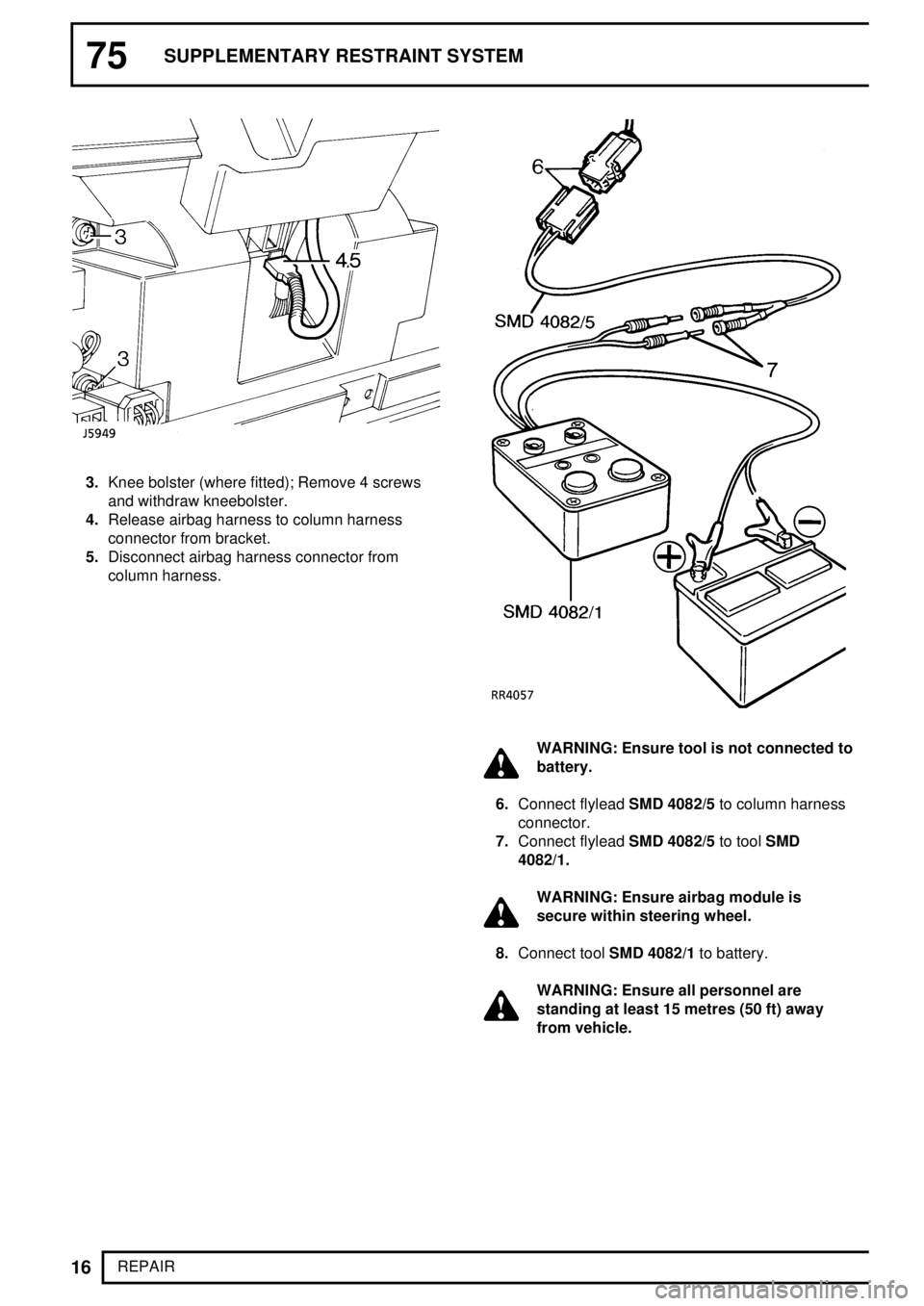

3.Knee bolster (where fitted); Remove 4 screws

and withdraw kneebolster.

4.Release airbag harness to column harness

connector from bracket.

5.Disconnect airbag harness connector from

column harness.

WARNING: Ensure tool is not connected to

battery.

6.Connect flyleadSMD 4082/5to column harness

connector.

7.Connect flyleadSMD 4082/5to toolSMD

4082/1.

WARNING: Ensure airbag module is

secure within steering wheel.

8.Connect toolSMD 4082/1to battery.

WARNING: Ensure all personnel are

standing at least 15 metres (50 ft) away

from vehicle.

Page 662 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

17

REPAIR

9.Press both operating buttons to deploy airbag

module.

10. DO NOTreturn to airbag module for 30 minutes.

11.Using gloves and face mask, remove airbag

module from steering wheel, place airbag

module in plastic bag and seal bag.

12.Transport deployed airbag module to designated

area for incineration.

NOTE: DO NOT transport airbag module in

the vehicle passenger compartment.

13.Scrap all remaining parts of airbag system.

DO NOTre-use or salvage any parts of the

airbag system including steering wheel.Deployment with module removed from vehicle.

Driver's Airbag Module

These guidelines are written to aid authorised

personnel to carry out the safe disposal of airbag

modules when removed from the vehicle.

WARNING: Only use the LAND ROVER

approved deployment equipment.

Deploy airbag modules in a well ventilated

designated area.

Ensure airbag module is not damaged or ruptured

before deploying.

1.Carry out deployment tool self test.

2.Remove airbag module from steering wheel.

See driver's airbag module.

3.Position toolSMD 4082/2in vice, ensuring that

vice jaws grip tool above bottom flange to

prevent possibility of tool being forced upwards

from vice. Tighten vice.

Page 664 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

19

REPAIR

9.Press both operating buttons to deploy airbag

module.

10. DO NOTreturn to airbag module for 30 minutes.

11.Using gloves and face mask, remove airbag

module from tool, place airbag module in plastic

bag and seal bag.

12.Wipe down tool with damp cloth.

13.Transport deployed airbag module to designated

area for incineration.

NOTE: DO NOT transport airbag module in

the vehicle passenger compartment. DO

NOT re-use or salvage any parts of the

airbag system including steering wheel or

steering column.Passenger's Airbag Module

1.Carry out deployment tool self test.

2.Remove airbag module from fascia.

See

passenger's airbag module.

3.Position toolSMD 4082/6in vice, ensuring that

vice jaws grip tool above bottom flange to

prevent possibility of tool being forced upwards

from vice. Tighten vice.

4.Position bracketsSMD 4082/7to tool; lightly

tighten bolts.

Page 667 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

1

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Airbag module screws 8 (6 lbf ft)...........................................................................

Steering wheel nut 50 (37 lbf ft)..............................................................................

Crash sensor screws (Distributed SRS) 10 (7 lbf ft)..............................................

Control unit 10 (7 lbf ft)...........................................................................................

Page 714 of 873

CHASSIS AND BODY

47

REPAIR

14.Remove 2 screws securing louvre panel.

15.Remove louvre panel from dash panel.

Refit

16.Position louvre panel, feed harness connectors

through their correct apertures,and align to dash

panel.

CAUTION: When refitting avoid trapping of

electrical wiring.

17.Fit and tighten screws securing louvre panel.

18.Fit panel retaining screw cover.

19.Position heater control unit to panel and secure

with screws.

20.Fit heater graphic display panel and secure with

screws.

21.Fit heater control and blower switch knobs.

22.Fit clock.

See ELECTRICAL, Repair, clock.

23.Position coin tray and secure to tags.

24.Position radio cage, feed electrical connectors

and aerial through cage, and position to panel.

25.Bend back radio cage retaining tags.

26.Fit radio.

See ELECTRICAL, Repair, radio.

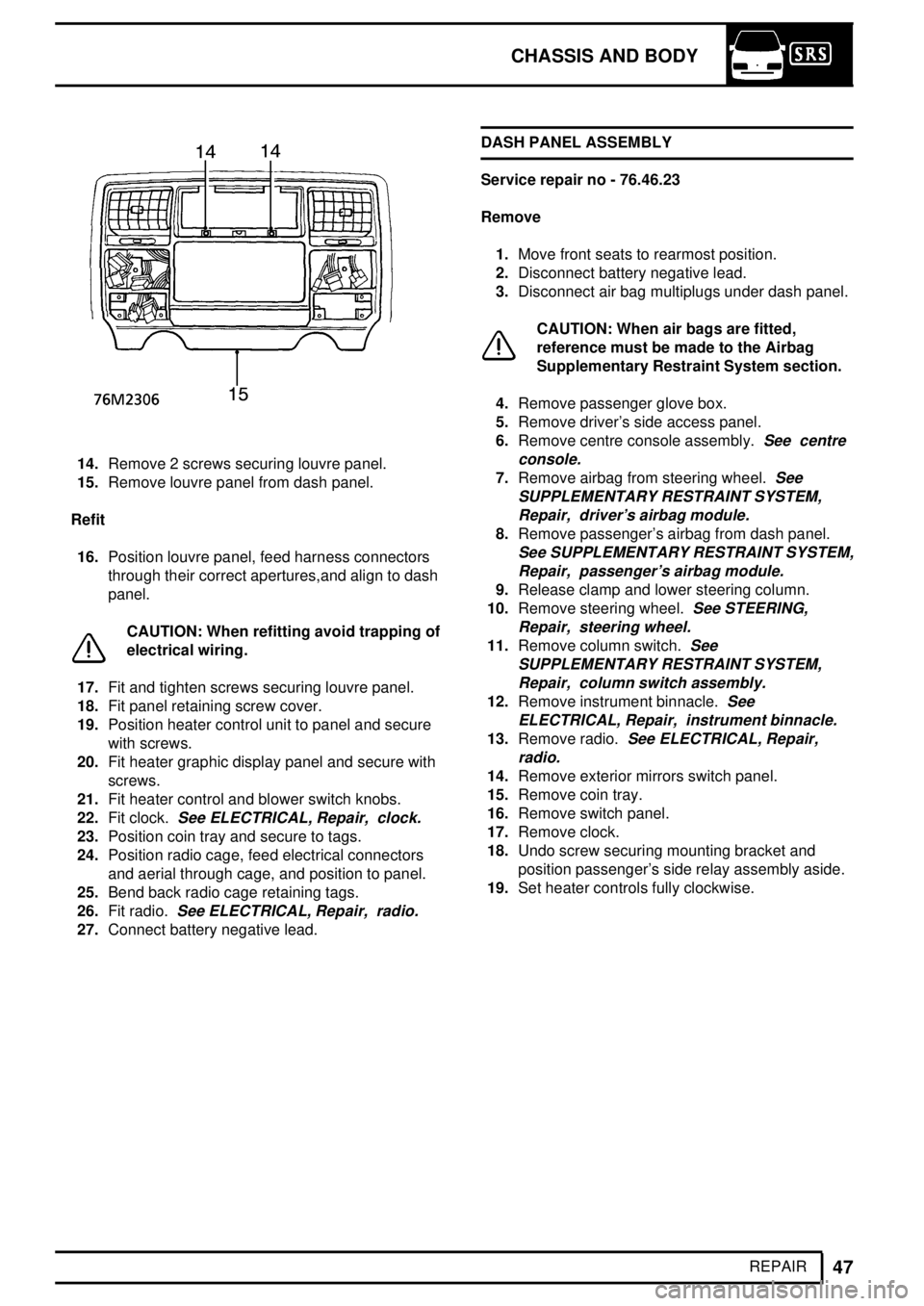

27.Connect battery negative lead.DASH PANEL ASSEMBLY

Service repair no - 76.46.23

Remove

1.Move front seats to rearmost position.

2.Disconnect battery negative lead.

3.Disconnect air bag multiplugs under dash panel.

CAUTION: When air bags are fitted,

reference must be made to the Airbag

Supplementary Restraint System section.

4.Remove passenger glove box.

5.Remove driver's side access panel.

6.Remove centre console assembly.

See centre

console.

7.Remove airbag from steering wheel.See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, driver's airbag module.

8.Remove passenger's airbag from dash panel.

See SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, passenger's airbag module.

9.Release clamp and lower steering column.

10.Remove steering wheel.

See STEERING,

Repair, steering wheel.

11.Remove column switch.See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, column switch assembly.

12.Remove instrument binnacle.See

ELECTRICAL, Repair, instrument binnacle.

13.Remove radio.See ELECTRICAL, Repair,

radio.

14.Remove exterior mirrors switch panel.

15.Remove coin tray.

16.Remove switch panel.

17.Remove clock.

18.Undo screw securing mounting bracket and

position passenger's side relay assembly aside.

19.Set heater controls fully clockwise.

Page 715 of 873

76CHASSIS AND BODY

48

REPAIR 20.Note position of levers, disconnect heater control

cables from levers and outer cable from retaining

clips.

21.Remove 4 bolts securing dash panel to centre

lower mounting brackets.

22.Remove 4 bolts securing dash panel to side

lower mounting brackets.

23.Undo 4 screws and remove 2 driver's knee

bolster pads from below steering column.

24.Remove 4 nuts securing instrument mounting

bracket to dash panel.

25. With assistance:Manoeuvre dash panel

partially rearward.

26.Driver's side: Disconnect 6 multiplugs

connecting dash harness to main harness.

27.Disconnect 3 multiplugs connecting dash

harness to fusebox.

28. With assistance:Lift dash panel rearward to

clear fixings and remove from vehicle.

Page 759 of 873

82AIR CONDITIONING

4

FAULT DIAGNOSISFAULT CAUSE REMEDY

E.

NOISY

EXPANSION

VALVE

(steady hissing)1. Low refrigerant charge; evident by

bubbles in sight glass.1. Leak test. Repair or replace

components as required.

F.1. Expansion valve not operating 1. Refer to C-2, C-3, D-1

INSUFFICIENTproperly. and E.

COOLING2. Low refrigerant charge-evident 2. Refer to B-1 and E.

by bubbles in sight glass.

3. Compressor not pumping. 3. Refer to B-2 and B-3

G.1. Belt tension. 1. Adjust belt tension.

COMPRESSOR2. Excessive head pressure. 2. Refer to A-1 through

BELTA-4 and C-6.

SLIPPING3. Incorrect alignment of pulleys 3. Repair as needed.

or worn belt not riding properly.

4. Nicked or broken pulley. 4. Replace as needed.

5. Seized compressor. 5. Replace compressor.

1. Loose or missing mounting bolts. 1. Repair as necessary.

2. Broken mounting bracket. 2. Replace bracket.

3. Loose flywheel or clutch 3. Repair as necessary.

retaining bolt.

H.4. Rough idler pulley bearing. 4. Replace bearing.

ENGINE5. Bent, loose, or improperly 5. Repair as necessary.

NOISEmounted engine drive pulley.

AND/OR6. Defective compressor bearing. 6. Replace bearing.

VIBRATION7. Insecure mountings of 7. Repair as necessary.

accessories; generator, power

steering, air filter, etc.

8. Excessive head pressure. 8. Refer to A-1, A-2, A-3

A-4 and C-6.

9. Incorrect compressor oil level. 9. Refer to compressor Oil

Level Check.

HEATER AND AIR CONDITIONING - CIRCUIT

DIAGRAMS

1.For details of heating and air conditioning

electrics

See Electrical Trouble Shooting

Manual.

Page 794 of 873

WIPERS AND WASHERS

1

DESCRIPTION AND OPERATION WINDSCREEN WIPER AND WASHER OPERATION

The illustration below locates and identifies the main

components of the windscreen and washer system

which is operated by a multi-switch on the right hand

side of the steering column.

All functions of the system are described in the

following paragraphs.

1. Multi-switch

2. Wiper motor

3. Wiper arm/blade

4. Washer reservoir

5. Windscreen washer motor/pump

6. Non return valve

7. Washer jet

8. Rear window washer motor pump

9. Non return valve10. Headlamp power wash motor/pump

11. Headlamp power washer jet

12. Non return valve

13. Rear window wiper switch

14. Rear window washer switch

15. Rear window wiper motor, arm and blade

16. Washer jet

Page 795 of 873

84WIPERS AND WASHERS

2

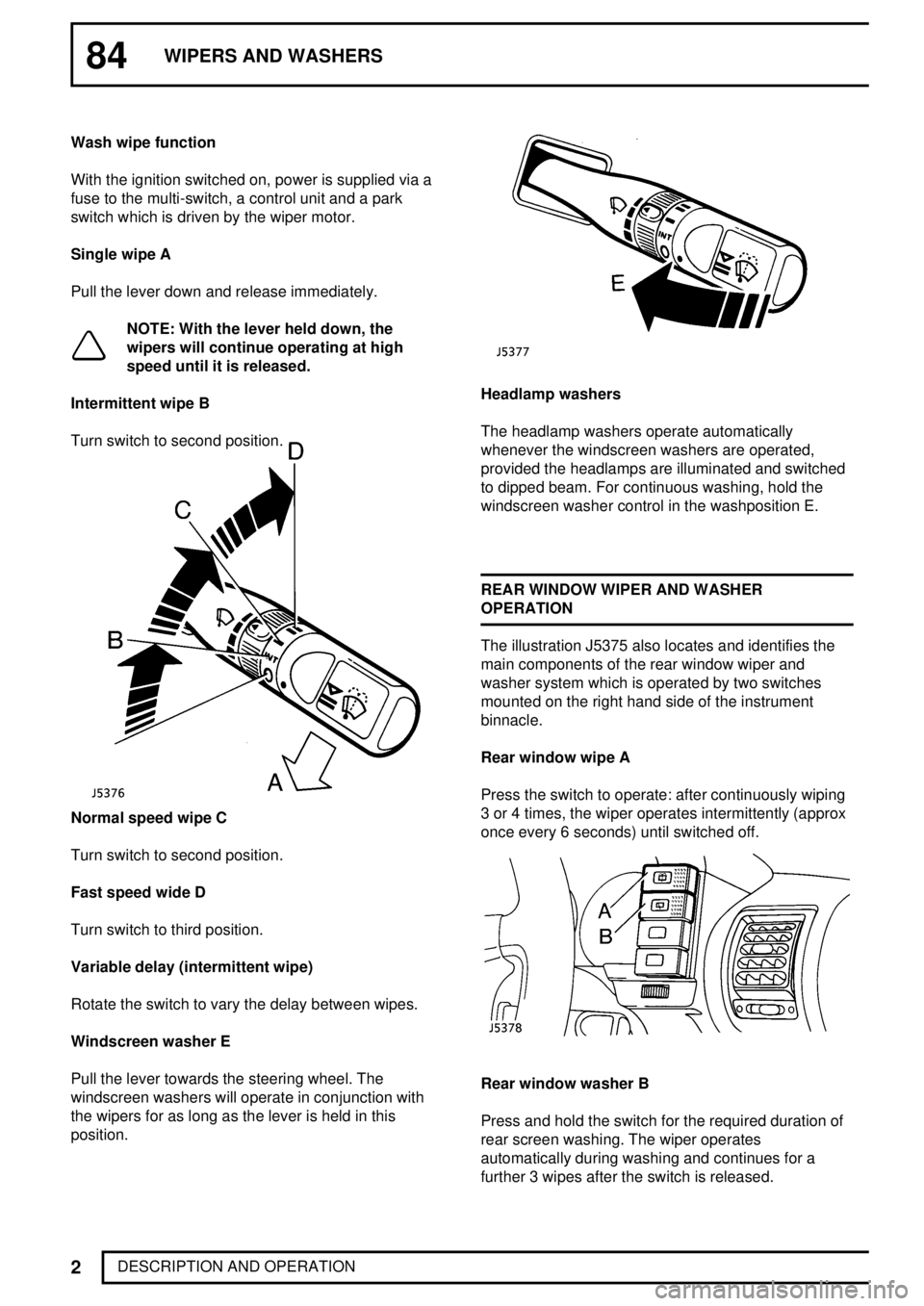

DESCRIPTION AND OPERATION Wash wipe function

With the ignition switched on, power is supplied via a

fuse to the multi-switch, a control unit and a park

switch which is driven by the wiper motor.

Single wipe A

Pull the lever down and release immediately.

NOTE: With the lever held down, the

wipers will continue operating at high

speed until it is released.

Intermittent wipe B

Turn switch to second position.

Normal speed wipe C

Turn switch to second position.

Fast speed wide D

Turn switch to third position.

Variable delay (intermittent wipe)

Rotate the switch to vary the delay between wipes.

Windscreen washer E

Pull the lever towards the steering wheel. The

windscreen washers will operate in conjunction with

the wipers for as long as the lever is held in this

position.

Headlamp washers

The headlamp washers operate automatically

whenever the windscreen washers are operated,

provided the headlamps are illuminated and switched

to dipped beam. For continuous washing, hold the

windscreen washer control in the washposition E.

REAR WINDOW WIPER AND WASHER

OPERATION

The illustration J5375 also locates and identifies the

main components of the rear window wiper and

washer system which is operated by two switches

mounted on the right hand side of the instrument

binnacle.

Rear window wipe A

Press the switch to operate: after continuously wiping

3 or 4 times, the wiper operates intermittently (approx

once every 6 seconds) until switched off.

Rear window washer B

Press and hold the switch for the required duration of

rear screen washing. The wiper operates

automatically during washing and continues for a

further 3 wipes after the switch is released.